![]() Lay Flat Water Hose Pipe for Agricultural Irrigation.pdf

Lay Flat Water Hose Pipe for Agricultural Irrigation.pdf

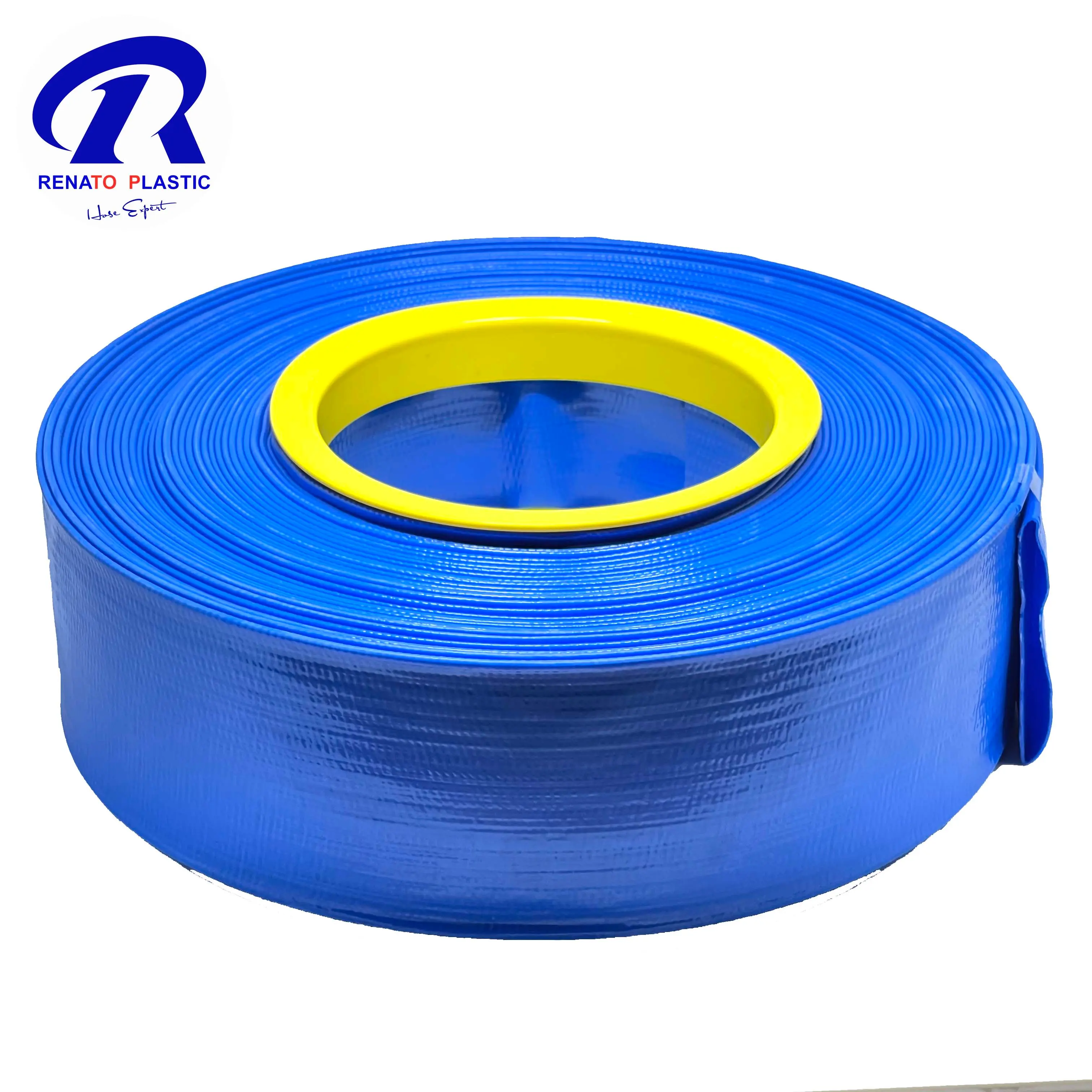

Medium Duty PVC Layflat Hose for Agricultural Irrigation

Are you seeking reliable irrigation solutions for your farm that deliver consistent performance without breaking the bank? Look no further than Renato Hose's Medium Duty PVC Layflat Hose.

With over 15 years of expertise in manufacturing top-tier PVC hoses, Renato Hose has established itself as a trusted name in the industry. Our Medium Duty PVC Layflat Hose is designed to meet the rigorous demands of farm irrigation, offering unparalleled durability and efficiency.

The Lay Flat Water Hose Pipe is designed to deliver water effectively and efficiently for agricultural irrigation purposes. It is made from a PVC tube and PVC cover with a fiber-reinforced layer, ensuring durability and longevity. With our one-step production process, this hose exhibits excellent anti-fracture properties, can withstand high pressure, and has minimal expansivity. Its increased radial fibers contribute to enhanced tensile strength, making it an ideal choice for your irrigation needs.

What is Lay Flat Water Hose Pipe?

A lay flat water hose pipe, also known simply as a lay flat hose, is a type of flexible hose used for the efficient conveyance of water. Unlike traditional hoses, which are typically cylindrical and rigid, lay flat hoses are designed to lay flat when not in use, hence their name. When pressurized with water, they expand and become round, allowing for the efficient flow of water.

