Basic Overview of PVC Suction Hose

PVC Suction Hose is a type of flexible tubing commonly used for liquid transfer in various industrial and agricultural applications. Designed primarily for water suction, drainage, and general liquid transportation, this hose is made from polyvinyl chloride (PVC), offering durability and adaptability to different working environments.

PVC Suction Hose is widely used in irrigation, construction drainage, wastewater management, and industrial liquid transfer. Its key advantage lies in its ability to perform reliably under varying conditions while maintaining efficient liquid flow. Due to the properties of PVC material, the hose resists deformation under normal use, ensuring long-term functionality.

Agriculture is an extremely important industry in Thailand. Irrigation farmland will require PVC suction hose. When selecting a PVC Suction Hose, users should consider factors such as hose size, compatibility with the intended liquid, and environmental suitability. Different hose diameters cater to varying flow requirements, so choosing the right specification based on actual usage is essential.

Primary Applications of PVC Suction Hose

(1) Agricultural Irrigation

PVC Suction Hose is extensively used in farm irrigation systems to efficiently transport water to crops. Its consistent flow performance ensures proper water distribution, making it suitable for both large-scale irrigation and small farmland watering.

(2) Construction Drainage

On construction sites, PVC Suction Hose is often employed to remove accumulated water or transport construction-related liquids. Its durability allows it to withstand rough terrain without significant wear or damage.

(3) Wastewater Management

This hose is used in wastewater treatment plants to transfer sewage or sediment. Its design enables it to handle liquids with minor impurities while maintaining smooth flow.

(4) Industrial Liquid Transfer

In certain industrial settings, PVC Suction Hose is utilized to move cooling water, lubricants, and other non-corrosive liquids. Its stable performance makes it a reliable choice for factory operations.

These applications in Thailand have played an important role in our PVC suction hose, while also allowing the Thai market to continue expanding.

Key Considerations When Purchasing PVC Suction Hose

| Selection Factor | Explanation |

|---|---|

| Hose Size | Choose the appropriate diameter based on flow requirements to ensure efficiency. |

| Liquid Compatibility | Verify that the hose is suitable for the intended liquid to avoid incompatibility. |

| Environmental Suitability | Consider temperature, humidity, and other conditions to ensure proper performance. |

| Connection Method | Check if the hose fittings match existing equipment to prevent installation issues. |

| Brand & Quality | Opt for reputable brands to ensure product reliability and after-sales support. |

We provide OEM/ODM PVC Success Hose services. To meet the demands of the Thai market, we offer any challenging services.

PVC Suction Hose with Water Pump

1. Choosing the Right PVC Suction Hose for Your Pump

Before connecting, ensure compatibility between the hose and pump:

Hose Diameter – Match the hose inner diameter (ID) to the pump’s inlet/outlet size. Common sizes: 1", 1.5", 2", etc.

Hose Length – Longer hoses may reduce suction efficiency; keep within the pump’s recommended suction lift capacity.

Reinforcement Type – Ensure the hose can handle the pump’s suction power without collapsing.

2. Connecting the PVC Suction Hose to the Pump

Step 1: Inspect the Hose and Pump

Check for cracks, kinks, or blockages in the hose.

Ensure the pump’s inlet (suction side) and outlet (discharge side) are clean and free of debris.

Step 2: Attach the Hose to the Pump’s Suction Inlet

If the pump has a threaded inlet, use a compatible PVC hose adapter or coupling.

For a smooth inlet, use a hose clamp to secure the connection and prevent air leaks.

Ensure a tight fit—air leaks can reduce suction efficiency.

Step 3: Submerge the Hose in the Liquid Source

Place the suction end of the hose fully underwater (e.g., in a pond, tank, or well).

Avoid placing it too close to the bottom, where sediment could enter the pump.

If using a foot valve (non-return valve), attach it to prevent backflow when the pump stops.

Step 4: Prime the Pump (If Required)

Some pumps (e.g., centrifugal pumps) need priming—filling the hose and pump with water to create suction.

Pour water into the pump inlet until the hose is full before starting.

Step 5: Connect the Discharge Hose (If Needed)

Attach another hose to the pump’s outlet for directing water to the desired location.

Secure with clamps or fittings to prevent leaks.

3. Operating the Pump with PVC Suction Hose

Start the pump and check for smooth water flow.

If the pump struggles or loses suction:

Check for air leaks at connections.

Ensure the suction hose isn’t kinked or blocked.

Verify the pump’s suction lift capacity isn’t exceeded.

Avoid running the pump dry, as it can damage the motor.

