High Pressure Flexible PVC Water Hose for farm Irrigation

When it comes to efficient and reliable farm irrigation, Qingdao Renato Plastic Co., Ltd. offers the ultimate solution: High-Pressure Flexible PVC Water Hose. Designed for durability and versatility, this hose meets the rigorous demands of agricultural applications. With more than 15 years of expertise in PVC hose production, we provide innovative and customized solutions that empower farmers worldwide to optimize irrigation processes.

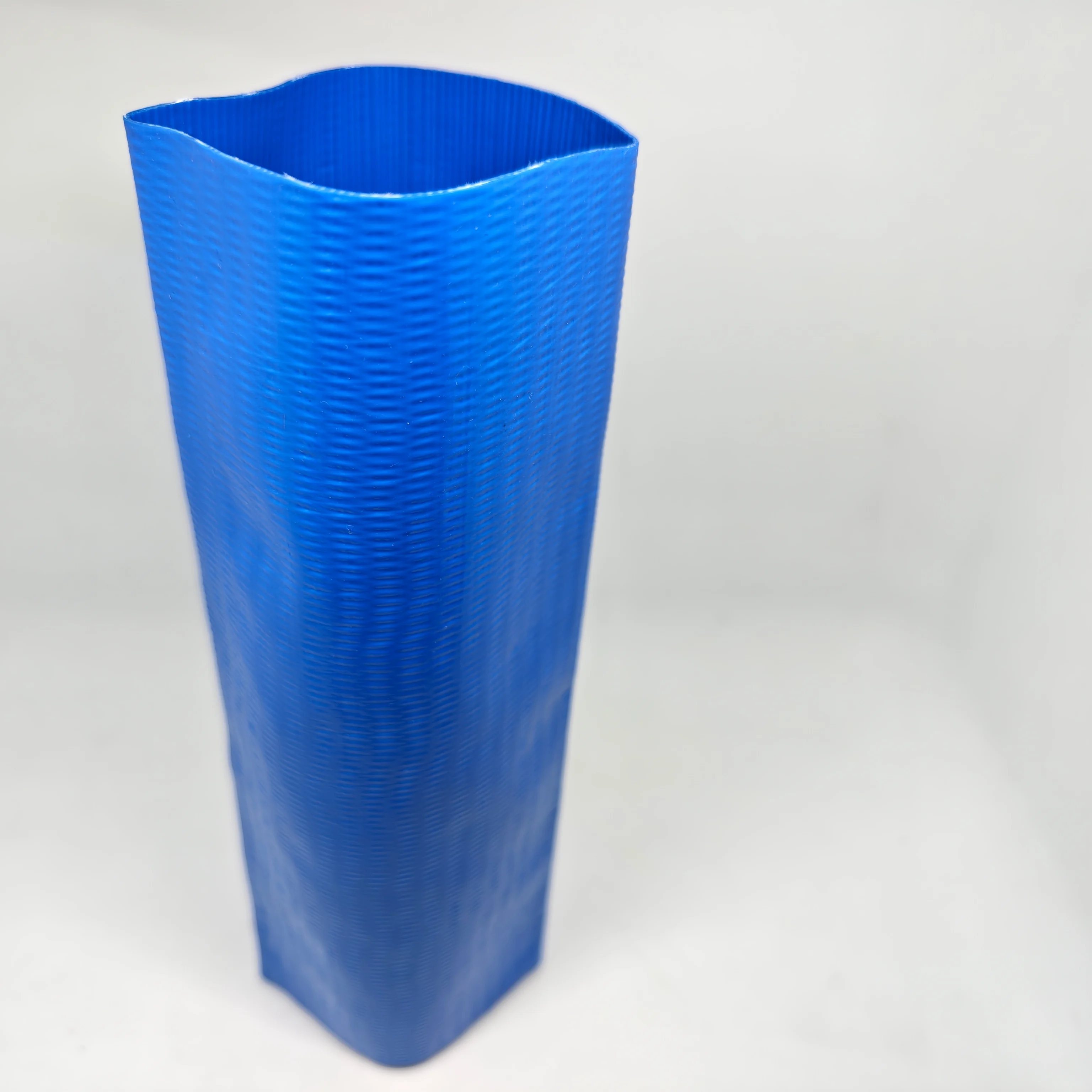

The fiber-reinforced woven high-pressure flexible PVC water pipe for farmland irrigation is a specifically designed piping product for agricultural irrigation systems. It combines the excellent properties of PVC materials with fiber reinforcement technology, offering high pressure resistance, flexibility, corrosion resistance, and wear resistance, making it ideally suited for use in farmland irrigation systems.

Product Features

High-Pressure Capability:

The PVC water pipe inherently possesses high pressure resistance, which is further enhanced by the fiber reinforcement. This allows it to withstand the demands of high-pressure water flow in farmland irrigation systems.

Flexible Design:

The pipe exhibits excellent flexibility, enabling it to adapt to various terrains and irrigation requirements. This facilitates easy installation and connection in farmland environments. Additionally, its flexibility reduces the risk of pipe damage due to terrain changes or external forces.

Corrosion Resistance:

PVC material is renowned for its exceptional resistance to acids, alkalis, and other chemicals, enabling it to withstand corrosion from soil chemicals and prolonging the pipe's service life.

Wear Resistance:

The fiber reinforcement layer enhances the pipe's wear resistance, ensuring that it maintains its integrity and stability even under prolonged water flow erosion and soil friction.

Woven Structure:

The woven structure strengthens the pipe's overall strength and stability, making it more robust and durable. This structure also contributes to the pipe's improved pressure resistance and impact resistance.

Specification Sheet

Technical Requirements

| Parameter | Details |

| Material | PVC & High-Strength Polyester Fiber |

| Construction | 3-layer structure: inner PVC layer, high-strength polyester fiber, and outer PVC cover |

