Lay flat discharge hoses are essential tools in various industries, including agriculture, construction, and firefighting. These hoses are designed to transport large volumes of water or other fluids efficiently and are known for their durability, flexibility, and ease of use. This article will focus on 3-inch and 4-inch lay flat discharge hose rolls, available in 20ft and 50ft lengths, highlighting their features, applications, and benefits.

Features of Lay Flat Discharge Hoses

Material:

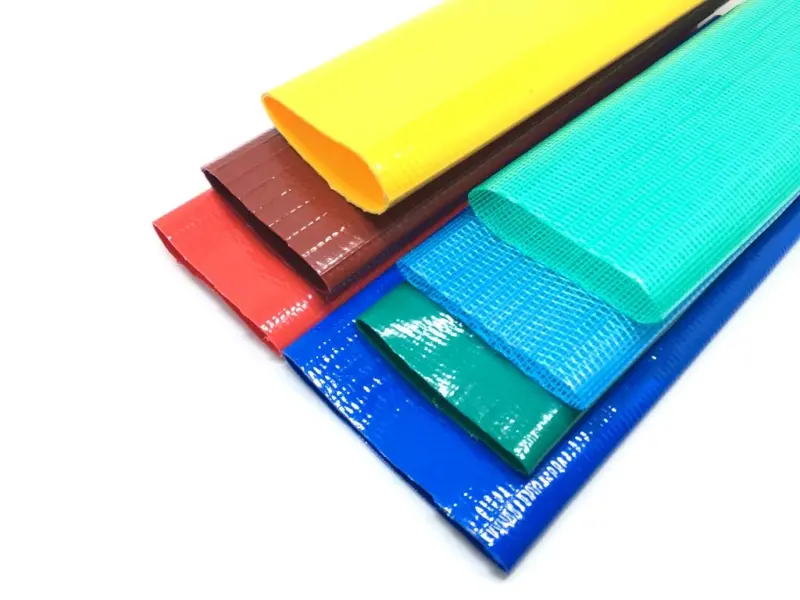

Typically made from durable PVC or rubber, these hoses are reinforced with polyester yarn for added strength and flexibility.

Design:

Lay flat hoses are designed to be flat when not in use, making them easy to roll up, store, and transport.

Sizes:

Available in various diameters, with 3-inch and 4-inch being popular choices for many applications.

Lengths:

Common lengths include 20ft and 50ft, catering to different operational needs.

Pressure Ratings:

Designed to handle a range of pressures, typically up to 150 PSI, depending on the material and construction.

Couplings:

Equipped with quick-connect couplings for easy attachment and detachment.

Applications

Agriculture:

Used for irrigation, watering crops, and transferring water from one location to another.

Construction:

Ideal for dewatering sites, transferring water for concrete mixing, and other fluid management tasks.

Firefighting:

Essential for transporting water from hydrants to the fire site, especially in rural or remote areas.

Industrial:

Used in various industrial processes where large volumes of water need to be moved efficiently.

Emergency Flood Response:

Deployed in flood control and mitigation efforts to remove water from affected areas quickly.

Benefits

Flexibility and Ease of Use:

Lay flat design makes these hoses easy to roll out and retrieve, reducing labor and time.

Space-Saving Storage:

When not in use, the hoses lay flat and can be coiled compactly, saving valuable storage space.

Durability:

Constructed from high-quality materials that resist abrasion, punctures, and UV damage, ensuring a long service life.

Cost-Effectiveness:

Their durability and efficiency make lay flat hoses a cost-effective solution for fluid transportation needs.

Versatility:

Suitable for a wide range of applications, making them a versatile tool for different industries.

Specifics: 3" and 4" Inch Hoses

3-Inch Lay Flat Discharge Hose:

20ft Roll:

Ideal for smaller projects or confined spaces where a shorter length is sufficient.

Easier to handle and maneuver, suitable for quick jobs or emergency use.

50ft Roll:

Provides greater reach and coverage, suitable for larger areas or more extensive operations.

Often used in agriculture and construction where longer distances need to be covered.

4-Inch Lay Flat Discharge Hose:

20ft Roll:

Suitable for medium-duty tasks where space is limited but a larger diameter is needed for higher flow rates.

Commonly used in construction sites for dewatering and fluid transfer.

50ft Roll:

Provides maximum coverage and is ideal for large-scale operations requiring high flow rates.

