Product Overview

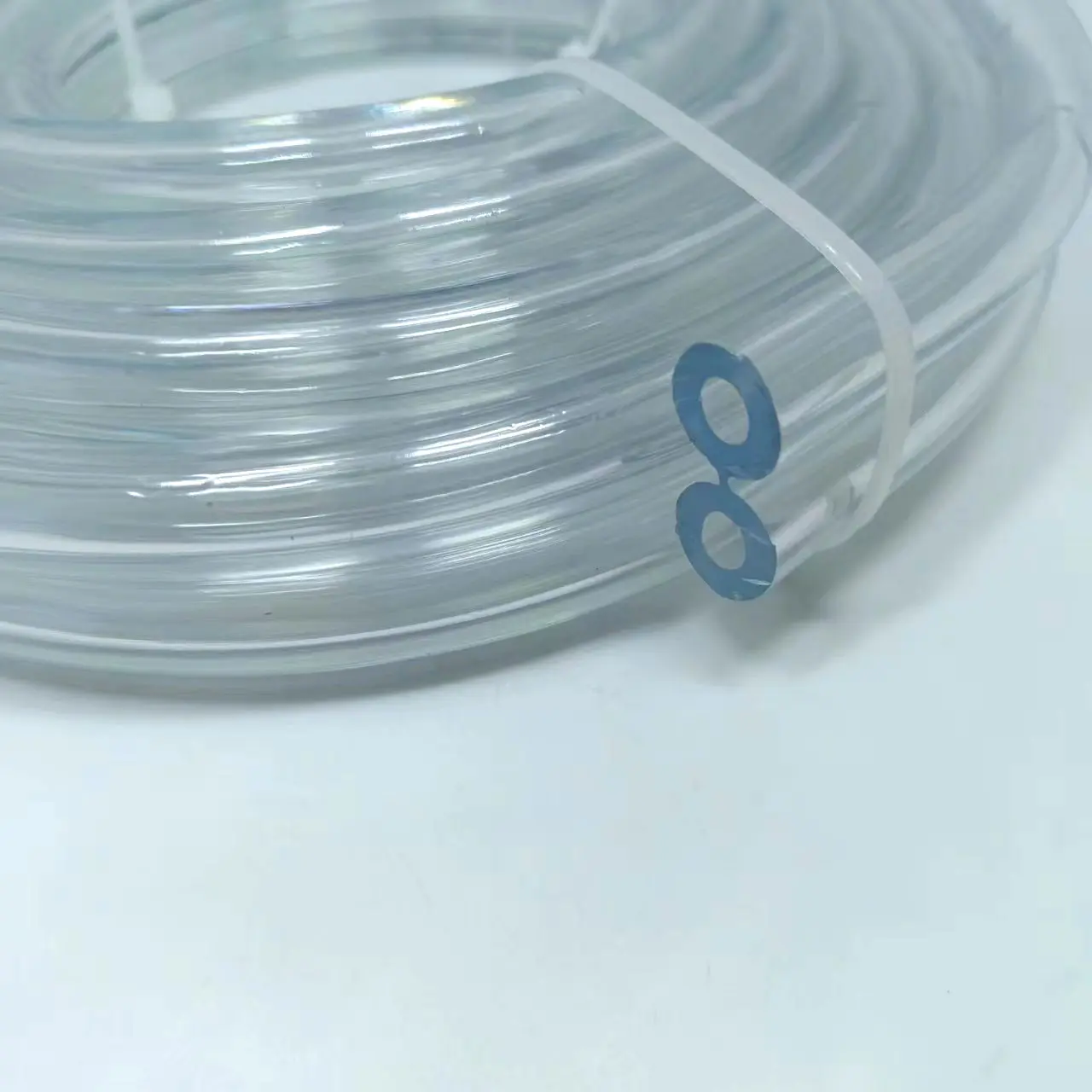

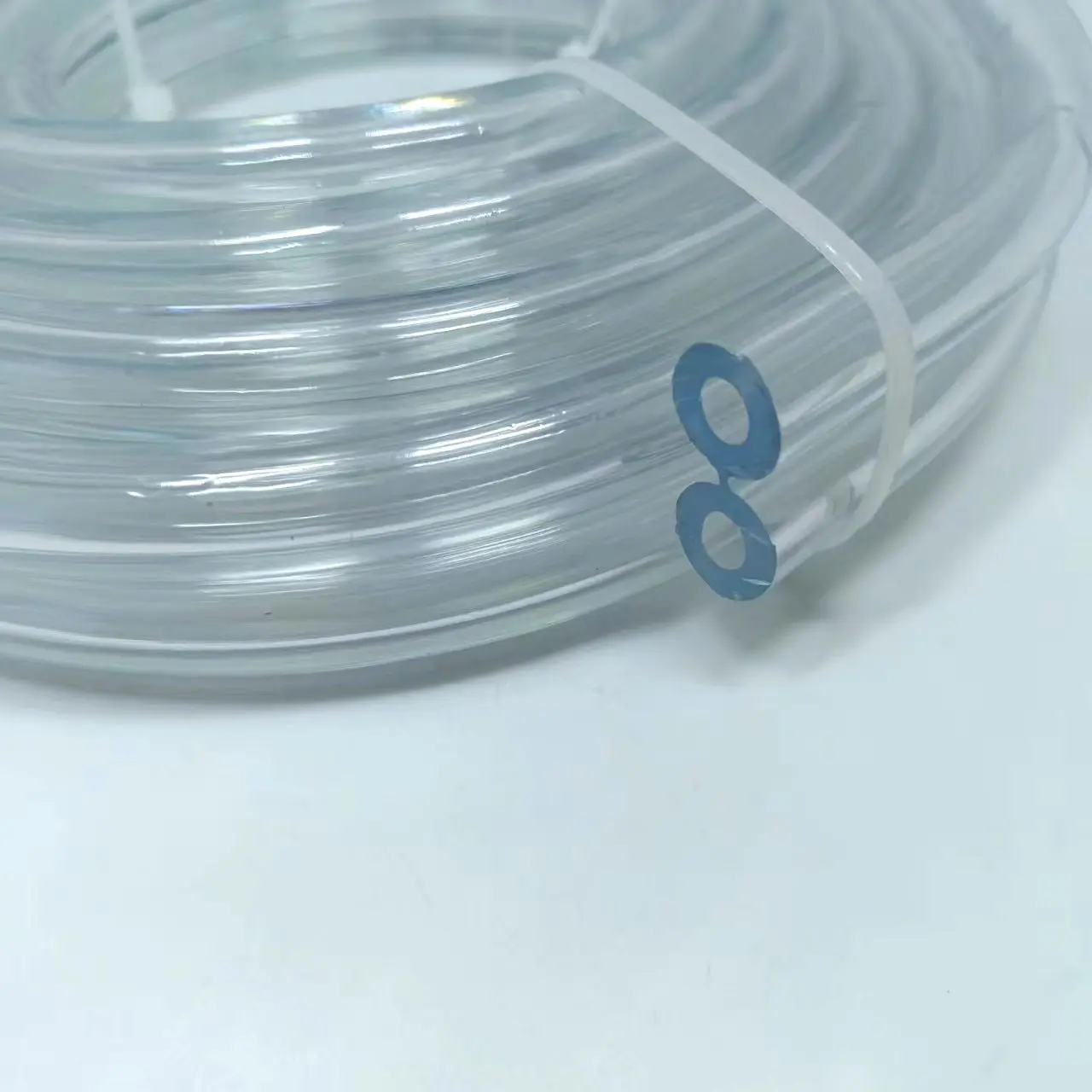

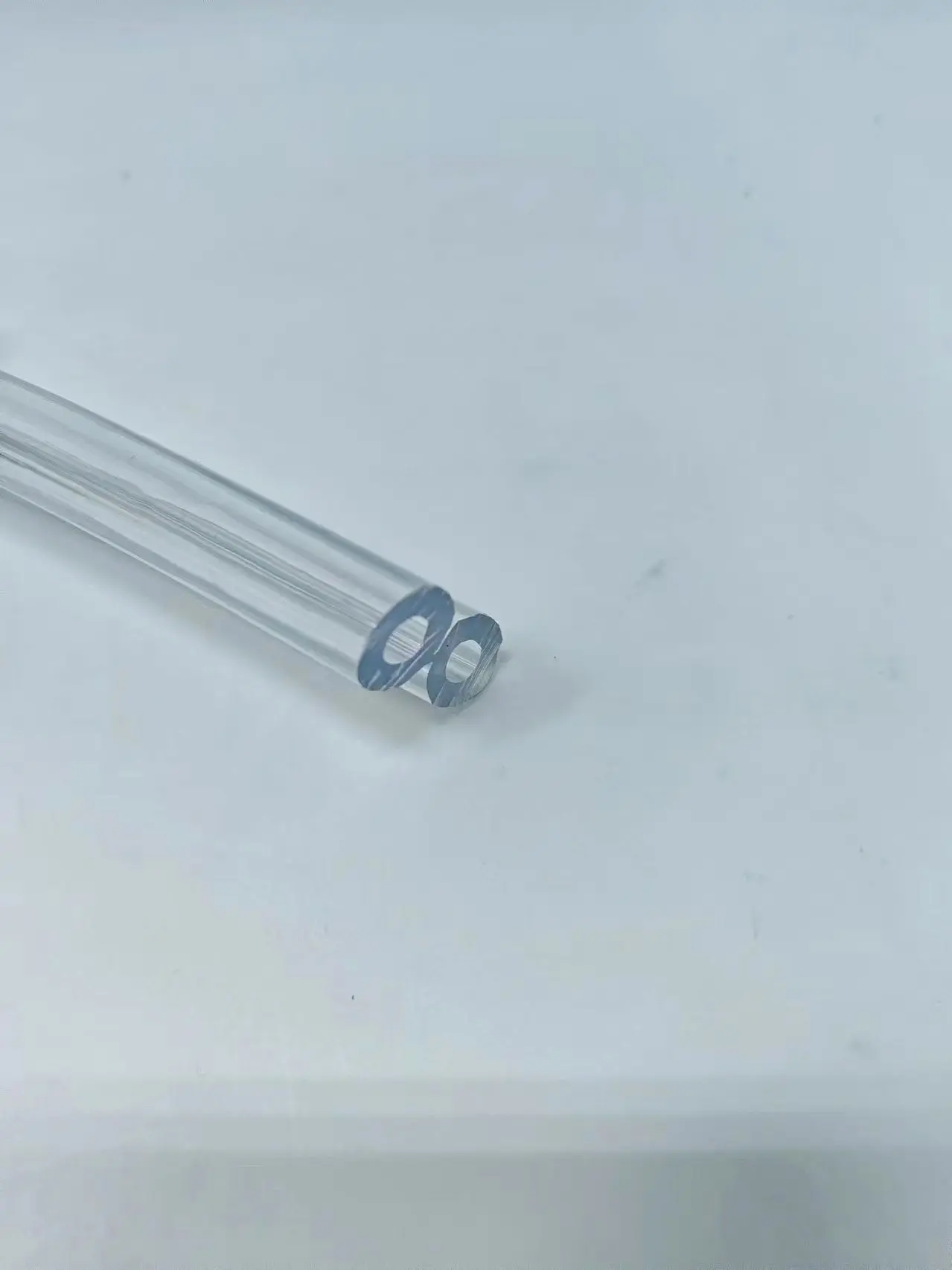

The PVC twin clear hose features a parallel dual-channel design, creating two independent flow paths within a single hose. This structure retains the visibility advantages of standard PVC clear hose while enabling simultaneous transfer of different liquids.

Made from food-grade PVC material, the hose has uniform wall thickness with a separation layer between the two channels to prevent liquid mixing. Common specifications include combinations like 6mm/8mm or 8mm/10mm inner diameters, with the overall outer diameter slightly larger than single hoses while maintaining good flexibility.

Compared to single hoses, the twin design reduces tangling issues and is particularly suitable for applications requiring concurrent transfer of two media. The transparent material allows visual monitoring of liquid flow in both channels.

Key Features

Independent Dual Channels

