Difference between Suction Hose and Delivery Hose

This article explains the distinctions between suction and delivery hoses, focusing on their structure, functionality, and applications. It highlights the importance of choosing the right hose for efficiency and safety. QINGDAO RENATO PLASTIC CO., LTD, a trusted PVC hose manufacturer with over 15 years of experience, offers a wide range of high-quality hoses and fittings for water systems in more than 60 countries.

Difference Between Suction Hose and Delivery Hose

In industrial operations and fluid management systems, suction hoses and delivery hoses play vital roles in moving fluids between two points. Although they might look similar, these hoses are designed for distinct purposes and come with specific structural and functional differences.

What Are Suction and Delivery Hoses?

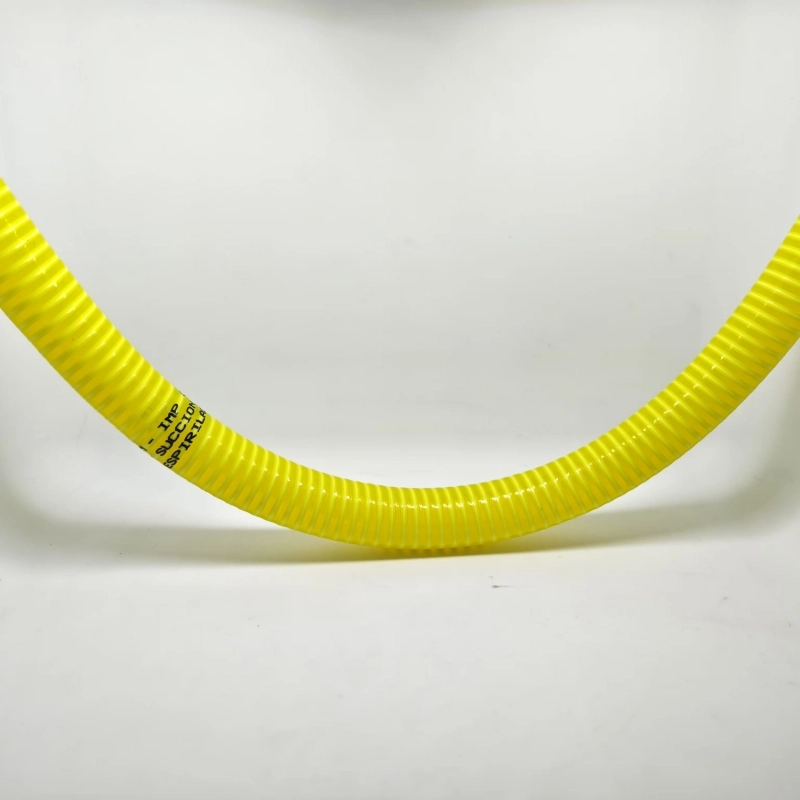

A suction hose is used to draw liquids or slurries into a system. It operates under negative pressure, meaning it can withstand the vacuum created during fluid suction. These hoses are typically reinforced to prevent collapsing.

