Air Compressor Hose Size Chart: A Comprehensive Guide

The Air Compressor Hose Size Chart provides a detailed comparison of hose sizes, maximum PSI, airflow (CFM), and recommended uses, helping users select the right hose for optimal pneumatic tool performance.

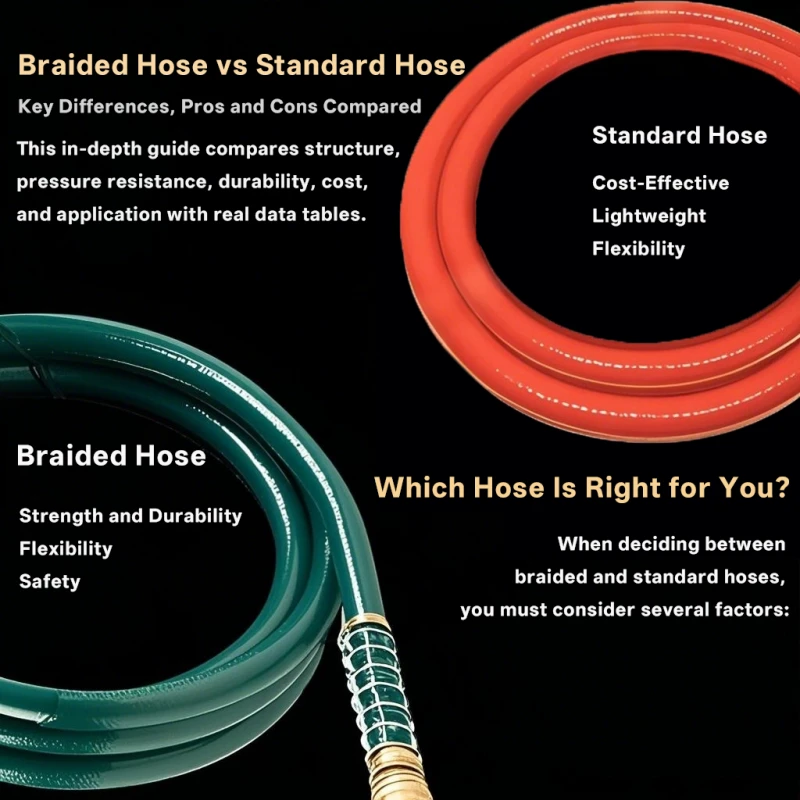

780.webp)

Choosing the correct air compressor hose size is crucial for optimal performance, safety, and efficiency when using pneumatic tools. An air compressor hose's size influences airflow, pressure, and the ability to run various tools effectively. This article covers the importance of selecting the right air compressor hose, provides a comprehensive hose size chart, and discusses factors that help determine the best size for your specific application.

369545.webp)

Why the Hose Size Matters

The size of an air compressor hose affects how much air can flow through it, which impacts the overall performance of your pneumatic tools. A hose that is too small for the compressor or tool being used can restrict airflow, leading to a loss of pressure and decreased efficiency. On the other hand, a hose that is too large may be unnecessarily bulky and more expensive without providing added benefits. Therefore, selecting the correct hose size ensures that your air tools function at their best.

Key Factors Influenced by Hose Size:

Airflow (CFM): Cubic Feet per Minute (CFM) is the amount of air passing through the hose. A hose with a larger inner diameter can deliver more air, which is necessary for high-demand tools.

Pressure (PSI): Pounds per Square Inch (PSI) measures the pressure of the air being delivered. A hose with a smaller inner diameter may cause a drop in pressure over long distances.

Flexibility and Maneuverability: Larger hoses can be harder to maneuver in tight spaces, while smaller hoses are lighter and more flexible.

Hose Length: The length of the hose also affects pressure and airflow. The longer the hose, the more the air pressure will drop before it reaches the tool.

580124.webp)

Air Compressor Hose Size Chart

Below is a size chart detailing common air compressor hose sizes, their diameters, and the typical applications each size is suited for.

| Hose Size (ID) | Maximum PSI | Airflow (CFM) | Recommended Use |

|---|---|---|---|

| 1/4 inch (6.35 mm) | Up to 150 PSI | 2-5 CFM | Light-duty tools (airbrushes, tire inflators, small nailers) |

| 3/8 inch (9.52 mm) | Up to 300 PSI | 5-10 CFM | Medium-duty tools (nail guns, impact wrenches, spray guns) |

| 1/2 inch (12.7 mm) | Up to 300 PSI | 10-30 CFM | Heavy-duty tools (sanders, larger impact wrenches) |

| 3/4 inch (19.05 mm) | Up to 300 PSI | 30+ CFM | High-demand tools (jackhammers, industrial pneumatic tools) |

1/4-Inch Hose

Application: A 1/4-inch air hose is best for light-duty applications where minimal airflow is needed, such as inflating tires or using an airbrush.

