Built with a rugged corrugated exterior and a smooth-flow interior, this 3 inch suction hose ensures minimal friction loss while maximizing flow efficiency. Whether you’re draining muddy construction pits, irrigating vast farmland, or handling heavy-duty industrial pumping, this hose delivers—day in, day out.

Basic Characteristics of 3 Inch Corrugated Suction Hose

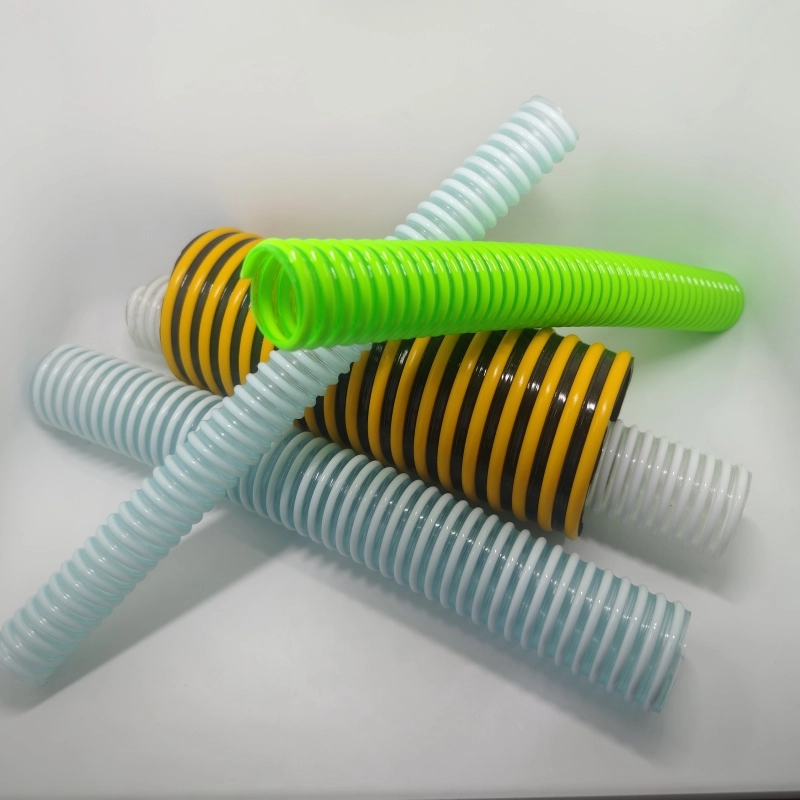

Corrugated Suction Hose is a flexible pipe made from polyvinyl chloride (PVC) and reinforced with polyester fiber layers, designed for suction applications involving water, air, and non-corrosive granular materials (e.g., sand). The outer wall features spiral PVC reinforcement ribs (plastic ribs) to enhance pressure resistance while maintaining flexibility. Common colors include orange (industrial use), yellow, and black (UV-resistant). Standard lengths are 20/30 meters, with diameters customizable from 25-150mm.

Advantages over rubber hoses:

35%-40% lighter weight, allowing for easy handling and deployment

Smooth inner wall (friction coefficient: 0.008) reduces water flow resistance

Approximately 25% lower cost

Limitations:

Becomes stiff in low temperatures (< -5°C); recommended to coil for winter storage

For prolonged sun exposure, choose UV-resistant models

Typical applications: Agricultural irrigation, construction site dewatering, municipal emergency water pumping, etc.

Key Performance Parameters

Pressure Resistance: Working pressure 4-10bar, burst pressure up to 2x working pressure

Flow Efficiency: 100mm diameter achieves ~80m³/h flow rate at 6bar

Abrasion Resistance: Reinforced ribs improve wear resistance by 3x compared to standard PVC hoses

Temperature Range: -5°C to +60°C

This image depicts a container filled with rolls of 3 - Inch Corrugated Suction Hose. The hoses, swathed in plastic film, are neatly piled, indicating they are prepared for transport or storage. These hoses, with a 3 - inch diameter, feature a corrugated design, which likely enhances flexibility and durability, making them suitable for suction - related tasks in various industrial or agricultural applications.

Pressure Rating Table for PVC Reinforced Hose (No Steel Wire)

| Inner Diameter (mm) | Wall Thickness (mm) | Working Pressure (bar) | Burst Pressure (bar) | Suitable Pump Type |

| 25-32 | 1.8-2.0 | 8 | 16 | Small centrifugal pump |

| 40-50 | 2.0-2.2 | 7 | 14 | Diesel pump |

| 65-80 | 2.3-2.5 | 6 | 12 | Electric submersible pump |

| 100-150 | 2.8-3.2 | 4-5 | 8-10 | Large drainage pump |

Note: Data based on 20°C water testing; reduce rating when handling granular materials.

Selection & Installation Guidelines (Bullet Points)

Diameter Matching:

25-50mm: Suitable for low-flow pumping (<30m³/h)

65-100mm: Ideal for medium drainage (50-100m³/h)

150mm: Used for high-flow emergency pumping

Pressure Compatibility: Select a working pressure ≥1.5x the pump’s max output

Installation Best Practices:

Lay with ribs facing outward for better abrasion resistance

Secure joints with stainless steel clamps (torque ≥2.5N·m)

Support suspended sections every 1.5 meters

Terrain Adaptability:

Flat surfaces: Direct laying

Rocky terrain: Use protective sleeves

This image features a 3 - Inch Corrugated Suction Hose. The hose is green and corrugated, providing flexibility for various suction tasks. It is equipped with a metallic coupling, which is securely fastened with metal clamps. This setup ensures a tight seal and reliable connection, making the hose suitable for applications that require efficient suction, such as in industrial fluid transfer or agricultural irrigation.

Maintenance & Troubleshooting

Routine Maintenance:

Flush inner walls after use to prevent sediment buildup

Coil storage diameter ≥15x hose diameter

Common Issues & Solutions:

Deformation: Soak in 60°C hot water to restore shape

Leaky Fittings: Replace O-rings (ensure size matches hose diameter)

Cracked Ribs: Temporarily wrap with PVC repair tape

Typical Use Cases

Agriculture: 50mm transparent hose with centrifugal pumps for visible water flow

Construction Sites: 80mm blue hose for dewatering excavations

Pond Management: 100mm black hose for algae-filled water (UV-resistant)

Municipal Drainage: 150mm reinforced hose for short-term silt pumping (requires filters)

Company Advantages

With over 15 years of specialized manufacturing experience, QINGDAO RENATO PLASTIC CO., LTD has grown into a global name in PVC hose innovation. Here’s what sets us apart:

Global Footprint: Trusted by clients in more than 60 countries.

Strong Production Capacity: 10 workshops, 60+ production lines, 120 skilled workers, and an efficient R&D team.

Rigorous Quality Control: 2 dedicated QC teams and ISO9001-compliant processes ensure every hose meets performance standards.

Comprehensive Assembly Solutions: We supply not only hoses but complete systems—Camlock, Storz, Nozzles, Hose Clamps, and more.

Responsiveness and Reliability: Our team is committed to 7x24 hour service with fast turnaround times and professional support.

Contact Us

Looking for a reliable supplier of 3 inch corrugated suction hose and related assemblies? We’re here to help you source the exact solution for your needs—fast, hassle-free, and always reliable.

Send us your inquiry—we guarantee a first-time response with full details, quotes, and lead time info. We’re your partner in performance.