Anti-Static Spiral Steel Wire Flexible Hose

The Anti-Static Spiral Steel Wire Flexible Hose represents a significant advancement in industrial tubing technology, specifically engineered to address the critical issue of static electricity buildup in sensitive environments. This innovative hose design combines the benefits of flexibility, durability, and static dissipation, making it an ideal solution for a wide range of applications where safety and performance are paramount.

Constructed with a robust spiral steel wire reinforcement, the hose offers exceptional strength and resistance to kinking, crushing, and abrasion. This ensures a long service life and reliable performance even in the most demanding industrial settings. The spiral configuration also enhances flexibility, allowing the hose to bend and maneuver easily around obstacles, reducing installation time and effort.

In summary, the Anti-Static Spiral Steel Wire Flexible Hose is a versatile and reliable tubing solution that combines the advantages of flexibility, durability, and static dissipation. Its advanced design and construction make it an invaluable asset in any industrial application where safety and performance are critical.

Characteristics

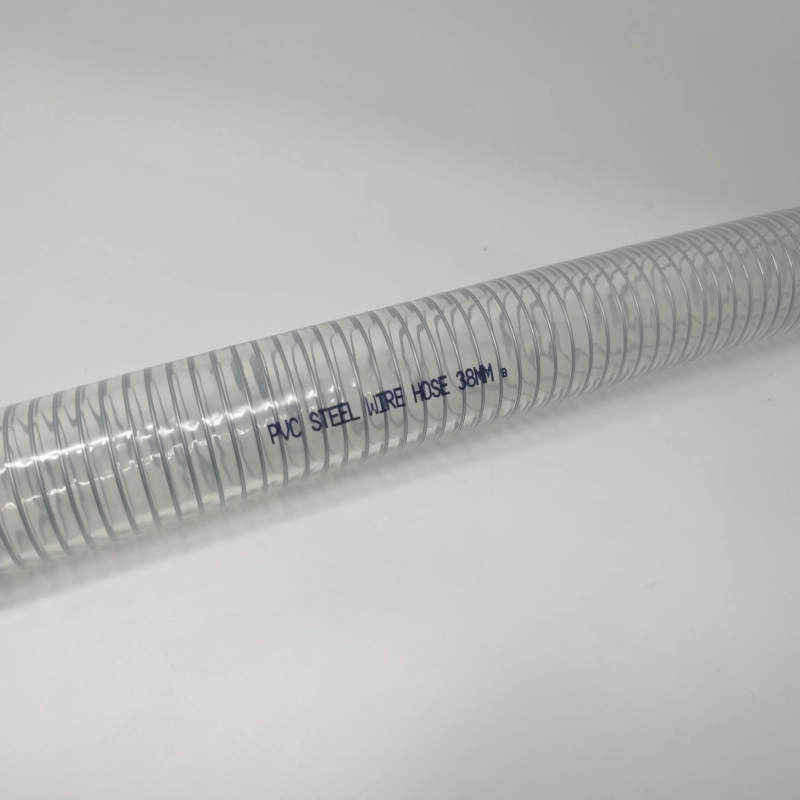

Pressure Resistance: PVC steel wire hose combines high-elasticity, high-strength steel wire with PVC synthetic materials, enabling it to withstand high-pressure working environments. It is suitable for use in scenarios where pressure resistance is required.

Corrosion Resistance: PVC material itself exhibits excellent corrosion resistance, capable of withstanding various chemical media, thereby extending its service life. This makes PVC steel wire hose outstanding for conveying corrosive liquids.

Flexibility: PVC steel wire hose is easy to install and arrange, adapting to complex working spaces. Its flexibility allows the pipe to bend and twist, meeting different layout requirements.

Transparency: Some PVC steel wire hoses have a clear and transparent body, allowing easy observation of fluid transportation, providing convenience and safety.

Pressure and Vacuum Resistance: PVC steel wire hose possesses excellent pressure and vacuum resistance, maintaining stable operation even in high-pressure or vacuum environments.

Cost-Effectiveness: Compared to pipes made of other materials, PVC steel wire hose is more competitive in cost, reducing procurement and operating costs for enterprises.

Environmental Friendliness: PVC material is recyclable, meeting the requirements of sustainable development. This makes PVC steel wire hose environmentally friendly and increasingly favored by enterprises.

Application Scenarios

Construction Industry: Used in drainage, ventilation, and other fluid transportation systems. The pressure resistance and corrosion resistance of PVC steel wire hose make it an indispensable material in the construction field.

Agriculture: In irrigation systems, PVC steel wire hose effectively transports water sources. Its flexibility allows the pipe to adapt to different terrains and layout requirements, improving irrigation efficiency.

Chemical Industry: Used for transporting chemicals and corrosive liquids. The corrosion resistance of PVC steel wire hose ensures the safety of the transportation process, preventing the leakage of hazardous substances.

