How to connect agricultural irrigation hoses with aluminum coupling

Agricultural irrigation hoses play a crucial role in farming, as their performance directly impacts irrigation efficiency and crop growth. Below is a detailed analysis of their performance characteristics:

I. Material Characteristics

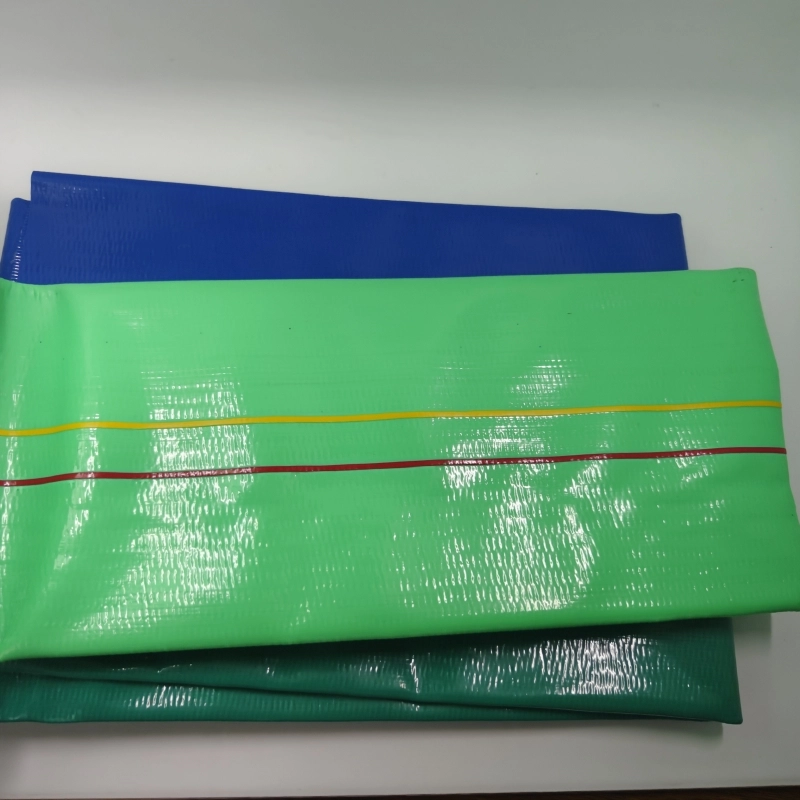

Material Selection: Agricultural irrigation hoses are primarily made of PVC, PE (Polyethylene), and TPU. Among these, PE is the most widely used due to its high pressure resistance, corrosion resistance, cold tolerance, as well as excellent flexibility and elasticity. PVC, while still in use, is less durable and mainly suited for home gardens or small farms. TPU, on the other hand, boasts a low-friction inner layer and a wear-resistant, easy-to-clean polyester outer layer, providing excellent compression resistance, flexibility, and oxygen barrier properties.

Durability: PE hoses excel in durability, resisting various chemicals and lasting for 5-6 years or more. In contrast, PVC hoses have a shorter lifespan and require frequent replacement.

II. Physical Properties

Flexibility: Crafted from high-strength polyester fibers and premium PVC or PE materials, agricultural hoses maintain flexibility even in cold water, making them easy to coil and maneuver.

Compression Resistance: Both PE and TPU hoses offer excellent compression resistance, enabling them to withstand high water pressures for uninterrupted irrigation.

Abrasion Resistance: TPU and PE hoses feature durable outer layers that resist scratches and abrasions from friction and dragging during use.

III. Chemical Properties

Corrosion Resistance: PE hoses are renowned for their corrosion resistance to a wide range of chemicals, including acids and alkalis, extending their service life.

UV Resistance: Certain hoses are equipped with UV resistance, ensuring they can withstand prolonged outdoor exposure without degrading their physical properties or appearance.

IV. Usability

Water Conservation: As water-saving irrigation tools, agricultural hoses contribute to water conservation, land efficiency, energy savings, and increased crop yields.

Convenience: Lightweight, flexible, and easy to roll up, these hoses are highly portable and customizable in length, enhancing irrigation flexibility and efficiency.

V. Other Features

Environmental Friendliness: Some hoses are crafted from eco-friendly materials, posing no harm to the environment or crops.

Cost-Effectiveness: Although PE and TPU hoses may have a slightly higher initial investment compared to PVC, their longer lifespan and reduced maintenance costs make them more economical in the long run.

In conclusion, agricultural irrigation hoses excel across material characteristics, physical properties, chemical resistance, usability, and other features. When selecting an irrigation hose, it is crucial to consider all these factors based on specific needs and irrigation conditions to ensure the best fit.

Connection Steps

Preparation:

Ensure that the agricultural irrigation hose and aluminum connector are of compatible models and sizes to avoid loose or leaky connections due to mismatch.

Inspect the interface areas of both the hose and the connector for cleanliness, ensuring there are no impurities, dirt, or sludge that could compromise the seal.

Connecting the Hose to the Connector:

Most aluminum connectors consist of two parts with a rubber gasket inside. To connect, hold the hose's interface firmly and insert the protruding part of the hose into the recess of one end of the connector.

Rotate the hose interface clockwise with your wrist to tighten the connection, ensuring a secure fit between the hose and connector. Depending on the design, the interface may require a clamp, bolt, or other fastener to secure the connection further.

Checking the Connection:

After connecting, gently pull on the hose to ensure the connector is firmly attached and does not loosen or slip.

Apply slight pressure to the connector area to check for leaks. If leakage occurs, reconnect the hose and connector to ensure a tight, leak-proof seal.

Precautions

Choosing the Right Connector:

Select an aluminum connector that matches the model, size, and pressure rating of the irrigation hose. High-pressure hoses require connectors with higher pressure capabilities.

Avoiding Over-tightening or Under-tightening:

When connecting, use moderate force to avoid over-tightening, which can strip the threads or damage the connector, and under-tightening, which can lead to leaks.

Regular Inspections:

Periodically inspect the connector joints during use to ensure they are tight and free from leaks. This is especially important after extended use or exposure to harsh weather conditions.

Protecting Against Drops and Impacts:

Prevent the connector from dropping, colliding, or being subjected to heavy pressure, as this can deform the connector and make it difficult to connect or disconnect. Handle and store the connector with care.

Removing Debris:

Before connecting, inspect the sliding grooves and sealing areas for dirt, mud, or sand particles. Remove any debris to ensure a proper seal and easy connection.

Proper Installation:

When connecting two hoses or connecting a hose to an outlet or other equipment, follow the correct sequence and method. Ensure that each connector is securely and reliably connected.

By following these steps and precautions, you can ensure a secure and leak-proof connection between the agricultural irrigation hose and the aluminum connector, thereby maintaining irrigation efficiency and supporting crop growth.