PVC Lay Flat Hose vs. HDPE Pipe: What is the difference

When it comes to fluid transfer systems, two popular options are PVC lay flat hoses and HDPE (High-Density Polyethylene) pipes. Both have unique characteristics that make them suitable for specific applications.

Understanding the differences between these two solutions is crucial for selecting the right one for your needs. This article provides a detailed comparison of PVC lay flat hoses and HDPE pipes, explores their respective use cases, and offers practical guidance on how to choose between them.

Key Differences Between PVC Lay Flat Hose and HDPE Pipe

1. Material Composition

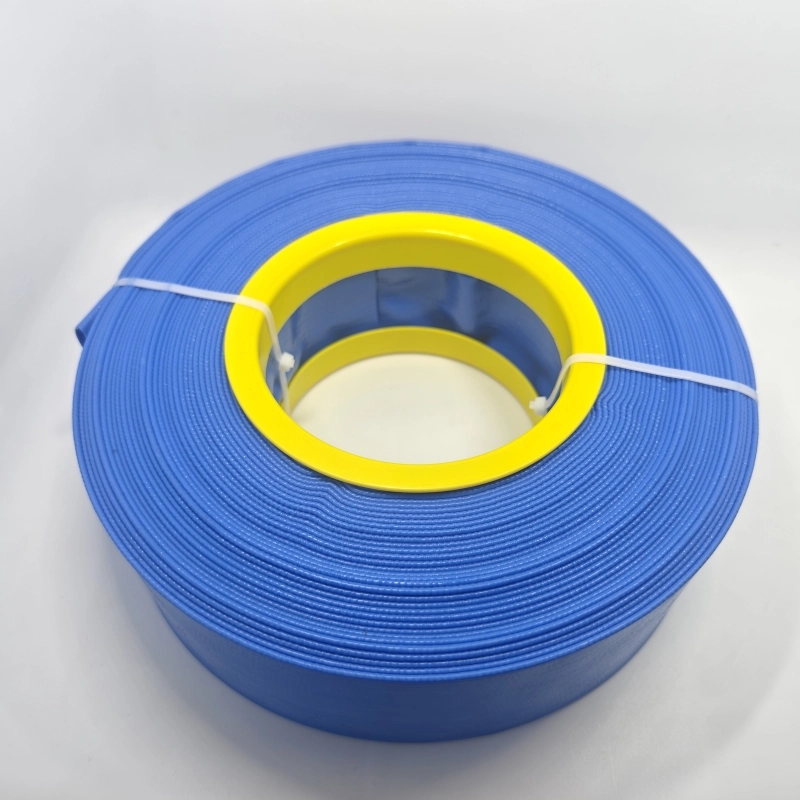

PVC Lay Flat Hose: Made from polyvinyl chloride (PVC), a lightweight and flexible thermoplastic. It often includes reinforcement layers of polyester or nylon for added strength.

