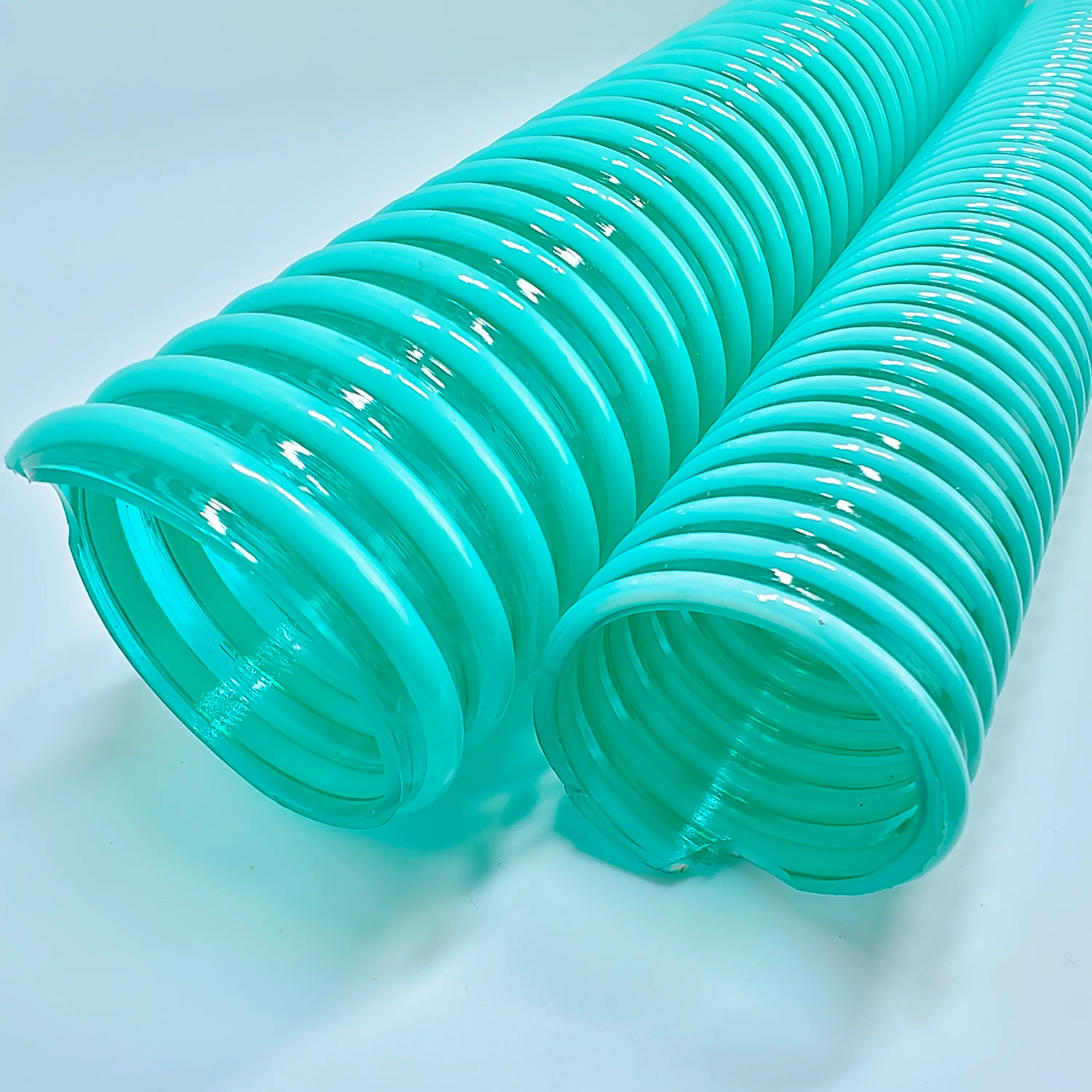

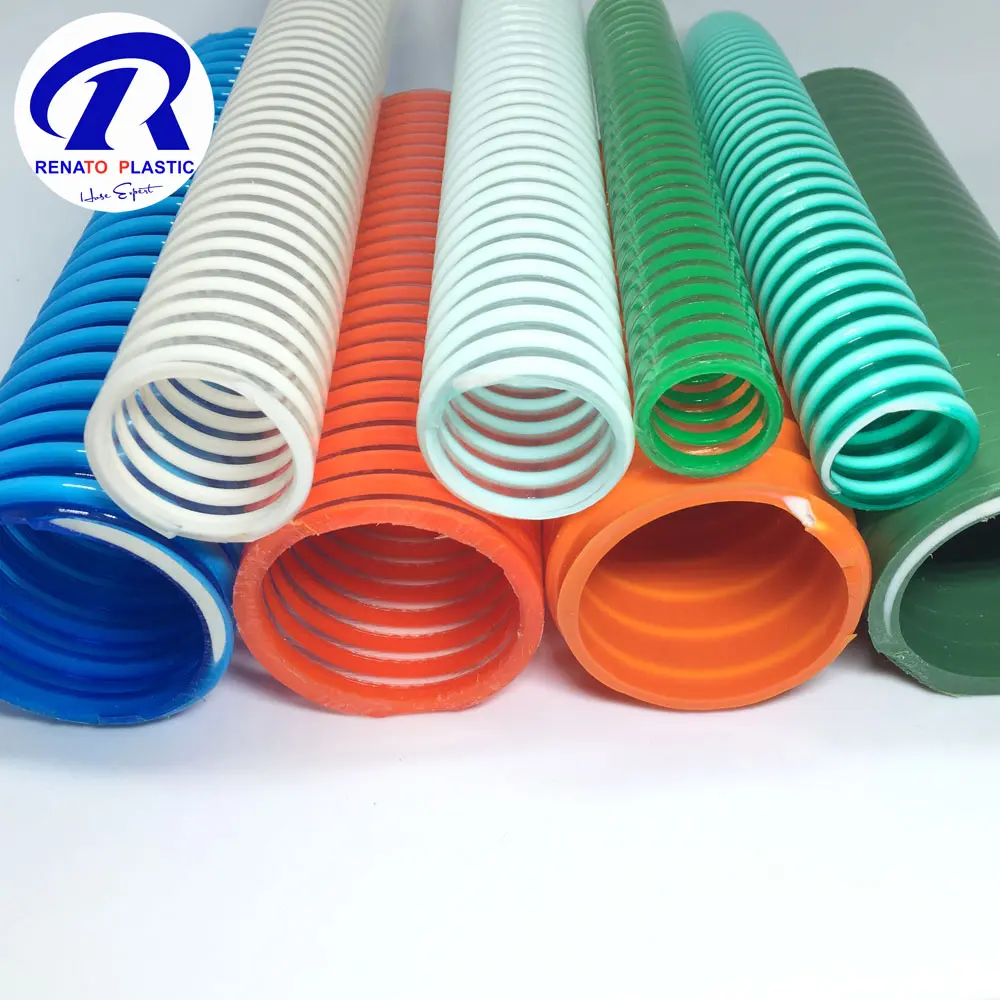

Heavy Duty PVC Spiral Reinforced Suction Hose for Oil

The Heavy Duty PVC Spiral Reinforced Suction Hose is specifically engineered to meet the rigorous demands of oil suction and transfer applications. This hose combines strength, flexibility, and durability to provide reliable performance in various industrial and commercial settings. Whether you are transferring petroleum products, diesel, or other oil-based substances, this hose ensures safe and efficient operation. At Renato Hose, we pride ourselves on delivering top-tier products crafted with precision and expertise honed over 15 years in the industry. Our Helix Spiral PVC Suction Hose stands as a testament to our commitment to quality and innovation.

Crafted with high-quality PVC reinforcement, our suction hose boasts a robust construction capable of withstanding up to -2 bar vacuum pressure, ensuring reliability even in demanding environments. Its long working life guarantees durability, providing you with a dependable solution for your water suction and discharge requirements.

Applications

This hose is widely used for industry in both positive and negative pressure applications, ideally for conveying and suction of water, oil, powder, granules in pump industries, constructions, mining industries, chemical factories and many other industry applications.

Characteristics

This hose is made from high quality flexible PVC material and high strengthen PVC bones. Excellent flexibility, light weight, crush and abrasion resistant, smooth tube for less friction loss, smooth cover allows easy dragging, weathering resistant, clear to have full visual flow of materials, corrosion resistant to light chemicals, various lengths available and can be supplied with different couplings and clamps, ideal replace for bulkier and heavier ply-wrapped rubber hose.

◢ This kind of hose is an ideal products to use for suction and discharge.

◢ It is cystal clear, flexible, bright colors, very easy to know what's going on inside the hose.

◢ No odor, environmental protection products.