Here are some key characteristics of lay flat water hose pipes:

Flexibility: Lay flat hoses are highly flexible, allowing them to be easily maneuvered and laid out across various terrains and landscapes. This flexibility makes them ideal for use in agricultural irrigation, firefighting, construction, and other applications where traditional hoses may be difficult to deploy.

Compact Storage: One of the main advantages of lay flat hoses is their ability to be rolled or folded flat for compact storage when not in use. This makes them easier to transport and store compared to traditional hoses, which can be bulky and cumbersome.

High Water Flow: Lay flat hoses are designed to provide a high volume of water flow, making them suitable for applications where a large volume of water needs to be conveyed quickly and efficiently. This makes them particularly well-suited for agricultural irrigation and firefighting operations.

Durable Construction: Lay flat hoses are typically constructed from durable materials such as PVC (polyvinyl chloride) or TPU (thermoplastic polyurethane), which are resistant to abrasion, punctures, and UV radiation. This ensures long-term performance and reliability in various environmental conditions.

Versatility: Lay flat hoses are versatile and can be used for a wide range of applications beyond water conveyance. They can be used for transferring liquids such as chemicals and fuels, as well as for dewatering and drainage purposes.

Overall, lay flat water hose pipes are valued for their flexibility, compact storage, high water flow, durability, and versatility, making them an essential tool in various industries and applications where efficient water conveyance is required.

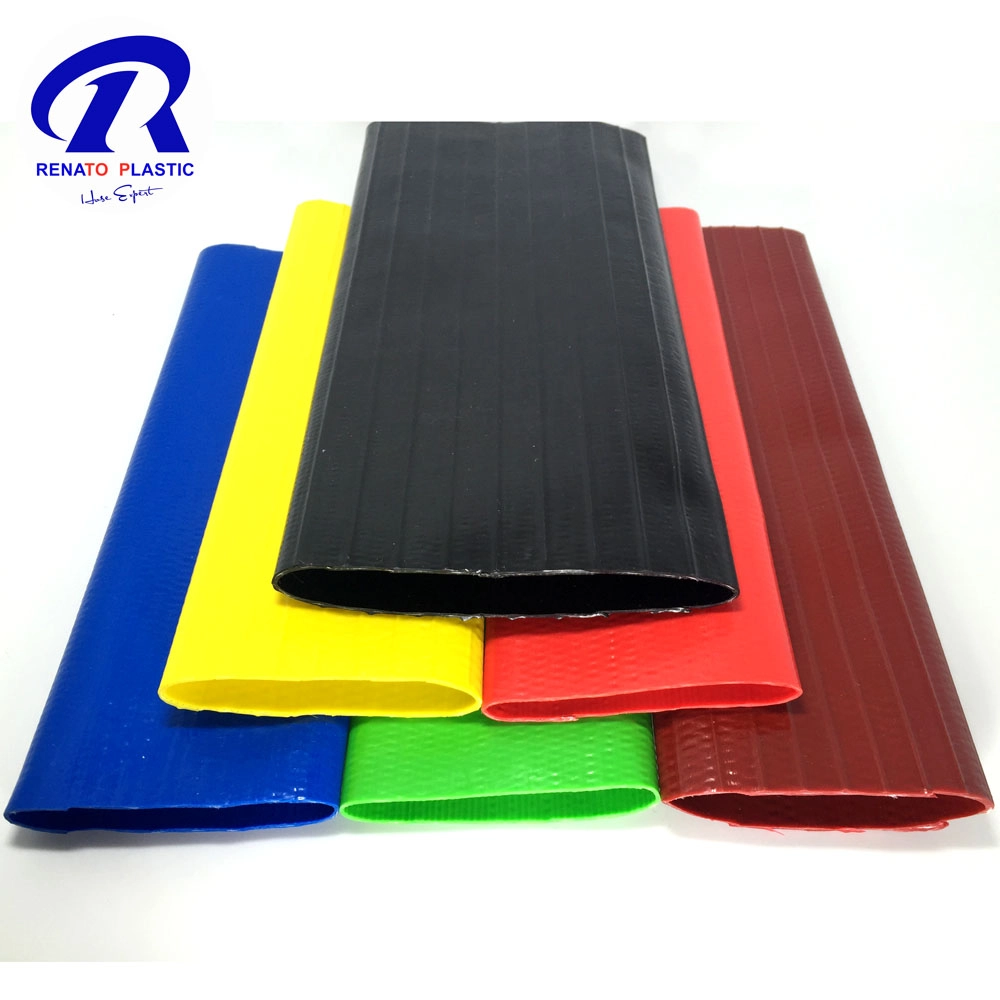

This is what the lay flat water hose pipe looks like after opening the package. It is naturally curled and the surface of the water hose pipe is smooth without protrusions or holes.