Frequently used in firefighting and flood response due to its capacity to move large volumes of water quickly.

Market Prices for 3" and 4" Inch Lay Flat Discharge Hose Rolls

| Hose Size | Length | Price Range (USD) |

|---|---|---|

| 3" Inch | 20 feet (approx. 6 meters) | $20 - $40 |

| 3" Inch | 50 feet (approx. 15 meters) | $50 - $100 |

| 4" Inch | 20 feet (approx. 6 meters) | $30 - $50 |

| 4" Inch | 50 feet (approx. 15 meters) | $70 - $120 |

These prices are based on standard quality hoses.

3-inch and 4-inch lay flat discharge hoses, available in 20ft and 50ft lengths, are versatile and essential tools for a variety of industries. Their design ensures ease of use, durability, and efficient fluid transfer, making them invaluable in agriculture, construction, firefighting, and more. Whether you need a hose for a small project or a large-scale operation, lay flat discharge hoses offer reliable performance and long-lasting value. Choosing the right size and length depends on your specific needs, but with their numerous benefits, these hoses are a smart investment for any fluid management task.

Manufacturing Standards for Lay Flat Discharge Hoses

When manufacturing 3" and 4" inch lay flat discharge hoses, adherence to specific standards ensures the products meet quality, safety, and performance criteria. These standards are set by various international, regional, and national organizations. Here are the key manufacturing standards for these hoses:

International Standards

ISO 9001: Quality Management Systems

Ensures that the manufacturing process follows a systematic approach to quality management, including continuous improvement and customer satisfaction.

ISO 14001: Environmental Management Systems

Specifies requirements for an effective environmental management system, ensuring the manufacturing process minimizes environmental impact.

ISO 10358: Plastics – Pipes and Fittings – Determination of the Degree of Pigment or Carbon Black Dispersion in Polyolefin Pipes, Fittings, and Compounds

Ensures consistent pigmentation and dispersion of materials used in hose manufacturing.

ISO 1452: Plastic Piping Systems for Water Supply and for Buried and Above-Ground Drainage and Sewerage under Pressure – Unplasticized Polyvinyl Chloride (PVC-U)

Provides guidelines for the quality and performance of PVC materials used in hose production.

American Standards

ASTM D5801: Standard Test Method for Toughness and Tenacity of Bituminous Materials

Measures the toughness and durability of materials used in hose coatings.

ASTM D2240: Standard Test Method for Rubber Property – Durometer Hardness

Tests the hardness of rubber components in hoses, ensuring they meet the necessary resilience and flexibility requirements.

ASTM D380: Standard Test Methods for Rubber Hose

Covers various tests for rubber hoses, including elongation, burst pressure, and tensile strength.

NFPA 1961: Standard on Fire Hose

Provides standards for the manufacture and performance of fire hoses, which can be relevant for high-pressure lay flat hoses used in emergency services.

European Standards

EN ISO 9001: Quality Management Systems

Similar to ISO 9001, ensures quality management processes are in place for consistent production.

EN 681-1: Elastomeric Seals – Material Requirements for Pipe Joint Seals Used in Water and Drainage Applications – Part 1: Vulcanized Rubber

Specifies material requirements for elastomeric seals in hoses.

EN 694: Fire Hoses – Semi-Rigid Hoses for Fixed Systems

Sets standards for the construction and performance of hoses used in fire safety systems.

EN ISO 14001: Environmental Management Systems

Ensures environmental management practices are in place to minimize ecological impact during manufacturing.

Chinese Standards

GB/T 9754: Polyvinyl Chloride (PVC) Compounds for Plastics Pipes and Fittings

Specifies the properties of PVC compounds used in the production of hoses.

GB/T 18242: Rubber, Vulcanized or Thermoplastic – Determination of Resistance to Ozone Cracking – Static Strain Testing

Tests the ozone resistance of rubber components in hoses to ensure longevity and performance.

GB/T 5563: Rubber and Plastics Hoses and Hose Assemblies – Determination of Pressure Loss

Measures the pressure loss in hose assemblies to ensure efficiency and performance.

GB/T 10654: Rubber and Plastics Hoses and Hose Assemblies – Determination of Compression Set

Determines the compression set of hose materials to ensure they maintain their shape and effectiveness under pressure.