◢ Working Temperature: -5°C-65°C

Specifications of PVC Suction Hose

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | ||

| inch | mm | mm | m | kg/m | bar | psi |

| 3/4 | 19 | 2.5 | 50 | 0.25 | 8 | 120 |

| 3 | 50 | 0.28 | 9 | 135 | ||

| 1 | 25 | 2.5 | 50 | 0.32 | 8 | 120 |

| 3 | 50 | 0.35 | 9 | 135 | ||

| 1 1/4 | 32 | 3 | 50 | 0.4 | 8 | 120 |

| 4 | 50 | 0.55 | 9 | 135 | ||

| 1 1/2 | 38 | 3 | 50 | 0.55 | 6 | 90 |

| 4 | 50 | 0.7 | 7 | 105 | ||

| 2 | 50 | 4 | 50 | 0.92 | 6 | 90 |

| 5 | 50 | 1.1 | 7 | 105 | ||

| 2 1/2 | 63 | 3.5 | 30 | 0.95 | 5 | 75 |

| 4.5 | 30 | 1.23 | 6 | 90 | ||

| 3 | 75 | 4 | 30 | 1.45 | 4 | 60 |

| 5 | 30 | 1.65 | 5 | 75 | ||

| 4 | 100 | 5 | 30 | 2.3 | 4 | 60 |

| 6 | 30 | 2.9 | 5 | 75 | ||

| 5 | 127 | 6 | 20 | 3.3 | 4 | 60 |

| 8 | 20 | 4.7 | 5 | 75 | ||

| 6 | 152 | 7 | 20 | 5 | 4 | 60 |

| 9 | 20 | 6.3 | 5 | 75 | ||

| 8 | 200 | 7 | 10 | 6.3 | 4 | 60 |

| 8 | 10 | 7 | 4 | 60 | ||

| 10 | 250 | 8 | 10 | 10 | 4 | 60 |

| 9 | 10 | 11 | 4 | 60 | ||

| 12 | 305 | 12 | 10 | 18 | 4 | 60 |

| 14 | 355 | 12 | 10 | 20 | 4 | 60 |

The Characteristics of PVC Suction Hose for Oil

Heavy Duty PVC Spiral Reinforced Suction Hose exhibits several distinctive characteristics when used for transporting oil. Firstly, its robust PVC construction combined with spiral reinforcement offers superior durability and strength, making it capable of handling high-pressure oil flows without compromising its structural integrity. Secondly, the hose's spiral design enhances flexibility, allowing it to navigate complex piping systems and adapt to various installation configurations. This flexibility also reduces the risk of kinking or twisting, ensuring smooth oil flow.

Furthermore, the hose's PVC material is specifically formulated to resist oil and other chemicals, preventing degradation or corrosion over time. This ensures long-term performance and reliability, even in harsh environments or under heavy use. Additionally, the hose's smooth interior surface minimizes friction and resistance, promoting efficient oil transfer with minimal energy loss.

Lastly, the Heavy Duty PVC Spiral Reinforced Suction Hose is easy to install and maintain, making it a practical and cost-effective solution for oil transportation applications. Overall, its unique combination of durability, flexibility, and oil resistance makes it an ideal choice for safely and efficiently transporting oil.

The Heavy Duty PVC Spiral Reinforced Suction Hose for Oil is the ideal solution for efficient and reliable oil suction and transfer operations. With its durable construction, spiral reinforcement, and chemical resistance, this hose ensures safe and effective performance in various industrial and commercial settings. Whether used in refineries, transportation, or marine environments, this hose delivers the strength and flexibility needed to handle demanding tasks.

For high-quality heavy-duty PVC spiral reinforced suction hoses that meet your specific needs, trust [Your Company Name] as your reliable supplier. Contact us today to learn more about our products and how we can support your fluid handling requirements.

How to Use Step by Step?

Step 1: Preparation

Select the Hose: Choose the appropriate size and length of the heavy-duty PVC spiral reinforced suction hose based on your specific oil transfer requirements.

Inspect the Hose: Before use, visually inspect the hose for any signs of damage, such as cuts, abrasions, or kinks. Ensure that fittings and connections are secure and in good condition.

Step 2: Setup

Connect Fittings: Attach the appropriate fittings to both ends of the hose. Use compatible fittings designed for oil transfer applications to ensure a secure and leak-proof connection.

Position Equipment: Position the equipment involved in the oil transfer process, such as pumps, tanks, and containers, in the desired location. Ensure that all equipment is stable and properly grounded.

Step 3: Prime the Pump (If Required)

Prime the Pump: If using a pump for oil transfer, prime the pump according to the manufacturer's instructions. This typically involves filling the pump casing and suction line with oil to remove any air and create a vacuum.

Step 4: Hose Deployment

Position the Hose: Position one end of the heavy-duty PVC suction hose in the oil source or container from which you will be transferring oil.