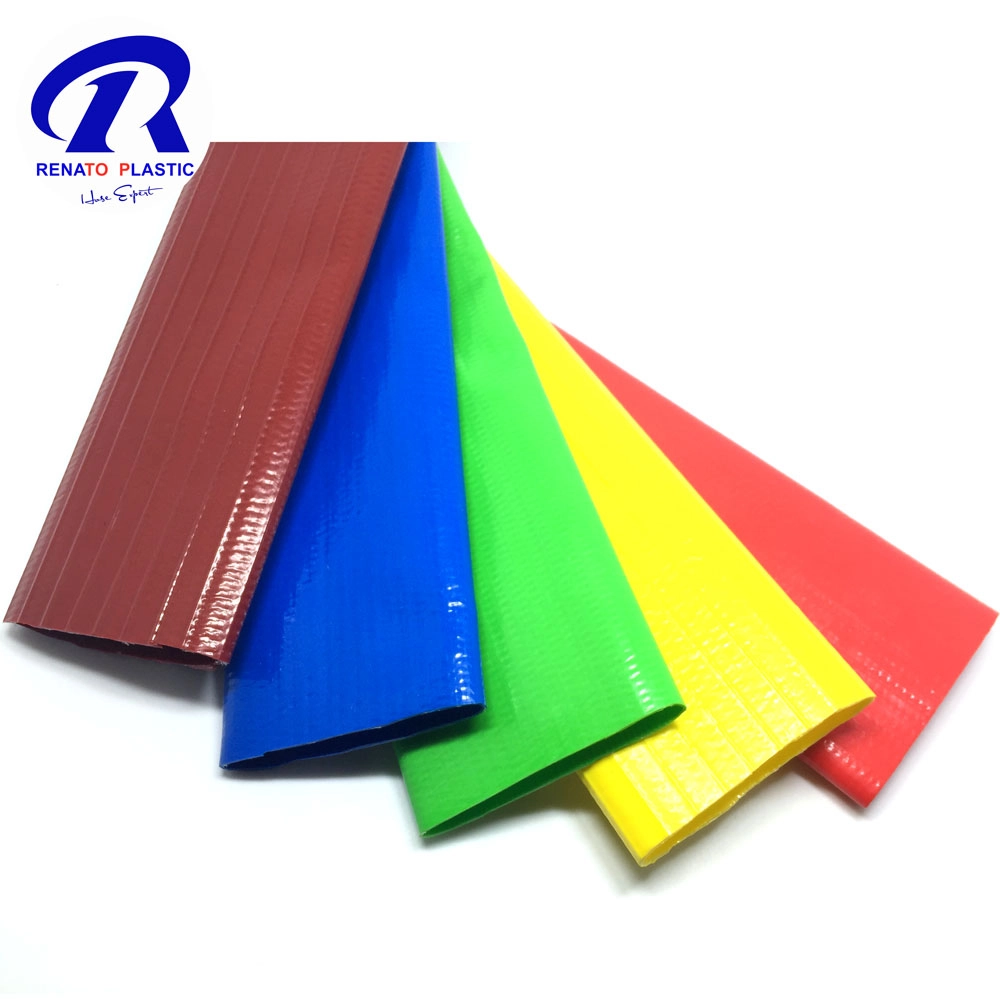

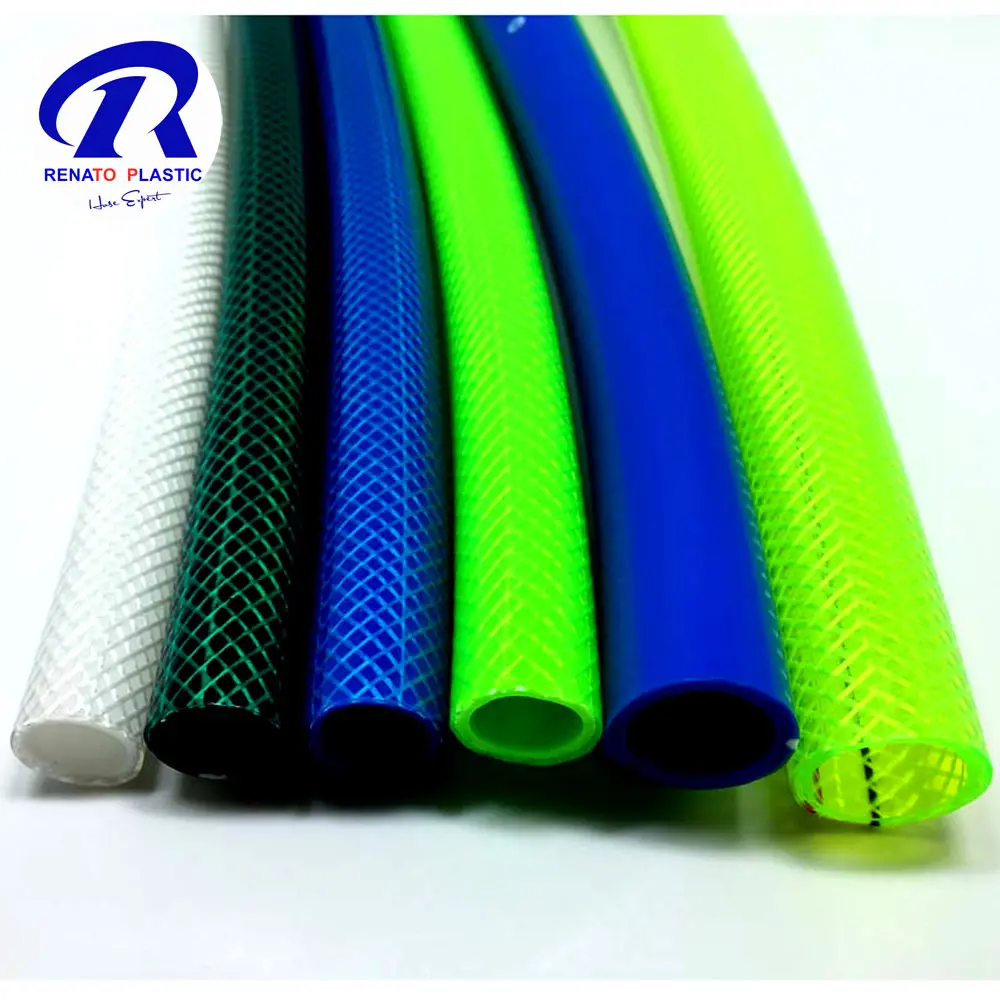

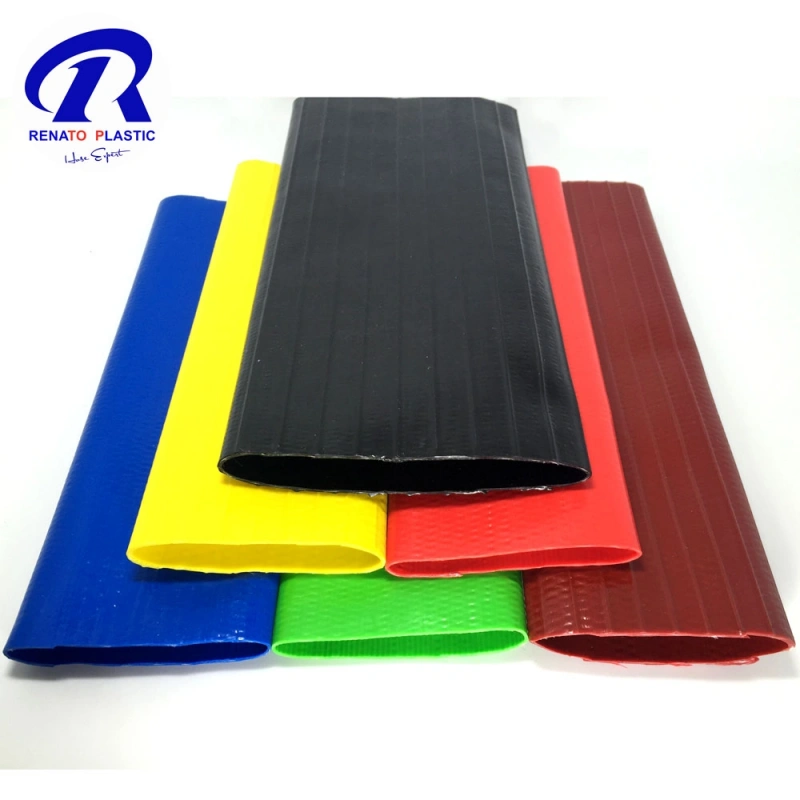

