In the world of industrial and agricultural applications, the importance of reliable and efficient discharge hoses cannot be overstated. Among the various types of hoses available, 2-inch and 4-inch lay flat discharge hoses stand out due to their versatility, durability, and ease of use. These hoses are designed to handle a wide range of fluids, from water and wastewater to chemicals and fertilizers, making them indispensable in various industries.

This ultimate guide will provide you with comprehensive information on 2-inch and 4-inch lay flat discharge hoses, including their specifications, applications, benefits, and tips for selection and maintenance. By the end of this guide, you will have a clear understanding of why these hoses are essential for your operations and how to choose the right one for your needs.

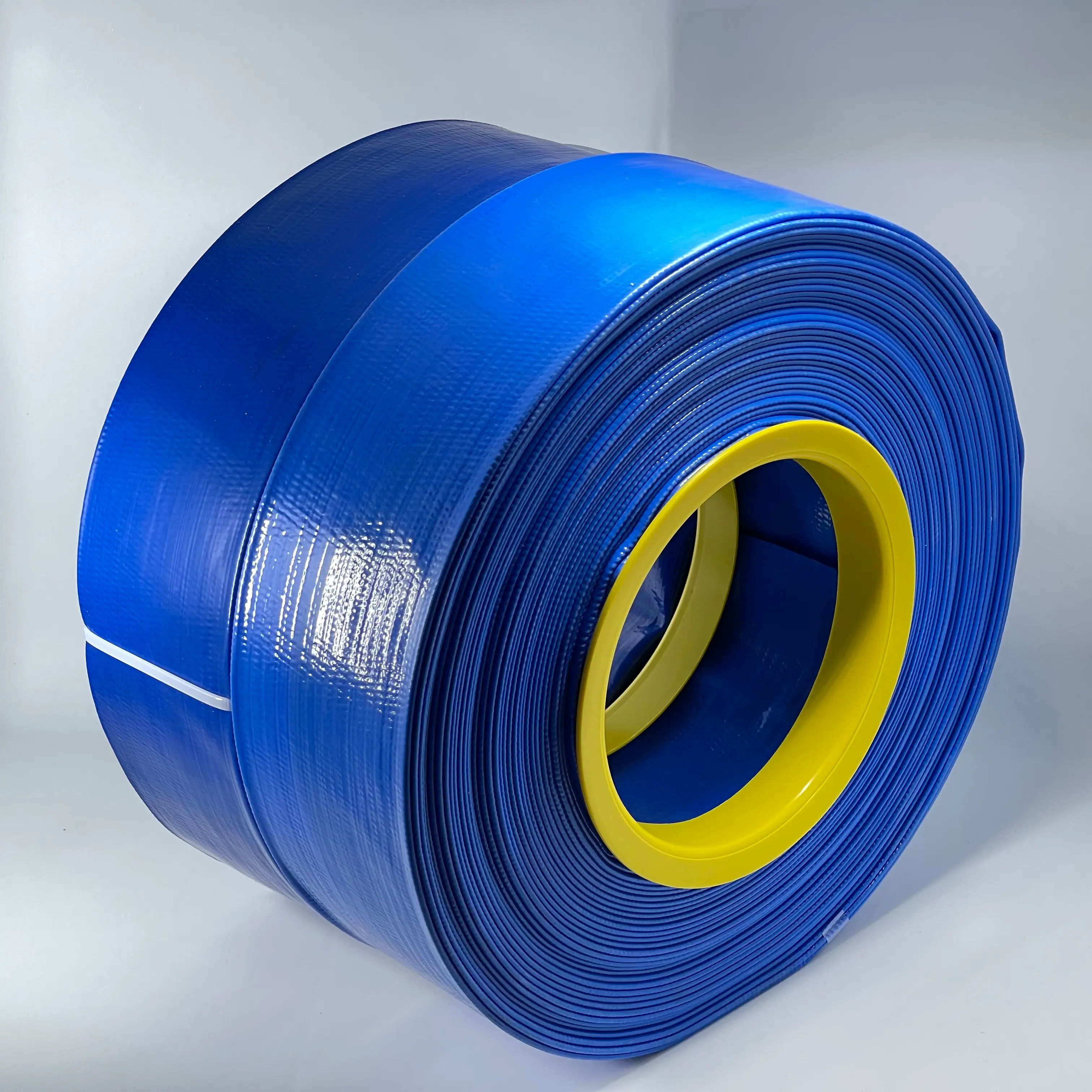

Specifications of 2 Inch and 4 Inch Lay Flat Discharge Hose

Before diving into the details of these hoses, it is essential to understand their specifications. The specifications of a lay flat discharge hose refer to its physical dimensions, material composition, pressure rating, and other critical factors that determine its performance and durability.

Below is a comparison table highlighting the key specifications of 2-inch and 4-inch lay flat discharge hoses:

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | Volume | ||

| inch | mm | mm | m | kg/m | bar | psi | cbm |

| 1 | 25 | 1.3 | 100 | 0.15 | 5 | 75 | 0.017 |

| 1.5 | 100 | 0.165 | 7 | 105 | 0.019 | ||

| 1 1/4 | 32 | 1.2 | 100 | 0.17 | 5 | 75 | 0.020 |

| 1.3 | 100 | 0.19 | 7 | 105 | 0.022 | ||

| 1 1/2 | 38 | 1.25 | 100 | 0.19 | 5 | 75 | 0.024 |

