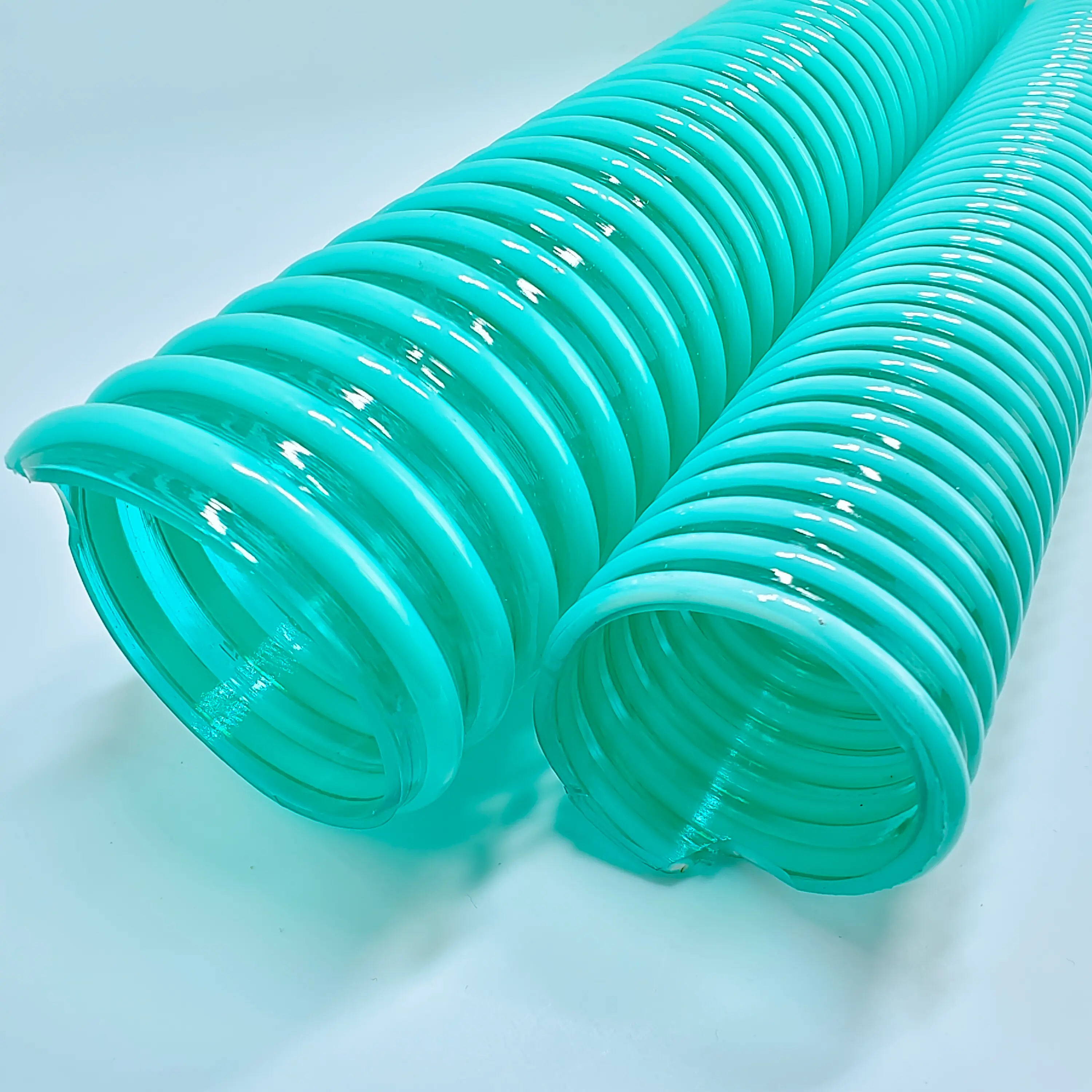

What is a Corrugated Spiral Suction Hose?

A Corrugated Spiral Suction Hose is a flexible hose reinforced with a spiral helix and corrugated exterior. The corrugated design enhances flexibility, while the spiral helix reinforcement provides structural integrity, enabling the hose to withstand vacuum and pressure conditions without collapsing. These hoses are typically made from durable materials such as polyvinyl chloride (PVC) or polyethylene (PE), ensuring long-term performance.

These hoses can operate efficiently in a broad temperature range, typically from -10°C to +60°C (14°F to 140°F), making them suitable for diverse climatic conditions.

