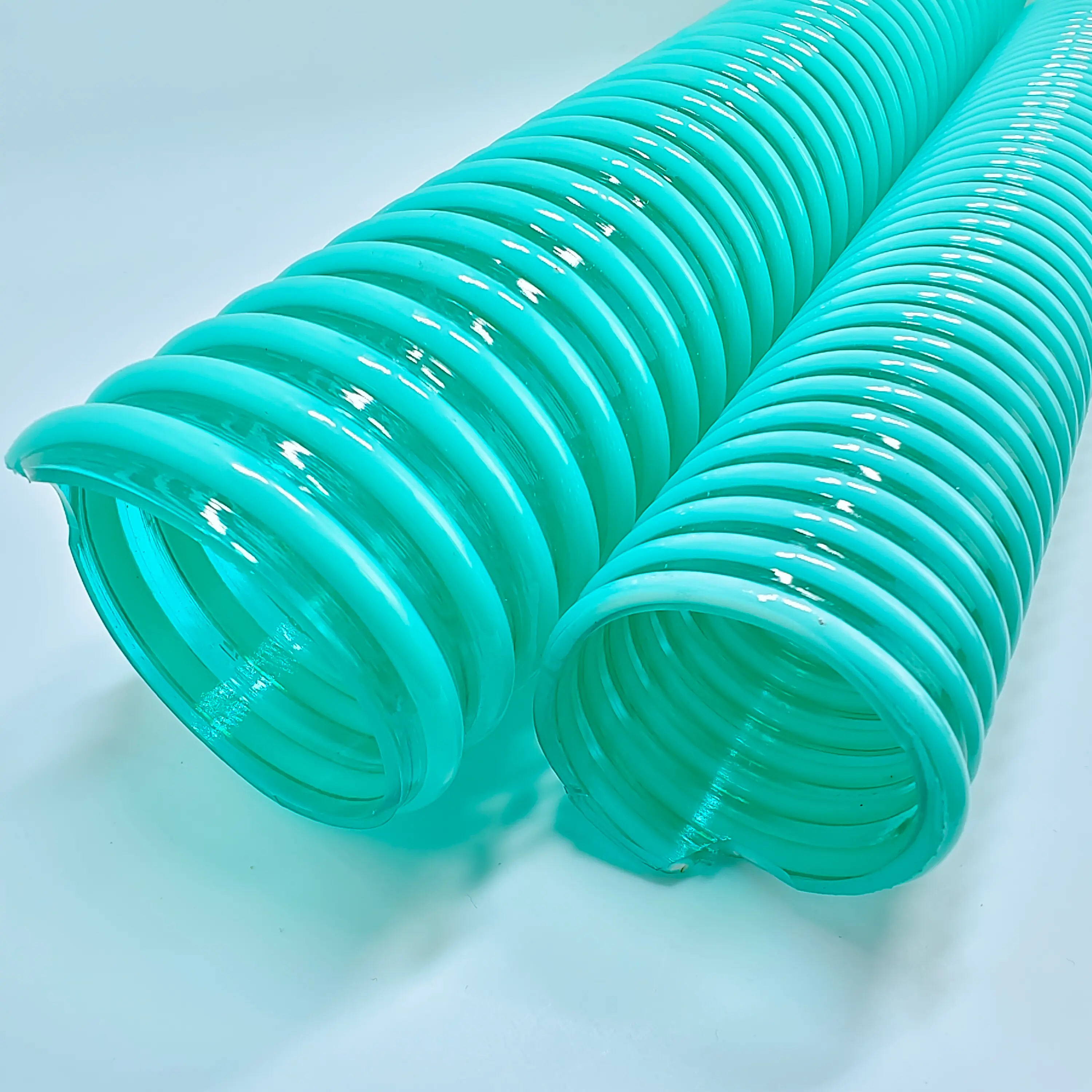

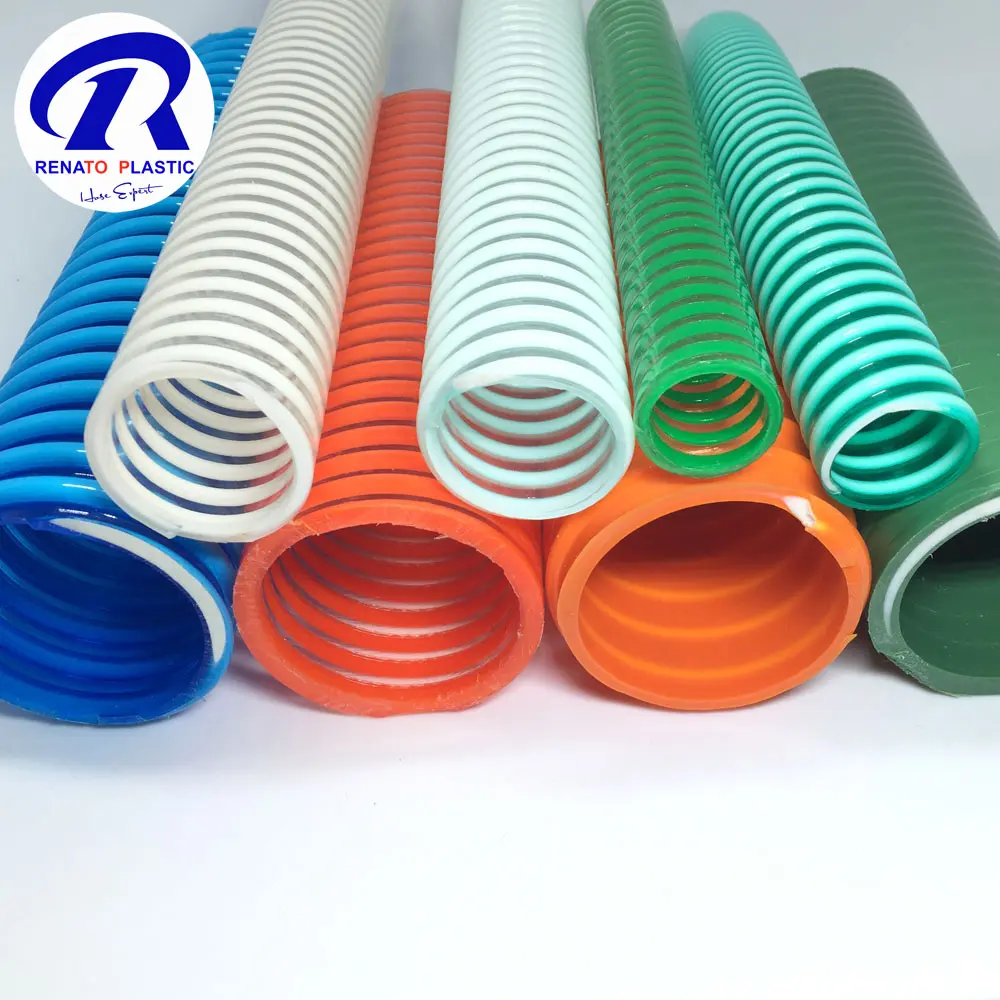

Helix Sprial Pvc Suction Hose For Water Suction And Discharge

At Renato Hose, we pride ourselves on delivering top-tier products crafted with precision and expertise honed over 15 years in the industry. Our Helix Spiral PVC Suction Hose stands as a testament to our commitment to quality and innovation.

Crafted with high-quality PVC reinforcement, our suction hose boasts a robust construction capable of withstanding up to -2 bar vacuum pressure, ensuring reliability even in demanding environments. Its long working life guarantees durability, providing you with a dependable solution for your water suction and discharge requirements.

Applications

This hose is widely used for industry in both positive and negative pressure applications, ideally for conveying and suction of water, oil, powder, granules in pump industries, constructions, mining industries, chemical factories and many other industry applications.

This is a photo of our suction hose when it is connected to a water pump for pumping water.

Characteristics

This hose is made from high quality flexible PVC material and high strengthen PVC bones. Excellent flexibility, light weight, crush and abrasion resistant, smooth tube for less friction loss, smooth cover allows easy dragging, weathering resistant, clear to have full visual flow of materials, corrosion resistant to light chemicals, various lengths available and can be supplied with different couplings and clamps, ideal replace for bulkier and heavier ply-wrapped rubber hose.

◢ This kind of hose is an ideal products to use for suction and discharge.

◢ It is cystal clear, flexible, bright colors, very easy to know what's going on inside the hose.

◢ No odor, environmental protection products.

◢ Working Temperature: -5°C-65°C

Our suction hose can be divided into flat surface and corrugated surface, which are suitable for different conditions and have multiple uses.