| 1.45 | 100 | 0.23 | 7 | 105 | 0.026 | ||

| 2 | 51 | 1.1 | 100 | 0.22 | 4 | 60 | 0.034 |

| 1.3 | 100 | 0.3 | 6 | 90 | 0.036 | ||

| 2 1/2 | 64 | 1.2 | 100 | 0.32 | 4 | 60 | 0.046 |

| 1.7 | 100 | 0.43 | 6 | 90 | 0.048 | ||

| 3 | 76 | 1.1 | 100 | 0.35 | 4 | 60 | 0.060 |

| 1.5 | 100 | 0.5 | 6 | 90 | 0.062 | ||

| 4 | 102 | 1.2 | 100 | 0.55 | 4 | 60 | 0.083 |

| 2.3 | 100 | 0.8 | 6 | 90 | 0.085 | ||

| 5 | 127 | 1.35 | 100 | 0.75 | 4 | 60 | 0.109 |

| 2.3 | 100 | 1.08 | 6 | 90 | 0.111 | ||

| 6 | 153 | 1.35 | 100 | 0.9 | 4 | 60 | 0.141 |

| 2.4 | 100 | 1.6 | 6 | 90 | 0.143 | ||

| 8 | 203 | 2.2 | 100 | 1.785 | 3 | 45 | 0.185 |

| 2.7 | 100 | 2.02 | 4 | 60 | 0.187 | ||

| 10 | 255 | 2.7 | 50 | 2.6 | 3 | 45 | 0.170 |

| 12 | 307 | 2.7 | 50 | 3 | 2 | 30 | 0.225 |

Materials and Construction

The choice of material and construction significantly impacts the performance and durability of lay flat discharge hoses. Here’s an overview of common materials used in 2-inch and 4-inch lay flat hoses:

PVC (Polyvinyl Chloride)

Pros: Lightweight, cost-effective, good chemical and UV resistance, and widely available.

Cons: Less flexible in cold weather, may degrade over time with exposure to UV light without proper protection.

Polyurethane

Pros: High flexibility, abrasion-resistant, good chemical resistance, and can withstand a broader temperature range.

Cons: More expensive than PVC, may degrade with prolonged exposure to certain chemicals.

Rubber

Pros: Excellent abrasion resistance, flexibility in extreme temperatures, and good chemical resistance.

Cons: Heavier than PVC or polyurethane, more expensive, and may require special handling due to its weight.