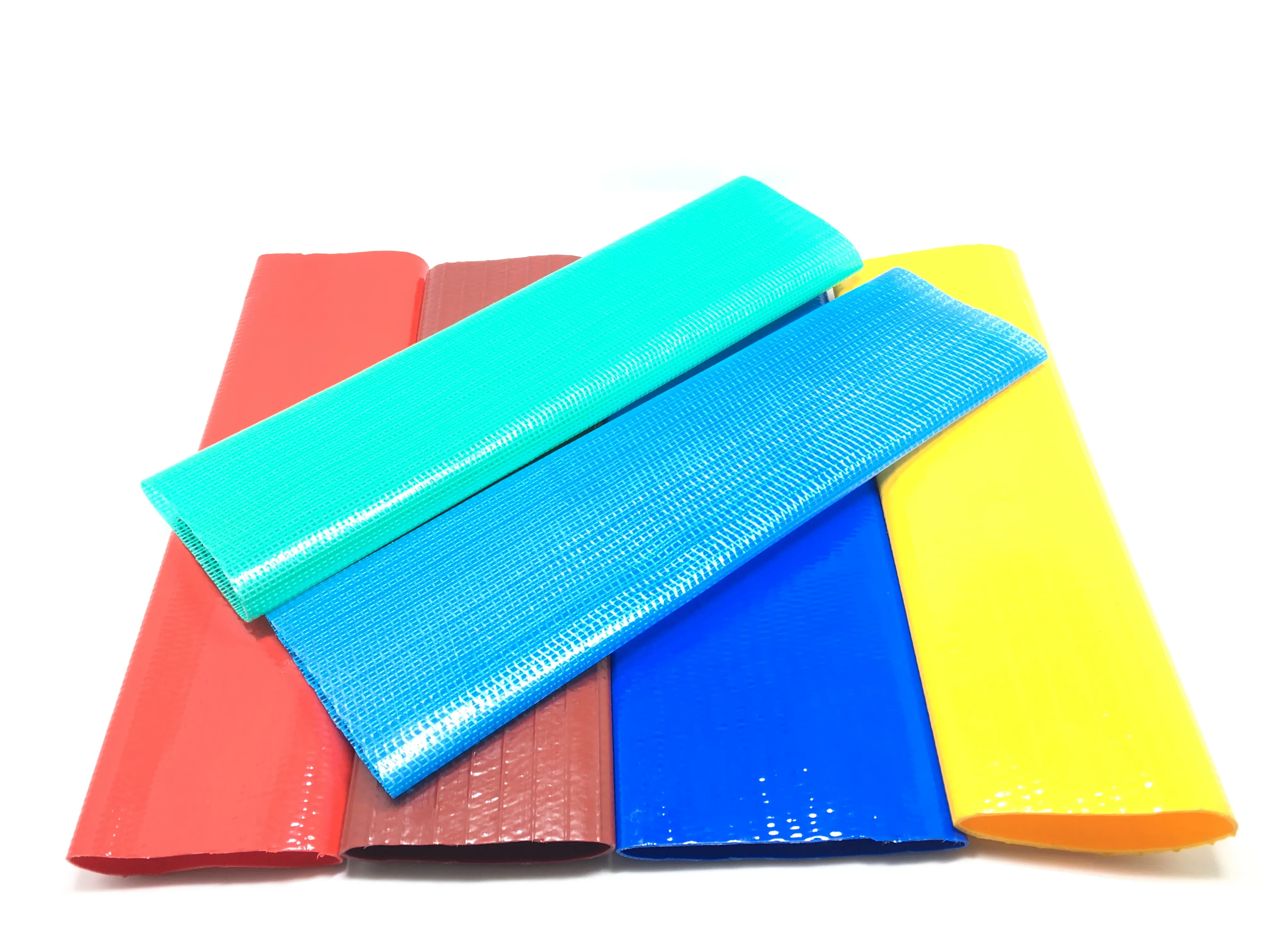

| Color Options | Blue, Red, Orange, Yellow, Green, or Customized |

| Working Pressure | 2 - 10 bar |

| Burst Pressure | Up to 30 bar |

| Working Temperature | -5°C to +65°C |

| Transport Medium | Water, Oil, Powder |

| Flexibility | Lightweight and easy to handle |

| UV Resistance | UV-stabilized material for outdoor durability |

| Abrasion Resistance | High resistance to wear and tear |

| Compliance Certifications | RoHS, REACH, CE |

Specification Sizes

| Diameter (Inches) | Diameter (mm) | Length Options (Meters) | Thickness (mm) | Working Pressure (Bar) |

| 1 | 25.4 | 10 / 20 / 50 / 100 / 150 | 1.0 - 2.0 | 10 |

| 1.5 | 38.1 | 10 / 20 / 50 / 100 / 150 | 1.5 - 3.0 | 10 |

| 2 | 50.8 | 10 / 20 / 50 / 100 / 150 | 2.0 - 4.0 | 8 |

| 3 | 76.2 | 10 / 20 / 50 / 100 / 150 | 3.0 - 5.0 | 8 |

| 4 | 101.6 | 10 / 20 / 50 / 100 / 150 | 4.0 - 6.0 | 6 |

| 6 | 152.4 | 10 / 20 / 50 / 100 / 150 | 4.0 - 6.0 | 6 |

| 8 | 203.2 | 10 / 20 / 50 / 100 / 150 | 4.0 - 6.0 | 6 |

| 10 | 254 | 10 / 20 / 50 / 100 | 5.0 - 6.0 | 5 |

| 12 | 304.8 | 10 / 20 / 50 | 5.0 - 6.0 | 5 |

| 16 | 406.4 | 10 / 20 / 50 | 5.0 - 6.0 | 5 |

Application Areas

Fiber-reinforced woven high-pressure flexible PVC water pipes for farmland irrigation are widely used in agricultural irrigation systems, garden landscaping sprinkler systems, and rural water supply projects. They can be flexibly laid and connected according to the growth needs and irrigation conditions of crops, achieving precise and water-saving irrigation goals.