Additional Guidelines and Certifications

CE Marking

Indicates that the product complies with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

RoHS (Restriction of Hazardous Substances Directive)

Ensures that the hoses do not contain hazardous substances that could harm users or the environment.

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

Ensures that the chemical substances used in hose manufacturing are registered and evaluated for safety.

NTPEP (National Transportation Product Evaluation Program)

A program by the American Association of State Highway and Transportation Officials (AASHTO) that evaluates transportation products, including hoses, to ensure they meet the necessary performance criteria.

Manufacturing 3" and 4" inch lay flat discharge hoses requires adherence to a variety of international, regional, and national standards to ensure quality, durability, and safety. These standards cover aspects such as material properties, environmental impact, performance testing, and chemical safety. By following these standards, manufacturers can produce high-quality hoses that meet the needs of various industries, including agriculture, construction, firefighting, and industrial applications.

How to Determine the Quality of Lay Flat Discharge Hose Rolls

When selecting 3" and 4" inch lay flat discharge hose rolls, it is crucial to assess their quality to ensure durability, reliability, and optimal performance. High-quality hoses will provide efficient fluid transport, withstand various environmental conditions, and last longer. Here are key factors to consider when evaluating the quality of these hoses:

1. Material Quality

PVC or Rubber Composition:

High-quality hoses are typically made from durable PVC or rubber materials. Check the material specifications to ensure they are designed to resist abrasion, punctures, and UV radiation.

Tip: Look for hoses that specify the use of high-grade PVC or synthetic rubber, which are known for their strength and flexibility.

Reinforcement:

Quality hoses are reinforced with polyester yarn or fabric layers to enhance strength and prevent kinks.

Tip: Inspect the hose for consistent and even reinforcement without weak spots or irregularities.

2. Tensile Strength

High Tensile Strength:

The hose should have a high tensile strength to withstand the pressures of fluid transport and environmental stress.

Tip: Check the tensile strength rating, which is usually measured in pounds per square inch (PSI). High-quality hoses typically have ratings above 150 PSI.

3. Pressure Ratings

Working Pressure:

The hose should be capable of handling the working pressure required for your specific application without bursting.

Tip: Ensure the hose has a working pressure rating suitable for your needs. For most applications, look for hoses with a working pressure of at least 150 PSI.

Burst Pressure:

High-quality hoses will have a burst pressure rating significantly higher than the working pressure, providing a safety margin.

Tip: The burst pressure should be at least three times the working pressure. For example, if the working pressure is 150 PSI, the burst pressure should be 450 PSI or higher.

4. Flexibility and Weight

Flexibility:

The hose should be flexible enough to lay flat when not in use and easily coil for storage.

Tip: Test the hose by bending and coiling it. High-quality hoses will remain flexible without cracking or showing signs of stress.

Weight:

A balance between lightweight and durable construction is essential. The hose should be easy to handle but robust enough to withstand heavy use.

Tip: Compare the weight of different hoses. While lighter hoses are easier to handle, they should not compromise on durability and strength.

5. Chemical and UV Resistance

Chemical Resistance:

Ensure the hose material is resistant to chemicals, oils, and other substances it may encounter during use.

Tip: Look for hoses with chemical resistance ratings and confirm compatibility with the fluids you will be transporting.

UV Resistance:

The hose should be resistant to UV radiation to prevent degradation and extend its lifespan when used outdoors.

Tip: Check for UV resistance specifications or treatments applied to the hose material.

6. Couplings and Fittings

High-Quality Couplings:

The couplings should be made from durable materials such as brass or stainless steel to ensure a secure and leak-free connection.

Tip: Inspect the couplings for solid construction, smooth threading, and a tight fit with the hose.

Ease of Attachment:

Quick-connect couplings are preferred for their ease of use and secure connection.

Tip: Test the couplings to ensure they attach and detach easily without requiring excessive force.

7. Brand Reputation and Certifications

Reputable Brands:

Choose hoses from well-known and reputable manufacturers who have a track record of producing high-quality products.

Tip: Read reviews, ask for recommendations, and check the manufacturer’s history and customer service.

Certifications:

Look for hoses that meet industry standards and certifications, such as ISO 9001 for quality management and other relevant standards.

Tip: Verify the certifications and ensure they are from recognized and credible organizations.

