Specifications for PVC Flexible Plastic Pipes

PVC flexible plastic pipes for water are available in various specifications to cater to different applications, including residential plumbing, irrigation systems, and industrial uses. Here are the common specifications for PVC flexible plastic pipes:

Common Specifications for PVC Flexible Plastic Pipes

Sizes (Diameter)

Small Sizes: 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, 1 inch

Medium Sizes: 1.5 inches, 2 inches, 2.5 inches, 3 inches, 4 inches

Large Sizes: 6 inches, 8 inches, 10 inches, 12 inches

Pressure Ratings

Low Pressure: 80 PSI (Pounds per Square Inch)

Medium Pressure: 100 PSI, 125 PSI, 160 PSI

High Pressure: 200 PSI, 250 PSI

Temperature Range

Suitable for temperatures up to 140°F (60°C)

Operating temperature range: 0°F to 140°F (-18°C to 60°C)

Length

Typically available in rolls of 50 feet, 100 feet, and 200 feet

Also available in custom lengths based on specific requirements

Wall Thickness (Schedule)

Schedule 40: Commonly used for lower pressure applications

Schedule 80: Thicker walls for higher pressure applications

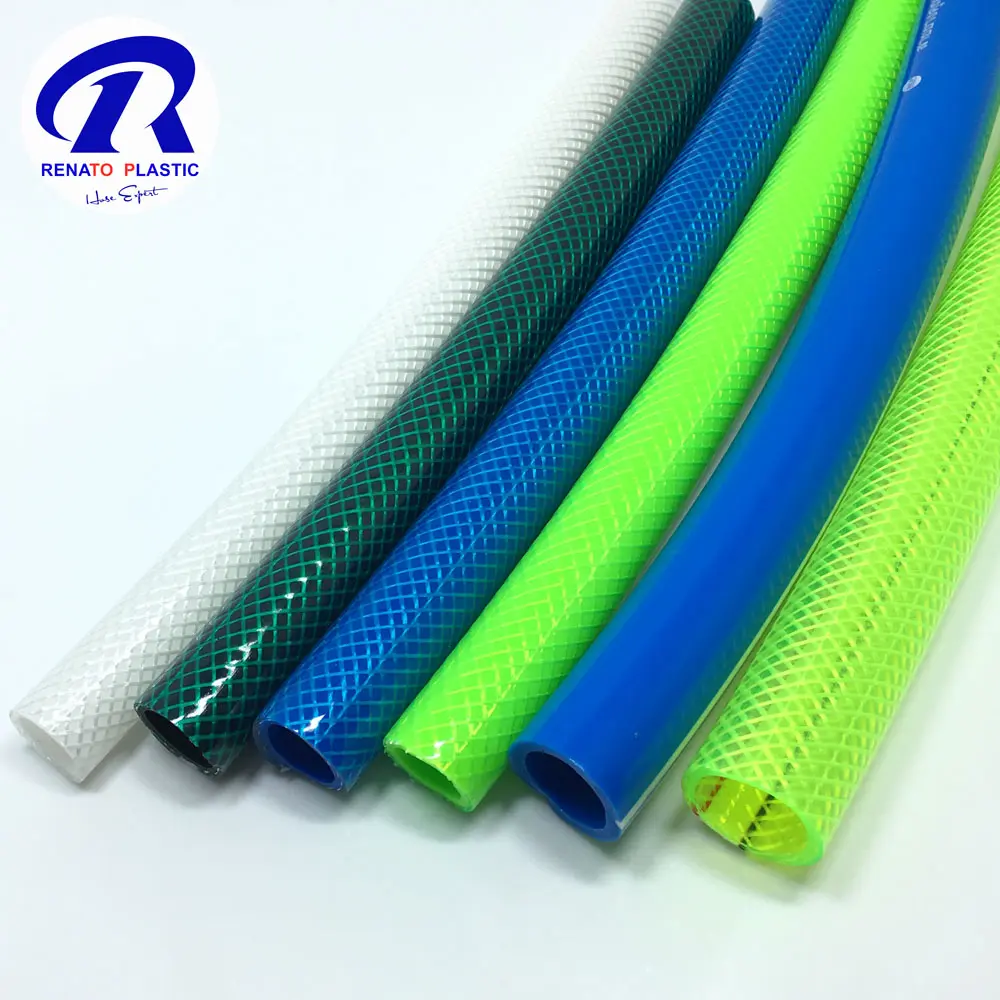

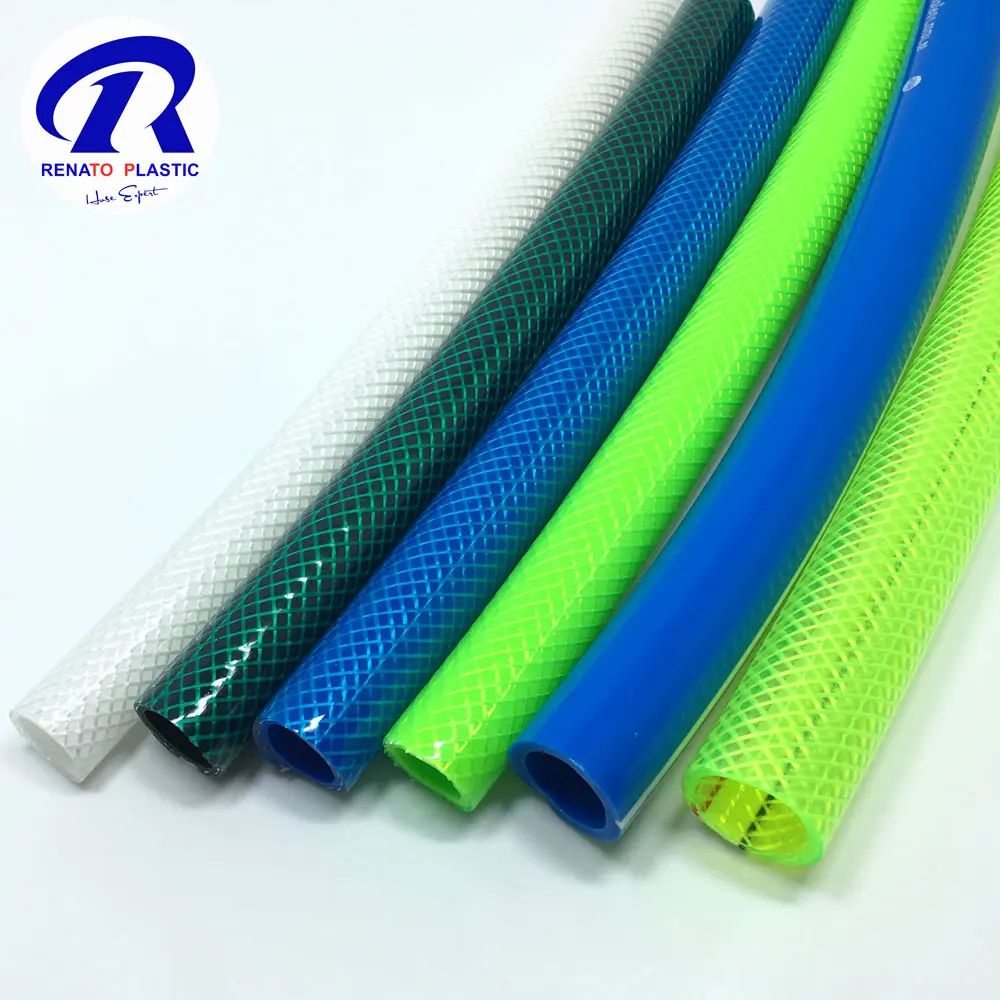

Color

Typically white, gray, or clear

Other colors may be available based on manufacturer specifications

Applications

Residential Plumbing:

Sizes: 1/2 inch to 1 inch

Use: Hot and cold water supply lines, irrigation systems

Agricultural Irrigation:

Sizes: 1 inch to 4 inches

Use: Field irrigation, garden watering systems

Industrial Applications:

Sizes: 2 inches to 12 inches

Use: Water transportation in industrial facilities, chemical processing

Municipal Water Supply:

Sizes: 4 inches to 12 inches

Use: Main water lines, distribution networks

Example Specifications

1. 1/2 Inch PVC Flexible Water Pipe

Pressure Rating: 160 PSI

Length: 100 feet roll

Color: White

Wall Thickness: Schedule 40

2. 1 Inch PVC Flexible Water Pipe

Pressure Rating: 125 PSI

Length: 50 feet roll

Color: Gray

Wall Thickness: Schedule 40

3. 2 Inch PVC Flexible Water Pipe

Pressure Rating: 200 PSI

Length: 50 feet roll

Color: White

Wall Thickness: Schedule 80

4. 4 Inch PVC Flexible Water Pipe

Pressure Rating: 100 PSI

Length: Custom lengths available

Color: Clear

Wall Thickness: Schedule 40

Advantages of PVC Flexible Plastic Pipes

Durability: Long lifespan and resistant to corrosion and chemicals

Flexibility: Easier to install in tight spaces and around obstacles

Lightweight: Easier to handle and transport compared to metal pipes

Cost-Effective: Lower cost compared to other piping materials

Conclusion

PVC flexible plastic pipes come in a wide range of sizes, pressure ratings, and lengths to suit various water distribution needs. Selecting the appropriate specification depends on the specific application requirements, including pressure, temperature, and environmental conditions.

PVC flexible water pipe price

The market price for PVC flexible water pipes can vary significantly based on several factors, including the pipe's diameter, wall thickness, length, and any additional features like reinforcement or special coatings. Here are some approximate market prices for various types of PVC flexible water pipes, based on recent market data:

1. Standard PVC Flexible Water Pipe

| Diameter | Wall Thickness | Length | Price per Meter |

|---|---|---|---|

| 1/2 inch | 2 mm | 100 m | $0.30 - $0.50 |

| 3/4 inch | 2.5 mm | 100 m | $0.50 - $0.70 |

| 1 inch | 3 mm | 100 m | $0.80 - $1.00 |

2. Reinforced PVC Flexible Water Pipe

| Diameter | Wall Thickness | Length | Price per Meter |

|---|---|---|---|

| 1/2 inch | 2 mm | 50 m | $0.60 - $0.80 |

| 3/4 inch | 2.5 mm | 50 m | $0.80 - $1.00 |

| 1 inch | 3 mm | 50 m | $1.20 - $1.50 |

3. High-Pressure PVC Flexible Water Pipe

| Diameter | Wall Thickness | Length | Price per Meter |

|---|---|---|---|

| 1/2 inch | 2.5 mm | 25 m | $0.90 - $1.20 |

| 3/4 inch | 3 mm | 25 m | $1.20 - $1.50 |

| 1 inch | 3.5 mm | 25 m | $1.50 - $1.80 |

4. PVC Flexible Water Pipe with Braided Reinforcement

| Diameter | Wall Thickness | Length | Price per Meter |

|---|---|---|---|

| 1/2 inch | 3 mm | 50 m | $1.00 - $1.30 |

| 3/4 inch | 3.5 mm | 50 m | $1.40 - $1.70 |

| 1 inch | 4 mm | 50 m | $1.80 - $2.10 |

Factors Affecting Price

Diameter and Wall Thickness: Larger diameters and thicker walls increase material costs.

Length of Purchase: Bulk purchases often result in lower per-meter costs.

Reinforcement: Pipes with additional reinforcement (e.g., braided or high-pressure) are more expensive.

Quality and Brand: Higher quality and well-known brands typically command higher prices.

Regional Variations: Prices can vary based on regional supply and demand, as well as local economic conditions.

Example Usage Scenarios

Residential Garden Hoses: Typically use 1/2 inch or 3/4 inch standard PVC pipes, costing around $0.30 to $0.70 per meter.

Commercial Landscaping: Often use 3/4 inch or 1 inch reinforced PVC pipes, costing around $0.80 to $1.50 per meter.

Industrial Applications: May require high-pressure or braided reinforcement pipes, with prices ranging from $1.00 to $2.10 per meter.

These prices are approximate and can fluctuate based on market conditions, raw material prices, and other economic factors. For the most accurate and current pricing, it's advisable to contact suppliers directly.

11 application scenarios of flexible plastic pipes for water

PVC flexible plastic pipes for water are versatile and commonly used in a variety of applications due to their durability, flexibility, and cost-effectiveness. Here are the main scenarios in which PVC flexible plastic pipes are used:

1. Residential Plumbing

Applications: Supply lines for hot and cold water, drainage systems, waste and vent pipes.

