Its unique design and material properties make it particularly suitable for handling the high-volume, intermittent flow characteristics of backwash operations.

Advantages of PVC Layflat Discharge Hose for Backwash Water

Space-saving design: The hose lies flat when not in use, requiring minimal storage space compared to rigid piping systems.

Quick deployment: Can be rapidly unrolled and connected for immediate use during backwash cycles.

High flow capacity: Smooth inner surface minimizes friction loss, allowing efficient discharge of large volumes of backwash water.

Lightweight construction: Easy to handle and reposition as needed, reducing labor requirements.

Chemical resistance: PVC material resists degradation from chlorine and other chemicals commonly present in backwash water.

Durability: Reinforced construction withstands the abrasive particles often found in backwash water.

Cost-effective: Lower initial cost and maintenance requirements compared to permanent piping systems.

Temperature resistance: Suitable for typical backwash water temperature ranges.

PVC Layflat Discharge Hose Specifications

| Parameter | Specification | Typical Value |

|---|---|---|

| Material | PVC (Polyvinyl Chloride) | High-grade PVC with reinforcement |

| Diameter Range | Available sizes | 2" to 12" (50mm to 300mm) |

| Working Pressure | Maximum operating pressure | 4-10 bar (depending on diameter) |

| Burst Pressure | Safety factor | 3-4 times working pressure |

| Temperature Range | Operational limits | -10°C to +60°C (14°F to 140°F) |

| Reinforcement | Strength layer | High-tensile polyester yarn |

| Collapsing Pressure | Resistance to vacuum | 0.3-0.8 bar |

| Abrasion Resistance | Test method | DIN 53516 (excellent) |

| Chemical Resistance | Compatibility | Resistant to chlorine, mild acids, and alkalis |

| Standard Lengths | Available options | 25m, 50m, 100m (82ft, 164ft, 328ft) |

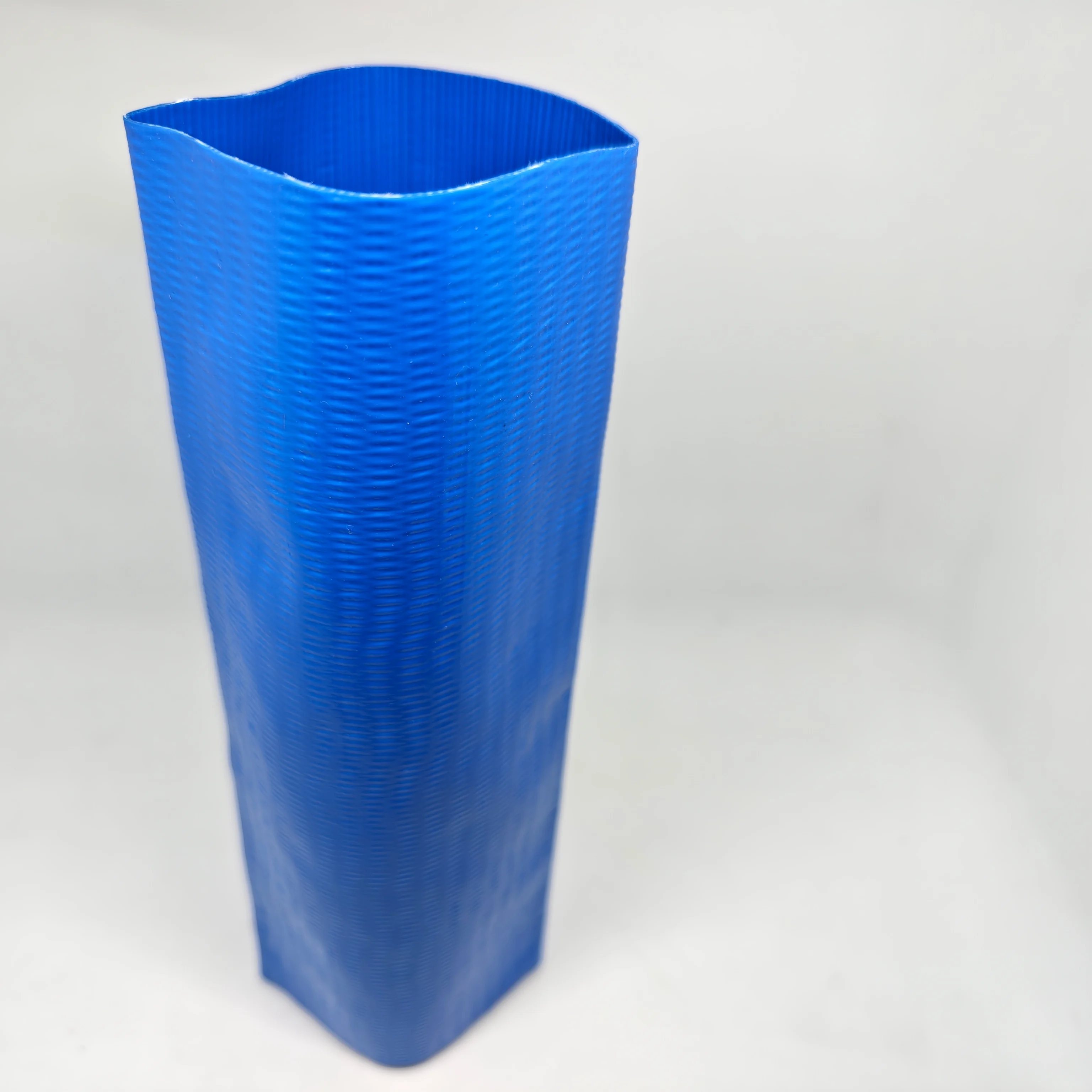

| Color | Standard options | Blue, black, or orange |

Simple Quality Tests for PVC Layflat Discharge Hose

To verify the quality and performance of PVC Layflat Discharge Hose, the following simple tests can be conducted:

