Introduction

In industries where hygiene, durability, and odor neutrality are non-negotiable, odorless steel wire-reinforced hoses have emerged as a revolutionary solution. As a leading Chinese factory with advanced technical capabilities, QINGDAO RENATO PLASTIC CO., LTD specializes in manufacturing high-performance hoses that meet global standards. This article explores the unique properties of our odorless steel wire hoses, their diverse applications, and the technical specifications that set our products apart.

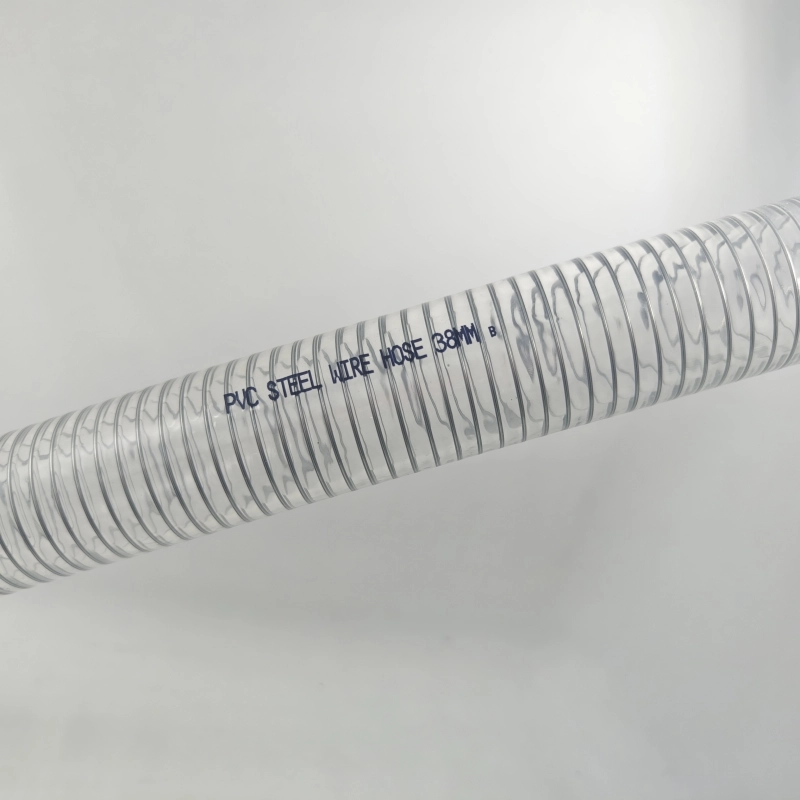

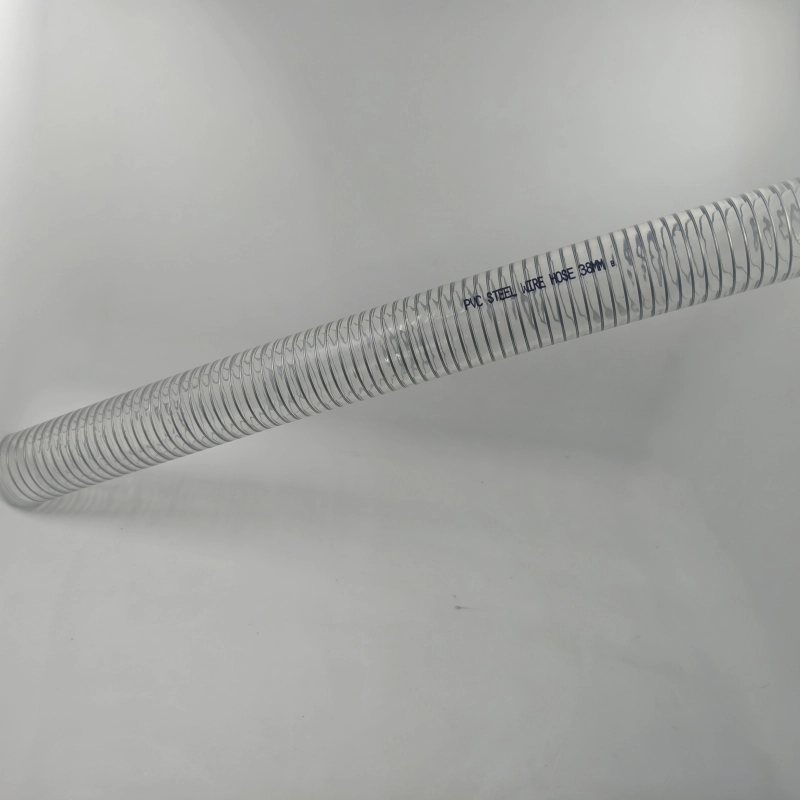