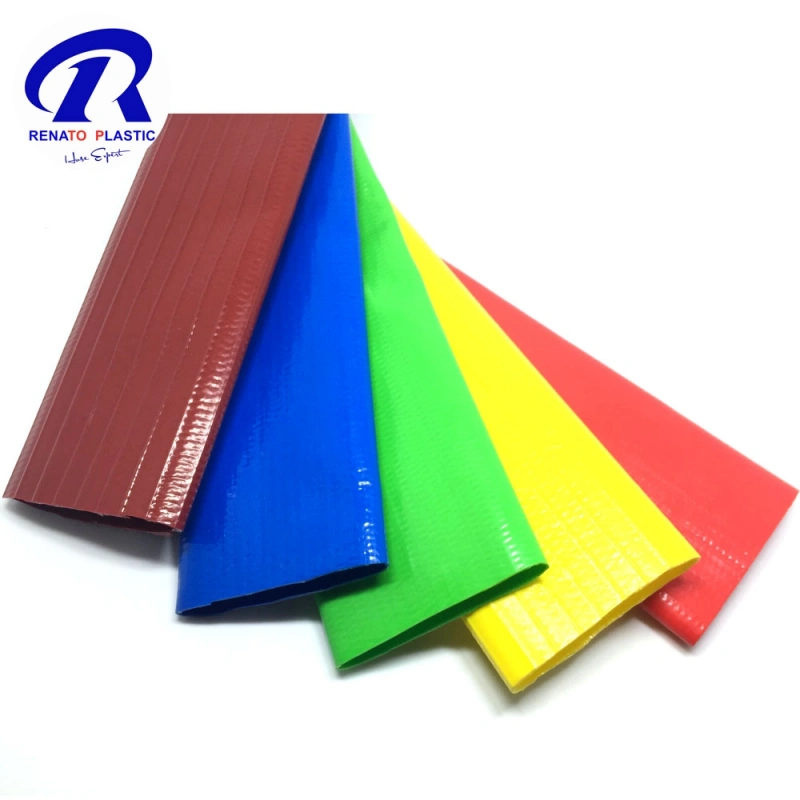

This is lay flat water hose pipe in 6 colors. Water hose pipe can be customized.

