3 Layers Green Home Garden Fiber Reinforced PVC Water Irrigation Hose 12mm 1/2inch

Three-layer braided garden hose, as a special type of piping, typically boasts excellent durability, flexibility, and resistance to twisting, making it ideally suited for use in gardens, outdoor landscapes, and similar settings.

Qingdao Renato Plastic Co., Ltd. proudly introduces its 3 Layers Green Home Garden Fiber Reinforced PVC Water Irrigation Hose, the ultimate solution for efficient and reliable irrigation. Designed to meet the diverse needs of gardeners, landscapers, and homeowners, this hose combines durability, flexibility, and style. Perfect for garden irrigation and water discharge, this lightweight and user-friendly hose is an essential tool for maintaining lush and vibrant gardens.

Material Composition

The three-layer braided garden hose consists of an inner layer, a middle layer, and an outer layer, with potentially differing materials for each layer, but all designed to enhance its overall performance.

Inner Layer: Typically made of smooth materials such as PVC or rubber to ensure smooth water flow and reduce friction resistance.

Middle Layer: Constructed using braided polyester fibers or other reinforcing materials to improve the hose's tensile strength and resistance to twisting.

Outer Layer: Also typically PVC or other wear-resistant, weather-resistant materials that protect the inner layers and enhance overall aesthetics.

Features & Advantages

Durability: The three-layer design imparts the hose with higher compression, tensile, and twisting resistance, enabling it to withstand various outdoor environments.

Flexibility: The braided structure of the middle layer gives the hose excellent flexibility, allowing it to easily accommodate bends and twists for easy installation in complex terrain.

UV Resistance: Some three-layer braided garden hoses are made with UV-resistant materials, ensuring prolonged outdoor use without degradation.

