What are the differences between PVC hose and PE hose?

Understanding the Differences Between PVC Hose and PE Hose When it comes to selecting the right type of hose for various applications, understanding the differences between PVC (Polyvinyl Chloride) hose and PE (Polyethylene) hose is crucial. Both types of hoses have unique characteristics that make them suitable for specific uses.

PE hose, also known as polyethylene hose, is a type of hose made from polyethylene (PE) material. It possesses a series of unique properties and characteristics that set it apart from PVC hose (Polyvinyl Chloride hose) in the following significant ways:

Materials and Properties

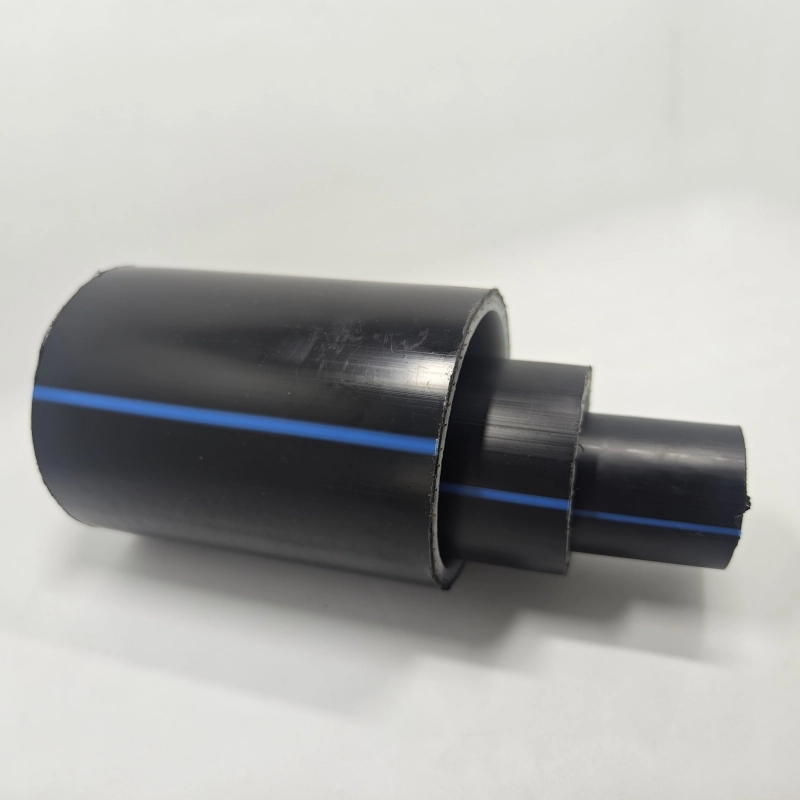

PE Hose:

Materials: Made from polyethylene, typically classified into High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Linear Low-Density Polyethylene (LLDPE).

Properties:

Excellent corrosion and acid-alkali resistance, impervious to chemical erosion or corrosion.

Low density, resulting in lightweight, wear-resistant, good flexibility, and elasticity.

High pressure resistance, capable of withstanding significant gas and liquid pressures.

Smooth inner wall, minimizing resistance to fluid flow.

Easy installation via electric fusion welding, hot-plug welding, and hot-melt sleeve connections, ensuring secure and leak-proof connections.

Environmentally friendly and non-toxic, free from harmful substances, and recyclable.