The Corrugated Spiral Suction Hose is an efficient and durable solution for various water suction applications. Its flexibility, strength, and versatility make it a valuable tool in agriculture, construction, industrial, and marine environments. By choosing the right hose and maintaining it properly, you can ensure reliable performance and longevity, making it a sound investment for your fluid handling needs.

Helix Sprial Pvc Suction Hose For Water Suction And Discharge

At Renato Hose, we pride ourselves on delivering top-tier products crafted with precision and expertise honed over 15 years in the industry. Our Helix Spiral PVC Suction Hose stands as a testament to our commitment to quality and innovation.

Crafted with high-quality PVC reinforcement, our suction hose boasts a robust construction capable of withstanding up to -2 bar vacuum pressure, ensuring reliability even in demanding environments. Its long working life guarantees durability, providing you with a dependable solution for your water suction and discharge requirements.

This is our flat surface suction hose, which is mainly used in many aspects such as building engineering reinforcement, water supply and drainage of water conservancy projects, urban water supply and drainage, road construction, wastewater treatment in environmental protection industry and material transmission in industrial fields. And it has wear resistance, compression resistance and chemical properties, as well as antistatic properties.

Applications

This hose is widely used for industry in both positive and negative pressure applications, ideally for conveying and suction of water, oil, powder, granules in pump industries, constructions, mining industries, chemical factories and many other industry applications.

Characteristics

This hose is made from high quality flexible PVC material and high strengthen PVC bones. Excellent flexibility, light weight, crush and abrasion resistant, smooth tube for less friction loss, smooth cover allows easy dragging, weathering resistant, clear to have full visual flow of materials, corrosion resistant to light chemicals, various lengths available and can be supplied with different couplings and clamps, ideal replace for bulkier and heavier ply-wrapped rubber hose.

◢ This kind of hose is an ideal products to use for suction and discharge.

◢ It is cystal clear, flexible, bright colors, very easy to know what's going on inside the hose.

◢ No odor, environmental protection products.

◢ Working Temperature: -5°C-65°C

Specifications of PVC Suction Hose

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | ||

| inch | mm | mm | m | kg/m | bar | psi |

| 3/4 | 19 | 2.5 | 50 | 0.25 | 8 | 120 |

| 3 | 50 | 0.28 | 9 | 135 | ||

| 1 | 25 | 2.5 | 50 | 0.32 | 8 | 120 |

| 3 | 50 | 0.35 | 9 | 135 | ||

| 1 1/4 | 32 | 3 | 50 | 0.4 | 8 | 120 |

| 4 | 50 | 0.55 | 9 | 135 | ||

| 1 1/2 | 38 | 3 | 50 | 0.55 | 6 | 90 |

| 4 | 50 | 0.7 | 7 | 105 | ||

| 2 | 50 | 4 | 50 | 0.92 | 6 | 90 |

| 5 | 50 | 1.1 | 7 | 105 | ||

| 2 1/2 | 63 | 3.5 | 30 | 0.95 | 5 | 75 |

| 4.5 | 30 | 1.23 | 6 | 90 | ||

| 3 | 75 | 4 | 30 | 1.45 | 4 | 60 |

| 5 | 30 | 1.65 | 5 | 75 | ||

| 4 | 100 | 5 | 30 | 2.3 | 4 | 60 |

| 6 | 30 | 2.9 | 5 | 75 | ||

| 5 | 127 | 6 | 20 | 3.3 | 4 | 60 |

| 8 | 20 | 4.7 | 5 | 75 | ||

| 6 | 152 | 7 | 20 | 5 | 4 | 60 |

| 9 | 20 | 6.3 | 5 | 75 | ||

| 8 | 200 | 7 | 10 | 6.3 | 4 | 60 |

| 8 | 10 | 7 | 4 | 60 | ||

| 10 | 250 | 8 | 10 | 10 | 4 | 60 |

| 9 | 10 | 11 | 4 | 60 | ||

| 12 | 305 | 12 | 10 | 18 | 4 | 60 |

| 14 | 355 | 12 | 10 | 20 | 4 | 60 |

The function of Corrugated Spiral Suction Hose For Suction Water

The corrugated spiral suction hose for suction water serves a crucial function in various water suction applications. Its design and material composition enable it to efficiently and reliably perform its duties.

Firstly, the corrugated spiral design of the hose offers flexibility and adaptability. This allows it to conform to different shapes and contours, making it suitable for use in various environments and scenarios. Whether it's for use in a garden, construction site, or industrial setting, the hose can easily be maneuvered to reach the desired water source.

