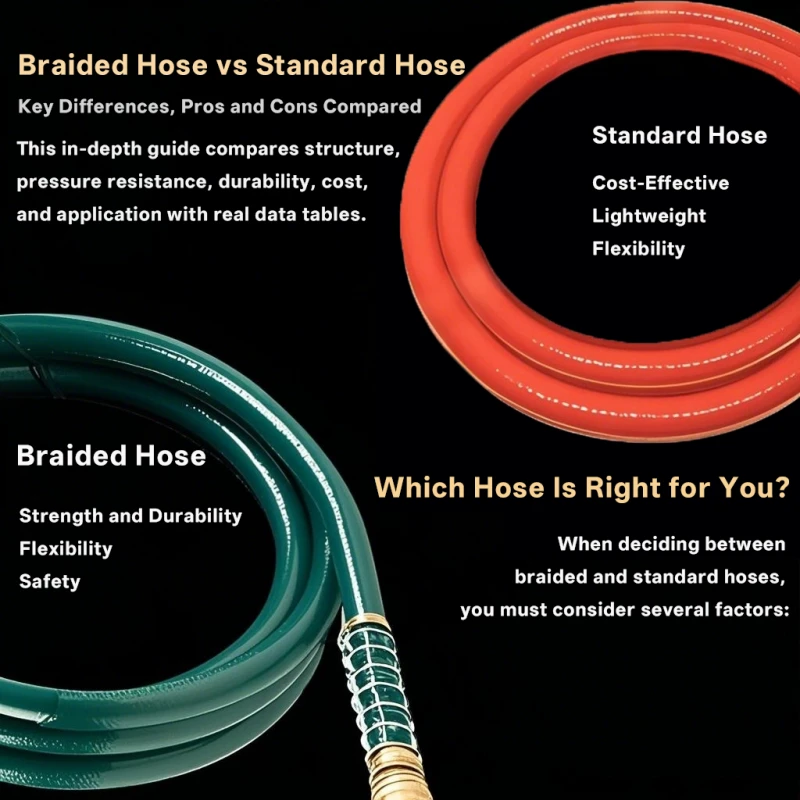

Braided Hose vs Standard Hose: Key Differences, Pros and Cons Compared

Braided hoses vs standard hoses—what’s the real difference? This in-depth guide compares structure, pressure resistance, durability, cost, and application with real data tables. Learn which hose suits your needs best, with expert insights from Qingdao Renato Plastic Co., Ltd., a trusted global manufacturer with over 15 years of experience in PVC hose solutions.

When it comes to selecting the right hose for your industrial or domestic applications, understanding the differences between braided hoses and standard hoses is essential. Both types of hoses serve crucial roles in various systems—whether in water supply, irrigation, or even more complex industrial processes. However, choosing the right type of hose can significantly impact the performance, longevity, and safety of your operation. In this article, we'll break down the key differences, pros, and cons of braided hoses versus standard hoses, comparing the two with relevant data and providing some insight into the product offerings from Qingdao Renato Plastic Co., Ltd., a professional manufacturer of PVC hoses with over 15 years of expertise.

1. What is a Braided Hose?

A braided hose is typically made from a flexible inner tube, reinforced by an outer layer of braided materials such as steel, polyester, or other synthetic fibers. The braid provides additional strength and resistance to internal and external pressure. Braided hoses are commonly used in applications where the hose is exposed to higher pressure or where extra durability is required, such as in hydraulic systems, industrial equipment, and even in home appliances like washing machines.

Advantages of Braided Hoses:

Strength and Durability: The braided construction gives the hose superior resistance to pressure and abrasion.

Flexibility: Despite its reinforced exterior, braided hoses are often more flexible than their unreinforced counterparts, making them easier to maneuver in tight spaces.

Safety: The braided design enhances safety by preventing the hose from bursting or expanding under pressure.

2. What is a Standard Hose?

In contrast, a standard hose typically refers to a hose without any reinforcement, or one that uses a single layer of material (usually PVC, rubber, or a similar compound). These hoses are often used in applications that do not require high-pressure resistance or reinforcement. Standard hoses are commonly found in low-pressure applications like garden hoses, watering systems, and basic irrigation.

Advantages of Standard Hoses:

Cost-Effective: Standard hoses are typically less expensive due to their simpler design and lack of reinforcement.

Lightweight: Without the added braid or reinforcement, these hoses are generally lighter and easier to handle.

Flexibility: Standard hoses tend to be more flexible than braided hoses, which makes them easier to roll up and store.

3. Key Differences Between Braided and Standard Hoses

The primary differences between braided and standard hoses come down to construction, performance, and the type of applications they are designed for.

| Feature | Braided Hose | Standard Hose |

| Construction | Reinforced with interwoven stainless steel or synthetic fiber | Single/double-layer PVC or rubber |

| Flexibility | Moderate to High (depends on core material) | High (more flexible without reinforcement) |

| Pressure Resistance | High – ideal for high-pressure systems | Moderate – for light to medium-duty applications |

| Durability | Long-lasting, with extra external protection | Can degrade faster due to UV or chemical exposure |

| Weight | Heavier due to braided structure | Lightweight and easy to maneuver |

| Installation Complexity | Requires fittings and some tools | Plug-and-play simplicity |

| Typical Applications | Industrial, chemical, HVAC, machinery | Gardening, light irrigation, household water discharge |

| Average Lifespan (Years) | 8 – 15 | 3 – 6 |

| Cost Range (per meter) | More expensive due to reinforced design | Less expensive |

| Temperature Tolerance Range | -40°C to 120°C+ | 0°C to 60°C |

4. Performance Comparison: Strength and Durability

One of the most noticeable differences between braided and standard hoses lies in their ability to withstand pressure. Braided hoses are designed for high-pressure applications and are built to handle the stress without bursting. The braided construction adds significant strength, which makes them ideal for industrial settings where safety is paramount.