Benefits: Resistant to corrosion, easy to install, lightweight, and long-lasting.

2. Agricultural Irrigation

Applications: Irrigation systems for farms, gardens, greenhouses, and lawn sprinklers.

Benefits: Flexibility allows easy maneuvering around obstacles, UV resistance, and efficient water delivery.

3. Industrial Use

Applications: Water transportation in manufacturing plants, cooling systems, chemical processing, and wastewater management.

Benefits: Resistant to chemicals, can handle high pressure, and easy to install and maintain.

4. Municipal Water Supply

Applications: Main water lines, distribution networks, and potable water systems.

Benefits: Long lifespan, resistance to contamination, and cost-effective for large-scale installations.

5. Aquaculture

Applications: Water supply and drainage systems for fish farms, aquariums, and other aquatic environments.

Benefits: Non-toxic, easy to clean, and resistant to algae and other biological growth.

6. Landscaping

Applications: Sprinkler systems, drip irrigation, and garden water features.

Benefits: Flexible for easy installation in various terrains, UV resistant, and durable.

7. Commercial Buildings

Applications: Water supply lines, heating and cooling systems, and drainage systems in commercial properties.

Benefits: Cost-effective, easy to install, and requires minimal maintenance.

8. Swimming Pools and Spas

Applications: Circulation lines, filtration systems, and drainage for pools and spas.

Benefits: Resistant to chemicals used in pool maintenance, durable, and leak-proof.

9. Marine Applications

Applications: Water supply and waste management systems on boats and ships.

Benefits: Resistant to saltwater corrosion, flexible for tight spaces, and durable.

10. Temporary Water Supply

Applications: Construction sites, emergency water supply, and temporary installations.

Benefits: Easy to transport, quick to set up and dismantle, and reusable.

11. Rainwater Harvesting

Applications: Collection systems for rainwater to be used for irrigation, flushing toilets, and other non-potable uses.

Benefits: Environmentally friendly, cost-effective, and easy to install.

Specific Examples:

Example 1: Residential Plumbing

Scenario: A homeowner needs to replace old metal pipes with a more durable and corrosion-resistant option.

Solution: Using 1/2 inch PVC flexible plastic pipes for water supply lines ensures easy installation and longevity.

Example 2: Agricultural Irrigation

Scenario: A farmer needs an efficient irrigation system for a vegetable garden.

Solution: Installing 1 inch PVC flexible pipes with drip irrigation helps deliver water directly to the plant roots, conserving water and enhancing growth.

Example 3: Industrial Use

Scenario: A factory requires a reliable water supply system for cooling machinery.

Solution: Utilizing 2 inch PVC flexible pipes ensures high-pressure water delivery and resistance to industrial chemicals.

Example 4: Municipal Water Supply

Scenario: A city is upgrading its aging water distribution network.

Solution: Deploying 4 inch PVC flexible pipes for main water lines provides a durable and cost-effective solution for long-term water distribution.

PVC flexible plastic pipes for water are essential in various scenarios due to their versatility, durability, and ease of installation. From residential plumbing to industrial applications, these pipes provide reliable and cost-effective solutions for efficient water distribution and management.

How to make PVC flexible plastic pipes for water?

Manufacturing PVC flexible plastic pipes for water involves multiple steps and various raw materials. The process includes mixing, extrusion, cooling, cutting, inspection, and packaging. Here’s a detailed overview of the manufacturing process:

Raw Materials

Polyvinyl Chloride (PVC) Resin: The primary material determining the basic properties of the pipe.

Plasticizers: Make the PVC more flexible.

Stabilizers: Protect PVC from decomposition during processing and use.

Fillers: Enhance the pipe’s strength and durability.

Color Masterbatch: Adds color as needed.

Manufacturing Steps

1. Mixing

The PVC resin, plasticizers, stabilizers, fillers, and color masterbatch are mixed in specific proportions. This process is usually carried out in a high-speed mixer to ensure all components are evenly distributed.

2. Extrusion

Heating in the Extruder: The mixed raw materials are fed into an extruder, where they are heated until molten.

Screw Extrusion: The molten material is pushed forward by a rotating screw into the mold.

