PVC Lay Flat Hose: Pros, Cons

PVC lay flat hoses are lightweight, portable, and versatile for fluid transfer, but vary in quality. Learn their pros, cons, and how to choose the right one for your needs.

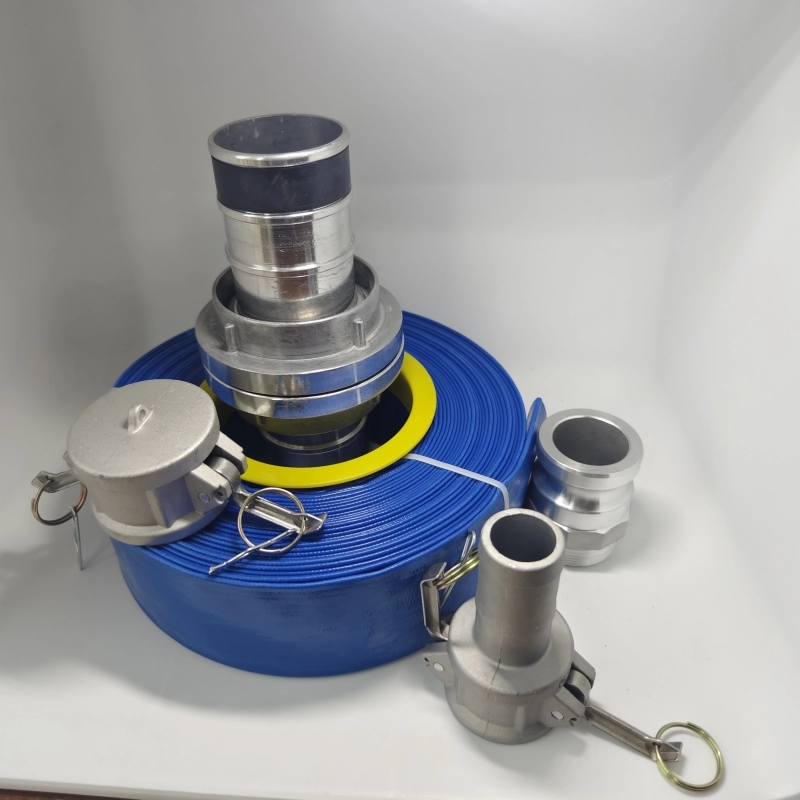

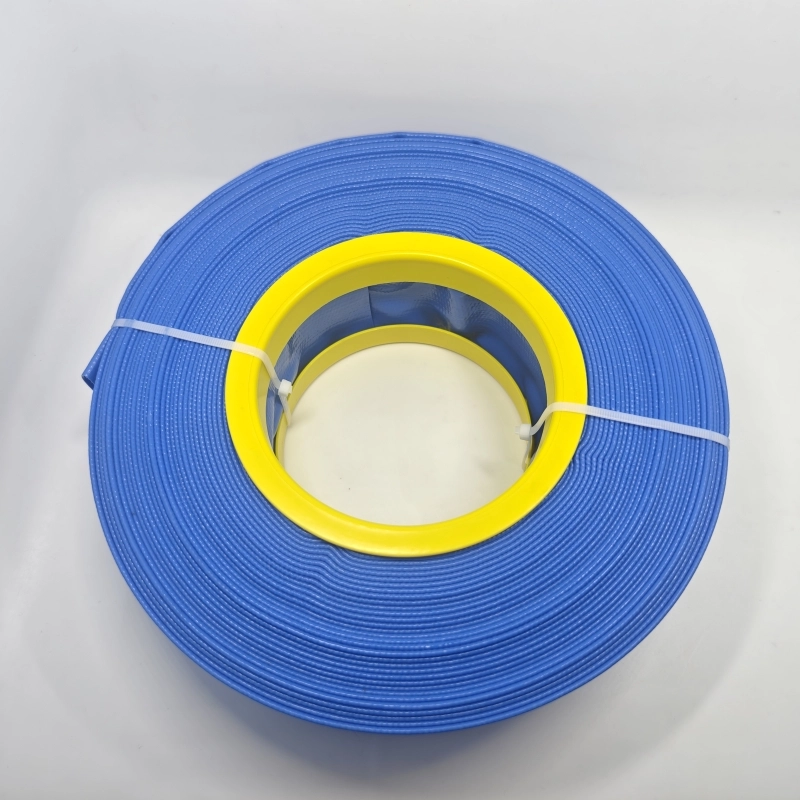

PVC lay flat hoses are versatile, lightweight, and widely used in various industries, including agriculture, construction, firefighting, and mining. They are designed to be easily transported, stored, and deployed, making them a popular choice for fluid transfer applications. However, not all PVC lay flat hoses are created equal. Understanding the pros and cons of these hoses, as well as how to distinguish between high-quality and low-quality options, is essential for making an informed purchase decision. This article will guide you through the key considerations when selecting a PVC lay flat hose and provide practical tips for choosing the right specifications for your needs.