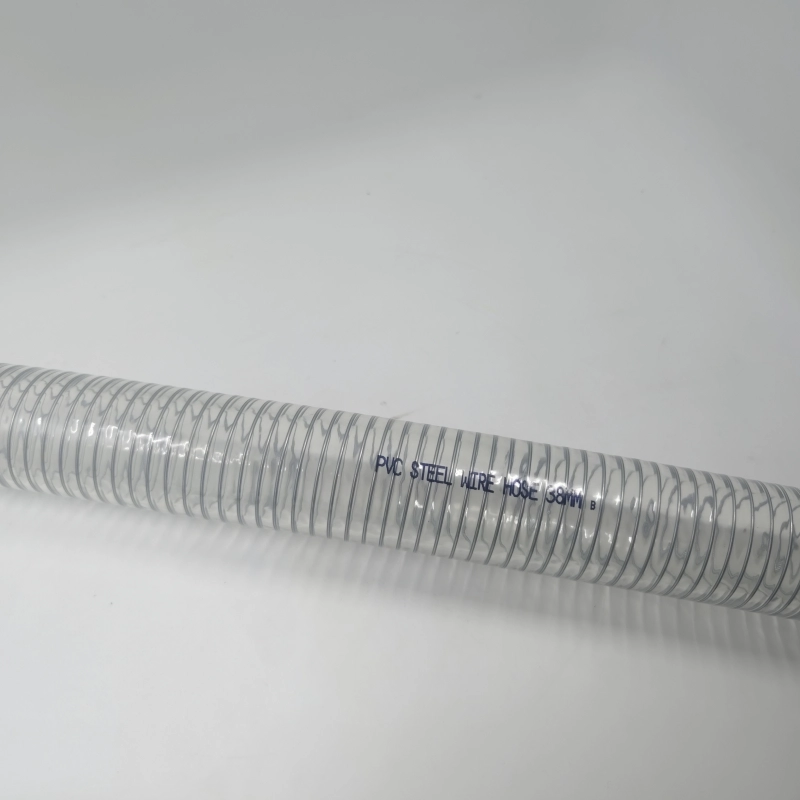

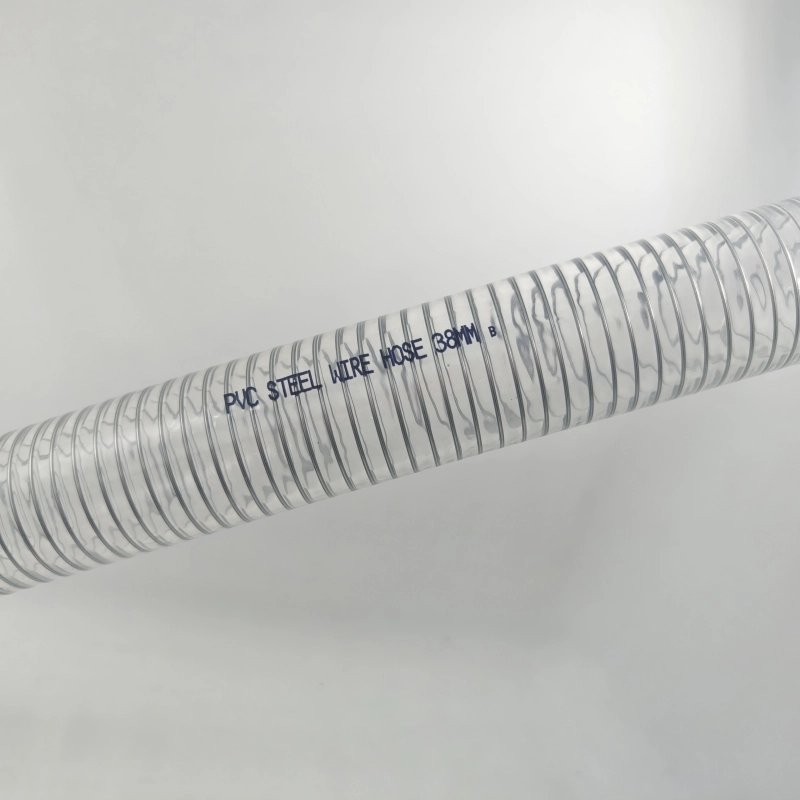

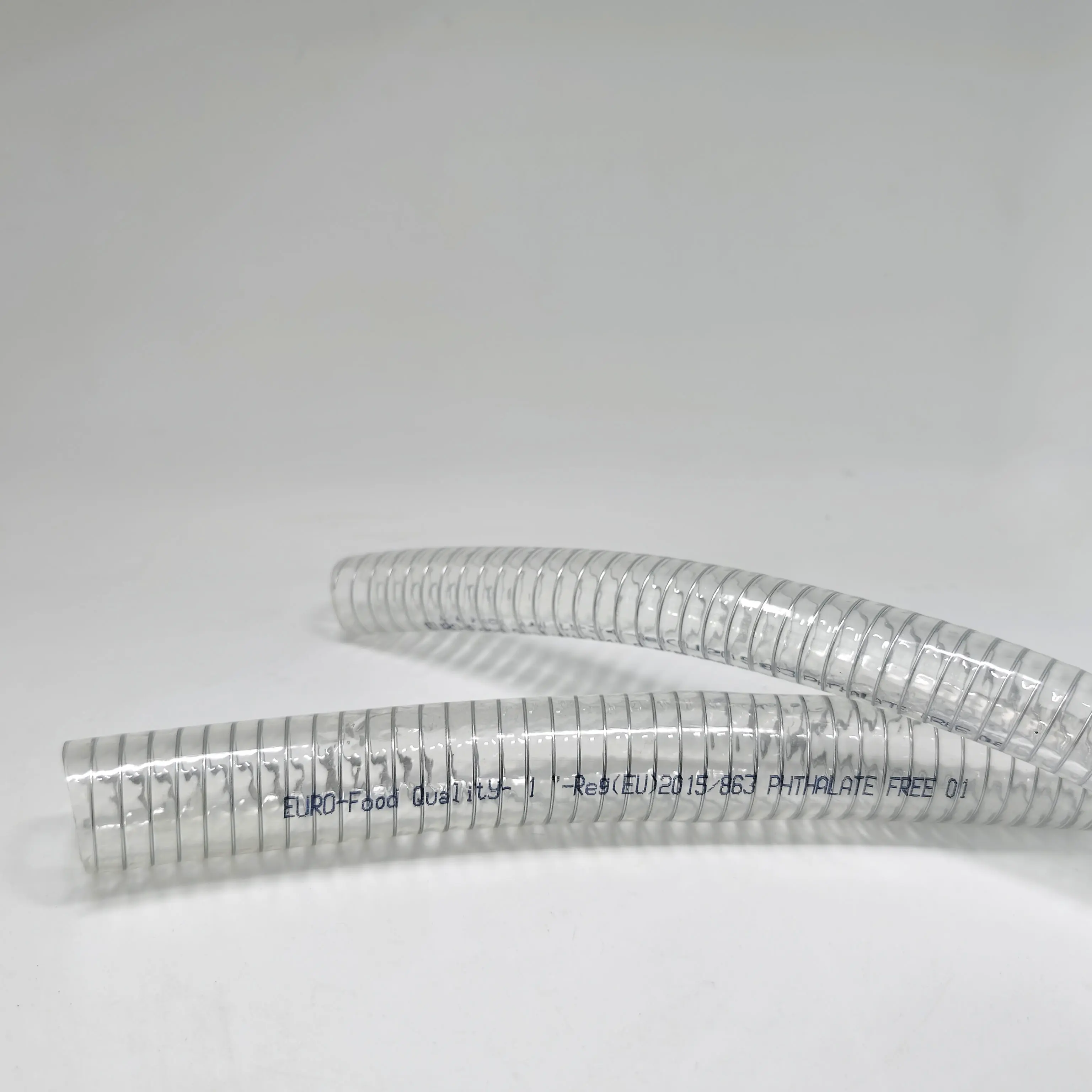

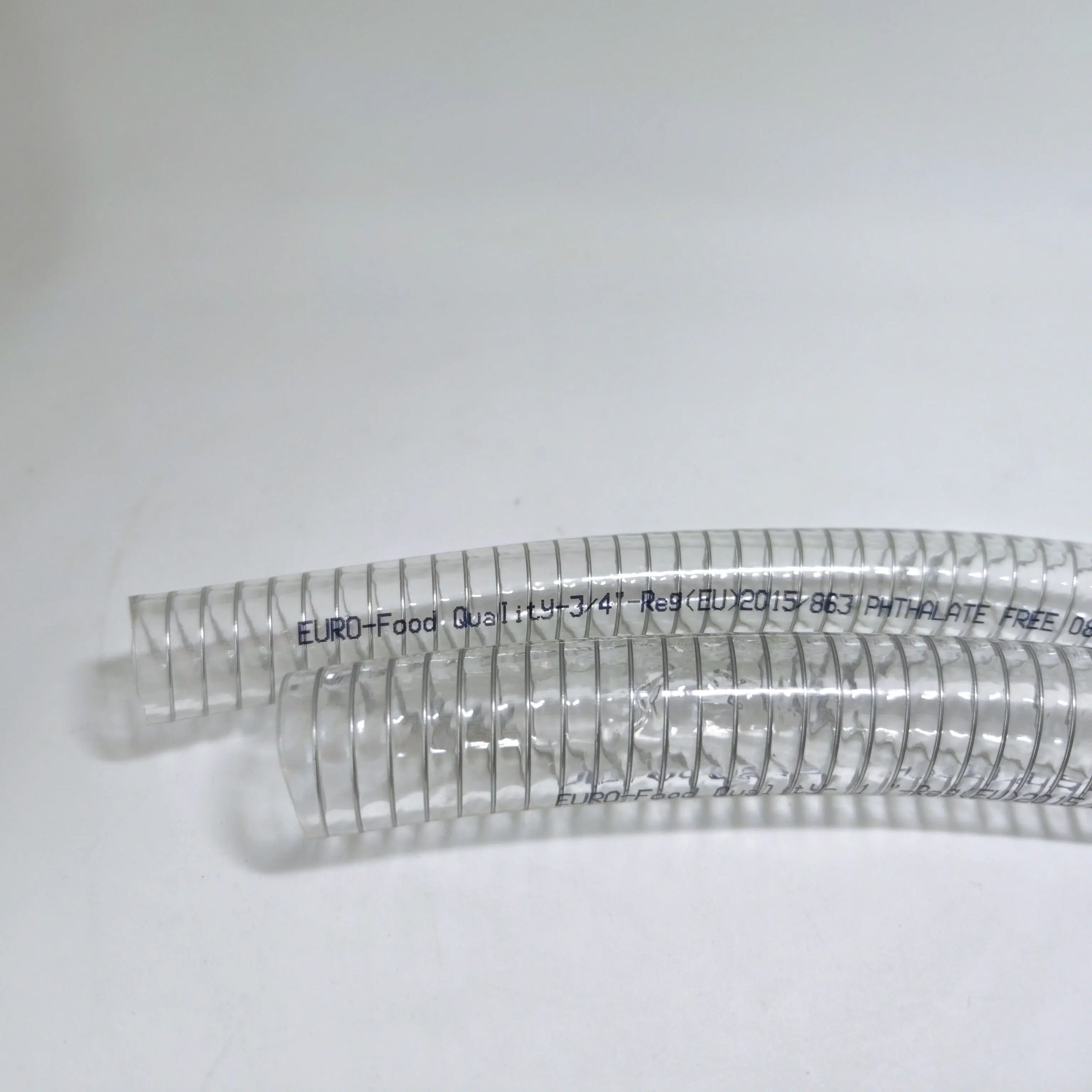

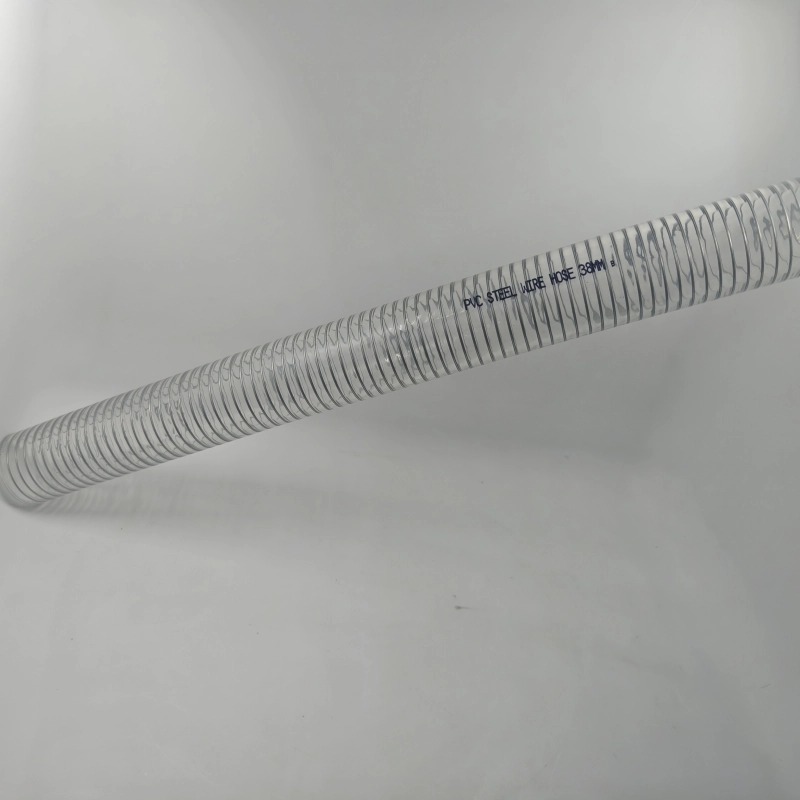

This is an odorless PVC steel wire discharge hose. The hose is transparent, with a built-in steel wire reinforcement structure and a diameter of 38 mm. It is suitable for scenes where materials need to be discharged, such as industrial drainage, agricultural irrigation drainage, etc. Its odorless characteristics ensure the cleanliness of the use environment.

Key Features of Odorless Steel Wire Reinforced Hoses