Characteristics

The hose is made from PVC tube and PVC cover with fibre reinforced layer , by one-step procedure .This product has the characteristics of anti-fracture, resisted high pressure and small expansivity. Increased the radial fibers , improved the tensile strength.

1. Anti-stretch, anti-fracture, resisted high pressure and small expansion rate.

2. Lightweight , flexible, bright colors, anti-erosion, anti-aging, abrasion resistance and anti-ultraviolet.

3. No odor, environmental protection products.

4. Good weather resistance and suitable for conveying liquids.

This picture shows the 5 colors of our Lay Flat Water Hose Pipe, these are also the most common colors on the market. If you have your own custom color, you can contact our experts to make a hose color that is unique on the market.

Application

This hose is Widely used for water discharge under medium or low working pressure in agriculture irrigation, forestry sprinkler irrigation, construction project, industrial and mining enterprise.

We use galvanized pipe fittings at both ends of the hose, which is not easy to rust, easy and fast to operate, and has good sealing performance.

Sepcification

These are the basic parameters of our hoses. If the parameters you need are not here, please contact our experts to give you

the answer.

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | Volume | ||

| inch | mm | mm | m | kg/m | bar | psi | cbm |

| 1 | 25 | 1.3 | 100 | 0.15 | 5 | 75 | 0.017 |

| 1.5 | 100 | 0.165 | 7 | 105 | 0.019 | ||

| 1 1/4 | 32 | 1.2 | 100 | 0.17 | 5 | 75 | 0.020 |

| 1.3 | 100 | 0.19 | 7 | 105 | 0.022 | ||

| 1 1/2 | 38 | 1.25 | 100 | 0.19 | 5 | 75 | 0.024 |

| 1.45 | 100 | 0.23 | 7 | 105 | 0.026 | ||

| 2 | 51 | 1.1 | 100 | 0.22 | 4 | 60 | 0.034 |

| 1.3 | 100 | 0.3 | 6 | 90 | 0.036 | ||

| 2 1/2 | 64 | 1.2 | 100 | 0.32 | 4 | 60 | 0.046 |

| 1.7 | 100 | 0.43 | 6 | 90 | 0.048 | ||

| 3 | 76 | 1.1 | 100 | 0.35 | 4 | 60 | 0.060 |

| 1.5 | 100 | 0.5 | 6 | 90 | 0.062 | ||