On the other hand, standard hoses are better suited for light-duty tasks. For instance, they perform excellently in low-pressure applications such as garden watering and simple irrigation systems. However, they may not fare well under high stress, especially if used in heavy-duty systems or exposed to extreme temperatures.

Test Data:

Braided Hose Pressure Tolerance: Typically rated for pressures ranging from 300 to 1000 psi.

Standard Hose Pressure Tolerance: Usually designed for pressures up to 150 psi.

5. Flexibility and Ease of Use

Standard hoses often win in terms of flexibility. Because they lack the reinforcement that braided hoses have, standard hoses tend to be more bendable and easy to handle. This is especially important for residential applications or when the hose needs to be frequently moved or coiled for storage. Furthermore, standard hoses are less likely to kink when bent.

However, braided hoses, while more flexible than some might think, can be less convenient when dealing with sharp bends due to the reinforcement. Nevertheless, their flexibility is often still sufficient for most high-pressure applications, especially when maneuverability isn't a critical factor.

6. Cost-Effectiveness and Value for Money

In terms of upfront cost, standard hoses are generally more budget-friendly. For customers who need hoses for non-industrial purposes, such as simple garden irrigation or light-duty use, standard hoses offer a highly affordable solution. Their ease of use and lower price point make them a go-to choice for everyday applications.

However, when it comes to long-term value, braided hoses can be a more cost-effective investment for those in need of hoses for high-pressure or industrial applications. The durability and pressure resistance of braided hoses mean they last longer, potentially saving money on replacements and repairs.

7. Applications: Where to Use Each Type of Hose

The choice between braided and standard hoses largely depends on the specific application. Here's a closer look at where each hose type excels:

Braided Hose Applications:

Hydraulic Systems: Due to their high pressure tolerance, braided hoses are commonly used in hydraulic systems where high pressure and durability are essential.

Fuel Lines: Braided hoses are often used in fuel lines, where fuel transfer must occur safely under pressure.

Industrial Machinery: They’re found in industrial machinery and equipment requiring high-pressure fluid transfer.

Automotive Applications: Braided hoses are often used in vehicles for brake lines, cooling systems, and fuel systems.

Standard Hose Applications:

Home Gardening and Irrigation: Standard hoses are ideal for watering gardens and lawns and for connecting outdoor spigots to irrigation systems.

Light Duty Industrial Use: Standard hoses can be used in some industrial settings, especially where low-pressure water flow is required.

Air and Water Delivery: For delivering air or water in low-pressure systems, standard hoses are perfect.

8. Which Hose Is Right for You?

When deciding between braided and standard hoses, you must consider several factors:

Pressure Requirements: If you’re working with high-pressure systems, braided hoses are the better option.

Application Type: For heavy-duty, industrial, or safety-critical applications, braided hoses shine. For casual, low-pressure, or residential tasks, standard hoses will be more than sufficient.

Budget: If cost is a significant factor, and you're not dealing with high-pressure systems, a standard hose may be the best choice.

| Need | Go With |

| Budget-friendly & highly flexible | Standard Hose |

| Long-lasting & high-pressure capable | Braided Hose |

| Frequent repositioning or coiling | Standard Hose |

| Safety-critical or industrial setting | Braided Hose |

| Hot/cold temperature tolerance needed | Braided Hose |

| Light residential use | Standard Hose |

9. Qingdao Renato Plastic Co., Ltd. – Your Hose Solution Provider

At Qingdao Renato Plastic Co., Ltd., we specialize in manufacturing high-quality PVC hoses for a variety of applications. With over 15 years of experience in hose production, we offer a broad range of products, including layflat hoses, suction hoses, fiber-reinforced hoses, steel wire hoses, garden hoses, and much more. Our hoses are widely used in water supply systems, water discharge systems, and irrigation applications.

Our factory in Shandong Province boasts 10 workshops, more than 60 production lines, and a dedicated team of experts. We are proud to have served over 60 countries worldwide, providing our customers with durable and reliable hoses designed to meet their specific needs. Whether you’re looking for a braided hose for high-pressure applications or a standard hose for light-duty use, we have you covered.

Conclusion

The decision between a braided hose and a standard hose depends on your unique requirements. Braided hoses offer strength, durability, and safety in high-pressure systems, while standard hoses excel in affordability and flexibility for everyday use. By considering your specific needs—whether for industrial, automotive, or domestic applications—you can make an informed decision that ensures both efficiency and safety.

For more information or to inquire about our high-quality hose products, feel free to contact Qingdao Renato Plastic Co., Ltd. We offer quick, 24/7 customer service and look forward to helping you find the perfect hose solution for your needs.