Product Fundamentals and Core Features

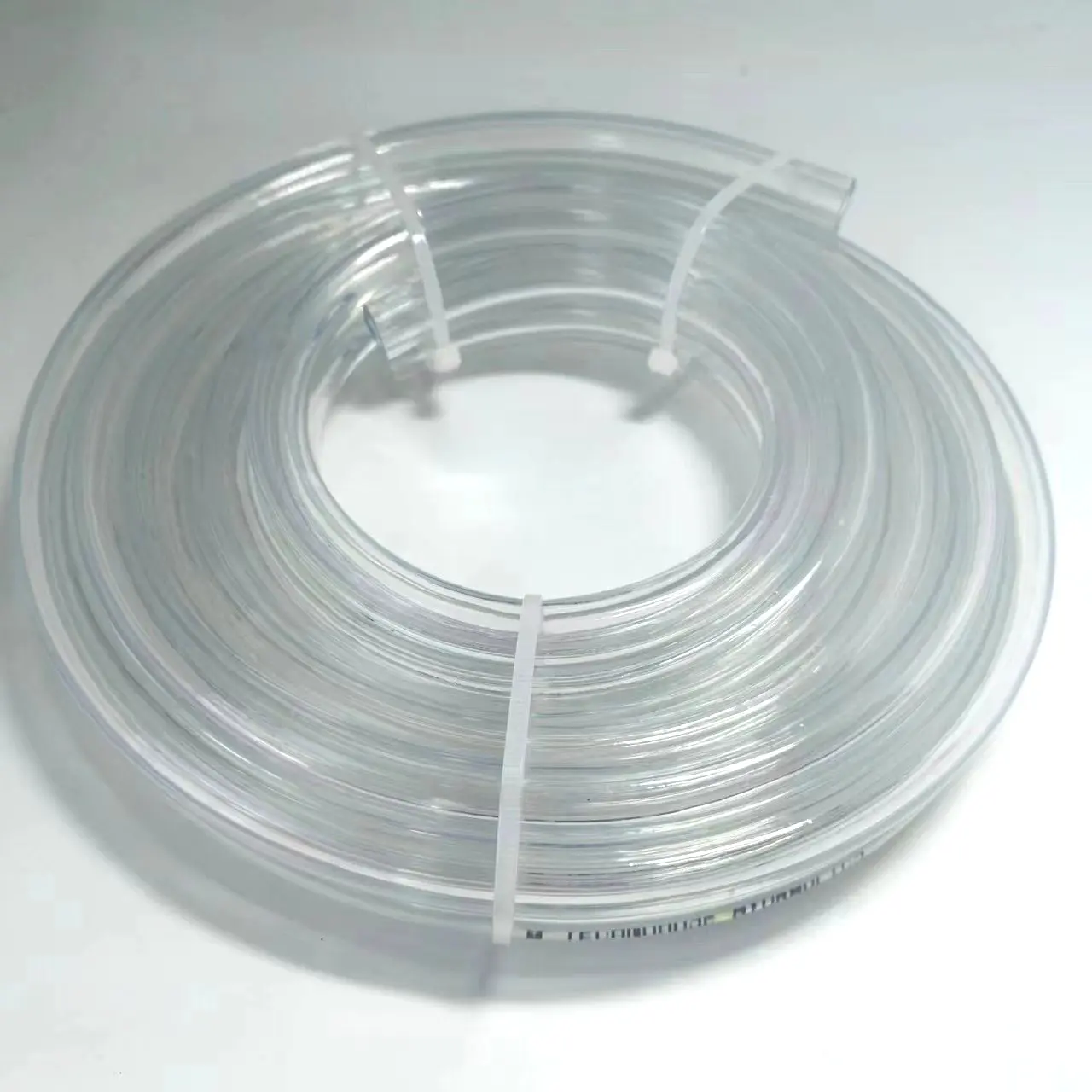

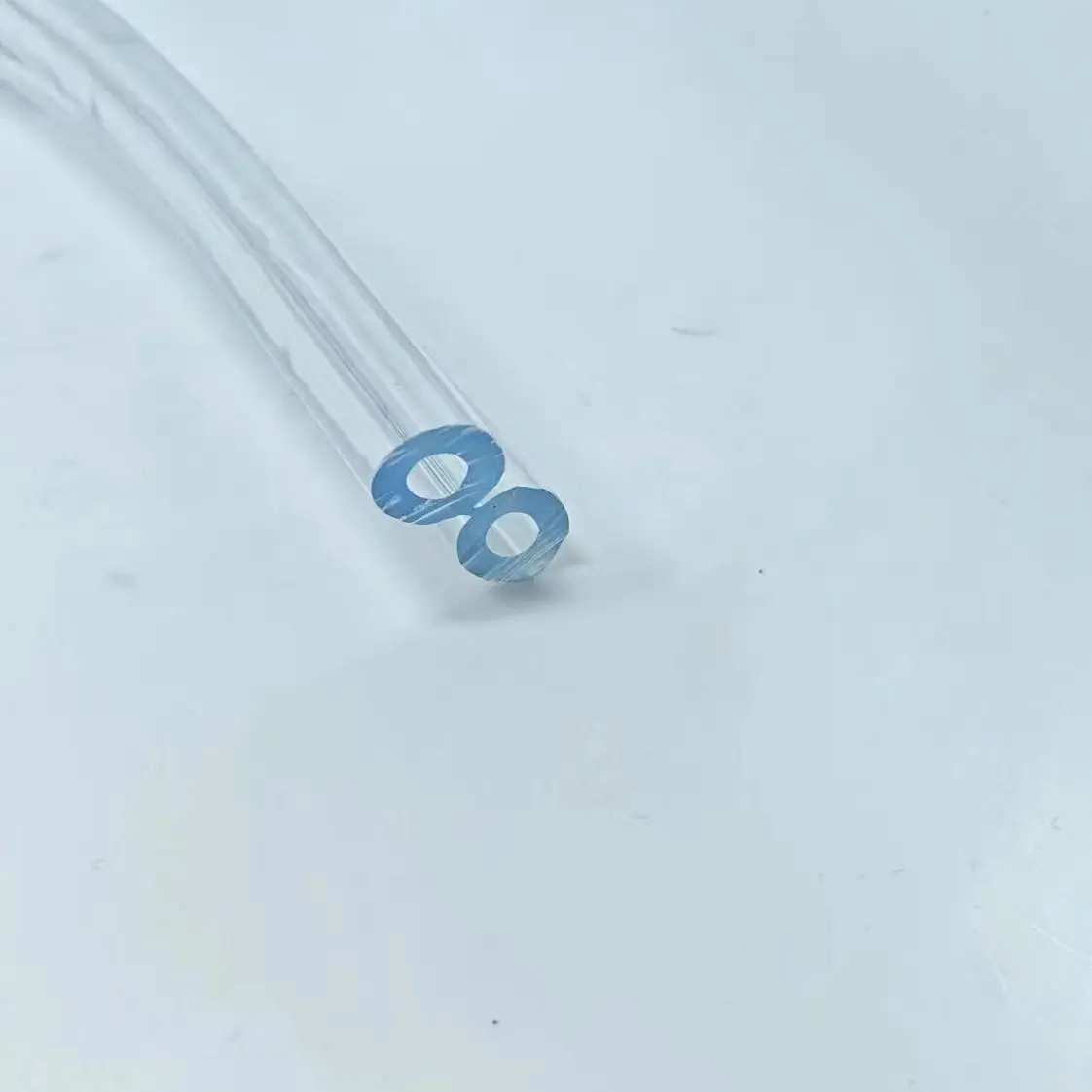

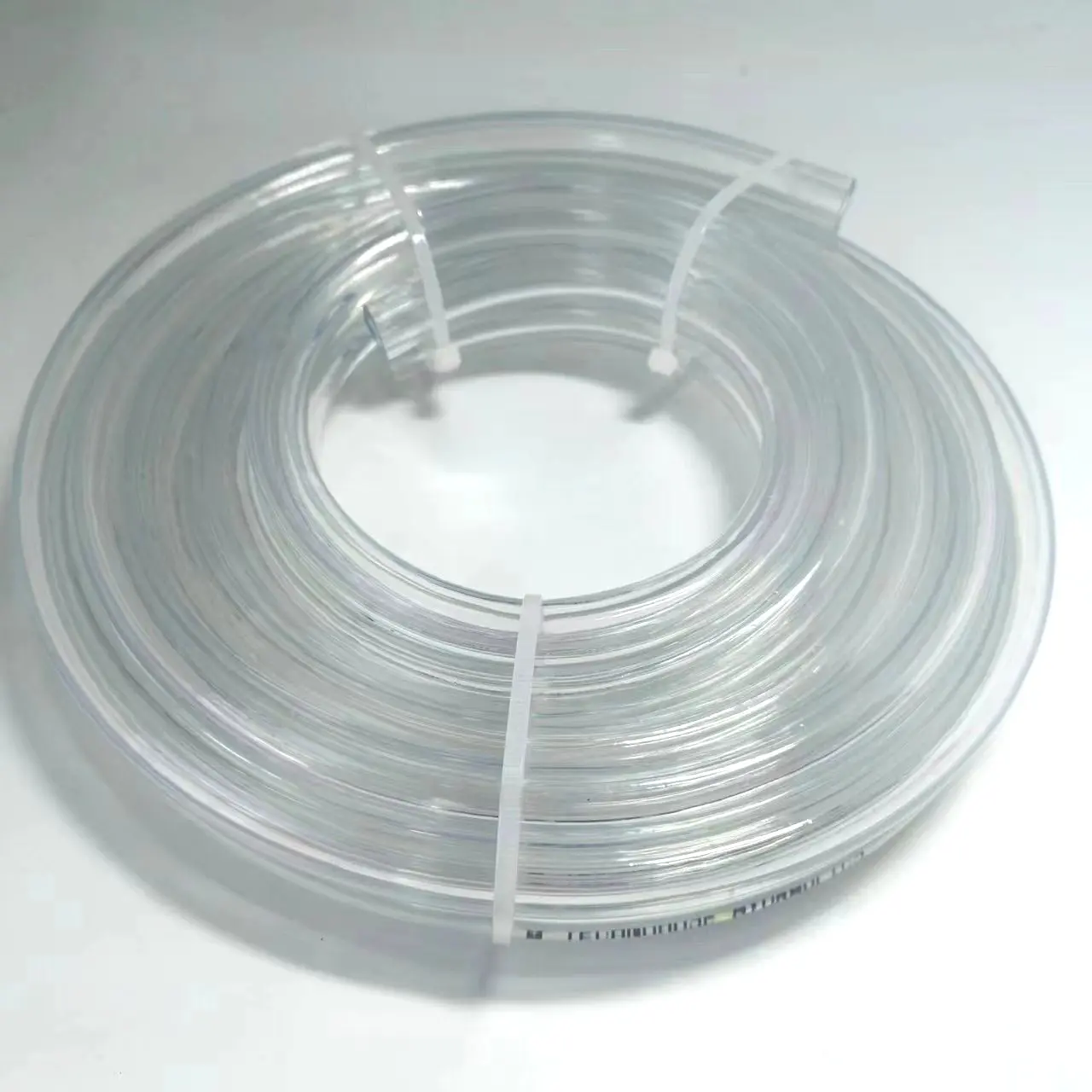

PVC clear milk hoses are essential transfer tools widely used in Mexico's dairy industry, highly valued for their unique transparent design and food safety characteristics. These hoses are typically divided into two main types: single-layer clear (PVC Single Clear Hose) and double-layer clear (PVC Twin Clear Hose), specifically designed for transferring milk and other liquid food products.

Core Product Features:

Fully transparent walls: Allow operators to monitor liquid flow throughout the process, facilitating detection of any abnormalities

Food-grade materials: Comply with Mexican food safety standards, ensuring no contamination of dairy products

Flexible and bendable: Suitable for complex milking environments and workflows in Mexican ranches

Lightweight design: Reduces operator fatigue and improves work efficiency

In Mexico, the transparency of these hoses is particularly valued, as the local dairy industry widely believes that "visible safety is real safety."

Analysis of Primary Application Scenarios in Mexico

Ranch Milking Operations

PVC clear milk hoses play a crucial role in Mexico's major dairy-producing regions:

Milking Applications:

• Main transfer pipes connecting milking machines to collection tanks

• Flexible connectors for mobile milking equipment

• Direct manual milk transfer in small ranches