Two completely isolated channels enable simultaneous transfer of different liquids without cross-contamination

Visual Monitoring

Transparent walls allow easy observation of flow rates and liquid purity in both channels

Space Saving

Replaces two separate hoses, reducing installation space requirements

Compatibility

Standard connectors ensure compatibility with most pumps and distributors

Easy Maintenance

Simpler to inspect and manage compared to multiple hose systems

Typical Applications

Food Processing

Simultaneous transfer of concentrate and purified water in beverage production

Parallel delivery of raw milk and additives in dairy processing

Medical Equipment

Dual-liquid circuit systems in dialysis machines

Reagent and cleaning solution transfer in laboratory analyzers

Agricultural Irrigation

Concurrent water and nutrient solution delivery in fertigation systems

Combined irrigation and chemical spraying in greenhouses

Industrial Cooling Systems

Inlet and return channels in cooling equipment

Dual-circuit cooling systems for small machinery

Selection Guide

| Selection Factor | Details |

|---|---|

| Channel Size Ratio | Choose based on required flow rates |

| Flexibility | Select high-flex models for frequent movement |

| Connector Compatibility | Ensure matching with existing equipment |

| Color Coding | Optional color-marked channels for easy identification |

Usage Precautions

Installation Notes

Verify channel correspondence before connection to avoid reversal

Minimum bending radius should exceed 5x hose diameter to prevent deformation

Operating Guidelines

Flush both channels with clean water before first use

Maintain temperature differences below 30°C when transferring liquids

Maintenance

Regularly inspect separation layer for leaks

Store flat or in large coils to avoid crushing

Cleaning and Care

Routine Cleaning

Flush both channels after each use, using soft brushes if necessary. For food/medical applications, monthly disinfection with 75% alcohol solution is recommended.

Long-Term Storage

Drain all liquid and store dry away from direct sunlight. Quarterly air pressure testing is advised to check separation integrity.