Market Situation

Currently, there are multiple manufacturers and brands producing these pipes in the market. They offer a range of specifications and models to cater to different user needs. With the acceleration of agricultural modernization and the promotion of water-saving irrigation technologies, the market demand for these products is continuously increasing.

Usage Recommendations

Select the Appropriate Specification and Model:

Choose the right specification and model of pipe based on the specific requirements and irrigation conditions of the farmland irrigation system.

Proper Installation and Connection:

Follow the product manual and relevant regulations when installing and connecting the pipes to ensure secure and leak-proof connections.

Regular Inspection and Maintenance:

Regularly inspect and maintain the irrigation system to promptly identify and address issues such as leaks or pipe damage, ensuring the smooth operation of the system.

Rational Use of Water Resources:

Use water resources wisely during irrigation, avoiding waste and over-irrigation. Adjust irrigation schedules and water usage based on weather changes and crop growth conditions.

How to do Quality Inspection

Ensuring the high quality and reliability of high-pressure flexible PVC layflat water hoses is essential for their effective use in farm irrigation. Here is a detailed description of the quality inspection process typically conducted in a factory, including the specific steps and data involved.

1. Raw Material Inspection

Objective: To ensure that the PVC resin and other raw materials meet the required standards before production begins.

Steps:

Visual Inspection: Check for contaminants and impurities.

Chemical Analysis: Conduct tests to confirm the chemical composition and properties.

Example Data: PVC purity level must be ≥ 99.5%.

Physical Properties Testing: Measure density, viscosity, and thermal properties.

Example Data: Density should be 1.4 g/cm³, viscosity between 50-60 mPa·s.

2. Extrusion and Coating Process Inspection

Objective: To monitor and ensure the quality of the extrusion and coating process.

Steps:

Temperature and Pressure Monitoring: Ensure the extrusion machine operates within the set parameters.

Example Data: Extrusion temperature 160-180°C, pressure 3-5 MPa.

Wall Thickness Measurement: Use micrometers to measure the hose wall thickness.

Example Data: Wall thickness should be uniform, typically 2-4 mm.

Diameter Check: Ensure the outer and inner diameters meet the specifications.

Example Data: Outer diameter ± 0.5 mm of the specified size.

3. Reinforcement Layer Inspection

Objective: To verify the integrity and quality of the reinforced polyester or nylon layers.

Steps:

Weave Pattern Check: Ensure the weave pattern is consistent and uniform.

Tensile Strength Test: Perform tests to measure the tensile strength of the reinforcement layer.

Example Data: Tensile strength ≥ 15 MPa.

Adhesion Test: Check the adhesion between the reinforcement layer and the PVC layers.

Example Data: Adhesion strength ≥ 3.0 N/mm.

4. Finished Product Inspection

Objective: To ensure the final product meets all required standards and specifications.

Steps:

Hydrostatic Pressure Test: Test the hose at high pressure to ensure it can withstand specified working pressures.

Example Data: Test pressure 1.5 times the working pressure, hold for 5 minutes with no leakage.

Burst Pressure Test: Determine the burst pressure of the hose.

Example Data: Burst pressure should be at least 3 times the working pressure.

Flexibility Test: Assess the hose's flexibility and ability to lay flat without kinking.

Example Data: Bend radius should be within specified limits without structural failure.

Dimensional Accuracy: Measure the length, diameter, and thickness.

Example Data: Length tolerance ± 1%, diameter and thickness within specified ranges.

5. Visual and Manual Inspection

Objective: To detect any visual defects or inconsistencies.