8. Visual Inspection

Uniformity and Finish:

Inspect the hose for uniform thickness, smooth surfaces, and even coloring. High-quality hoses will have a consistent appearance without blemishes or defects.

Tip: Run your hand along the length of the hose to feel for any irregularities or weak spots.

Branding and Labeling:

High-quality hoses often have clear branding, model numbers, and specifications printed along their length.

Tip: Ensure the labeling is clear and matches the product description and specifications provided by the manufacturer.

Evaluating the quality of 3" and 4" inch lay flat discharge hose rolls involves checking the material, tensile strength, pressure ratings, flexibility, chemical and UV resistance, couplings, brand reputation, and conducting a visual inspection. By considering these factors, you can select a high-quality hose that meets your specific needs, ensuring reliable performance and longevity. Always prioritize reputable brands and verified certifications to guarantee the best results.

After-Sales Services for Lay Flat Discharge Hoses

Providing excellent after-sales service is crucial for ensuring customer satisfaction and maintaining a strong reputation in the market. Here are the key after-sales services that should be offered for 3" and 4" inch lay flat discharge hoses:

1. Warranty

Comprehensive Warranty:

Offer a comprehensive warranty that covers manufacturing defects, material defects, and workmanship issues. The warranty period typically ranges from 1 to 5 years, depending on the product and manufacturer.

Service: If any defects are found within the warranty period, provide free repairs or replacements.

2. Technical Support

24/7 Customer Support:

Provide 24/7 customer support through various channels, including phone, email, and online chat. This ensures that customers can get assistance whenever they need it.

Service: Assist customers with installation, troubleshooting, and maintenance questions.

On-Site Technical Assistance:

Offer on-site technical support for large-scale or complex installations and troubleshooting.

Service: Send a qualified technician to the customer’s location to assist with setup, repair, or maintenance.

3. Maintenance Services

Regular Maintenance Checks:

Provide scheduled maintenance checks to ensure the hoses are in good condition and functioning properly.

Service: Inspect the hoses for wear and tear, pressure test them, and replace any damaged parts.

Maintenance Contracts:

Offer maintenance contracts for customers who want regular servicing of their hoses.

Service: Include periodic inspections, cleaning, and preventive maintenance services.

4. Repair Services

Quick Repair Turnaround:

Offer quick repair services to minimize downtime for the customer.

Service: Provide express repair services for urgent issues and ensure a fast turnaround time.

Authorized Repair Centers:

Establish authorized repair centers in various regions to provide convenient access to repair services.

Service: Train technicians at these centers to perform high-quality repairs.

5. Replacement Services

Easy Replacement Process:

Implement an easy and hassle-free replacement process for defective or damaged hoses.

Service: Provide pre-paid shipping labels for customers to return defective products and expedite the replacement shipment.

Stock Availability:

Ensure that replacement hoses and parts are always in stock to avoid delays in providing replacements.

Service: Maintain a well-stocked inventory of hoses and parts.

6. Training and Education

User Training:

Offer training sessions to educate customers on the proper use, maintenance, and storage of lay flat discharge hoses.

Service: Provide on-site training, online webinars, and detailed user manuals.

Installation Guides:

Provide comprehensive installation guides and videos to help customers set up their hoses correctly.

Service: Create step-by-step installation videos and detailed manuals.

7. Customer Feedback and Improvement

Feedback Collection:

Regularly collect customer feedback to improve products and services.

Service: Use surveys, feedback forms, and direct customer interactions to gather insights.

Continuous Improvement:

Use customer feedback to continuously improve product quality and after-sales services.

Service: Implement changes based on feedback to enhance customer satisfaction.

8. Return Policy

Flexible Return Policy:

Offer a flexible return policy that allows customers to return hoses if they are not satisfied with the product.

Service: Provide clear guidelines for returns and ensure a hassle-free process.

9. Extended Service Plans

Extended Warranty Plans:

Offer extended warranty plans for customers who want additional protection beyond the standard warranty period.

Service: Provide options for extending the warranty coverage.

Premium Support Plans:

Offer premium support plans that include additional services such as priority support, extended maintenance, and faster replacement services.

Service: Provide tiered support plans to cater to different customer needs.