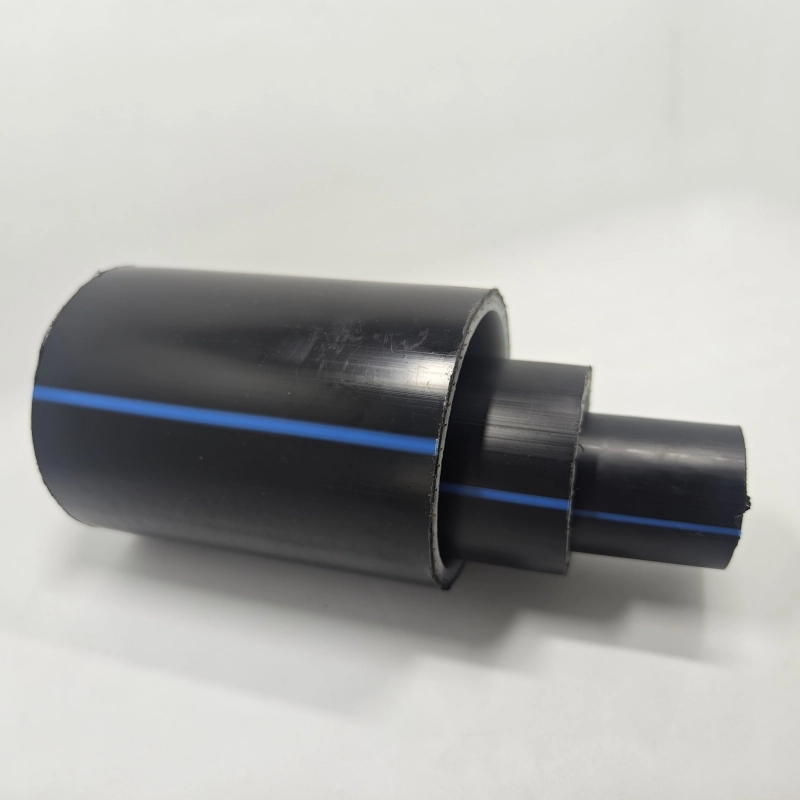

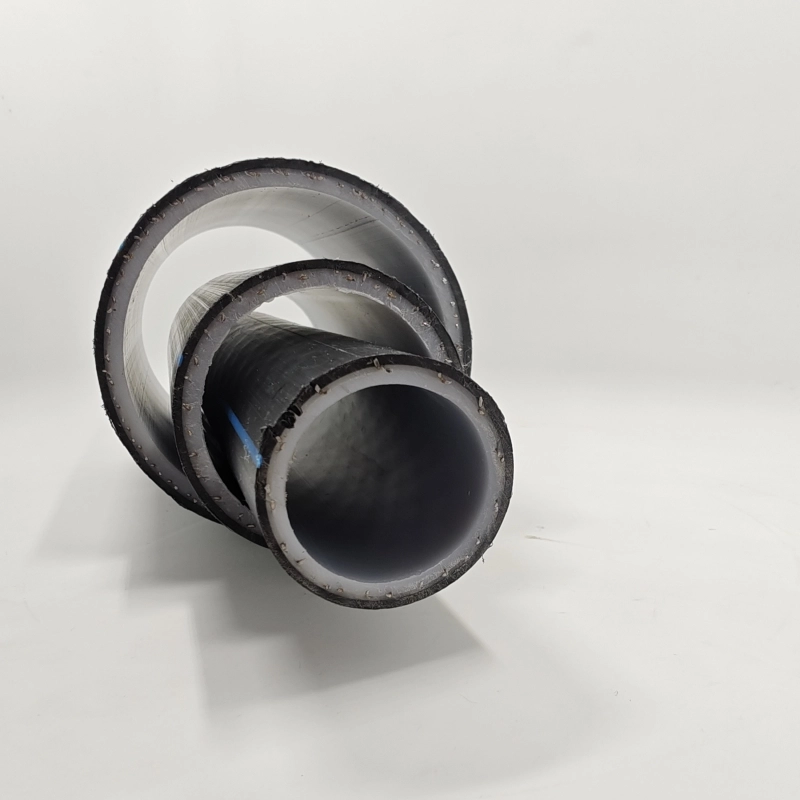

HDPE Pipe: Constructed from high-density polyethylene, a rigid and durable thermoplastic known for its high strength-to-density ratio.

2. Flexibility and Portability

PVC Lay Flat Hose: Highly flexible and can be rolled or folded for easy storage and transport. Ideal for temporary or mobile applications.

HDPE Pipe: Rigid and inflexible, requiring cutting and joining for installation. Best suited for permanent or semi-permanent setups.

3. Installation and Setup

PVC Lay Flat Hose: Quick and easy to deploy, requiring minimal tools or expertise. Can be connected using simple couplings or clamps.

HDPE Pipe: Requires specialized equipment for welding or fusion, making installation more time-consuming and labor-intensive.

4. Durability and Lifespan

PVC Lay Flat Hose: Durable but has a shorter lifespan compared to HDPE pipes, especially under harsh conditions. Susceptible to UV degradation and abrasion.

HDPE Pipe: Extremely durable with a lifespan of 50 years or more. Resistant to UV rays, chemicals, and abrasion.

5. Pressure and Temperature Tolerance

PVC Lay Flat Hose: Suitable for low to medium-pressure applications. Limited temperature range (typically -10°C to 60°C).

HDPE Pipe: Can handle higher pressures and a wider temperature range (typically -40°C to 60°C), making it suitable for more demanding environments.

6. Cost

PVC Lay Flat Hose: Generally more affordable upfront, with lower installation and maintenance costs.