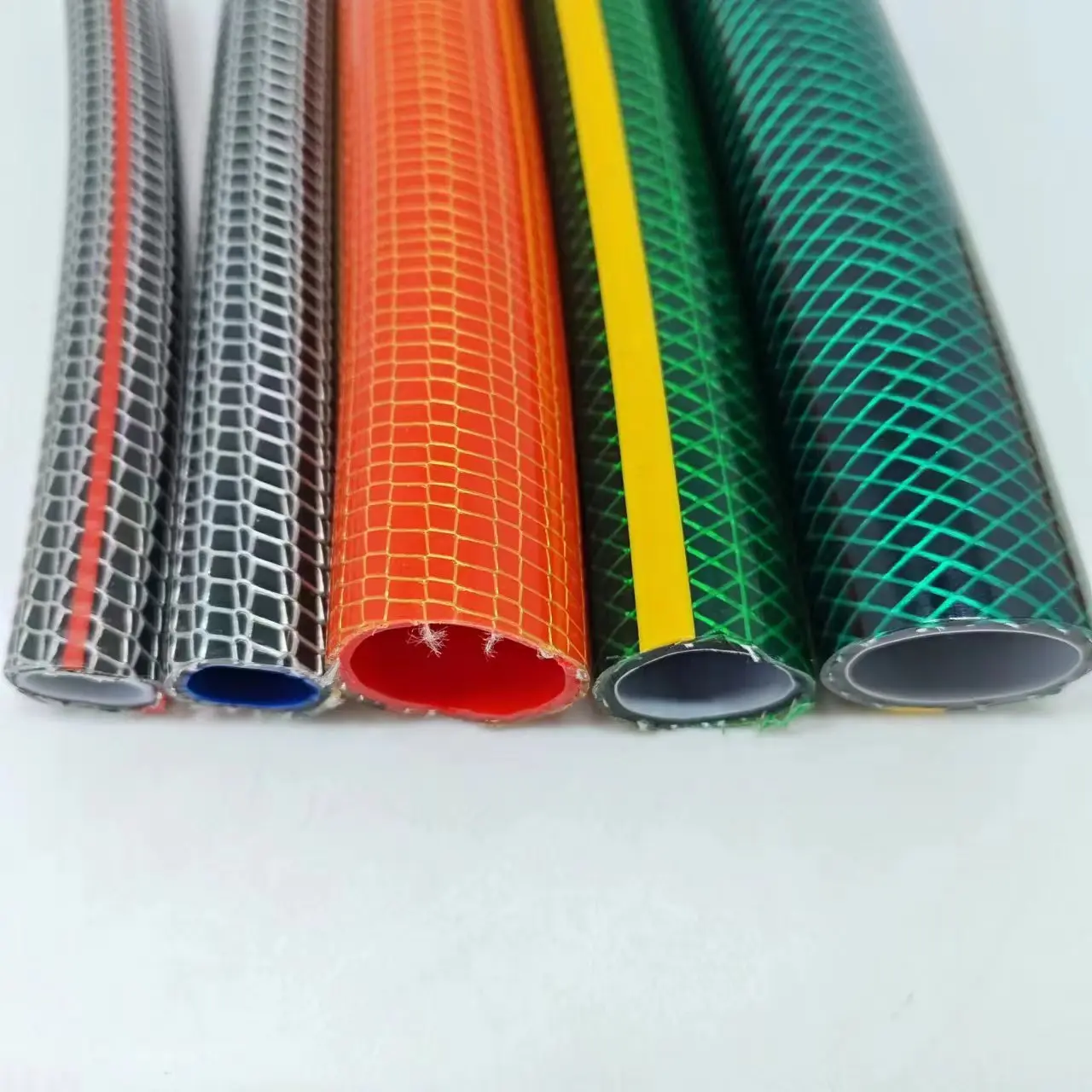

Aesthetics: The outer layer comes in vibrant, customizable colors, adding a touch of brightness to your garden.

Specification Sheet

Technical Requirements

| Parameter | Details |

|---|---|

| Brand Name | Renflex |

| Material | High-quality PVC with fiber reinforcement |

| Structure | 3-layer construction: Inner PVC layer, fiber reinforcement layer, and outer PVC layer |

| Diameter | 12mm (1/2 inch) |

| Thickness Range | 1.6mm to 6mm |

| Working Pressure | 4 - 20 bar |

| Burst Pressure | Up to 60 bar |

| Working Temperature Range | -5°C to +65°C |

| UV Resistance | Yes |

| Color Options | Green (standard), customizable colors |

| Certification | RoHS, REACH, CE |

| Flexibility | Excellent flexibility and kink resistance |

| Transporting Medium | Water |

| Packaging | Paper card or shrink wrap |

| Connection Type | Compatible with brass fittings and nozzle guns |

| Features | Lightweight, portable, weather-resistant, durable |

Specification Sizes

| Diameter (mm/inch) | Wall Thickness (mm) | Length (m) | Working Pressure (bar) | Burst Pressure (bar) |

|---|---|---|---|---|

| 12mm (1/2 inch) | 1.6 - 2.5 | 10 / 20 / 50 / 100 / 150 | 4 - 10 | Up to 30 |

| 19mm (3/4 inch) | 2.0 - 3.0 | 10 / 20 / 50 / 100 | 6 - 15 | Up to 45 |

| 25mm (1 inch) | 2.5 - 4.0 | 10 / 20 / 50 | 8 - 20 | Up to 60 |

Application Scenarios

Three-layer braided garden hoses are widely used for irrigation, drainage, and landscaping decoration in gardens, lawns, golf courses, and other outdoor areas. Their exceptional durability and flexibility make them the ideal choice for these settings.

Purchase Recommendations

Material Selection: Prioritize three-layer braided garden hoses made from high-quality PVC or rubber to ensure durability and safety.

Specifications: Choose the appropriate specifications, including diameter, wall thickness, and length, based on your actual needs.

Brand Reputation: Opt for products from reputable brands to ensure product quality and after-sales service.

Performance Parameters: Pay attention to the hose's compressive strength, tensile strength, weather resistance, and other performance parameters to select a product that meets your requirements.

Precautions

Avoid scratching the hose surface with sharp objects during installation.

Regularly check the tightness of hose connections to prevent leaks.

In cold seasons, take precautions to prevent the hose from freezing and bursting due to ice formation.

In conclusion, the three-layer braided garden hose is highly favored in the market for its excellent performance and versatility. When selecting and using this product, attention should be paid to material composition, specifications, brand reputation, and performance parameters to ensure product quality and safety.