Secondly, the corrugated design also provides excellent resistance to kinking and twisting. This ensures a smooth and uninterrupted flow of water through the hose, minimizing any potential for blockages or flow restrictions.

Moreover, the material used in the manufacture of the corrugated spiral suction hose is typically lightweight but strong, making it easy to handle and transport. This is particularly beneficial in applications where the hose needs to be frequently moved or repositioned.

Additionally, the hose is designed to withstand the rigors of suction operations. It can handle the suction pressure generated by water pumps, ensuring a continuous and efficient flow of water through the hose.

Comparing High-Quality and Low-Quality Corrugated Spiral Suction Hoses

When choosing a Corrugated Spiral Suction Hose, understanding the differences between high-quality and low-quality options is crucial for ensuring performance, durability, and overall satisfaction. Here’s a comparison to help you make an informed decision:

Material Composition

High-Quality Hose:

Made from premium-grade polyvinyl chloride (PVC) or polyethylene (PE).

Enhanced resistance to chemicals, abrasion, and UV radiation.

Contains additives for improved flexibility and longevity.

Low-Quality Hose:

Made from lower-grade materials, often with a higher filler content.

Reduced chemical and abrasion resistance.

Lacks UV stabilizers, making it prone to degradation from sunlight exposure.

Reinforcement and Structure

High-Quality Hose:

Features robust spiral helix reinforcement for superior structural integrity.

Corrugated design provides excellent flexibility while maintaining shape under vacuum and pressure.

Uniform and precise construction ensures consistent performance.

Low-Quality Hose:

May have weaker or poorly constructed spiral helix reinforcement, leading to potential collapse under pressure.

Inconsistent corrugated structure can cause uneven flexibility and kinking.

Variability in manufacturing can result in weak spots and reduced durability.

Durability and Lifespan

High-Quality Hose:

Long lifespan due to high-grade materials and superior construction.

Resistant to environmental factors such as extreme temperatures, UV exposure, and harsh chemicals.

Maintains performance and integrity over years of use.

Low-Quality Hose:

Shorter lifespan due to inferior materials and construction.

Susceptible to cracking, wear, and degradation from environmental exposure.

Frequent replacements may be necessary, leading to higher long-term costs.

Performance

High-Quality Hose:

Smooth inner surface ensures efficient fluid flow with minimal friction loss.

Consistently handles high suction and discharge pressures.

Reliable performance across various applications, including water, oil, and chemical suction.

Low-Quality Hose:

Rough inner surface can cause friction loss and reduce flow efficiency.

May struggle to handle high pressures, leading to potential failures.

Inconsistent performance, especially in demanding or harsh conditions.

Cost and Value

High-Quality Hose:

Higher upfront cost but provides better value due to longevity and reliable performance.

Lower maintenance and replacement costs over time.

Enhanced safety and efficiency in operations.

Low-Quality Hose:

Lower initial cost but higher long-term costs due to frequent replacements and repairs.

Increased risk of operational failures and downtime.

Potential safety issues due to inferior performance and reliability.

Applications and Suitability

High-Quality Hose:

Suitable for demanding applications such as industrial fluid handling, agricultural irrigation, construction dewatering, and marine bilge pumping.

Versatile and adaptable to a wide range of conditions and requirements.

Low-Quality Hose:

Limited suitability for heavy-duty applications.

Best for light-duty, non-critical tasks where performance and durability are not primary concerns.

May not meet the demands of more challenging environments and applications.

Conclusion

Choosing a high-quality Corrugated Spiral Suction Hose ensures reliable performance, durability, and long-term cost savings. While the initial investment may be higher, the benefits far outweigh the drawbacks of opting for a low-quality alternative. Consider your specific needs and applications to select the right hose that will deliver the best results for your operations.

About Us

Qingdao Renato Plastic Co., Ltd. specializes in the production and sales of various PVC hoses. With over 13 years of professional manufacturing experience, our company focuses on providing prompt inquiry, production, and shipping services, customized specifications, strict quality control, cost savings, and comprehensive after-sales service and technical support. In addition, our product range also includes rubber hoses, hose fittings, hose clamps, hose reels, fire hose nozzles, and more.

Welcome to Contact Us!

QINGDAO RENATO PLASTIC CO., LTD.

Contact: Mr. Kevin Ren

Phone/Whatsapp/Wechat: 0086-18653281131

Skype: bizchen2012

Email: sales@renatoplastic.com

kevin@renatoplastic.com

bizchen2012@foxmail.com