In industrial drainage, agricultural irrigation, firefighting emergencies, and construction sites, you may often notice a distinctive blue flat hose - this is the Blue PVC Layflat Discharge Hose with Camlock Couplings we're examining today. This specialized drainage hose has become indispensable in liquid transfer applications due to its unique structure and performance characteristics. This guide will provide a complete understanding of this product's features, manufacturing process, quality comparisons, and selection tips.

Part 1: Product Fundamentals

1. What is a Blue PVC Layflat Discharge Hose?

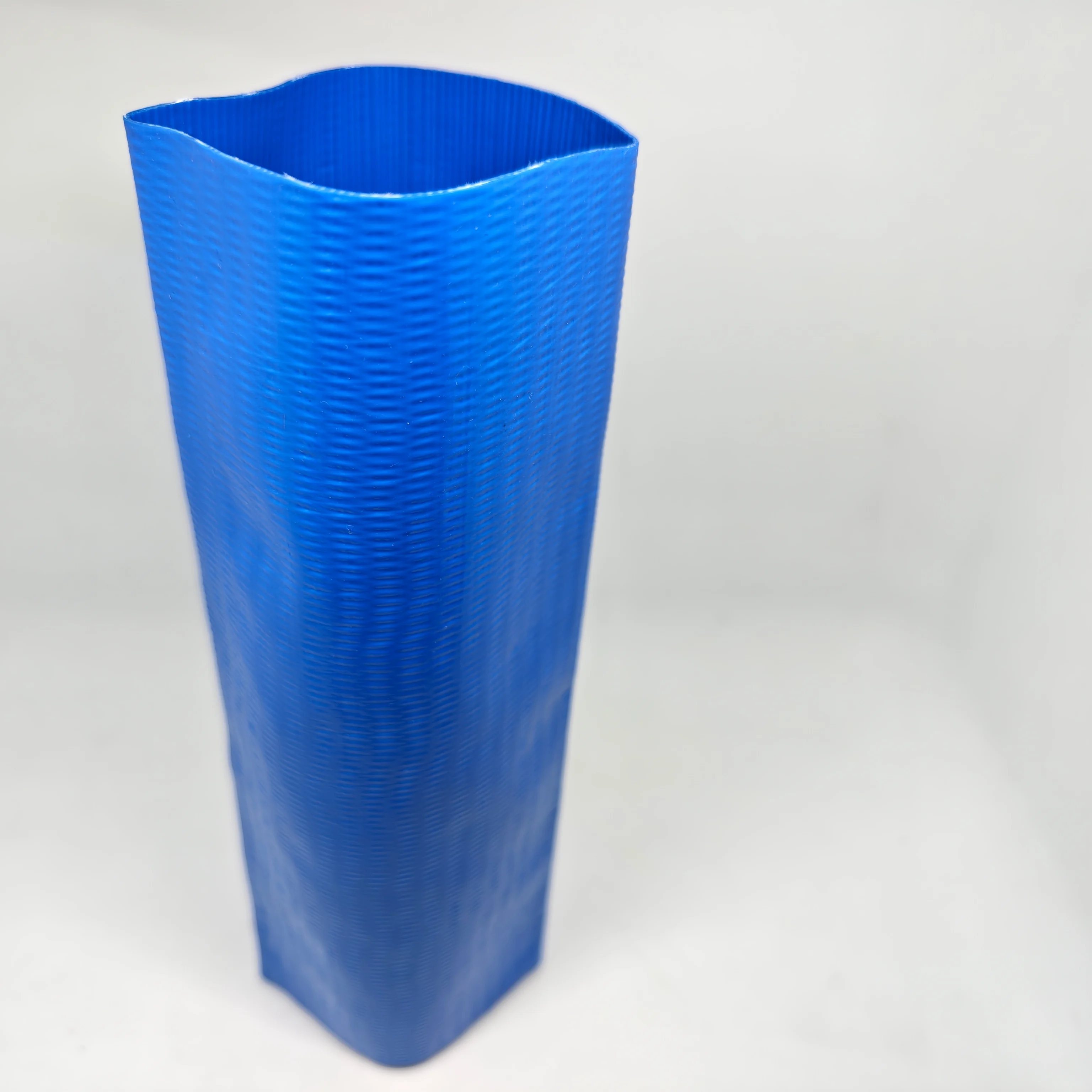

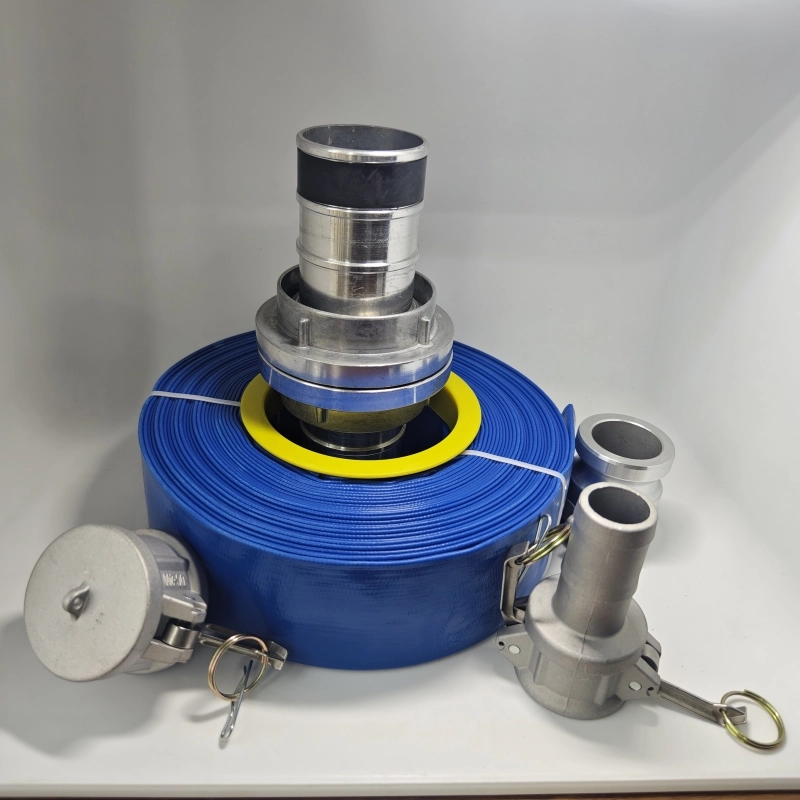

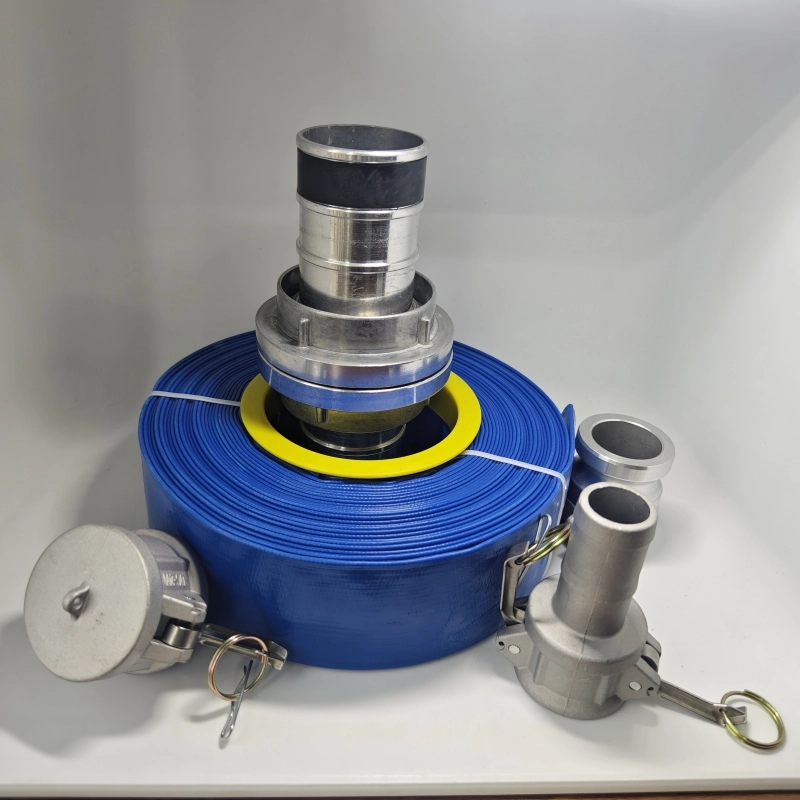

A blue PVC layflat discharge hose is a collapsible flat hose made from polyvinyl chloride (PVC) material that assumes a cylindrical shape when filled with liquid and flattens for storage when emptied. Equipped with Camlock quick-connect couplings (a tool-free connection system), it becomes a highly efficient liquid transfer solution.