Food Processing: Suitable for food production lines, ensuring product safety and hygiene. The transparency of PVC steel wire hose allows operators to easily observe fluid transportation, ensuring food quality.

Other Industrial Fields: PVC steel wire hose is also widely used in fields such as petroleum, mining, and sewage treatment for transporting various liquids, gases, oils, and dust.

The Advantages of Anti-Static PVC Steel Wire Hose

Excellent Anti-Static Performance:

Through special formulation and process treatment, the anti-static PVC steel wire hose exhibits extremely low surface resistivity, effectively dissipating static charges accumulated during production processes and preventing damage to the surrounding environment and products caused by electrostatic discharge.

This anti-static performance is crucial for scenarios where electrostatic interference and damage need to be prevented, such as electronic production lines, medical device manufacturing, and the aerospace field.

Outstanding Durability and Dust-Proof Characteristics:

Made from high-quality PVC materials and reinforced through processing, the anti-static PVC steel wire hose is wear-resistant and scratch-resistant, maintaining a smooth surface even under high-frequency use and resisting aging and deformation.

Its unique dust-proof design effectively reduces the adhesion of dust particles, maintaining the cleanliness of the production environment, which is particularly important for industries requiring high cleanliness conditions.

Good Corrosion Resistance and Chemical Stability:

PVC material itself has strong resistance to oxidants, reductants, and strong acids. Although it can be corroded by concentrated oxidizing acids, it performs well in general industrial environments.

Wide Range of Applications:

The anti-static PVC steel wire hose is not only suitable for high-tech fields such as electronics, medical, and aerospace but is also widely used in chemicals, machinery, electrical appliances, food packaging, pharmaceuticals, decoration, and water treatment.

Its outstanding anti-static performance and stable operating temperature (up to 100 degrees Celsius) make it an indispensable material in various industries.

Flexible Processing Performance:

The anti-static PVC steel wire hose is lightweight and easy to process, allowing for cutting, bending, welding, and other processing treatments according to different needs, meeting diverse production requirements.