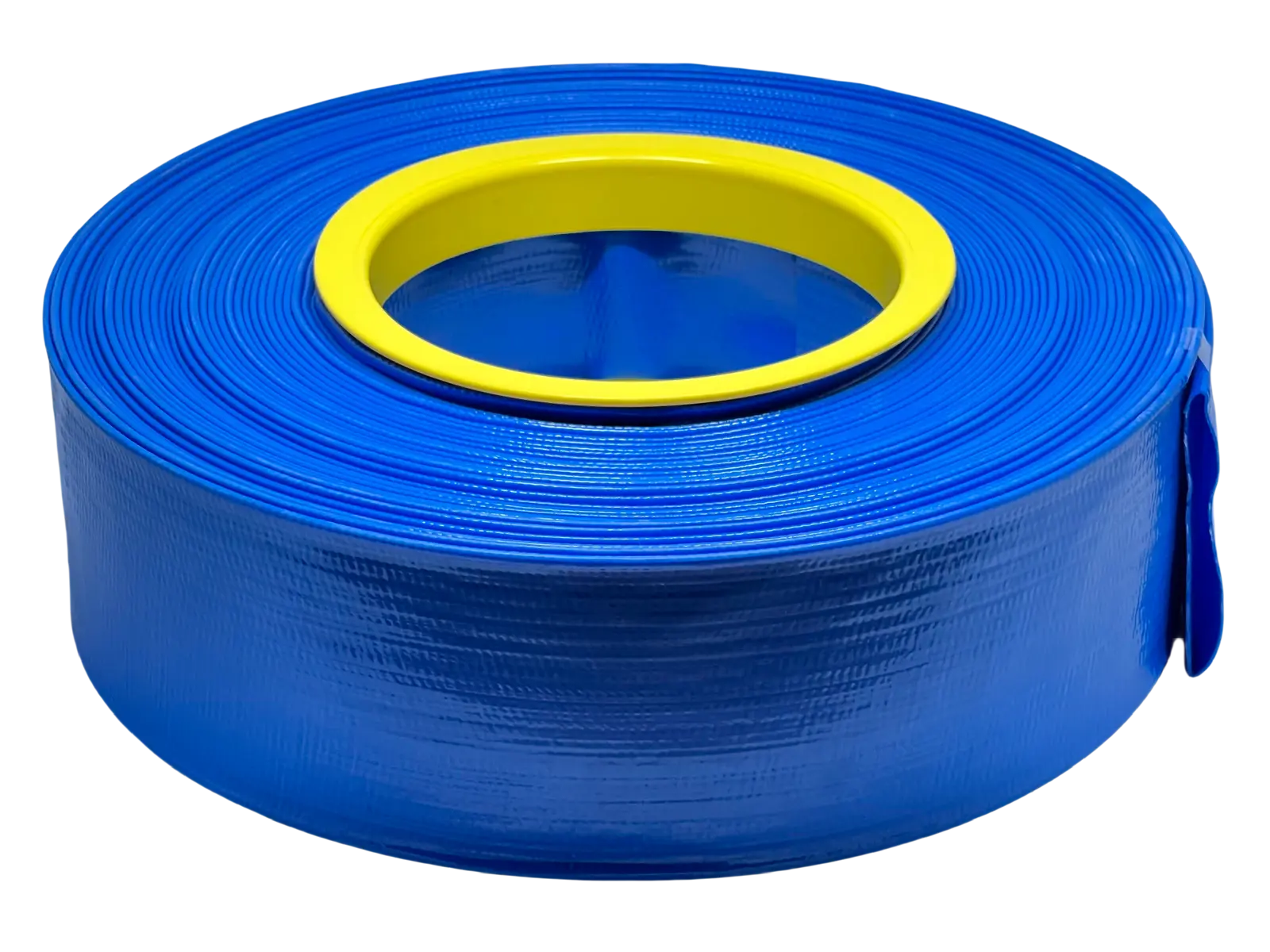

PVC Hose:

Materials: Made from polyvinyl chloride (PVC) material, often requiring additives such as stabilizers and lubricants.

Properties:

High mechanical strength and acid-alkali resistance, but prone to decomposition at high temperatures.

Relatively poor cold resistance, prone to brittleness in low-temperature environments.

Diverse connection methods, though potentially less secure than PE hose connections.

Lower cost but possibly inferior environmental performance compared to PE hose.

Flexibility and Durability

PVC Hose:

PVC hoses are highly flexible, making them easy to handle and maneuver, especially in tight spaces. However, one notable drawback is their tendency to become stiff in cold weather, which can limit their usability in certain climates. Despite this, PVC hoses are generally durable and can withstand significant wear and tear, making them suitable for industrial and agricultural applications.

PE Hose:

PE hoses excel in flexibility, maintaining their pliability even at lower temperatures. This characteristic makes them ideal for outdoor applications where temperature variations are common. Additionally, PE hoses are highly durable and resistant to abrasion, ensuring a long lifespan even under harsh conditions. Their lightweight nature further enhances their ease of use and transport.

Application Scenarios

PE Hose:

Widely used in sectors such as tap water, natural gas, agricultural irrigation, chemicals, and electricity due to its excellent corrosion resistance, pressure resistance, flexibility, and environmental friendliness.

Particularly suitable for applications requiring high pressure and chemical resistance.

PVC Hose:

Also applied in various fields, including drainage systems and electrical wire and cable sheaths.

However, its relatively poor cold resistance may render it unsuitable for extreme cold regions or applications requiring low-temperature performance.

Chemical Resistance

PVC Hose:

PVC hoses offer good resistance to a variety of chemicals, including acids, alkalis, and some solvents. This makes them suitable for applications involving chemical transfer and industrial processes. However, the plasticizers in PVC can sometimes leach out, particularly in food-grade applications, potentially affecting the hose's integrity and safety over time.

PE Hose:

PE hoses are renowned for their excellent chemical resistance, capable of withstanding a broader range of chemicals compared to PVC hoses. This makes them an excellent choice for applications involving harsh chemicals and solvents. Additionally, PE hoses do not leach harmful substances, making them safer for potable water and food-related uses.

Temperature Range

PVC Hose:

PVC hoses can operate effectively across a wide range of temperatures, typically from -20°C to 60°C (-4°F to 140°F). This makes them versatile for various environments and applications. However, their performance can be compromised in extremely cold conditions, where they may become less flexible and more prone to damage.