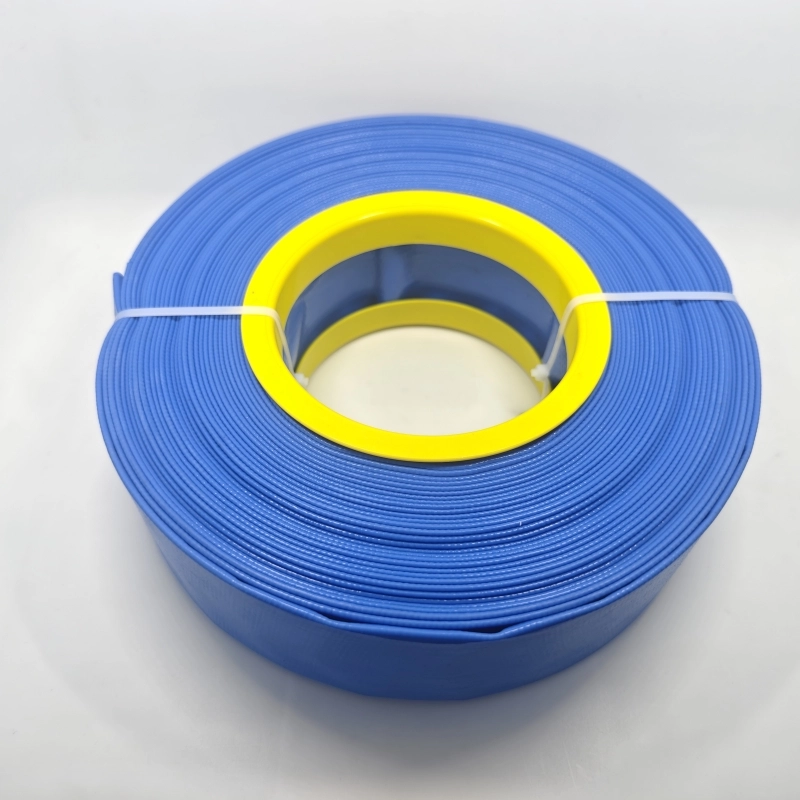

A delivery hose, on the other hand, is designed to discharge fluids from a system under positive pressure. These hoses are engineered to handle high-pressure environments and maintain their integrity during fluid transport.

Key Differences Between Suction and Delivery Hoses

1. Structural Composition

Suction Hose:

Reinforced with a spiral helix or rigid structures to provide added strength.

Specifically engineered to resist collapsing under vacuum pressure, making them ideal for scenarios involving suction and heavy-duty operations.

The materials used, such as PVC or rubber, contribute to their durability and ability to handle challenging conditions, including exposure to abrasive materials.

Due to their robust construction, suction hoses tend to have a longer lifespan when used within their intended parameters.

Delivery Hose:

Typically reinforced with high-tensile fibers or woven materials to ensure they can withstand the positive pressure of fluid discharge.

Designed for flexibility, which allows easier handling and maneuvering in dynamic environments.

The reinforcement materials also help maintain structural integrity during high-pressure applications, extending the hose's durability in demanding tasks.

Delivery hoses are often optimized for specific industries, offering tailored solutions such as chemical resistance or lightweight designs for portability.

Suction Hose:

Reinforced with spiral helix or rigid structures.

Designed to resist collapsing under vacuum pressure.

Flexible but robust.

Delivery Hose:

Typically reinforced with high-tensile fibers or woven materials.

Constructed to handle pressure from fluid discharge.

More flexible compared to suction hoses for easier maneuverability.

2. Functionality

Suction Hose:

Used for drawing fluids, slurries, or powders into pumps.

Commonly employed in water supply, fuel transfer, and slurry systems.

Delivery Hose:

Transfers fluids to a specified location or system.

Often used in firefighting, irrigation, and industrial discharge systems.

3. Pressure Ratings

Suction Hose: Typically designed to withstand vacuum pressures up to -0.9 bar, making it ideal for applications like slurry suction in construction or water intake in agriculture. For example, a 100mm diameter suction hose can endure vacuum pressure for depths up to 10 meters.

Delivery Hose: Constructed to handle positive pressures up to 400 psi (27.6 bar). For instance, delivery hoses used in firefighting can deliver water at high pressures to reach distances over 30 meters, ensuring efficiency and safety in critical scenarios. Suction hoses operate under negative pressure (vacuum).

Delivery hoses are built to endure high positive pressure.

4. Applications

Suction Hose Applications:

Agricultural water suction.

Industrial chemical handling.

Construction site debris removal.

Delivery Hose Applications:

Firefighting water discharge.

Irrigation systems.

Industrial fluid transfer.