Key Features:

High visibility: Standard blue color for easy identification

Space-saving: Flattens for compact storage when empty

Rapid deployment: Camlock couplings enable second-fast connections

Durability: Special PVC formulation enhances service life

2. Why Blue Color?

Blue holds special significance in industrial fluid transfer:

Industry standard: Internationally recognized for non-potable water transfer

Safety marking: High contrast with surroundings reduces tripping hazards

UV protection: Blue pigments typically contain UV stabilizers

Psychological impact: Blue conveys reliability and professionalism

Interesting fact: Different colors indicate different uses - red for firefighting, green for irrigation, while blue is standard for industrial drainage.

Part 2: Technical Specifications

1. Basic Specifications

| Parameter | Specification Range | Notes |

|---|---|---|

| Diameter | 2"-12" (50-300mm) | 4"-6" most common |

| Working Pressure | 4-10 bar | Depends on diameter |

| Burst Pressure | 12-30 bar | 3:1 safety factor |

| Temperature Range | -10°C to +60°C | Avoid freezing |

| Standard Lengths | 15m/30m/50m | Customizable |

| Bend Radius | 5× diameter | Avoid sharp bends in use |

| Weight | 0.5-3kg/m | Varies by diameter/thickness |

2. Camlock Coupling Specifications

| Parameter | Specification |

|---|---|

| Material | Aluminum alloy/Stainless steel/Polypropylene |

| Type | Type A (Female)/Type B (Male) |

| Sealing | O-ring (NBR/FKM) |

| Working Pressure | Up to 10 bar |

| Connection Time | <10 seconds |

| Corrosion Resistance | 500-hour salt spray test |

3. Performance Comparison

| Test Item | Standard Requirement | Premium Product Performance |

|---|---|---|

| Tensile Strength | ≥15MPa | 18-22MPa |

| Tear Resistance | ≥40N/mm | 50-60N/mm |

| Abrasion Resistance | 500 cycles no breach | 1000+ cycles |

| UV Stability | 500 hours no brittleness | 1000 hours remains flexible |

| Cold Flexibility | No cracks at -10°C | Flexible at -20°C |

Part 3: Advantages and Limitations

Advantages (Pros)

1.Space Efficiency

Thickness when empty is 1/5 of filled state

100m of 6" hose rolls to ~80cm diameter

2.Rapid Deployment

Camlock connects 10× faster than flanges

3-person team can lay 200m line in 15 minutes

3.Cost Effectiveness

Priced at 1/3 of rubber hoses

Service life reaches 5-8 years (normal use)

4.Easy Maintenance

Smooth surface resists dirt accumulation

Localized damage easily repaired

5.Versatility

Handles water, wastewater, slurry

Suitable for both suction and discharge

Limitations (Cons)

1.Temperature Limits

Prolonged high temps (>60°C) cause softening

Low temps (< -10°C) may cause brittleness

2.Chemical Compatibility

Not resistant to strong acids/bases (pH<3 or >11)

Organic solvents cause swelling

3.Mechanical Strength

Lower pressure rating than metal pipes

Vulnerable to sharp objects

4.UV Degradation

Prolonged sunlight reduces lifespan (even with blue UV protection)

5Fouling Issues

Wastewater can cause interior buildup

Requires periodic backflushing

Part 4: Quality Comparison Guide

Premium vs Economy Product Comparison

| Comparison | Premium Hose | Economy Hose |

|---|---|---|

| Material | Virgin PVC+polyester reinforcement | Recycled material+cheap fibers |

| Thickness | Uniform | Irregular |

| Color | Consistent deep blue | Fading/discoloration |

| Seam | HF welded seamless | Visible adhesive marks |

| Pressure Rating | 30% above rating | Barely meets standards |

| Flexibility | Remains flexible when cold | Hardens in cold |

| Abrasion Resistance | Meets DIN53516 | Rapid wear |

| Odor | Mild plastic smell | Strong chemical odor |

| Certifications | ISO/CE/UL etc. | None |

| Warranty | Typically 2-5 years | None or months only |

Real case: A construction site using budget hoses experienced multiple bursts within 3 months. After switching to premium hoses, they've operated 2+ years without failure.