Offering comprehensive after-sales services for 3" and 4" inch lay flat discharge hoses is essential for ensuring customer satisfaction and building long-term relationships. By providing robust warranties, technical support, maintenance services, quick repairs, easy replacements, user training, and flexible return policies, manufacturers can address customer needs effectively and maintain a positive reputation in the market. Implementing these after-sales services will not only enhance customer loyalty but also contribute to the overall success of the product.

Increased demand for flat hoses in agriculture

The growth in food demand has led to an increase in orders for agricultural activities, resulting in a surge in the use of flat hoses. In agriculture, low-pressure pipeline water delivery is a new type of irrigation method, and its application rate is increasing. Traditional farmland irrigation uses aqueducts to deliver water to farmland, which has the problem of wasting water resources and energy consumption of water delivery facilities. The low-pressure pipeline water delivery system uses a pipe network for water delivery, distribution and irrigation, which can avoid water delivery loss and evaporation loss. Generally, the efficiency of pipeline water distribution and irrigation is twice that of the open channel system. In addition, since most of the water pipes are buried underground, less arable land is occupied, and the land utilization rate is improved. At present, agricultural pipeline irrigation mainly uses plastic pipes such as PVC pipes and PE pipes. Plastic pipes have the advantages of corrosion resistance, long life and convenient transportation. With the expansion of agricultural scale, the popularization of mechanization and the increase in water-saving requirements, there is a great demand for plastic pipes. At the same time, in order to solve the problem of drinking water safety in rural areas, the government is also actively promoting the construction of plastic pipe networks. Therefore, the growing agricultural demand has driven the rapid growth of the flat hose market.

According to the statistics and forecast data given in the 2024 Flat Hose Market Report, in 2023, the global and Chinese flat hose market will reach US$2.031 billion and US$387 million respectively. During the forecast period, the global flat hose market is expected to grow at a compound annual growth rate of 7.51%, and it is predicted that the total global flat hose market will reach US$3.091 billion by 2029.

From the analysis data, it can be seen that flat hose has great market potential. If you want to expand your market share, you can contact our PVC flat hose factory.

Factory Profile: Renatoflex

About Us

Renatoflex is a leading manufacturer of 3" and 4" lay flat drain hose reels available in 20' and 50' lengths. Our factory is located in China and is dedicated to producing high-quality hoses for a variety of applications in the agriculture, construction, fire and industrial sectors.

Our Mission

At Renatoflex, our mission is to provide durable, efficient and cost-effective fluid transfer solutions. Our goal is to lead the industry with innovative designs and premium products that meet the highest quality and performance standards. Our commitment to excellence ensures that our customers receive reliable products that exceed their expectations.

Our Facilities

Our state-of-the-art manufacturing facility is equipped with advanced machinery and technology that enables us to produce hoses that meet stringent quality standards. We have a team of experienced professionals who oversee every step of the production process to ensure precision and consistency in our products. We can produce to your required manufacturing standards.

Our Products

Renatoflex specializes in the production of lay flat drain hoses in two popular sizes:

3" Lay Flat Drain Hose Reel:

Available in 20' and 50' lengths.

Ideal for medium-duty applications requiring efficient water delivery and durability.

Ideal for agricultural irrigation, building drainage, and more.

4" Lay-Flat Drain Hose Reel:

Available in 20-foot and 50-foot lengths.

Designed for heavy-duty applications with higher flow rates.

Ideal for large-scale irrigation, firefighting, and industrial fluid transfer.

Quality Assurance

We pride ourselves on our stringent quality control process, which ensures that every hose we produce meets the highest standards of durability and performance. Our hoses are made from premium materials, reinforced with polyester yarn for added strength, and designed to withstand high pressures and harsh environmental conditions.

Certifications

Renatoflex adheres to international manufacturing standards and has received several certifications to guarantee the quality and safety of our products, including:

ISO 9001: Quality Management System

ISO 14001: Environmental Management System

Customer Support

We are committed to providing our customers with excellent after-sales service. Our comprehensive support includes:

Technical Assistance: 24/7 customer support for troubleshooting and maintenance.

Warranty: Comprehensive warranty covering manufacturing defects.

Contact Us

Renatoflex Factory is your trusted partner for high-quality lay flat discharge hoses. For more information on our products and services, visit our website or contact our customer service team. We are always ready to help you with your fluid transfer needs.

820 Buliding C Qingdao Plaza, No.379 Dunhua Road, Qingdao 266034 China.

+86 - 186 5328 1131