This picture shows two different types of hoses. The one on top is a suction hose, which has some textures on the surface to increase friction or provide some protection. It is often used to draw liquid from a water source. The one on the bottom is a delivery hose, which is blue with a yellow ring in the middle. This color design makes it easy to identify and distinguish, and is mainly used to deliver liquid to a specific location. The two types of hoses play an important role in different scenarios. The suction hose focuses on absorbing liquid, while the delivery hose focuses on delivering liquid to the destination. They are both indispensable components of the pipeline system and are widely used in many fields such as industry, agriculture, and construction.

Technical Specifications

The following table highlights key technical specifications of suction and delivery hoses:

| Specification | Suction Hose | Delivery Hose |

|---|---|---|

| Internal Diameter | 19mm to 152mm | Varies based on application |

| External Diameter | 25.6mm to 172.4mm | Varies based on application |

| Working Pressure | Up to 16 bar | Up to 400 psi |

| Temperature Range | -35°C to +80°C | Depends on construction materials |

| Reinforcement | Spiral helix | Woven polyester or nylon fibers |

Selection Criteria

When choosing between suction and delivery hoses, consider the following factors:

1. Application Requirements

Identify whether the hose is for suction or discharge purposes.

Ensure compatibility with the system’s operational requirements.

2. Pressure Conditions

Suction hoses should withstand negative pressures without collapsing.

Delivery hoses must handle high positive pressures effectively.

3. Fluid Properties

Check the fluid’s viscosity, temperature, and chemical composition.

Ensure the hose’s inner lining is resistant to the fluid being transported.

4. Environmental Conditions

Consider temperature variations, exposure to abrasive materials, and external stresses.

5. Compliance and Standards

Verify that the hoses meet industry standards and certifications.

Advantages of Using the Right Hose

Using the correct hose for a specific application provides several tangible benefits that impact both short-term operations and long-term system efficiency:

Improved Efficiency: By ensuring fluid transfer is optimized for the intended application, the correct hose reduces downtime and enhances overall performance. For example, a well-matched delivery hose ensures consistent pressure in firefighting, leading to faster extinguishing of fires.

Safety Assurance: Using the appropriate hose minimizes the risk of malfunctions, such as bursting or collapsing, thereby protecting equipment and operators. Suction hoses with proper reinforcement prevent failures during heavy-duty operations like construction slurry suction.

Longevity: Correctly matched hoses experience less wear and tear as they are designed to handle specific pressures and conditions. This results in fewer replacements and better overall performance. For instance, suction hoses used for water intake in agriculture can last for years when chosen and maintained correctly.

Cost Savings: Reduced maintenance requirements and fewer replacements translate into significant cost savings over time. In industrial settings, selecting the right delivery hose for high-pressure fluid discharge prevents costly system repairs and downtime.

Enhanced Operational Safety: Proper hoses mitigate risks such as leaks or bursts in critical applications like chemical transfer, ensuring a safer work environment and protecting valuable resources.

Industry Insights

Market Trends

The demand for suction and delivery hoses is expected to grow in industries like agriculture, construction, and manufacturing. Advancements in materials like high-grade polymers are enhancing hose durability and performance.

Research Data

| Metric | Suction Hose | Delivery Hose |

| Global Market Share (2023) | 45% | 55% |

| Average Lifespan | 5-7 years | 3-5 years |

| Material Innovation | 20% CAGR | 15% CAGR |

Conclusion

For high-quality PVC hoses and assemblies, QINGDAO RENATO PLASTIC CO., LTD is your reliable partner. With over 15 years of experience, we specialize in producing a wide range of hoses, including Layflat Hose, Suction Hose, Fiber Reinforced Hose, and more. Our products are trusted in water supply systems, irrigation, and industrial applications across 60+ countries. Contact us today for customized solutions and excellent service. We are here to meet your needs with our philosophy: Customers are always first, with 7x24 hours quick response.

Understanding the differences between suction and delivery hoses is crucial for selecting the right tool for your application. While suction hoses are built to resist vacuum pressures, delivery hoses are designed for high-pressure discharge. By evaluating factors like structural composition, pressure ratings, and application needs, you can ensure optimal performance and safety in your operations.