Visual Inspection Test

Check for uniform thickness and consistent reinforcement pattern

Verify smooth inner surface without visible defects

Confirm proper printing of specifications on hose surface

Flatness Test

Lay hose on flat surface

Measure thickness when fully flattened

Expected: Should not exceed 10% of nominal diameter in flattened state

Water Pressure Test

Connect to water source at rated pressure

Check for leaks along length and at couplings

Measure diameter expansion (should not exceed 5% at working pressure)

Flexibility Test

Roll and unroll hose 5 times

Check for cracking or deformation

Verify it still lies flat after rolling

Abrasion Resistance Test

Rub hose surface with coarse sandpaper (120 grit) with 1kg weight

50 strokes should not expose reinforcement layer

Collapse Resistance Test

Create vacuum of 0.3 bar

Hose should not collapse completely

Should regain original shape when pressure normalizes

Tensile Strength Test

Apply 1.5 times working pressure as tensile load

Hose should not separate at couplings

Reinforcement should not break

High-Quality vs. Low-Quality PVC Layflat Discharge Hose

PVC Layflat Discharge Hoses are widely used for backwash water discharge in applications such as pool filtration systems, wastewater treatment plants, and industrial filtration equipment. High-quality hoses significantly improve efficiency, extend service life, and reduce maintenance costs, while low-quality products may lead to leaks, ruptures, and frequent replacements.

1. Differences in Materials and Manufacturing

Feature High-Quality PVC Layflat Hose Low-Quality PVC Layflat Hose PVC Material Uses high-purity PVC, resistant to UV and chemicals (e.g., chlorine, acids, alkalis) Made from recycled or inferior PVC, prone to aging and cracking Reinforcement Layer High-tensile polyester yarn for pressure resistance and durability Low-density fibers or poor-quality nylon, prone to deformation and breakage Inner Surface Smoothness Smooth interior for minimal friction and optimal water flow Rough inner surface, prone to clogging and increased flow resistance Seam Technology High-frequency welding or seamless construction, leak-proof Glued or poorly stitched seams, prone to splitting and leaks 2. Performance Comparison

Test Parameter High-Quality Hose Low-Quality Hose Pressure Resistance Withstands 4-10 bar (depending on diameter) May fail below rated pressure, prone to bursting Abrasion Resistance Complies with DIN 53516, resistant to sand and debris Easily scratched by particles, shorter lifespan UV Resistance Contains UV stabilizers, remains flexible outdoors Becomes brittle and cracks after 1-2 years Flexibility Stays pliable even at low temperatures (-10°C) Hardens in cold weather, prone to cracking Collapse Resistance Maintains shape under suction (0.3 bar vacuum) Collapses easily under negative pressure, reducing efficiency 3. Performance in Real-World Applications

Advantages of High-Quality Hoses

✅ Longer lifespan (5-10 years vs. 1-3 years for low-quality hoses)

✅ Higher flow efficiency (smooth interior minimizes resistance)

✅ Lower maintenance costs (fewer leaks and bursts, less downtime)

✅ Better environmental adaptability (UV-resistant, chemical-resistant, abrasion-resistant)Common Issues with Low-Quality Hoses

❌ Prone to bursting (under high pressure or low temperatures)

❌ Easily clogged (rough interior traps debris)

❌ Deforms over time (fails to return to flat shape after use)

❌ Weak couplings (poor connections lead to leaks)4. How to Identify High-Quality vs. Low-Quality Hoses?

Simple Testing Methods

Bend Test: High-quality hoses spring back to shape; low-quality ones retain creases.

Pressure Test: Fill with water at rated pressure—high-quality hoses expand <5% with no leaks.

Abrasion Test: Rub with sandpaper—high-quality hoses resist fiber exposure.

UV Exposure Test: Leave in sunlight for a month—low-quality hoses become brittle and fade.

Odor Test: Inferior PVC may emit a strong plastic smell (excessive plasticizers).

Choosing a high-quality PVC Layflat Discharge Hose significantly enhances the reliability and cost-effectiveness of backwash water discharge. While the initial cost may be higher, its longevity, low maintenance, and high efficiency result in lower total cost of ownership. Low-quality hoses may seem cheaper upfront but lead to higher expenses due to frequent replacements and repairs.

Recommended Applications:

Pool backwashing

Industrial water treatment

Agricultural drainage

Emergency dewatering

Conclusion

PVC Layflat Discharge Hose offers an optimal solution for backwash water applications, combining practical advantages with reliable performance. Its flexibility, durability, and cost-effectiveness make it superior to traditional rigid piping for many backwash scenarios. By performing simple quality tests, users can ensure they're getting hose that meets the demanding requirements of backwash operations while providing long service life and trouble-free performance.