Steps:

Surface Inspection: Check for surface defects such as bubbles, cracks, or discoloration.

Manual Inspection: Feel the hose for uniformity and consistency.

End Finishing: Inspect the ends of the hose for proper finishing and cuts.

6. Final Quality Assurance

Objective: To ensure that all inspected products meet the factory's quality standards before shipping.

Steps:

Random Sampling: Select random samples from the batch for a comprehensive quality check.

Compliance Check: Ensure all test results comply with industry standards and customer specifications.

Example Data: All hoses must pass ISO 9001 quality management system standards.

7. Documentation and Traceability

Objective: To maintain detailed records of the inspection process for traceability and quality control.

Steps:

Record Keeping: Document all inspection results and data.

Batch Identification: Assign batch numbers for traceability.

Certification: Issue quality certificates for each batch of hoses.

The quality inspection process for high-pressure flexible PVC layflat water hoses involves multiple stages and rigorous testing to ensure that each hose meets high standards of performance and reliability. By adhering to detailed procedures and maintaining strict quality control, factories can ensure that their products are safe, durable, and effective for farm irrigation use.

Packaging Specifications

Roll Packaging:

Hoses are rolled and secured with heavy-duty straps.

Covered with plastic film or heavy-duty plastic sheets for protection.

Palletized for easy handling and transportation.

Each hose is rolled tightly and secured with plastic straps.

Wrapped in a plastic film to protect against dust and moisture.

Rolls are then placed in a durable cardboard box or wrapped with a protective plastic cover.

Small Sizes (1 inch to 4 inch):

Large Sizes (5 inch to 16 inch):

Pallet Packaging:

Pallets can be stacked for efficient space utilization in shipping containers.

Stacking height is adjusted to comply with shipping regulations and avoid damage.

Each pallet can accommodate multiple rolls of hose, depending on the hose size.

Pallet size typically 1.2m x 1.0m (or customized to fit the shipment).

Secured with stretch film and straps to prevent movement during transit.

Standard Pallet Dimensions:

Stacking:

Labeling:

Brand Name: Renflex

Specification Details: Diameter, length, thickness

Color and Customization Information

Certification Marks: RoHS, REACH, CE

Batch Number and Production Date

Each package or pallet is labeled with:

Transportation

Domestic Shipping:

Transported by trucks to distribution centers or directly to customers.

Properly secured to prevent shifting and damage during transit.

International Shipping:

20-foot containers for smaller orders.

40-foot containers for larger bulk orders.

Packaged hoses are loaded into shipping containers.

Container Types:

Secured with blocking and bracing to prevent movement during sea transit.

Shipping documents include certification copies (RoHS, REACH, CE) and product details for customs clearance.

The Renflex high-pressure flexible PVC layflat water hoses are carefully packaged and transported to ensure they arrive in perfect condition. The use of roll and pallet packaging, combined with proper labeling and secure transportation methods, guarantees the product's integrity and readiness for immediate use in agricultural, mining, and construction applications.

The high-pressure flexible PVC layflat water hose is an essential tool for modern farm irrigation. Its combination of high pressure capacity, flexibility, durability, and ease of use makes it an ideal choice for farmers looking to improve their irrigation efficiency. By investing in this versatile and robust hose, farmers can ensure a reliable water supply for their crops and livestock, ultimately enhancing productivity and sustainability on the farm.

Company Advantages

Extensive Experience

With over 15 years in the PVC hose manufacturing industry, our expertise ensures top-quality products.

State-of-the-Art Facility

Our factory in Shandong Province features 10 workshops, over 60 production lines, and a dedicated team of 120 skilled workers, ensuring efficient production and timely delivery.

Global Reach

Our hoses serve customers in more than 60 countries, earning widespread praise for reliability and performance.

Quality Assurance

We maintain stringent quality control with 2 QC teams and ensure compliance with international standards like RoHS, REACH, and CE certifications.