Advantages: This size is lightweight and easy to handle, making it ideal for small, portable compressors.

Limitations: Limited to low-CFM tools, this size may not be suitable for more demanding pneumatic tools like impact wrenches or large nailers.

3/8-Inch Hose

Application: A 3/8-inch air hose is commonly used in most household and workshop applications, such as running nail guns, impact wrenches, and spray guns.

Advantages: Provides a good balance between airflow and maneuverability. It is the most popular size for general-purpose use.

Limitations: Slightly heavier and less flexible than 1/4-inch hoses but offers significantly more airflow, making it more versatile.

1/2-Inch Hose

Application: A 1/2-inch air hose is used for high-demand tools, including heavy-duty impact wrenches and air sanders. It can supply larger volumes of air efficiently.

Advantages: Delivers more CFM, which is essential for running more powerful tools without pressure drops.

Limitations: Heavier and more difficult to handle than smaller hoses, especially in confined spaces.

3/4-Inch Hose

Application: This large-diameter hose is often used in industrial settings for running high-CFM tools like jackhammers or industrial pneumatic equipment.

Advantages: Capable of delivering large amounts of air with minimal pressure loss, even over longer distances.

Limitations: Bulkier and harder to maneuver, making it less practical for small or medium workshops.

100536.webp)

How to Choose the Right Air Compressor Hose Size

When selecting the right air compressor hose, consider the following factors:

1. Type of Tools Used

Light-duty tools (e.g., inflators, nail guns) can operate effectively with a 1/4-inch hose.

Medium-duty tools (e.g., impact wrenches, spray guns) work well with a 3/8-inch hose.

Heavy-duty tools (e.g., air sanders, large impact wrenches) require at least a 1/2-inch hose.

2. Airflow (CFM) Requirements

Determine the CFM requirements of your tools. The hose size must support the airflow your tools need without causing pressure loss. For instance, a 1/4-inch hose is not sufficient for tools requiring high CFM.

3. Compressor Output

Ensure the hose size matches the output of your compressor. If your compressor can produce high PSI and CFM, pairing it with a small hose will bottleneck the airflow, causing inefficiency.

4. Length of the Hose

The longer the hose, the more pressure loss occurs, especially with smaller diameter hoses. For long distances, consider using a 3/8-inch or larger hose to maintain airflow and minimize pressure loss.

5. Portability and Flexibility

Smaller hoses like 1/4-inch and 3/8-inch are lighter and easier to handle, making them ideal for portable compressors or tight workspaces.

Larger hoses, while heavier, are necessary for larger tools but can be cumbersome in small or intricate work areas.

Price Comparison of Air Compressor Hoses by Size

| Hose Size (ID) | Price Range (USD) |

|---|---|

| 1/4 inch (25-50 ft) | $10 - $25 |

| 3/8 inch (25-50 ft) | $15 - $35 |

| 1/2 inch (25-50 ft) | $20 - $50 |

| 3/4 inch (25-50 ft) | $40 - $75 |

Tips for Beginners: How to Choose the Right Hose Size

Start Small: If you’re using basic tools such as tire inflators or airbrushes, a 1/4-inch hose will likely meet your needs without taking up much space or costing too much.

Go Versatile: For beginners unsure of their future needs, a 3/8-inch hose is the most versatile choice, capable of running a wide range of tools.

Consider Expansion: If you plan to use heavier tools in the future, opt for a larger hose size to avoid having to upgrade later.

Measure Twice, Buy Once: Always check the CFM and PSI ratings of both your air compressor and tools to ensure the hose can handle the load.

Conclusion

Selecting the right air compressor hose size is crucial for the efficiency, safety, and longevity of your pneumatic tools. The correct size ensures optimal airflow, pressure, and performance, regardless of whether you’re using light-duty inflators or heavy-duty industrial tools. By understanding the relationship between hose size, CFM, PSI, and tool requirements, you can choose a hose that meets your needs effectively. For beginners, a 3/8-inch hose offers the most flexibility, while professionals may require the added capacity of a 1/2-inch or 3/4-inch hose for high-demand tools.

![]() Air Compressor Hose Size Chart.pdf

Air Compressor Hose Size Chart.pdf