PE Hose:

PE hoses generally have a lower maximum operating temperature compared to PVC hoses, often up to 50°C (122°F). Despite this, they perform exceptionally well in cold environments, maintaining their flexibility and structural integrity. This makes them ideal for outdoor and cold-weather applications where other hoses might fail.

Cost and Installation

PVC Hose:

PVC hoses are usually more cost-effective, making them a popular choice for budget-conscious projects. Their installation is straightforward, often requiring standard fittings and minimal tools. This ease of installation, combined with their lower cost, makes PVC hoses an attractive option for many applications.

PE Hose:

PE hoses can be more expensive than PVC hoses, but their superior properties often justify the higher cost. Installing PE hoses may require special fittings and tools, which can add to the complexity and overall expense. However, their durability, flexibility, and chemical resistance make them a worthwhile investment for long-term applications.

Both PVC and PE hoses have their distinct advantages and drawbacks. PVC hoses offer a balance of flexibility, durability, and cost-effectiveness, making them suitable for a wide range of applications. On the other hand, PE hoses provide superior chemical resistance, flexibility in cold weather, and a safer option for food and potable water uses. Understanding these differences will help you choose the right hose for your specific needs, ensuring optimal performance and longevity.

PVC Hose vs. PE Hose: Pros and Cons

PVC (Polyvinyl Chloride) Hose

Pros:

Durability: PVC hoses are known for their durability and long lifespan.

Chemical Resistance: They have good resistance to a variety of chemicals, making them suitable for industrial and agricultural applications.

Flexibility: PVC hoses are highly flexible, which makes them easy to handle and install.

Cost-Effective: Generally, PVC hoses are less expensive compared to other types of hoses.

Temperature Range: They can operate in a wide range of temperatures, typically from -20°C to 60°C (-4°F to 140°F).

Variety: Available in various types, including reinforced, braided, and clear PVC, catering to different needs.

Cons:

Stiffness in Cold Weather: PVC hoses can become stiff and less flexible in very cold conditions.

Potential for Kinking: They can kink easily if not handled properly.

Plasticizers: The plasticizers used to make PVC flexible can leach out over time, especially in food-grade applications, potentially affecting the hose's integrity and safety.

Weight: They are generally heavier than PE hoses.

PE (Polyethylene) Hose

Pros:

Lightweight: PE hoses are lighter than PVC hoses, making them easier to transport and handle.

Chemical Resistance: Excellent resistance to a wide range of chemicals, including acids and alkalis.

Flexibility in Cold Weather: PE hoses maintain their flexibility even at lower temperatures, reducing the risk of cracking or breaking.

Environmental Resistance: Resistant to UV radiation and weathering, making them suitable for outdoor use.

Non-Toxic: Generally safer for food and potable water applications, as they do not leach harmful substances.

Durability: Highly durable and resistant to abrasion.

Cons:

Temperature Range: PE hoses typically have a lower maximum operating temperature compared to PVC hoses, often up to 50°C (122°F).

Cost: PE hoses can be more expensive than PVC hoses.

Pressure Rating: PE hoses usually have a lower pressure rating compared to PVC hoses.

Connection Methods: They often require special fittings and tools for connections, which can be more complex than PVC hose connections.

Summary

Both PVC and PE hoses have their own set of advantages and disadvantages, making them suitable for different applications. Here's a quick comparison:

| Feature | PVC Hose | PE Hose |

|---|---|---|

| Durability | High | High |

| Chemical Resistance | Good | Excellent |

| Flexibility | High | High (better in cold weather) |

| Cost | Lower | Higher |

| Temperature Range | Wider | Narrower |

| Weight | Heavier | Lighter |

| Environmental Resistance | Moderate | High |

| Non-Toxicity | Potential leaching | Generally safer |

| Ease of Connection | Easier | More complex |

| Pressure Rating | Higher | Lower |

Choosing between PVC and PE hoses depends on the specific requirements of your application, such as chemical compatibility, temperature range, flexibility, and cost considerations.

About Renato Hose

Renato Hose is a leading PVC hose manufacturer and supplier based in China, renowned for its commitment to quality and innovation. Specializing in a diverse range of PVC hoses, Renato Hose caters to various industries, including agriculture, construction, and chemical processing. With state-of-the-art manufacturing facilities and a dedicated team of experts, the company ensures that each product meets stringent international standards.

Renato Hose offers an extensive selection of PVC hoses, including reinforced, braided, and clear PVC options, designed to withstand rigorous applications and environmental conditions. The company’s dedication to customer satisfaction is reflected in its customizable solutions, competitive pricing, and prompt delivery services. Trusted by clients worldwide, Renato Hose continues to set the benchmark for excellence in the PVC hose industry.