Reinforced Polyester

Pros: High strength, excellent kink resistance, and lightweight.

Cons: Less common, may have limited chemical resistance compared to other materials.

Applications

The versatility of 2-inch and 4-inch lay flat hoses makes them suitable for a wide range of applications. Here are some common uses:

Agricultural Irrigation

2-Inch Hose: Ideal for small to medium-sized fields, drip irrigation systems, and portable watering setups.

4-Inch Hose: Suitable for large-scale irrigation systems, pivot irrigation, and high-flow applications.

Water Transfer

2-Inch Hose: Perfect for transferring water from one location to another in residential and light commercial settings.

4-Inch Hose: Effective for transferring large volumes of water in construction sites, fire fighting, and industrial applications.

Construction

2-Inch Hose: Useful for small-scale construction projects like landscaping, minor excavations, and site cleanup.

4-Inch Hose: Essential for larger construction projects involving concrete mixing, site drainage, and heavy-duty water transfer.

Industrial Use

2-Inch Hose: Suitable for light industrial applications such as plant maintenance, small equipment cooling, and chemical transfer (with compatible materials).

4-Inch Hose: Ideal for heavy-duty industrial use, including factory cooling systems, waste water transfer, and process fluid handling.

Mining and Oil & Gas

4-Inch Hose: Often used in mining for dewatering operations and in oil & gas exploration for transporting drilling fluids and other industrial applications.

Benefits of Using Lay Flat Discharge Hoses

Using 2-inch and 4-inch lay flat discharge hoses offers several benefits, making them a preferred choice for various applications:

Portability and Storage

Lightweight and Compact: Lay flat hoses are easy to transport and store due to their lightweight nature and ability to lay flat when not in use.

Space-Saving: These hoses can be coiled tightly, taking up minimal storage space compared to traditional round hoses.

Flexibility and Durability

High Flexibility: Reinforced and non-reinforced lay flat hoses offer excellent flexibility, making them easy to maneuver around obstacles and tight spaces.

Abrasion Resistance: Materials like PVC, polyurethane, and rubber provide good to excellent abrasion resistance, ensuring long-term durability.

Kink Resistance

Smooth Bore Design: The smooth bore design of lay flat hoses minimizes friction and resistance to flow, reducing the risk of kinking and clogging.

Reinforced Construction: Reinforced models offer additional support to prevent kinking, especially in longer lengths and heavy-duty applications.

Cost-Effectiveness

Affordable Pricing: Lay flat hoses are generally more affordable than other types of industrial hoses, offering a cost-effective solution for various applications.

Long Lifespan: With proper care and maintenance, these hoses can last for several years, providing excellent value for money.

Versatility

Multiple Applications: Suitable for a wide range of applications, from irrigation and water transfer to construction and industrial use.

Compatible Fittings: Can be equipped with various fittings, including camlocks, threaded connections, and hose clamps, to suit different systems and requirements.

Maintenance Tips

To ensure the longevity and optimal performance of your 2-inch and 4-inch lay flat discharge hoses, follow these maintenance tips:

Regular Inspection

Visual Inspection: Regularly inspect the hose for cracks, tears, or wear and tear. Replace any damaged sections immediately to prevent failures.

Pressure Testing: Periodically test the hose under pressure to check for leaks and weaknesses.

Cleaning and Drying

Flush with Water: After use, flush the hose with clean water to remove any debris or contaminants.

Air Dry: Allow the hose to air dry completely before storing to prevent mildew and bacteria growth.

Storage

Coil Properly: Store the hose in a coiled position, avoiding kinks and twists that can damage the material.

Shade and Shelter: Store the hose in a shaded and sheltered area to protect it from UV light and extreme weather conditions.

Avoid Excessive Heat

Keep Away from Heat Sources: Avoid exposing the hose to direct heat sources, such as open flames or hot surfaces, which can degrade the material.

Temperature Limits: Operate within the hose’s

516.webp)