Milk Transfer Applications:

Intermediate transfer from ranches to refrigerated transport vehicles

Connections between different milk storage tanks

Backup transfer lines for emergency situations

Dairy Processing

Connections for raw milk entering pre-processing systems

Short-distance transfer during pasteurization

Final inspection sections before product filling

Analysis of Market Consumption Characteristics in Mexico

| Selection Criteria | Large Dairy Companies | Medium-Sized Ranches | Small Family Ranches |

|---|---|---|---|

| Type Preference | Double-layer clear | Single-layer clear | Economy single-layer |

| Diameter Choice | Larger sizes | Medium sizes | Smaller sizes |

| Purchase Frequency | Regular replacement | As-needed purchases | Replacement when damaged |

Reasons for These Differences:

Budget variations among differently sized operations

Differences in usage intensity and work environments

Varying understanding of food safety standards

Availability of technical support services

Core Reasons for the Product's Popularity in Mexico

Industry Tradition Influence:

Long-standing visualization practices in Mexico's dairy industry

Adherence to the "seeing is believing" quality control philosophy

Adaptation to Mexico's unique ranch work models

Product Advantages:

Fully transparent walls build trust

Compliance with strict national regulations for food contact materials

Flexibility adapts to various ranch terrain conditions

Easy installation and maintenance features

Economic Practicality:

Better cost-performance than stainless steel piping systems

Lowers equipment investment thresholds for small ranches

Relatively low repair and replacement costs

Professional Usage and Maintenance Recommendations

Daily Usage Tips:

Check for changes in hose transparency before use

Avoid contact with sharp objects and excessive bending

Regularly inspect seal performance at connection points

Observe working temperature range limits

Cleaning and Sanitization Protocols:

• Clean immediately after each use

• Regularly sanitize with specialized disinfectants

• Ensure complete drying before storage

• Avoid corrosive cleaning agents

Storage Requirements:

Store away from direct sunlight

Maintain a ventilated, dry environment

Avoid storage with chemicals

Use proper coiling methods for storage

Real-World User Case Studies in Mexico

After fully adopting PVC Twin Clear Hose, milking efficiency increased by 25%, downtime due to piping issues decreased by 40%, and staff found it easier to monitor hygiene conditions.

Particularly praised the cost-performance advantages of single-layer clear hoses, ensuring food safety while effectively controlling costs, making them especially suitable for medium-sized ranches.

Economy clear hoses significantly lowered their equipment investment threshold, enabling small-scale dairy farmers to use professional equipment that meets hygiene standards.