1. Odorless Design

Material Innovation: Our hoses use food-grade thermoplastic polyurethane (TPU) or FDA-compliant PVC for the inner tube. These materials undergo a proprietary stabilization process to eliminate plasticizer migration, the primary source of chemical odors.

Certified Safety: Compliant with FDA 21 CFR 177.2600, EU REACH, and RoHS standards, ensuring zero VOC emissions.

2. Superior Durability

Reinforcement: High-tensile 304/316L stainless steel wire spiral or braid provides crush resistance and maintains shape under pressure.

Temperature Resilience: Operates in extreme conditions (-40°C to +135°C standard; customizable up to +200°C).

Abrasion Resistance: Outer cover made of hybrid polymers with UV and ozone resistance for outdoor use.

3. Chemical Compatibility

Resists acids, alkalis, oils, and solvents (pH 2–12), making it ideal for aggressive industrial environments.

4. Flexibility and Ease of Use

Minimum bend radius of 5× the inner diameter (ID) prevents kinking, even in tight spaces.

Applications Across Industries

1. Food and Beverage

Steam Transfer: Safely conveys steam for sterilization without contaminating products.

CIP (Clean-in-Place) Systems: Resists high-pressure cleaning agents and maintains odor neutrality.

2. Pharmaceuticals

Sterile Fluid Handling: Used in purified water distribution and API (active pharmaceutical ingredient) transfer.

Bio-Reactor Connections: Meets USP Class VI standards for biocompatibility.

3. Automotive and Manufacturing

Paint Spray Systems: Ensures odor-free airflow in automated painting lines.

Coolant Transfer: Resists glycol-based fluids and extreme temperatures.

4. Environmental Technology

Wastewater Management: Transfers corrosive chemicals in treatment plants.

Semiconductor Manufacturing: Compatible with ultra-pure water systems.