| 4 | 102 | 1.2 | 100 | 0.55 | 4 | 60 | 0.083 |

| 2.3 | 100 | 0.8 | 6 | 90 | 0.085 | ||

| 5 | 127 | 1.35 | 100 | 0.75 | 4 | 60 | 0.109 |

| 2.3 | 100 | 1.08 | 6 | 90 | 0.111 | ||

| 6 | 153 | 1.35 | 100 | 0.9 | 4 | 60 | 0.141 |

| 2.4 | 100 | 1.6 | 6 | 90 | 0.143 | ||

| 8 | 203 | 2.2 | 100 | 1.785 | 3 | 45 | 0.185 |

| 2.7 | 100 | 2.02 | 4 | 60 | 0.187 | ||

| 10 | 255 | 2.7 | 50 | 2.6 | 3 | 45 | 0.170 |

| 12 | 307 | 2.7 | 50 | 3 | 2 | 30 | 0.225 |

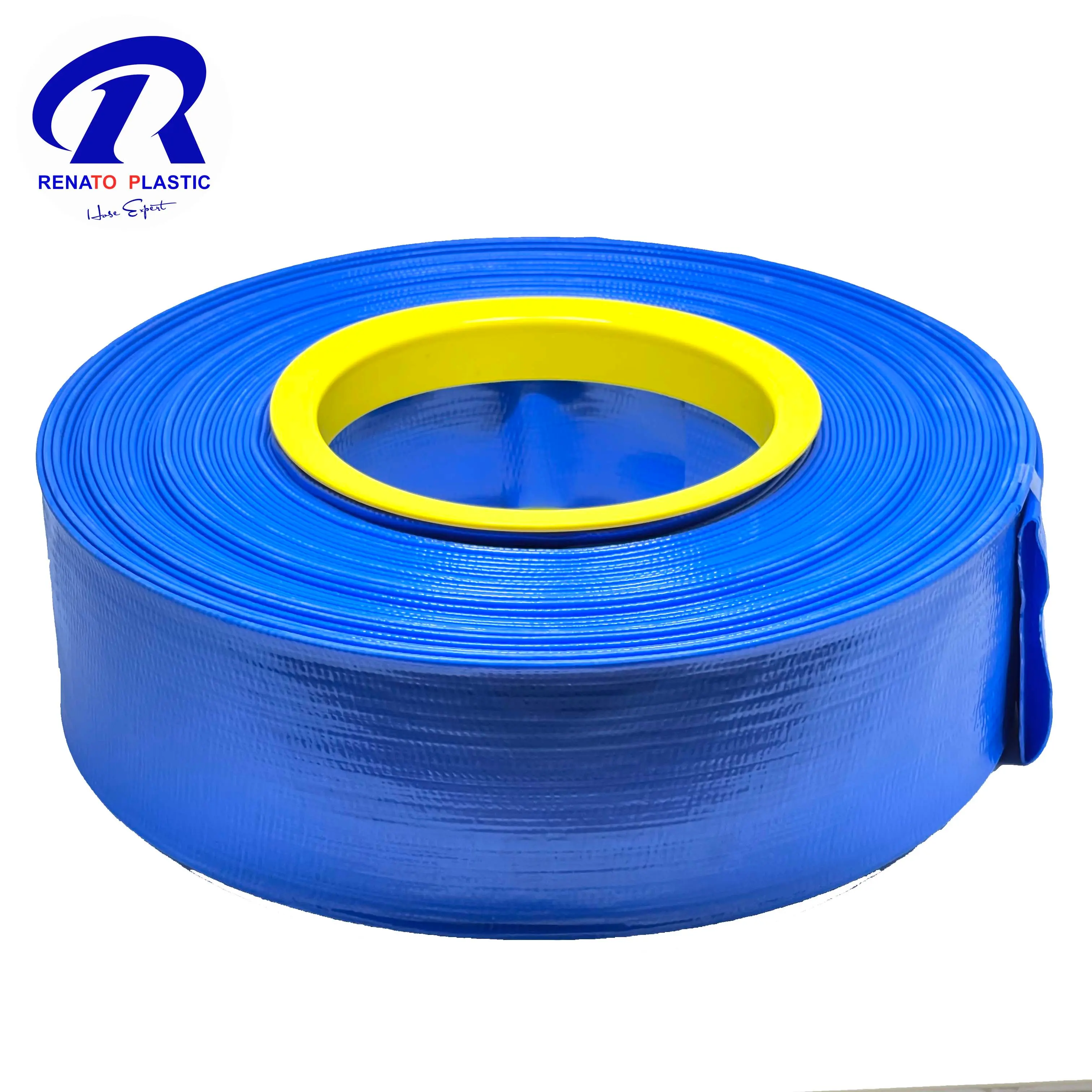

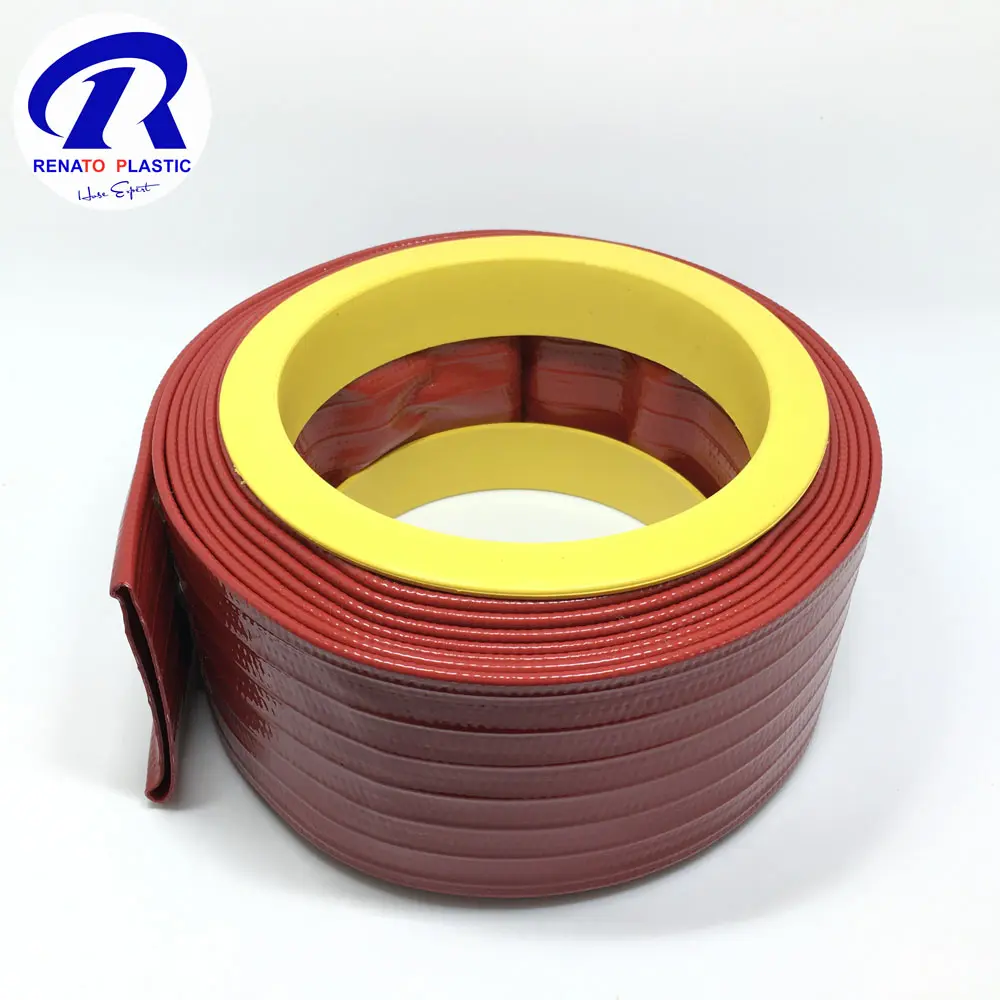

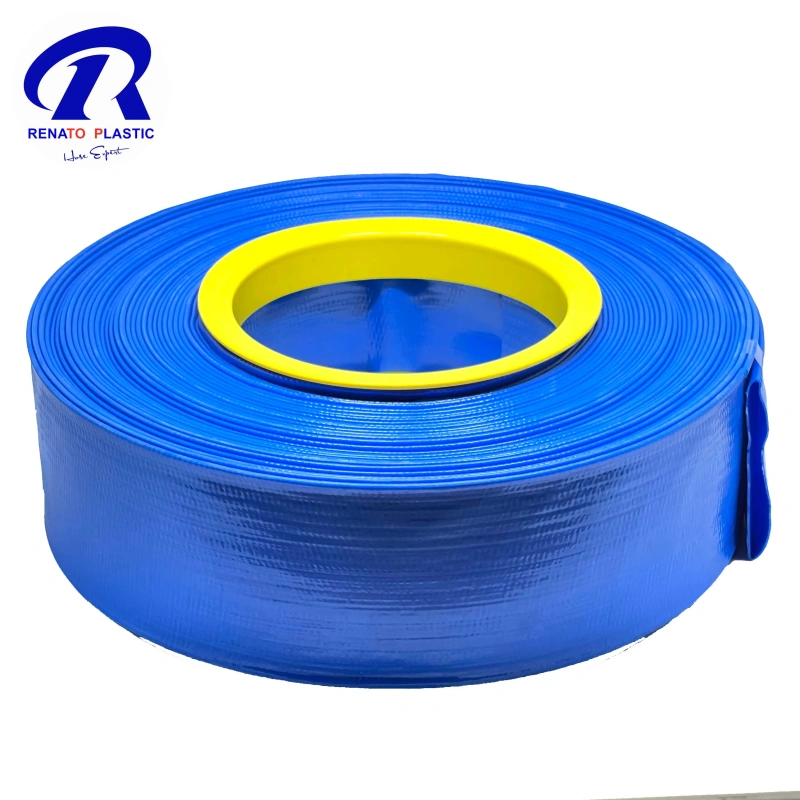

This is what our finished hose looks like after it’s packaged for easy handling.

The appliction of Lay Flat Water Hose Pipe for Agricultural Irrigation

The application of lay flat water hose pipe for agricultural irrigation is widespread and highly effective. Here are some of the primary applications and benefits of using lay flat water hose pipe for agricultural irrigation:

Efficient Water Delivery: Lay flat water hose pipe is designed to deliver water efficiently over long distances, making it ideal for large-scale agricultural fields. The pipe's flat design allows for easy placement and distribution of water across the field, ensuring that crops receive the necessary water supply.

Flexible and Easy to Use: Lay flat water hose pipe is known for its flexibility, which makes it easy to lay out and adjust according to the shape and size of the field. This flexibility also allows for easy storage and transportation, reducing the overall cost and effort required for irrigation.

Durable and Long-Lasting: Made from durable materials, lay flat water hose pipe is designed to withstand the rigors of outdoor use and exposure to sunlight, water, and other elements. This durability ensures that the pipe can be used season after season without significant wear or tear.

