Basic Introduction to PVC Corrugated Sediment Suction Hose

PVC Corrugated Sediment Suction Hose is a flexible pipe widely used for liquid suction and transportation, primarily made of polyvinyl chloride (PVC) material. Designed to operate under negative pressure, it is suitable for extracting liquids from water sources, storage tanks, or other containers. PVC material offers excellent durability and anti-aging properties, ensuring stability in various environments.

Common specifications of PVC Corrugated Sediment Suction Hose include inner diameter, wall thickness, and length, allowing users to select the appropriate model based on their specific needs. The inner diameter typically ranges from 25mm to 100mm, while the wall thickness is adjusted according to working pressure and the nature of the suction medium. The hose's outer surface is usually smooth, making it easy to clean and maintain. Additionally, some models feature UV-resistant treatments, making them suitable for outdoor use.

The main advantages of this hose are its durability and adaptability. However, users should be aware of its operating temperature range, typically between -10°C and +60°C, as performance may be affected outside this range. Additionally, PVC Corrugated Sediment Suction Hose is relatively heavy, and handling and installation may require more manpower or equipment support.

Main Application Areas of PVC Suction Hose

Agricultural Irrigation: Used to extract water from sources such as rivers, lakes, or wells to support farmland irrigation systems. Its weather resistance and UV protection make it ideal for long-term outdoor use.

Construction Drainage: Used on construction sites to pump water from foundations, basements, or other low-lying areas, helping to dewater and keep the site dry.

Industrial Liquid Transportation: Used in manufacturing and food processing industries to extract water or other non-corrosive liquids, such as drinking water or edible oils, from tanks or containers.

Household Use: Used for garden watering, pool cleaning, or water suction, making it an ideal choice for home users due to its durability and ease of operation.

Performance Characteristics of PVC Suction Hose

Durability: PVC material offers excellent anti-aging properties, ensuring stability in various environments and extending the hose's service life.

Pressure Resistance: The hose's design allows it to operate under negative pressure, making it suitable for liquid suction applications.

Smooth Inner Wall: The hose's inner wall is usually smooth, reducing fluid resistance during transportation and improving efficiency.

Heavy Weight: Due to the high density of PVC material, the hose is relatively heavy, and handling and installation may require more manpower or equipment support.