Part 5: Manufacturing Process

1. Raw Material Preparation

PVC compound: Base resin+plasticizers+stabilizers+blue masterbatch

Reinforcement: High-tenacity polyester yarn (warp+weft)

Camlock couplings: Aluminum cast or injection molded

2. Production Process

Hose Manufacturing:

Extrusion: PVC melted into dual-layer film

Reinforcement weaving: Polyester yarn cross-woven at 45°

HF welding: Edges sealed to form tube

UV treatment: Surface coated with UV protection

Coupling Production:

Casting: Aluminum alloy melted and cast

Precision machining: Lathe machining sealing surfaces

Surface treatment: Anodizing or zinc plating

Assembly testing: O-ring installation and pressure testing

3. Quality Control Points

Material inspection: PVC resin K-value (optimal 67-68)

Weave density: 16-20 yarns per inch

Weld strength: ≥90% of base material strength

Color fastness: ΔE<3 after 500h QUV test

Part 6: Purchasing Guide

1. Needs Assessment "5 Questions"

What medium will it transfer? (Water/wastewater/chemicals)

Required working pressure? (Choose 30% above need)

Operating environment? (Indoor/outdoor/extreme temps)

Connection requirements? (Standardize Camlock type)

Frequency of movement? (Higher mobility needs better abrasion resistance)

2. On-Site Inspection "5 Steps"

Visual: Uniform color, no impurities, even weave pattern

Tactile: Smooth interior/exterior, uniform thickness, no burrs

Olfactory: No strong odor (low-quality PVC often smells)

Flex: No white marks when folded (material toughness test)

Pull: Minimal radial deformation (reinforcement quality)

3. Cost-Effectiveness Formula

Total Cost of Ownership = (Purchase price/service life) + maintenance costs

Example:

PVC Layflat hose A: $100/m, 3-year life, $10 annual maintenance → (100/3)+10=$43.3/year

PVC Layflat hose B: $150/m, 6-year life, $5 annual maintenance → (150/6)+5=$30/year

4. Brand Selection Advice

International brands: Alfagomma, Continental (30-50% premium)

Quality domestic: Renato flex, Jiaolong (best value)

Avoid: Products without manufacturer info or test reports

Part 7: Usage and Maintenance

1. Installation "3 Musts"

Keep straight: Avoid twisting during installation

Support properly: Provide support every 5-10m

Align correctly: Fully insert Camlock before rotating to lock

2. Usage Precautions

Pressure control: Avoid sudden pressure surges

Temperature management: Bleed air before moving in extreme temps

Chemical compatibility: Test unknown liquids first

Mechanical protection: Use edge guards when crossing sharp surfaces

3. Maintenance Methods

Cleaning: Flush interior after use

Drying: Hang to dry when empty (avoid folded storage)

Inspection: Check coupling O-rings monthly

Repair: Use PVC repair kits for small holes

4. Troubleshooting Guide

| Issue | Possible Cause | Solution |

|---|---|---|

| Leaky coupling | Worn O-ring | Replace seal (keep common sizes) |

| Bulging hose | Localized reinforcement break | Cut and reinstall coupling |

| Reduced flow | Interior fouling | Chemical/mechanical cleaning |

| Surface cracks | UV degradation | Apply waterproof tape |

Conclusion: Smart Selection Maximizes Value

The blue PVC layflat discharge hose, as an essential tool in modern industrial fluid transfer, demonstrates value not just in purchase price but more importantly in operational efficiency and reliability. Through this comprehensive guide, you should now understand:

Key indicators of genuine quality products

The engineering rationale behind blue coloring

Practical techniques to extend service life

How to make optimal cost-performance purchases

Remember: The most suitable is the best - by matching product specifications and quality levels to your specific application scenarios, usage frequency, and budget, you can maximize the value of this efficient drainage solution.

142.webp)