Specifications of PVC Suction Hose

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | ||

| inch | mm | mm | m | kg/m | bar | psi |

| 3/4 | 19 | 2.5 | 50 | 0.25 | 8 | 120 |

| 3 | 50 | 0.28 | 9 | 135 | ||

| 1 | 25 | 2.5 | 50 | 0.32 | 8 | 120 |

| 3 | 50 | 0.35 | 9 | 135 | ||

| 1 1/4 | 32 | 3 | 50 | 0.4 | 8 | 120 |

| 4 | 50 | 0.55 | 9 | 135 | ||

| 1 1/2 | 38 | 3 | 50 | 0.55 | 6 | 90 |

| 4 | 50 | 0.7 | 7 | 105 | ||

| 2 | 50 | 4 | 50 | 0.92 | 6 | 90 |

| 5 | 50 | 1.1 | 7 | 105 | ||

| 2 1/2 | 63 | 3.5 | 30 | 0.95 | 5 | 75 |

| 4.5 | 30 | 1.23 | 6 | 90 | ||

| 3 | 75 | 4 | 30 | 1.45 | 4 | 60 |

| 5 | 30 | 1.65 | 5 | 75 | ||

| 4 | 100 | 5 | 30 | 2.3 | 4 | 60 |

| 6 | 30 | 2.9 | 5 | 75 | ||

| 5 | 127 | 6 | 20 | 3.3 | 4 | 60 |

| 8 | 20 | 4.7 | 5 | 75 | ||

| 6 | 152 | 7 | 20 | 5 | 4 | 60 |

| 9 | 20 | 6.3 | 5 | 75 | ||

| 8 | 200 | 7 | 10 | 6.3 | 4 | 60 |

| 8 | 10 | 7 | 4 | 60 | ||

| 10 | 250 | 8 | 10 | 10 | 4 | 60 |

| 9 | 10 | 11 | 4 | 60 | ||

| 12 | 305 | 12 | 10 | 18 | 4 | 60 |

| 14 | 355 | 12 | 10 | 20 | 4 | 60 |

The Features of PVC Helix Anti-shock Suction Hose

Light and Flexible PVC Helix Reinforced Anti-Shock Spiral Suction Hose is renowned for its exceptional characteristics that cater to diverse suction needs. Constructed from high-grade PVC, it offers superior durability and resilience against wear and tear, even in harsh environments. The helix reinforcement not only adds strength but also maintains the hose's shape, ensuring consistent performance even under high pressure.

The anti-shock property is a standout feature, allowing the hose to withstand shocks and impacts without sustaining damage. This ensures uninterrupted flow and enhances the overall reliability of the suction system.

Moreover, its spiral design offers flexibility and ease of use, making it suitable for tight spaces and complex layouts. The hose can be easily maneuvered and stored, reducing operational hassles.

The lightweight nature of the hose further simplifies handling and transportation, making it an ideal choice for on-site suction applications. Whether for industrial or domestic use, this hose delivers exceptional suction performance while ensuring safety and durability.

How to Make Suction Hose?

The production process of PVC suction hose typically involves several key steps to ensure the hose is durable, flexible, and suitable for its intended purpose. Here is a general overview of the production process for PVC suction hose:

Material Preparation:

PVC resin: PVC (Polyvinyl Chloride) resin is the primary component of the hose. It provides the structure and durability.

Plasticizers: Added to improve flexibility and workability. Common plasticizers include phthalates or epoxidized soybean oil.

Stabilizers: Used to prevent degradation caused by heat, light, and oxygen.

Colorants: Optional, added to provide the desired color.

Fillers: Optional, used to reduce cost and improve properties like hardness or abrasion resistance.

Mixing and Compounding:

All the ingredients are weighed and mixed in a high-speed mixer to form a homogeneous mixture called compound.

The compound is then heated and sheared in a mixer to ensure proper dispersion of additives.

Extrusion:

The PVC compound is fed into an extruder, which heats and presses the material through a die to form the shape of the hose.

The extruder controls the temperature, speed, and pressure to achieve the desired hose dimensions and properties.

Calibration and Cooling:

The extruded hose passes through a calibration unit to maintain the desired dimensions.

It is then cooled using water sprays or air to solidify the hose and prevent deformation.

Cutting and Trimming:

The hose is cut into the desired lengths using automated cutting machines.

Edges may be trimmed to remove any imperfections or excess material.

Testing and Quality Control:

The hoses undergo various tests to ensure they meet quality standards, including burst pressure tests, flexibility tests, and dimensional checks.

Defective hoses are discarded or reworked.

Packaging and Shipping:

The tested and approved hoses are packaged in rolls or boxes.

Labels are attached with product information, including size, color, material, and manufacturer details.

The packaged hoses are then shipped to distributors or end customers.

Company Advantages

Qingdao Renato Plastic Co., Ltd. has over 15 years of experience in the production of high-quality PVC hoses. Our factory, located in Shandong province, spans 10 workshops and features more than 60 production lines, operated by 120 skilled workers, 5 technicists, and 2 QC teams. We offer a wide range of hoses and fittings, including Layflat Hose, Suction Hose, Fiber Reinforced Hose, Steel Wire Hose, Garden Hose, and more. Our commitment to quality and customer satisfaction has earned us praise from customers in over 60 countries worldwide.

Contact Us

If you are looking for a reliable partner for your hose and assembly needs, Qingdao Renato Plastic Co., Ltd. is here to assist you. Our philosophy, "Customers are always first," drives us to provide a 7x24 hours quick response to your inquiries. Please feel free to contact us anytime for more information or to place an order. We look forward to building a successful partnership with you.