How to Make a 3-Layer PVC Water Irrigation Hose

Creating a 3-layer fiber-reinforced PVC water irrigation hose involves a series of steps that combine materials and processes to produce a durable, flexible, and reliable product. Below is a detailed guide on the manufacturing process:

Materials Needed:

PVC Resin: The primary material for the inner and outer layers.

Plasticizers: To enhance flexibility.

Stabilizers: To ensure durability and resistance to weathering.

Fiber Reinforcement: Typically polyester yarn for the middle layer.

Color Pigments: If colored hoses are desired.

Equipment Needed:

Extrusion Machine: For forming the inner and outer PVC layers.

Braiding Machine: For applying the fiber reinforcement layer.

Cooling Tank: To solidify the extruded PVC layers.

Cutting and Winding Machine: For cutting the hose to length and winding it onto reels.

Manufacturing Process:

Preparation of PVC Compound:

Mix PVC resin with plasticizers, stabilizers, and color pigments in a high-speed mixer to create a homogeneous compound. This mixture will be used to form both the inner and outer layers of the hose.

Extrusion of Inner Layer:

Feed the PVC compound into the extrusion machine.

The compound is heated and extruded through a die to form the inner layer of the hose with a diameter of 12mm (1/2 inch).

The extruded hose passes through a cooling tank where it solidifies.

Application of Fiber Reinforcement:

The cooled inner PVC layer is then fed into a braiding machine.

Polyester yarn is braided around the PVC layer, providing the fiber reinforcement that enhances the hose’s strength and flexibility.

Ensure that the braiding is tight and uniform to maintain consistent reinforcement throughout the hose.

Extrusion of Outer Layer:

The fiber-reinforced inner layer is then passed through a second extrusion machine.

Another layer of PVC compound is extruded over the braided layer, forming the outer protective layer of the hose.

This layer protects the fiber reinforcement and provides additional durability and weather resistance.

Cooling and Solidifying:

The 3-layer hose is again passed through a cooling tank to solidify the outer PVC layer.

This process ensures that all layers are firmly bonded together, creating a unified structure.

Cutting and Winding:

Once cooled, the hose is inspected for quality and any defects are removed.

The hose is then cut to the desired lengths.

The finished hoses are wound onto reels or coils, ready for packaging and distribution.

Quality Control:

Perform pressure tests to ensure the hose can withstand the required water pressure.

Check for uniform wall thickness and diameter consistency.

Inspect the hose for any surface defects or imperfections.

Conclusion

Manufacturing a 3-layer fiber-reinforced PVC water irrigation hose involves a series of precise and controlled steps, from material preparation to the final winding. Ensuring high-quality materials and maintaining strict quality control throughout the process will result in a durable, flexible, and reliable hose suitable for various irrigation needs.

About Renato Hose

Qingdao Renato Plastic Co., Ltd. is a leading manufacturer specializing in the production of high-quality 3-layer fiber reinforced PVC water irrigation hoses, specifically in the 12mm (1/2 inch) size. With our own state-of-the-art factory located in China, we are committed to delivering durable, reliable, and efficient irrigation solutions for agricultural, commercial, and residential use.

Our manufacturing process utilizes advanced technology and strict quality control measures to ensure each hose meets international standards. The 3-layer construction of our hoses includes a robust PVC inner layer, a durable fiber reinforcement layer, and a resilient PVC outer layer. This design provides exceptional strength, flexibility, and resistance to kinking, ensuring long-lasting performance even in demanding conditions.

At Qingdao Renato Plastic Co., Ltd., customer satisfaction is our top priority. We offer customizable solutions to meet specific client requirements, backed by competitive pricing and prompt delivery services. Our dedicated team of experts continuously works to innovate and improve our products, maintaining our reputation as a trusted name in the PVC hose industry.

Whether you need hoses for irrigation, water supply, or industrial applications, Renato Hose delivers excellence with every product. Trust us for all your PVC hose needs and experience the quality and reliability that set us apart in the market.

Contact Us

For inquiries about the 3 Layers Green Home Garden Fiber Reinforced PVC Water Irrigation Hose or any of our other products, please don’t hesitate to contact us. Our team is ready to provide professional assistance and tailored solutions to meet your needs.