Mold Shaping: The material is extruded through a mold to form the pipe with the desired diameter and thickness.

3. Cooling

Water Bath Cooling: The hot pipe is immediately passed through a water bath to cool and solidify.

Cooling Control: The water temperature and cooling time are adjusted to control the final quality and performance of the pipe.

4. Cutting

The cooled pipe is cut to the required length. The cutting machine usually operates in sync with the extrusion line to ensure consistent pipe lengths.

5. Inspection

Quality Inspection: The pipe’s appearance, dimensions, and physical properties are checked to ensure they meet quality standards.

Pressure Testing: In some cases, the pipes undergo pressure testing to ensure safety in use.

6. Packaging

The qualified pipes are packaged according to specifications, usually bundled or coiled for easy transportation and storage.

Equipment and Technology

High-Speed Mixer: Used for mixing raw materials.

Extruder: Used to extrude molten PVC material into the desired shape.

Cooling Water Bath: Used to cool and solidify the pipe.

Cutting Machine: Used to cut the pipe to the required length.

Quality Inspection Equipment: Used to check the pipe’s dimensions, appearance, and physical properties.

Production Flow Chart

Raw Material Preparation → 2. Mixing → 3. Extrusion → 4. Cooling → 5. Cutting → 6. Inspection → 7. Packaging

Conclusion

Manufacturing PVC flexible plastic pipes for water involves a complex process and various equipment. Each step requires precise control to ensure the final product's quality and performance. By following strict production processes and quality inspections, high-quality PVC flexible plastic pipes can be produced to meet the demands of different applications.

How to pack pvc flexible pipe?

When procuring PVC flexible water pipes in bulk, proper packaging is essential to ensure the products are protected during transportation, handling, and storage. Here are several methods typically used for packaging PVC flexible water pipes:

1. Coiling

Description: The pipes are coiled into manageable loops or rolls.

Diameter: Commonly coiled in diameters of 50m, 100m, or 200m.

Securing: Each coil is secured with cable ties, plastic straps, or rope to prevent uncoiling.

Protection: Coils are often wrapped in plastic film to protect against dust and moisture.

Labeling: Each coil is labeled with product details such as size, length, pressure rating, and manufacturer information.

2. Bundling

Description: Multiple coils or straight lengths of pipe are bundled together.

Quantity: Bundles can vary in size depending on the diameter and length of the pipes.

Securing: Bundles are tightly secured with plastic or metal straps.

Protection: Bundles may be wrapped in plastic film or covered with plastic sheeting for additional protection.

Palletizing: Bundles can be placed on pallets for easier handling and stacking.

3. Palletizing

Description: Coiled or bundled pipes are stacked on wooden or plastic pallets.

Securing: The entire pallet is shrink-wrapped or strapped to ensure stability during transport.

Stacking: Pallets can be stacked, provided the weight and stability are within safe handling limits.

Labeling: Pallets are labeled with product details and handling instructions.

4. Boxed or Crated

Description: Pipes are placed in cardboard boxes or wooden crates.

Protection: Boxes or crates provide excellent protection against physical damage.

Handling: Boxes and crates are easier to handle with forklifts and other equipment.

Labeling: Detailed labels with product information and handling instructions are affixed to each box or crate.

5. Reel and Drum Packaging

Description: For very long lengths, pipes can be wound onto large reels or drums.

Material: Reels and drums can be made of wood, metal, or plastic.

Protection: The pipes are protected from kinking and tangling, and the reel can be covered with plastic wrap for additional protection.

Handling: Reels and drums can be handled using specialized lifting equipment.

Packaging Considerations

Protection: Ensure the packaging protects against physical damage, UV light, and moisture.

Handling: Consider ease of handling and transport. Packaging should facilitate easy loading, unloading, and movement using forklifts or pallet jacks.

Stacking: Packaging should allow for safe stacking without damaging the pipes.

Labeling: Clear and accurate labeling is crucial for inventory management and quick identification.

Environmental Considerations: Use recyclable or reusable packaging materials where possible.

Example Packaging

For 1/2 inch (100m coil):

Packaging: Coiled and secured with plastic straps, wrapped in plastic film, placed on a pallet.