Technical Specifications

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | Volume | ||

| inch | mm | mm | m | kg/m | bar | psi | cbm |

| 1/4 | 6 | 2.5 | 100 | 0.115 | 10 | 145 | 0.028 |

| 5/16 | 8 | 3 | 100 | 0.15 | 10 | 145 | 0.039 |

| 3/8 | 10 | 3 | 100 | 0.2 | 10 | 145 | 0.045 |

| 1/2 | 12 | 3 | 100 | 0.22 | 8 | 120 | 0.049 |

| 5/8 | 15 | 3.5 | 100 | 0.31 | 8 | 120 | 0.074 |

| 3/4 | 19 | 3.5 | 50 | 0.36 | 8 | 120 | 0.052 |

| 1 | 25 | 3.5 | 50 | 0.54 | 8 | 120 | 0.085 |

| 1 1/4 | 32 | 4.5 | 40 | 0.775 | 7 | 100 | 0.106 |

| 1 1/2 | 38 | 5 | 40 | 1.05 | 6 | 90 | 0.154 |

| 1 3/4 | 45 | 5.5 | 40 | 1.3 | 6 | 90 | 0.190 |

| 1 7/8 | 48 | 5.5 | 40 | 1.4 | 6 | 90 | 0.208 |

| 2 | 50 | 6 | 40 | 1.6 | 5 | 75 | 0.276 |

| 2 1/4 | 58 | 6 | 40 | 2 | 5 | 75 | 0.35 |

| 2 1/2 | 63 | 8.5 | 30 | 2.8 | 5 | 75 | 0.331 |

| 3 | 75 | 8 | 30 | 3.5 | 4 | 60 | 0.436 |

| 3 1/2 | 90 | 9 | 20 | 4.5 | 4 | 60 | 0.64 |

| 4 | 100 | 9 | 20 | 4.8 | 3 | 45 | 0.505 |

| 5 | 127 | 8 | 20 | 6 | 3 | 45 | 1.243 |

| 6 | 152 | 9 | 10 | 9 | 3 | 45 | 0.765 |

| 8 | 200 | 12 | 10 | 12 | 3 | 45 | 1.426 |

| 10 | 250 | 13 | 10 | 23 | 2 | 30 | 1.95 |

Why Choose QINGDAO RENATO PLASTIC?

1. Technical Expertise

R&D Leadership: Our in-house engineering team collaborates with global partners to innovate hose materials and designs.

Custom Solutions: Tailor hoses for unique pressure, temperature, or chemical requirements.

2. Quality Assurance

Advanced Manufacturing: Automated extrusion lines and ISO 9001-certified processes ensure consistency.

Rigorous Testing: Every batch undergoes pressure decay tests (SAE J343), odor emission checks (ASTM D5517), and helix integrity inspections.

3. Global Compliance

Certifications include NSF, WRAS, and CE, enabling seamless export to North America, Europe, and Asia.

4. After-Sales Support

24/7 technical consultation, on-site installation guidance, and a 12-month warranty.

The odorless PVC steel wire discharge hose is measured with a vernier caliper in the picture. The transparent hose is reinforced with steel wire, has good toughness and can be bent flexibly. The vernier caliper accurately measures the pipe diameter and other dimensions to ensure that the product specifications meet the standards. It is suitable for a variety of discharge scenarios such as industry and agriculture.

Case Study: Success in the Dairy Industry

A European dairy producer required odorless hoses for milk homogenization systems. Our team developed a 2" ID hose with:

316L stainless steel reinforcement.

Enhanced temperature resistance (+150°C).

Accelerated FDA certification turnaround.

Result: 40% longer service life compared to previous PTFE hoses, with zero odor complaints.

Installation and Maintenance Tips

Use corrosion-resistant clamps (e.g., stainless steel DIN 3017).

Avoid sharp bends—maintain a minimum radius of 5×ID.

Clean with pH-neutral solutions to preserve inner tube integrity.

Future Innovations

We are developing:

Smart Hoses: Embedded sensors for real-time pressure/temperature monitoring.

Eco-Friendly Materials: Bio-based TPU to reduce carbon footprint.

Company Advantages

15+ Years of Manufacturing Excellence: With over 15 years of production experience, Qingdao Renato Plastic Co., Ltd. has developed a deep understanding of industry requirements, ensuring we meet and exceed customer expectations.

State-of-the-Art Facility: Our factory in Shandong Province is equipped with 10 workshops, over 60 production lines, and a skilled team of 120 workers, including 5 technicists and 2 QC teams. This infrastructure enables us to maintain high production capacity and stringent quality standards.

Global Presence: We have served clients in over 60 countries, earning a reputation for high-quality PVC hoses and fittings.

Custom Solutions and Accessories: In addition to PVC hoses, we offer a range of hose assemblies and fittings (Camlock, Storz, Nozzle, Hose Clamps) to provide complete solutions for your fluid transfer needs.

Dedicated Customer Service: Our customer-first philosophy ensures 7x24 hours quick response and support, addressing your inquiries and requirements promptly and efficiently.

Conclusion

QINGDAO RENATO PLASTIC CO., LTD combines cutting-edge technology, strict quality control, and customer-centric service to deliver odorless steel wire hoses that excel in performance and reliability. As a trusted Chinese manufacturer, we empower industries worldwide to achieve contamination-free operations.