4. Maintenance & Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Weak or No Suction | Air leaks, clogged hose, or insufficient priming | Tighten connections, clear blockages, re-prime pump |

| Hose Collapsing | Excessive suction or weak hose structure | Use a reinforced hose or reduce pump speed |

| Pump Overheating | Dry running or blockage | Ensure water supply, check for obstructions |

5. Safety Tips

Always turn off the pump before adjusting hoses.

Avoid sharp bends in the suction hose to maintain flow efficiency.

Store the hose properly when not in use to prevent damage.

By following these steps, you can effectively use a PVC suction hose with a water pump for reliable liquid transfer in various applications.

Usage Precautions for PVC Suction Hose

Avoid Excessive Bending: While PVC Suction Hose is flexible, prolonged sharp bends may cause deformation and hinder liquid flow.

Prevent External Wear: When used on rough surfaces or near sharp objects, protective measures such as hose sleeves should be applied.

Regular Inspection: Before use, check for cracks, aging, or loose fittings to ensure safe operation.

Proper Storage: When not in use, store the hose in a cool, dry place away from direct sunlight or high temperatures.

Maintenance and Care for PVC Suction Hose

Clean Internal Residue: After use, drain any remaining liquid to prevent clogging or buildup.

Avoid Heavy Pressure: Do not place heavy objects on the hose during storage to prevent deformation or damage.

Inspect Connections Regularly: Ensure fittings are leak-free and replace seals or tighten connections if necessary.