Pros of PVC Lay Flat Hoses

Lightweight and Portable

PVC lay flat hoses are significantly lighter than traditional rubber hoses, making them easy to transport and handle. Their flat design allows for compact storage, reducing the space required when not in use.Flexibility and Ease of Use

These hoses are highly flexible, even at low temperatures, which makes them easy to roll out and connect. They can be quickly deployed in emergency situations, such as firefighting or flood control.Cost-Effective

Compared to rubber hoses, PVC lay flat hoses are generally more affordable. They offer a good balance between performance and cost, making them a budget-friendly option for many applications.Resistance to Abrasion and Chemicals

High-quality PVC lay flat hoses are designed to resist abrasion, UV rays, and certain chemicals, ensuring durability and longevity in harsh environments.Wide Range of Applications

These hoses are suitable for various uses, including irrigation, dewatering, slurry transfer, and industrial fluid handling. They are available in different sizes and pressure ratings to meet diverse needs.Easy to Repair

In the event of damage, PVC lay flat hoses can often be repaired quickly using patch kits or heat welding, minimizing downtime.

Cons of PVC Lay Flat Hoses

Limited Temperature Range

PVC lay flat hoses are not suitable for extremely high or low temperatures. They can become brittle in cold conditions and may deform or weaken when exposed to high heat.Lower Pressure Tolerance

While PVC lay flat hoses are suitable for low to medium-pressure applications, they are not ideal for high-pressure tasks. Overloading the hose can lead to bursting or failure.Susceptibility to Kinking

If not handled properly, these hoses can kink, which may restrict water flow and cause damage over time.Variable Quality

The market is flooded with both high-quality and low-quality PVC lay flat hoses. Low-quality options may lack durability, chemical resistance, or proper reinforcement, leading to premature failure.Environmental Concerns

PVC is not biodegradable, and improper disposal can contribute to environmental pollution. However, some manufacturers are now producing eco-friendly PVC hoses with reduced environmental impact.

How to Distinguish Between High-Quality and Low-Quality PVC Lay Flat Hoses

When selecting a PVC lay flat hose, it’s crucial to evaluate its quality to ensure it meets your requirements. Here are some key factors to consider:

1. Material Composition

High-Quality Hoses: Use premium-grade PVC with added UV stabilizers, anti-fungal agents, and plasticizers to enhance durability and flexibility.

Low-Quality Hoses: May contain inferior PVC or excessive fillers, resulting in reduced strength and shorter lifespan.

2. Reinforcement

High-Quality Hoses: Feature multiple layers of high-tensile polyester or nylon reinforcement, which provides excellent burst strength and resistance to stretching.

Low-Quality Hoses: Often have minimal or no reinforcement, making them prone to tearing or bursting under pressure.

3. Thickness and Weight

High-Quality Hoses: Have a consistent wall thickness and are heavier due to the use of robust materials.

Low-Quality Hoses: May have uneven walls or be excessively lightweight, indicating poor material quality.

4. Pressure Rating

High-Quality Hoses: Clearly specify their working pressure and burst pressure ratings, ensuring they can handle the intended application.

Low-Quality Hoses: May lack proper pressure ratings or overstate their capabilities, leading to safety risks.

5. Flexibility and Kink Resistance

High-Quality Hoses: Remain flexible even in cold conditions and resist kinking, ensuring smooth water flow.

Low-Quality Hoses: May become stiff or kink easily, reducing efficiency and increasing the risk of damage.

6. Certifications and Standards

High-Quality Hoses: Comply with international standards such as ISO, DIN, or FDA (for food-grade applications).

Low-Quality Hoses: Often lack certifications or fail to meet industry standards.

7. Manufacturer Reputation

High-Quality Hoses: Produced by reputable manufacturers with a history of delivering reliable products.

Low-Quality Hoses: Often sold by unknown or unverified brands with limited customer support.

Choosing the Right Specifications for Your Needs

Selecting the appropriate PVC lay flat hose requires careful consideration of your specific application and operating conditions. Here’s a step-by-step guide to help you make the right choice:

1. Determine the Application

Identify the primary use of the hose (e.g., irrigation, dewatering, firefighting). This will help you narrow down the required specifications, such as pressure rating, diameter, and length.

2. Check the Pressure Rating

Ensure the hose’s working pressure and burst pressure ratings are suitable for your application. For example, firefighting hoses typically require higher pressure ratings than irrigation hoses.

3. Select the Correct Diameter

Choose a diameter that matches your flow rate requirements. Common sizes range from 1 inch to 12 inches, with larger diameters accommodating higher flow rates.

4. Consider the Length

Measure the distance between the water source and the destination to determine the required hose length. Avoid using excessively long hoses, as they can reduce water pressure and increase the risk of kinking.

5. Evaluate Environmental Conditions

Consider factors such as temperature, exposure to UV rays, and the presence of chemicals or abrasive materials. Select a hose with appropriate resistance properties to ensure longevity.

6. Look for Additional Features

Food-Grade Hoses: Required for applications involving potable water or food processing.

Anti-Microbial Hoses: Ideal for environments where bacterial growth is a concern.

Heavy-Duty Hoses: Suitable for rugged applications such as mining or construction.

7. Compare Prices and Warranties

While cost is an important factor, prioritize value over price. High-quality hoses may have a higher upfront cost but offer better performance and durability. Additionally, check if the manufacturer provides a warranty or guarantee.

Conclusion

PVC lay flat hoses are a practical and cost-effective solution for many fluid transfer applications. However, their performance and lifespan depend heavily on the quality of materials, construction, and adherence to industry standards. By understanding the pros and cons of these hoses and following the guidelines outlined in this article, you can confidently select a high-quality PVC lay flat hose that meets your specific needs. Always prioritize reputable manufacturers and verify product certifications to ensure you’re investing in a reliable and durable solution. Whether you’re irrigating a field, dewatering a construction site, or fighting a fire, the right PVC lay flat hose can make all the difference in achieving efficient and effective results.