Flexible Food Grade Hose

Flexible food grade hoses are essential for safe, hygienic transport of food and beverages across industries. This article covers key features, benefits, and materials like PVC, silicone, and rubber. It also discusses industry applications, regulatory compliance, and future trends. For high-quality hoses and assemblies, Qingdao Renato Plastic Co., Ltd. offers durable, reliable solutions with over 15 years of experience.

Flexible Food Grade Hose

Flexible food grade hoses play a crucial role in various industries, particularly in the food and beverage sector, where hygiene, safety, and flexibility are paramount. These hoses are designed to safely transport food and beverage products while ensuring compliance with stringent health regulations. In this article, we will explore the main characteristics, benefits, and applications of flexible food grade hoses, backed by research data and key insights from the industry.

What is a Flexible Food Grade Hose?

A flexible food grade hose is a specialized hose designed to carry food and beverage products without contaminating them. These hoses are constructed from high-quality materials, such as FDA-approved PVC, rubber, and silicone, which ensure they meet safety standards for transporting consumables. Flexible food grade hoses are typically used in environments where products like milk, juice, oils, and other edible liquids are transported or processed.

Key Features of Food Grade Hoses

Non-Toxic Materials: Flexible food grade hoses are made from materials that are non-toxic and safe for use in food processing and transportation.

Compliance with FDA and EU Regulations: These hoses are designed to meet regulatory standards such as the FDA 21 CFR 177.2600 (Food Contact Substance) and the European Regulation (EC) No. 1935/2004.

Flexibility and Durability: They offer flexibility for easy handling and installation, while also providing durability against wear and tear, as well as resistance to abrasion, UV rays, and extreme temperatures.

Smooth Inner Surface: The inner surface is smooth to reduce the buildup of bacteria and other contaminants.

Benefits of Flexible Food Grade Hoses

1. Hygiene and Safety

The primary advantage of flexible food grade hoses is their ability to maintain product purity. Because they are made from FDA-approved materials, they ensure that food and beverages remain free from contamination during transportation. This is particularly important in industries where product quality and safety are non-negotiable.

2. Versatility

Flexible food grade hoses are used in a wide range of applications, including:

Milk and Dairy Transport: Ensuring the safe transport of milk and cream without contamination.

Beverage Production: Used in breweries, juice plants, and soft drink production.

Food Processing: In plants that handle raw and cooked food products.

Chemical Applications: Used in transporting food-safe chemicals and additives that are added to the production process.

3. Easy to Clean

Food-grade hoses are designed for easy cleaning and sterilization, making them ideal for use in environments that require frequent sanitation, such as dairy farms and food manufacturing plants. Their smooth surfaces help reduce the accumulation of food particles, oils, and residues, which can harbor bacteria.

4. Cost-Effectiveness

While initially more expensive than other hoses, flexible food grade hoses are highly durable and reduce the risk of product contamination or damage, leading to cost savings in the long term. The low-maintenance and long lifespan of these hoses also contribute to overall cost efficiency.

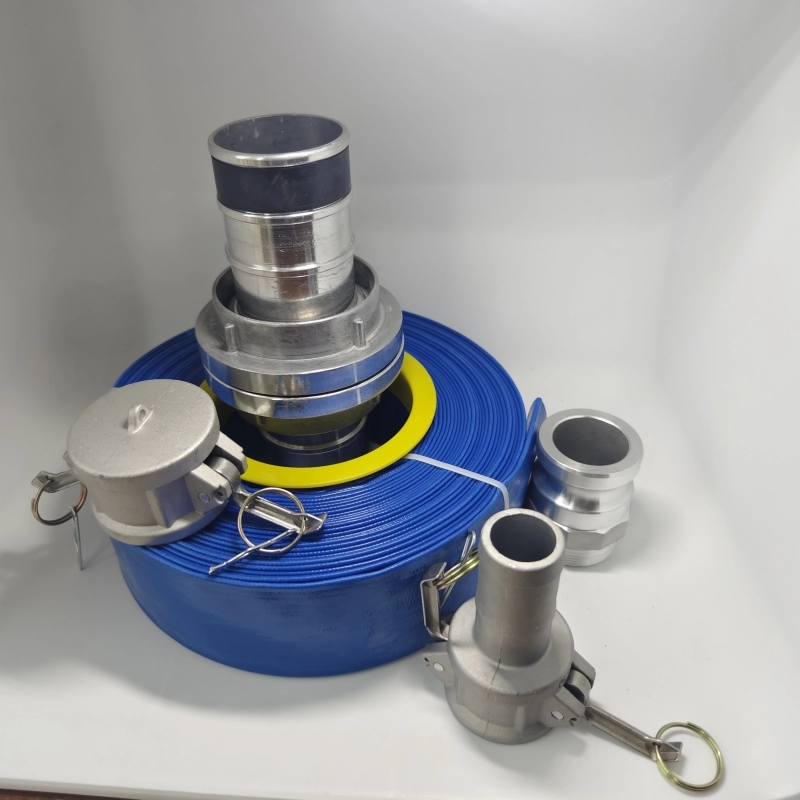

The object in the picture is a food-grade hose, which complies with relevant safety standards and can be safely used in food contact scenarios such as food processing and beverage delivery. Its non-toxic properties ensure that no harmful substances are released during contact with food, ensuring food safety. It is often used in food processing plants to transport liquid foods such as juice and milk, or in the catering industry to connect equipment for the transmission of food raw materials.

Industry Applications

Flexible food grade hoses are widely used in various sectors, including:

1. Food & Beverage Industry

The food and beverage industry is one of the largest consumers of flexible food grade hoses. They are used for:

Transporting raw materials such as sugar, flour, or oils.