Protection: Plastic wrap protects against dust and moisture.

Handling: Coils are easily moved with forklifts.

For 1 inch (50m coil):

Packaging: Coiled and secured with rope, wrapped in plastic film, bundled in groups of five, placed on a pallet.

Protection: Each coil is individually wrapped, and the bundle is shrink-wrapped for additional protection.

Handling: Bundles are moved with forklifts, with secure stacking on pallets.

By paying attention to these packaging methods and considerations, bulk procurement of PVC flexible water pipes can be managed efficiently, ensuring the product arrives in optimal condition and is easy to handle and store.

What are the implementation standards for pvc flexible pipe?

PVC flexible pipes are subject to various standards that ensure their quality, safety, and performance. These standards may vary depending on the region, application, and specific type of pipe. Below are some key standards and regulations that PVC flexible pipes typically comply with:

International Standards

ISO 1452: Plastics piping systems for water supply and for buried and above-ground drainage and sewerage under pressure. This standard specifies the requirements for PVC-U pipes, fittings, and the system.

ISO 3994: Plastics hoses – General-purpose thermoplastics hoses for liquids and gases.

ISO 4422: Pipes and fittings made of unplasticized polyvinyl chloride (PVC-U) for water supply – Specifications.

American Standards

ASTM D1785: Standard Specification for Polyvinyl Chloride (PVC) Plastic Pipe, Schedules 40, 80, and 120. This standard covers PVC pipes for pressure applications.

ASTM D2241: Standard Specification for Polyvinyl Chloride (PVC) Pressure-Rated Pipe (SDR Series).

ASTM F441/F441M: Standard Specification for Chlorinated Polyvinyl Chloride (CPVC) Plastic Pipe, Schedules 40 and 80.

NSF/ANSI 61: Drinking Water System Components – Health Effects. This standard ensures that the pipe materials do not leach harmful substances into the water supply.

European Standards

EN 1452: Plastics piping systems for water supply – Unplasticized polyvinyl chloride (PVC-U). This standard specifies the requirements for PVC-U pipes, fittings, and the system.

EN 12201: Plastic piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE).

EN 1329: Plastics piping systems for soil and waste discharge (low and high temperature) within the building structure – Unplasticized polyvinyl chloride (PVC-U).

EN ISO 15493: Plastics piping systems for industrial applications – Acrylonitrile-butadiene-styrene (ABS), unplasticized polyvinyl chloride (PVC-U), chlorinated polyvinyl chloride (PVC-C) – Specifications for components and the system.

Australian Standards

AS/NZS 1477: PVC pipes and fittings for pressure applications.

AS/NZS 4765: Modified PVC (PVC-M) pipes for pressure applications.

AS/NZS 1260: PVC-U pipes and fittings for drain, waste, and vent applications.

Additional Standards

ISO 4065: Thermoplastics pipes – Universal wall thickness table.

ISO 3126: Plastics piping systems – Plastics components – Determination of dimensions.

ISO 2507: Thermoplastics pipes and fittings – Vicat softening temperature – Test method.

Regional and Application-Specific Standards

DIN 8061/8062: German standards for PVC pipes for drinking water installations.

BS 3505: British standard for unplasticized PVC pipe for cold water services.

GB/T 10002.1: Chinese standard for PVC-U pipes for water supply.

IS 4985: Indian standard for unplasticized PVC pipes for potable water supplies.

Application of Standards

Water Supply: Standards like ISO 1452 and ASTM D1785 ensure that PVC pipes used for potable water are safe and durable.

Drainage and Sewerage: Standards such as EN 1329 and AS/NZS 1260 cover the requirements for pipes used in waste discharge and sewer systems.

Industrial Applications: ISO 15493 and ASTM F441/F441M are relevant for industrial use, where chemical resistance and high-pressure capabilities are essential.

Health and Safety: Standards like NSF/ANSI 61 ensure that PVC pipes do not contaminate drinking water, making them safe for human consumption.

Ensuring that PVC flexible pipes comply with these standards is crucial for their performance, longevity, and safety in various applications. Always check for certification and compliance with relevant standards when purchasing PVC flexible pipes.If you are planning to purchase PVC flexible pipes in bulk, then if you have special requirements, such as quality execution standards.