HDPE Pipe: Higher initial cost due to material and installation expenses but offers long-term savings due to its durability and low maintenance.

Use Cases and Application Scenarios

PVC Lay Flat Hose

Agriculture and Irrigation

Advantages: Lightweight, easy to move, and ideal for temporary irrigation systems. Can be rolled up and stored when not in use.

Disadvantages: Less durable in harsh weather conditions and prone to damage from sharp objects.

Construction and Dewatering

Advantages: Quick to deploy and effective for removing water from construction sites.

Disadvantages: May not withstand heavy debris or high-pressure requirements.

Firefighting and Emergency Response

Advantages: Portable and easy to transport, making it suitable for rapid deployment in emergencies.

Disadvantages: Limited pressure tolerance compared to specialized fire hoses.

Mining and Slurry Transport

Advantages: Flexible and resistant to abrasion, making it suitable for slurry transfer.

Disadvantages: May degrade over time when exposed to harsh chemicals or abrasive materials.

HDPE Pipe

Water Supply and Distribution

Advantages: High durability and resistance to corrosion, making it ideal for long-term water supply systems.

Disadvantages: Higher installation costs and less flexibility for temporary setups.

Sewage and Drainage Systems

Advantages: Resistant to chemicals and abrasion, ensuring long-lasting performance in sewage applications.

Disadvantages: Requires specialized installation techniques, such as fusion welding.

Industrial Fluid Transport

Advantages: Can handle high pressures and a wide range of chemicals, making it suitable for industrial use.

Disadvantages: Not portable or easy to modify once installed.

Gas and Oil Pipelines

Advantages: Excellent resistance to corrosion and environmental stress cracking, ideal for transporting hydrocarbons.

Disadvantages: High initial investment and complex installation process.

Advantages and Disadvantages in Different Scenarios

Temporary vs. Permanent Installations

PVC Lay Flat Hose: Best for temporary or mobile applications where flexibility and portability are essential.

HDPE Pipe: Better suited for permanent installations where durability and long-term performance are critical.

High-Pressure vs. Low-Pressure Applications

PVC Lay Flat Hose: Suitable for low to medium-pressure tasks but may fail under high-pressure conditions.

HDPE Pipe: Capable of handling high-pressure applications, making it a safer choice for demanding environments.

Harsh Environments

PVC Lay Flat Hose: May degrade when exposed to UV rays, extreme temperatures, or abrasive materials.

HDPE Pipe: Highly resistant to environmental factors, ensuring reliable performance in harsh conditions.

How to Choose Between PVC Lay Flat Hose and HDPE Pipe

1. Assess Your Application

Choose PVC lay flat hose if you need a portable, flexible, and cost-effective solution for temporary or low-pressure tasks.

Opt for HDPE pipe if you require a durable, long-lasting solution for permanent or high-pressure applications.

2. Consider Installation Requirements

If you need a quick and easy setup, PVC lay flat hose is the better choice.

For projects requiring specialized installation and long-term reliability, HDPE pipe is more suitable.

3. Evaluate Environmental Conditions

For harsh environments with exposure to UV rays, chemicals, or abrasion, HDPE pipe offers superior performance.

In milder conditions, PVC lay flat hose may suffice and provide cost savings.

4. Budget and Long-Term Costs

If upfront cost is a concern, PVC lay flat hose is more affordable.

For long-term savings and reduced maintenance, HDPE pipe is a better investment.

5. Pressure and Temperature Needs

For low to medium-pressure tasks, PVC lay flat hose is adequate.

For high-pressure or extreme temperature applications, HDPE pipe is the safer and more reliable option.

Conclusion

Both PVC lay flat hoses and HDPE pipes have their unique strengths and weaknesses, making them suitable for different applications. PVC lay flat hoses excel in temporary, portable, and low-pressure scenarios, offering flexibility and cost-effectiveness. On the other hand, HDPE pipes are ideal for permanent, high-pressure, and harsh environment applications, providing unmatched durability and longevity.

When choosing between the two, carefully evaluate your specific needs, including the nature of the application, environmental conditions, pressure requirements, and budget. By doing so, you can select the most appropriate solution that ensures efficiency, reliability, and cost-effectiveness for your project. Whether you opt for the versatility of a PVC lay flat hose or the robustness of an HDPE pipe, understanding their differences will help you make an informed decision.