Customer-Centric Philosophy

Guided by the philosophy “Customers are always first,” we offer 24/7 quick response to inquiries and exceptional after-sales service.

FAQ for Bulk Purchase of High Pressure Flexible PVC Water Hose

1. What are the available sizes for the Renflex high pressure PVC water hose?

Diameter Range: 1 inch to 16 inches

Length Options: 10m, 20m, 50m, 100m, 150m

Thickness Options: 1mm, 2mm, 3mm, 4mm, 5mm, 6mm

2. What materials are used in the construction of the Renflex PVC water hose?

The hoses are made from high-quality PVC and reinforced with high strength polyester fiber for enhanced durability and pressure resistance.

3. What colors are available?

Standard colors include Blue, Red, Orange, Yellow, and Green. Custom colors are also available upon request.

4. What certifications do the Renflex PVC water hoses have?

The hoses are certified with RoHS, REACH, and CE, ensuring they meet international standards for safety and environmental compliance.

5. What is the working temperature range of the Renflex PVC water hose?

The hoses can operate in temperatures ranging from -5°C to +65°C, making them suitable for various climates and conditions.

6. What is the working pressure range of these hoses?

The hoses can handle working pressures between 2 to 10 bar, suitable for high-pressure irrigation needs.

7. What applications are the Renflex PVC water hoses suitable for?

These hoses are ideal for agriculture, mining, and construction dewatering applications, and can transport water, oil, and powder.

8. What are the packaging specifications?

Roll Packaging: Smaller sizes (1 inch to 4 inches) are rolled tightly and secured with plastic straps, wrapped in plastic film, and placed in cardboard boxes or protective plastic covers. Larger sizes (5 inches to 16 inches) are rolled, secured with heavy-duty straps, and palletized.

Pallet Packaging: Pallets typically measure 1.2m x 1.0m, secured with stretch film and straps. Pallets can be stacked for efficient shipping.

Labeling: Each package or pallet is labeled with the brand name, specification details, color, customization information, certification marks, batch number, and production date.

9. What are the transportation methods for bulk orders?

Domestic Shipping: Transported by trucks to distribution centers or directly to customers.

International Shipping: Packaged hoses are loaded into 20-foot or 40-foot shipping containers, secured with blocking and bracing to prevent movement during transit.

10. Can I customize the hoses for my specific needs?

Yes, Renflex offers OEM and private label manufacturing services, allowing you to customize the hose specifications, color, and branding to meet your specific requirements.

11. How do I place a bulk order?

Contact our sales team with your requirements. You can reach us via email or phone. Provide details on the size, length, thickness, color, and any customization needs. Our team will guide you through the ordering process and provide a quote.

12. What is the minimum order quantity (MOQ) for bulk purchases?

The MOQ varies depending on the size and customization requirements. Please contact our sales team for specific details.

13. What payment methods are accepted?

We accept various payment methods, including bank transfers (T/T), Letters of Credit (L/C), and other secure payment options. Terms and conditions will be discussed during the order placement.

14. What is the delivery lead time for bulk orders?

Delivery times vary based on order size and customization requirements. Standard orders typically ship within 2-4 weeks. Our sales team will provide an estimated delivery timeline when you place your order.

15. Is there a warranty on the Renflex PVC water hoses?

Yes, Renflex offers a warranty on all our PVC water hoses. The warranty period and terms vary based on the product and usage conditions. Please contact our customer service for detailed warranty information.

For more information or to place an order, please visit our website or contact our sales team. We look forward to partnering with you to provide high-quality irrigation solutions for your farming needs.

![]() High Pressure Flexible PVC Layflat Water Hose for Farm Irrigation .pdf

High Pressure Flexible PVC Layflat Water Hose for Farm Irrigation .pdf

![]() Manufacturing_Standards_High_Pressure_PVC_Layflat_Hose.pdf

Manufacturing_Standards_High_Pressure_PVC_Layflat_Hose.pdf