Specification

| Item | Details |

| Product Name | PVC Corrugated Sediment Suction Hose |

| Brand Name | Renflex |

| Material | High-Quality PVC |

| Size Range | 1 inch to 16 inch |

| Length Options | 10m / 20m / 30m / 40m / 50m (Customizable) |

| Wall Thickness | 2mm to 12mm |

| Working Temperature | -5°C to +65°C |

| Working Pressure | 2 - 10 bar |

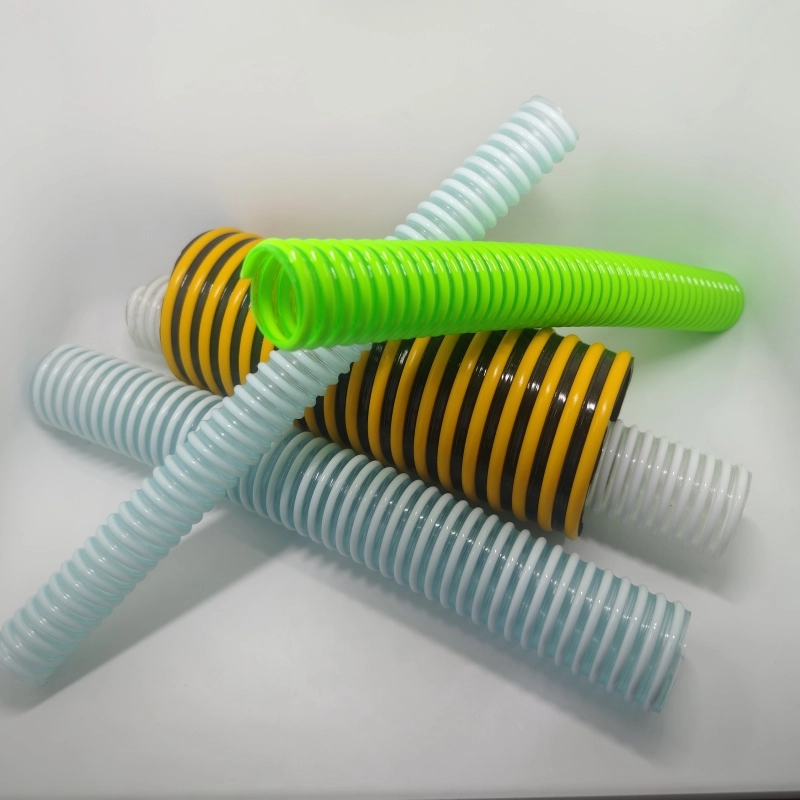

| Color Options | Transparent / Blue / Green / Black / Custom |

| Transport Medium | Water / Oil / Powder |

| Applications | Agriculture, Mining, Construction |

| Certification | ISO9001 |

| Features | Flexible, Durable, Long Lifespan, Lightweight |

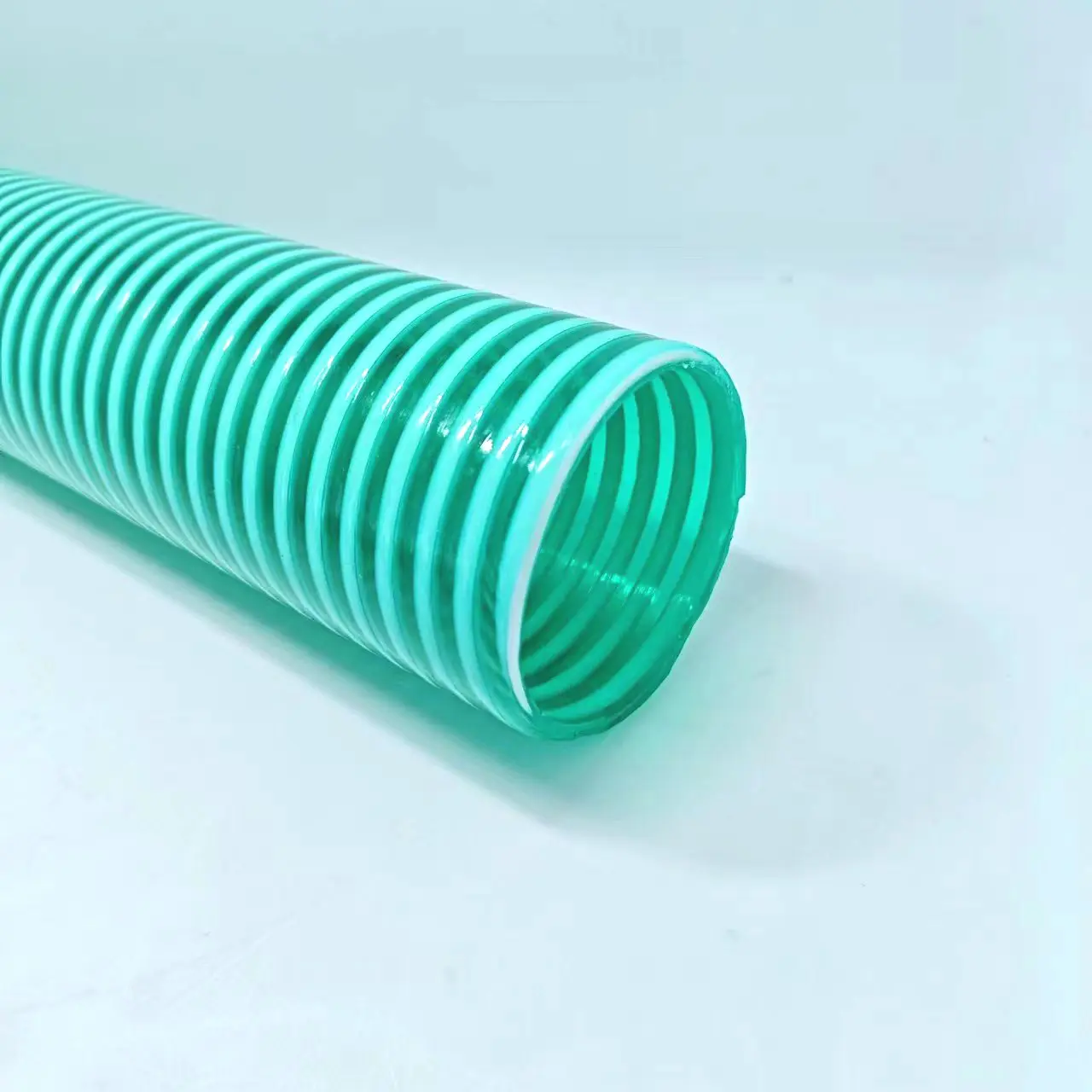

A roll of green PVC corrugated sediment suction hose, which is designed for suctioning sediment and is commonly used in construction, dredging and other engineering - related scenarios for its durability and flexibility.