Cost-Effective: Compared to other irrigation systems, lay flat water hose pipe is often a more cost-effective solution. Its simplicity and ease of use reduce the need for expensive equipment or maintenance, making it a practical choice for farmers and agricultural operations.

Uniform Water Distribution: The design of lay flat water hose pipe allows for uniform water distribution across the field. This ensures that crops receive the appropriate amount of water, promoting healthy growth and yield.

Versatile Use: Lay flat water hose pipe can be used in a variety of agricultural settings, including fields, orchards, and vineyards. It can also be easily connected to pumps and other water sources, providing a flexible and adaptable irrigation solution.

How to Make PVC Lay Flat Hose ?

The production process of PVC Lay Flat Hose typically involves several key steps to ensure the hose is durable, flexible, and suitable for its intended use. Here is an overview of the PVC Lay Flat Hose production process:

Material Preparation:

PVC Resin: PVC (Polyvinyl Chloride) resin is the primary component of the hose, providing structure and durability.

Plasticizers: Added to improve flexibility and processability. Common plasticizers include phthalates or epoxidized soybean oil.

Stabilizers: Used to prevent degradation caused by heat, light, and oxygen.

Colorants: Optional, used to provide the desired color.

Fillers: Optional, used to reduce costs and improve properties like hardness or abrasion resistance.

Mixing and Compounding:

All ingredients are weighed and mixed in a high-speed mixer to create a homogeneous compound.

The compound is then heated and sheared in the mixer to ensure proper dispersion of additives.

Extrusion:

The PVC compound is fed into an extruder, which heats and forces the material through a die to form the shape of the hose.

The extruder controls temperature, speed, and pressure to achieve the desired hose dimensions and properties.

Calibration and Cooling:

The extruded hose passes through a calibration device to maintain the desired dimensions.