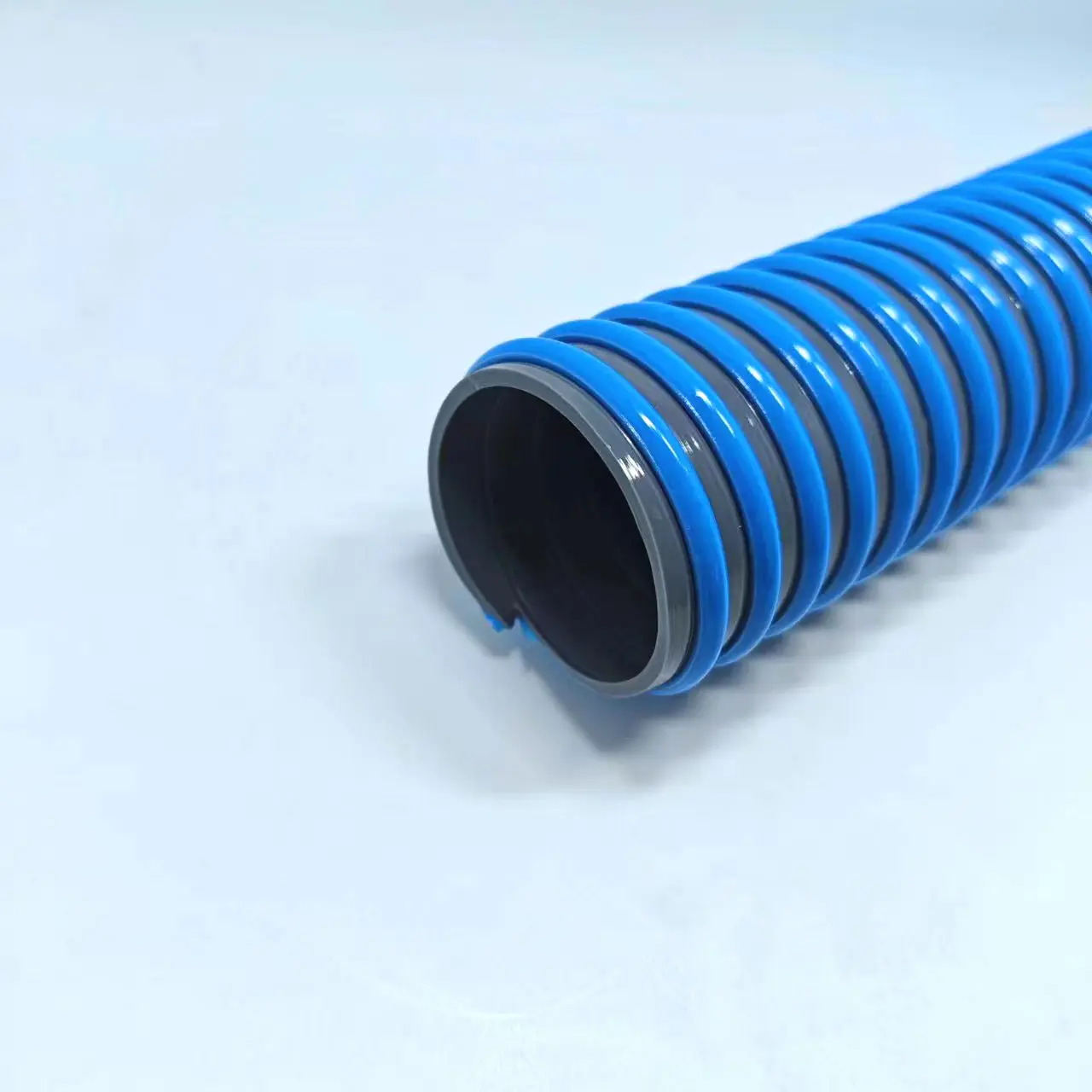

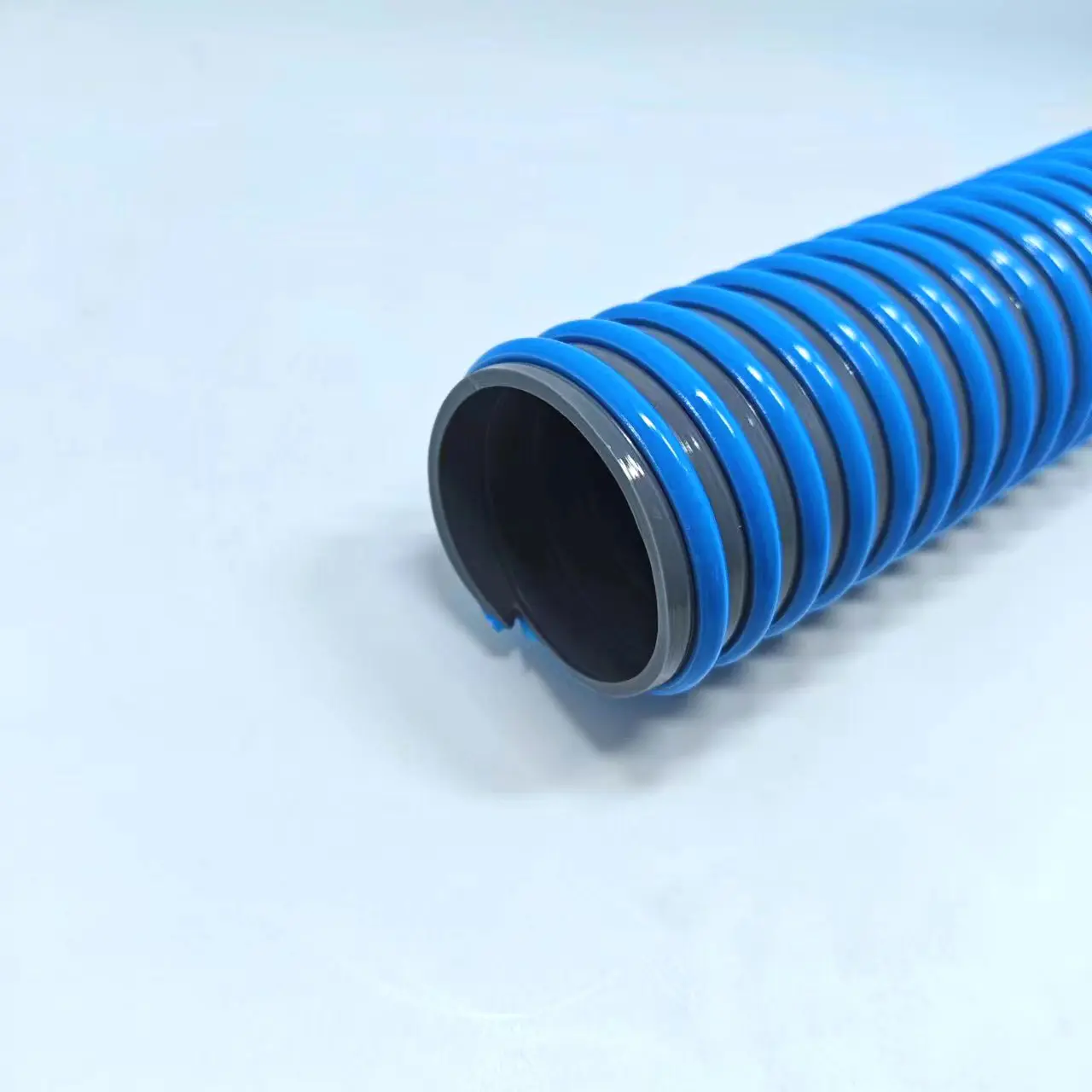

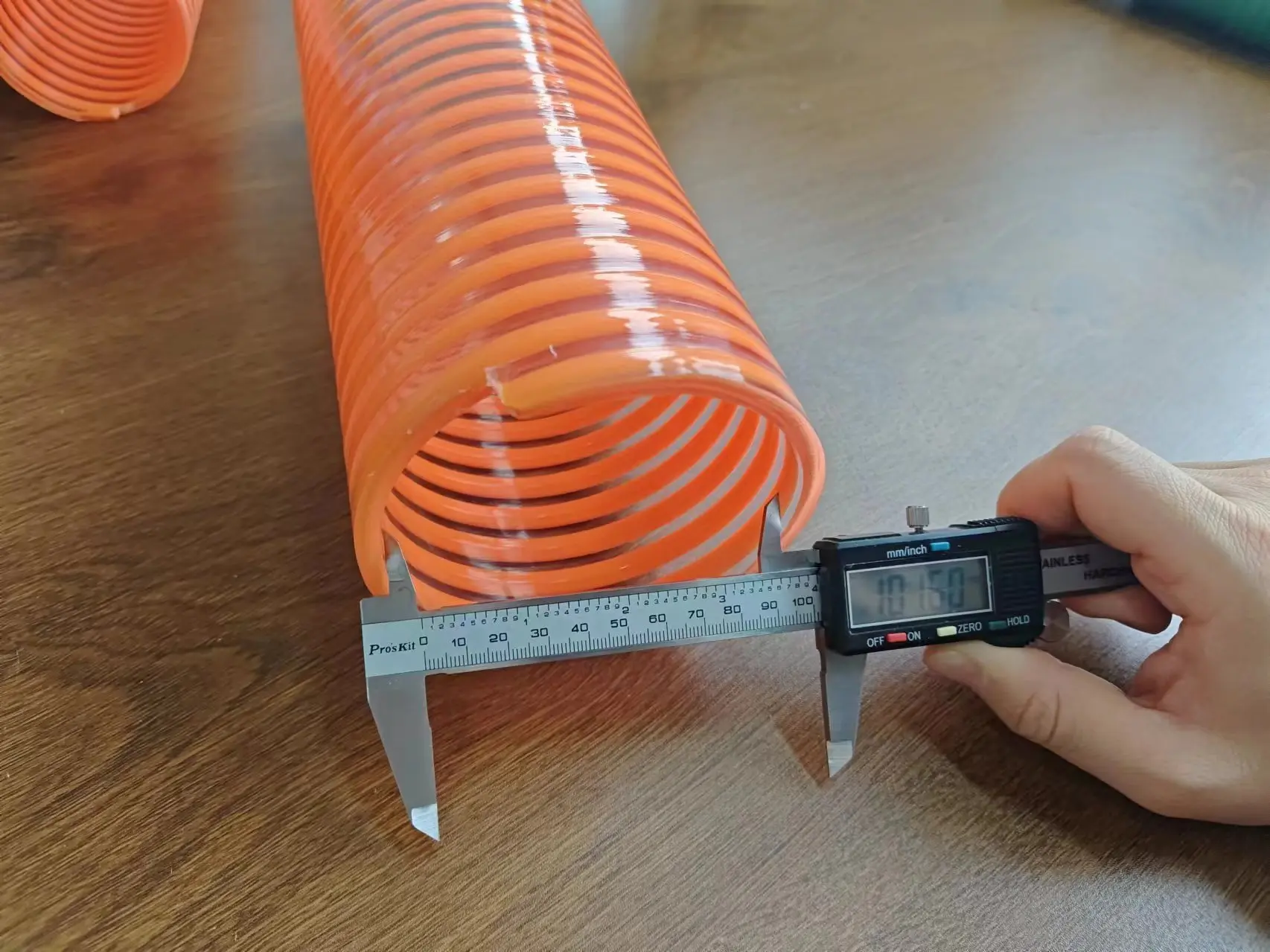

This picture shows the PVC suction hose we supply to the Thai market. This is one of the specifications with an inner diameter of 100mm.

Common Market Issues with PVC Suction Hose

Hose Hardening or Brittleness: Often caused by prolonged exposure to extreme temperatures or UV rays. Replace the hose or improve storage conditions.

Reduced Liquid Flow: May result from excessive bending or internal blockages. Adjust hose placement or clear obstructions.

Leaking Fittings: Could be due to poor sealing or damaged connectors. Reinstall or replace the fittings as needed.

In the Thai market, if you are engaged in PVC hose services. You can strengthen your connection with our factory. By making wise choices, using hoses correctly, and performing regular maintenance, PVC suction hoses can reliably meet various liquid transportation needs in different applications.