Installation and Maintenance of PVC Suction Hose

When installing PVC Suction Hose, it is essential to select the appropriate specifications and models based on the specific application scenario. The hose's length, inner diameter, and wall thickness should match the working pressure, suction medium, and environmental conditions. During installation, avoid excessive bending or twisting of the hose to prevent structural damage or internal collapse.

When connecting the hose, specialized joints or clamps are typically used. Ensure the joint matches the hose's size and use appropriate tools for tightening to prevent leaks. For high-pressure or high-negative-pressure applications, double clamps or flange connections are recommended to improve sealing and safety. Additionally, avoid contact between the hose and sharp objects during installation to prevent external damage.

The key to maintaining PVC Suction Hose lies in regular inspection and cleaning. Below are maintenance tips:

Regular Inspection: After use, promptly drain any residual liquid from the hose to prevent bacterial growth or odors during storage.

Cleaning and Maintenance: For hoses used outdoors, regularly check the outer surface for cracks or signs of aging and replace them if necessary.

Preventing Clogs: If the hose is used to transport granular media, clean it thoroughly after use to prevent clogging or wear.

Advantages and Disadvantages of PVC Suction Hose

Advantages:

Cost-Effectiveness: The material cost is relatively low, and the mature production process makes the hose competitively priced.

Strong Adaptability: Its can adapt to complex installation environments, reducing the need for connectors and fittings.

High Durability: PVC material offers excellent anti-aging properties, ensuring stability in various environments.

Smooth Inner Wall: The smooth inner wall reduces fluid resistance and improves efficiency.

Disadvantages:

Heavy Weight: Due to the high density of PVC material, the hose is relatively heavy, and handling and installation may require more manpower or equipment support.

Temperature Limitations: Its operating temperature range is limited, making it unsuitable for extreme high or low temperatures.

Aging Risk: Prolonged exposure to UV rays or high temperatures may cause PVC material to age, affecting the hose's lifespan.

Market Status of PVC Suction Hose

Currently, PVC Suction Hose has a broad market demand worldwide, especially in agriculture, construction, and industrial sectors. With the increasing global demand for efficient, durable, and cost-effective liquid suction solutions, PVC Suction Hose has a vast market space.

In the agricultural sector, the popularity of irrigation systems and the promotion of efficient farming have driven the demand for PVC Suction Hose. Its weather resistance and UV protection make it an ideal choice for outdoor use. In the construction sector, the growth of infrastructure and real estate development projects has also boosted the demand for hoses, particularly in drainage and dewatering applications.

In the industrial sector, wastewater treatment, food processing, and manufacturing are the primary markets. These industries require hoses with high durability, mechanical strength, and hygiene standards, which PVC Suction Hose can meet effectively.

Overall, PVC Suction Hose has a promising market outlook, but it also faces competition from other materials such as rubber and polyurethane. Manufacturers need to maintain market competitiveness through technological innovation and product optimization.

Why Choose Qingdao Renato Plastic Co., Ltd.?

It’s not just about the product—it’s about who’s behind it. And this is where Qingdao Renato Plastic Co., Ltd. stands tall.

15+ Years of Manufacturing Excellence

This isn’t a pop-up operation. We’ve built our reputation over time, with hands-on experience and continuous improvement.State-of-the-Art Facilities

10 fully operational workshops. 60+ production lines. Over 120 trained workers, backed by 5 skilled technicists and 2 professional QC teams.Global Reach

Our hoses are trusted in more than 60 countries. Whether you're in Southeast Asia, Africa, the Middle East, or Europe—our name means reliability.Full Hose Assembly Solutions

Need Camlock fittings, Storz couplings, nozzles, or clamps? We’ve got you covered from hose to connector.Customer-Centric Philosophy

“Customers Always First” isn’t just a slogan. We’re here 24/7, ready to respond, assist, and support your project.

★ Your inquiry will be answered promptly. Let’s build a solution that works—together.