Water spray or air cooling is then used to solidify the hose and prevent deformation.

Cutting and Trimming:

The hose is cut into the desired lengths using an automatic cutting machine.

Edges may be trimmed to remove any imperfections or excess material.

Testing and Quality Control:

The hose undergoes various tests to ensure it meets quality standards, including burst pressure tests, flexibility tests, and dimensional checks.

Defective hoses are discarded or reworked.

Packaging and Shipment:

Tested and approved hoses are wound or boxed for packaging.

Labels with product information, including dimensions, color, material, and manufacturer details, are attached.

The packaged hoses are then shipped to distributors or end customers.

PVC Lay Flat Hose Inspection Standards

PVC Lay Flat hoses are common pipeline materials widely used in industries, agriculture, construction, and other fields. To ensure the quality and safety performance of PVC Lay Flat hoses, a series of inspection standards have been established for strict inspection and monitoring. This article will detail the inspection standards for PVC Lay Flat hoses to help industry professionals better understand and master the relevant knowledge.

1. Appearance Quality Inspection

Appearance quality inspection is an important part of PVC Lay Flat hose quality inspection and includes the following aspects:

Surface Smoothness: The surface of the PVC Lay Flat hose should be free of visible bubbles, cracks, color differences, and other defects. The surface should be smooth and flat without any unevenness.

Surface Flatness: The surface of the PVC Lay Flat hose should be flat without noticeable unevenness or wrinkles.

Dimensional Deviation: The outer diameter, wall thickness, length, and other dimensions of the PVC Lay Flat hose should meet national standards and should not exceed the specified deviation range.

2. Physical Performance Inspection

Physical performance inspection is another critical aspect of PVC Lay Flat hose quality inspection, including the following areas:

Tensile Strength: The tensile breaking load of the PVC Lay Flat hose under certain conditions is an important indicator of its tensile resistance.

Pressure Resistance: The PVC Lay Flat hose's ability to withstand pressure under certain conditions, primarily used to test its pressure resistance during use.

Heat Resistance: The thermal stability of the PVC Lay Flat hose within a specific temperature range, primarily used to test its performance in high-temperature environments.

3. Chemical Performance Inspection

Chemical performance inspection is another essential part of PVC Lay Flat hose quality inspection, including the following aspects:

Acid and Alkali Resistance: The ability of the PVC Lay Flat hose to withstand acids and alkalis under certain conditions, mainly used to test its performance in acidic and alkaline environments.

Aging Resistance: The PVC Lay Flat hose's ability to resist aging under certain conditions, mainly used to test its performance during long-term use.

4. Packaging and Labeling Inspection

Packaging and labeling inspection is also an important part of PVC Lay Flat hose quality inspection, including the following areas:

Packaging Appearance: The packaging of the PVC Lay Flat hose should be intact without damage or oil leakage.

Label Clarity: The labels on the PVC Lay Flat hose should be clear and visible.

Label Content: The label content should be complete and accurate, including information such as the manufacturer, specifications, production date, etc.

Inspection Methods

To ensure compliance with the above indicators, the following inspection methods are usually adopted:

Visual Inspection: Used to check surface smoothness, flatness, and label clarity.

Measurement Tools: Such as vernier calipers and thickness gauges, used to check dimensional deviations.

Tensile Testing Machine: Used to test tensile strength.

Pressure Testing Equipment: Used to test pressure resistance.

Thermal Aging Test Chamber: Used to test heat resistance and aging resistance.

Chemical Reagents: Used to test acid and alkali resistance.

Company Advantages

Extensive Experience: With more than 15 years of experience in PVC hose manufacturing, QINGDAO RENATO PLASTIC CO., LTD has established a solid reputation for delivering high-quality products. Our expertise and commitment to excellence ensure that you receive reliable and efficient solutions for your agricultural irrigation needs.

State-of-the-Art Facilities: Equipped with 10 workshops, over 60 production lines, and a team of skilled workers and technicians, our factory is well-equipped to meet your demands. We adhere to strict quality control measures and employ two dedicated QC teams to ensure that our products surpass industry standards.

Global Reach: Our products have gained widespread recognition and are trusted by customers in over 60 countries worldwide. We take pride in the positive feedback we've received, and we continue to strive for excellence in meeting our customers' expectations.

Conclusion

The inspection standards for PVC Lay Flat hoses involve various aspects such as appearance quality, physical performance, chemical performance, packaging, and labeling. These inspections must be conducted in strict accordance with national standards. Only through rigorous inspection can the quality and safety of PVC Lay Flat hoses be ensured, providing reliable pipeline materials for related industries and promoting their development and progress.

Renato is a leading PVC Lay Flat hoses factory based in China. Specializing in high-quality hose manufacturing, Renato serves various industries with durable and reliable products, ensuring excellent performance and customer satisfaction.

If you're seeking a reliable partner for high-quality hose and assemblies, QINGDAO RENATO PLASTIC CO., LTD is here to assist you. We prioritize customer satisfaction and offer 7x24 hours quick response. Don't hesitate to reach out to us with your inquiries or requirements. Our dedicated team will promptly provide you with the information and support you need.