Ensure Proper Orientation: Ensure that the hose is positioned with the suction end immersed in the oil and the discharge end connected to the pump or receiving container.

Step 5: Start Transfer

Start the Pump: If using a pump, start the pump according to the manufacturer's instructions to begin the oil transfer process. The pump creates suction, drawing oil through the hose.

Monitor the Transfer: Monitor the oil transfer process closely to ensure smooth operation. Check for leaks, proper flow, and any abnormalities in the system.

Step 6: End Transfer

Stop the Pump: Once the desired amount of oil has been transferred, stop the pump to halt the suction process.

Disconnect the Hose: Disconnect the heavy-duty PVC suction hose from the pump or oil source by removing the fittings from both ends.

Drain Residual Oil: If necessary, drain any residual oil from the hose by elevating one end and allowing gravity to empty the hose completely.

Step 7: Maintenance and Storage

Clean the Hose: After use, clean the heavy-duty PVC suction hose with a mild detergent and water to remove any oil residue and debris. Rinse thoroughly and allow the hose to dry completely before storage.

Inspect for Damage: Inspect the hose for any signs of damage or wear after each use. Replace any damaged or worn parts to ensure safe and efficient operation.

Proper Storage: Store the heavy-duty PVC suction hose in a clean, dry, and well-ventilated area away from direct sunlight and sources of heat. Coil the hose neatly to prevent kinks and damage.

By following these detailed steps, you can effectively and safely use the Heavy Duty PVC Spiral Reinforced Suction Hose for Oil in your oil transfer operations. Always prioritize safety and proper maintenance to ensure optimal performance and longevity of the hose.

Company Advantages

At QINGDAO RENATO PLASTIC CO., LTD, we pride ourselves on over 15 years of manufacturing experience in the PVC hose industry. Our state-of-the-art factory, located in Shandong province, features 10 workshops, over 60 production lines, and a dedicated team of 120 skilled workers. Our commitment to quality is further supported by our two quality control teams, ensuring that every product meets the highest standards. With a customer base spanning over 60 countries, our hoses and fittings have earned widespread acclaim for their reliability and performance.

Contact Us

If you`re looking for a reliable partner in hose and assemblies, look no further! We are here to assist you. For inquiries or to place an order, please reach out to us, and we will respond promptly. At QINGDAO RENATO PLASTIC CO., LTD, our motto is "Customers First," and we are committed to providing you with quick responses 24/7.

Let us be your trusted source for all your oil transfer needs with our Heavy Duty PVC Spiral Reinforced Suction Hose!

FAQ

1. What factors should I consider when selecting a Heavy Duty PVC Spiral Reinforced Suction Hose for Oil?

Size and Length: Choose the appropriate diameter and length to match your application requirements.

Pressure Rating: Ensure the hose can handle the maximum pressure of your oil transfer system.

Chemical Compatibility: Verify that the hose material is compatible with the type of oil or petroleum-based fluid being transferred.

Temperature Range: Check the temperature range the hose can withstand to ensure it's suitable for your operating conditions.

2. How do I ensure proper installation and maintenance of the hose?

Follow the manufacturer's instructions for installation, including proper fitting attachment and securing.

Regularly inspect the hose for signs of wear, damage, or leaks.

Clean the hose after each use to remove oil residue and debris.

Store the hose in a clean, dry area away from sunlight and sources of heat when not in use.

3. Where can I purchase a Heavy Duty PVC Spiral Reinforced Suction Hose for Oil?

You can purchase this specialized hose from us and reputable industrial supply companies, distributors, and manufacturers. Ensure to choose a supplier with a proven track record of providing high-quality products and reliable customer service.

4. Can I request customizations or special configurations for the hose?

Many suppliers offer customization options for hose lengths, fittings, and specifications to meet specific application requirements. Contact the supplier directly to discuss your customization needs and inquire about available options.

5. What are the typical lead times and shipping options for purchasing this hose?

Lead times and shipping options may vary depending on the supplier and your location. It's advisable to inquire about lead times and available shipping methods when placing your order to ensure timely delivery of the hose.

6. Are there any warranty or quality assurance guarantees provided with the purchase?

Most reputable suppliers offer warranties or quality assurance guarantees for their products. Be sure to inquire about warranty coverage and any applicable terms and conditions when purchasing the hose to ensure your satisfaction and peace of mind.

7. How do I contact customer support for further assistance or inquiries?

If you have any further questions or need assistance with your purchase, don't hesitate to contact the supplier's customer support team. They will be happy to provide additional information, answer your inquiries, and assist you with your hose purchase.