Processing liquids like milk, wine, beer, and fruit juices.

Handling dry foods such as grains and cereals.

2. Dairy Industry

Flexible food grade hoses are integral in the dairy industry, where hygiene standards are extremely high. These hoses are used to transport milk from farms to processing plants and then to packaging facilities. They are designed to prevent contamination, especially when moving dairy products that are sensitive to bacteria.

3. Pharmaceutical & Chemical Manufacturing

Although primarily used for food, flexible food grade hoses also have applications in pharmaceutical and chemical manufacturing, where clean and safe handling of ingredients is necessary. Their ability to handle various substances without degradation or contamination makes them suitable for various non-food grade applications.

Research Data on Flexible Food Grade Hose Materials

In the following sections, we will explore some key materials used in the production of flexible food grade hoses and their respective properties. These materials are selected based on safety standards, durability, and resistance to environmental conditions.

Comparison of Food Grade Hose Materials

| Material | FDA Approval | Temperature Range | Chemical Resistance | Flexibility | Durability |

|---|---|---|---|---|---|

| PVC | Yes | -10°C to 60°C | Moderate | High | Moderate |

| Silicone | Yes | -50°C to 180°C | High | High | High |

| Rubber | Yes | -30°C to 100°C | High | Moderate | High |

| Polyurethane | Yes | -20°C to 80°C | High | Moderate | Very High |

Analysis:

PVC: Commonly used due to its cost-effectiveness and flexibility. It is ideal for less demanding applications but may not be suitable for high-temperature environments.

Silicone: The ideal material for high-temperature applications. It is highly resistant to chemicals and offers superior durability.

Rubber: Preferred for its resistance to wear and tear. It is widely used in the dairy industry for its ability to withstand frequent cleaning and sterilization processes.

Polyurethane: Known for its exceptional durability and resistance to abrasion, making it suitable for industries with more demanding environments.

Applications of Food Grade Hoses by Industry

| Industry | Common Applications | Hose Material Used |

|---|---|---|

| Food & Beverage | Juice transport, dairy, oils | PVC, Silicone, Rubber |

| Pharmaceutical | Ingredient handling | Silicone, Rubber |

| Dairy | Milk, cream transport | Rubber, Silicone |

| Chemical Processing | Food-safe chemical transport | Polyurethane, Silicone |

Analysis:The flexibility of the hoses used in different industries can vary based on the requirements. For instance, silicone hoses are commonly used in dairy and pharmaceutical industries due to their high temperature tolerance and durability, while PVC hoses are more common in food and beverage sectors.

Key Considerations When Choosing a Flexible Food Grade Hose

When selecting a flexible food grade hose, several factors must be considered:

Compliance with Regulations: Ensure the hose material complies with FDA and EU standards for food contact.

Temperature Resistance: Different applications require hoses that can withstand varying temperature ranges. For instance, dairy transportation may require hoses that handle lower temperatures, while hot liquids require high-temperature-resistant hoses.

Chemical Compatibility: Make sure the hose material is resistant to the specific chemicals it will encounter in the processing of food and beverages.

Durability: Choose hoses that can withstand the physical demands of frequent handling, cleaning, and transportation.

Ease of Cleaning: Look for hoses with smooth internal surfaces to reduce bacterial growth and ease cleaning procedures.

Future Trends in Flexible Food Grade Hoses

The future of flexible food grade hoses lies in improving materials to enhance hygiene, extend product life, and meet sustainability goals. Trends to watch include:

Increased Use of Bio-Based Materials: Growing concern about environmental sustainability has led to the development of food grade hoses made from renewable materials.

Technological Integration: Sensors and smart hoses are being integrated to monitor the quality of food being transported in real-time.

Greater Customization: Food grade hoses are being designed to fit specific applications, such as those with antimicrobial properties or those that can handle higher pressures and temperatures.

Conclusion

Flexible food grade hoses are indispensable in industries that require safe and hygienic handling of food and beverage products. With their compliance to regulatory standards, versatile applications, and the ability to maintain the safety and quality of the product, they are a crucial component in food manufacturing, transportation, and processing. As technology and sustainability concerns evolve, the future of food-grade hoses will continue to improve, ensuring both the safety of the end consumer and the efficiency of production.

Key Takeaways:

Flexible food grade hoses ensure the safe and hygienic transport of food products.

The materials used in these hoses vary by industry needs and include PVC, silicone, rubber, and polyurethane.

Factors such as compliance with FDA standards, temperature resistance, and ease of cleaning must be considered when choosing a food grade hose.

The industry is likely to see an increase in the use of bio-based materials and smart technology in hose production.

By understanding these features and considerations, businesses can make informed decisions when selecting flexible food grade hoses that meet both regulatory and operational requirements.

Qingdao Renato Plastic Co., Ltd.

At Qingdao Renato Plastic Co., Ltd., we are a leading manufacturer with over 15 years of experience in producing high-quality PVC hoses. Our extensive product range includes Layflat Hoses, Suction Hoses, Fiber Reinforced Hoses, Steel Wire Hoses, Garden Hoses, and Mix Rubber High Pressure Air/Water Hoses, among others. We also offer various hose assemblies such as Camlock Fittings, Storz Fittings, Nozzle Fittings, and Hose Clamps, widely used in water supply and discharge systems, as well as irrigation for homes and public places.

With over 60 production lines and 10 workshops at our factory in Shandong Province, we provide reliable and durable hose solutions to customers in over 60 countries globally. Our commitment to quality and customer satisfaction has earned us the trust and praise of our clients.

If you are looking for a dependable partner for your hose and fitting needs, feel free to contact us. We promise quick responses and dedicated support, available 24/7. Your satisfaction is our priority.