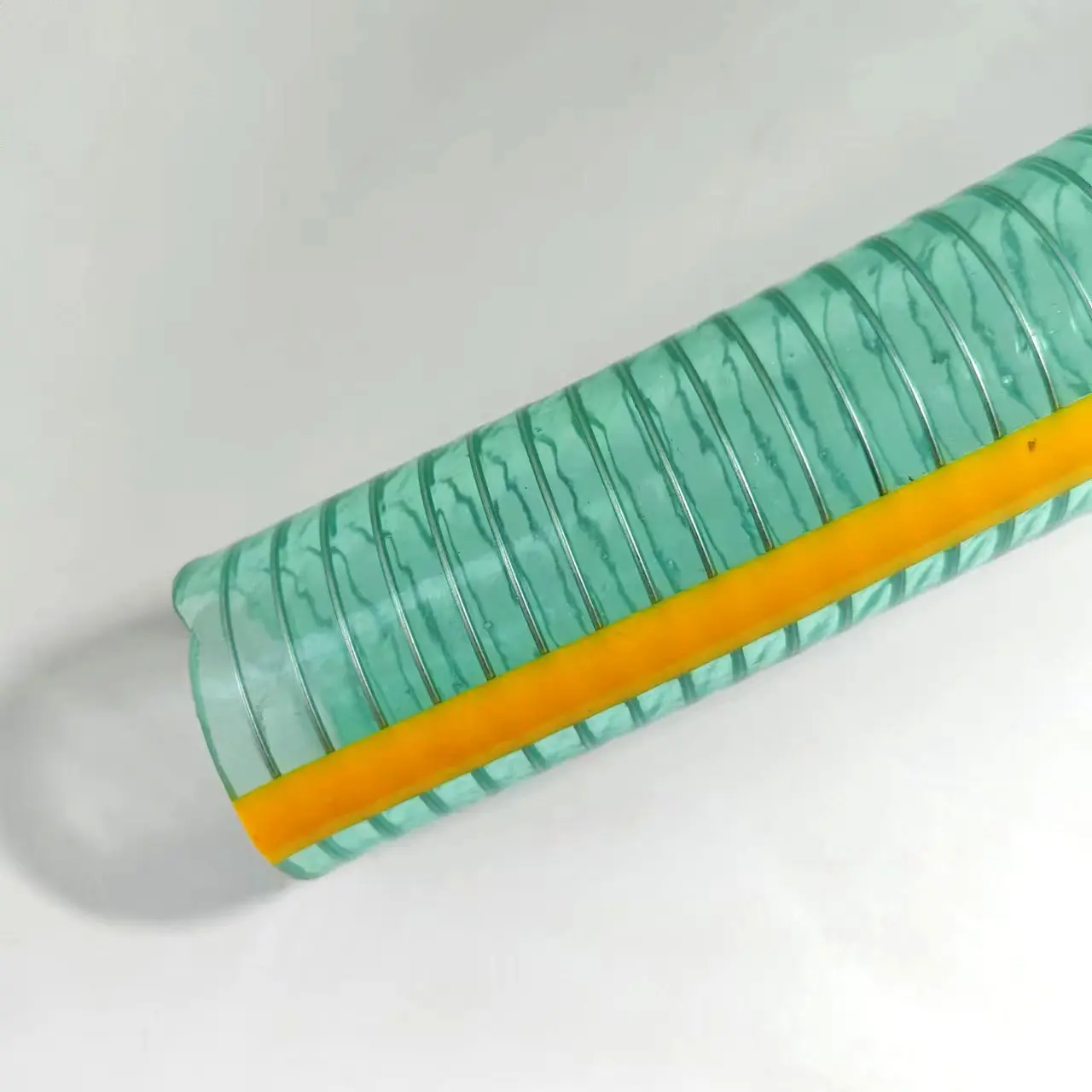

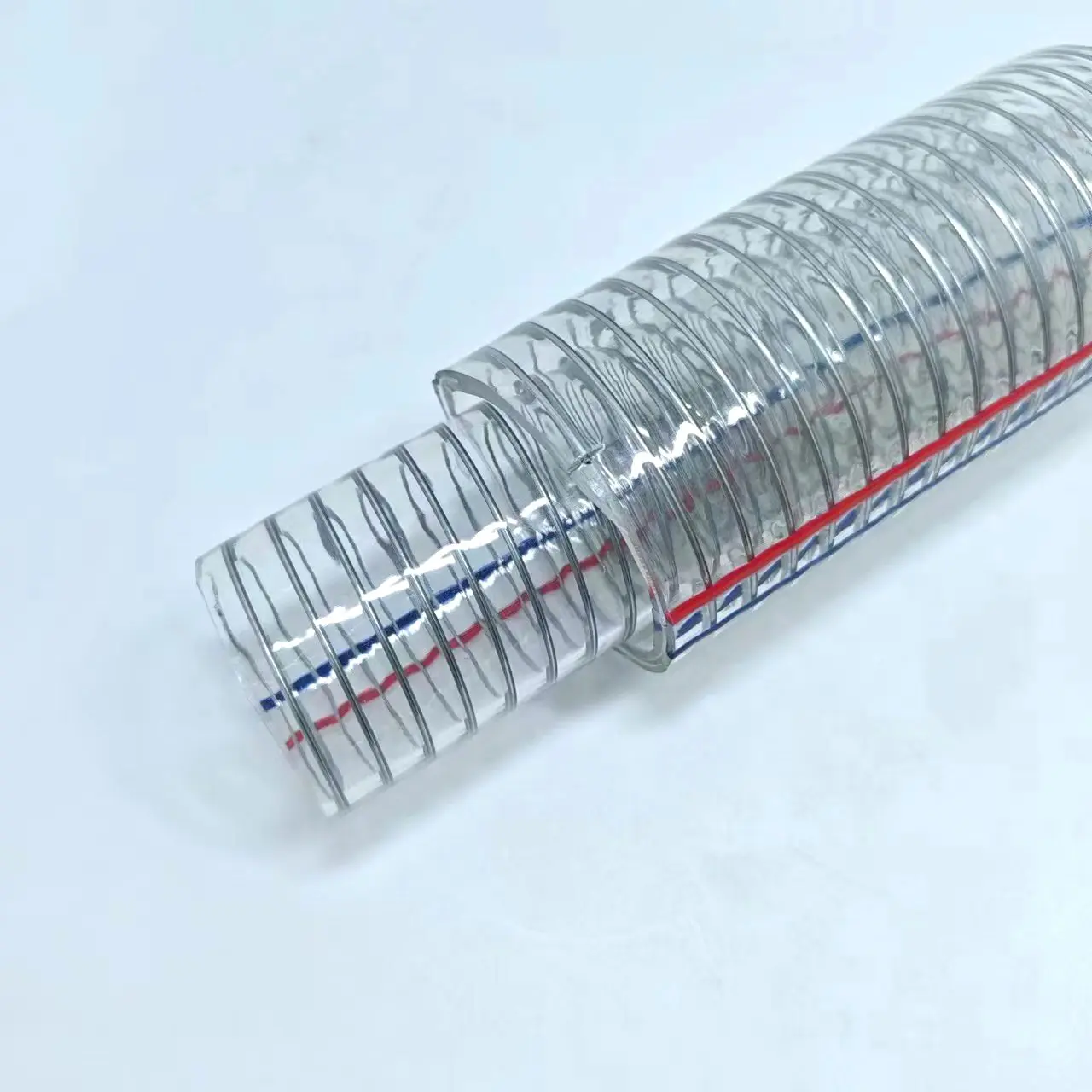

Aesthetic Appeal and Customization:

The anti-static PVC steel wire hose comes in various colors and can be customized according to the needs of different work areas, meeting both functional and aesthetic requirements.

Differences

The main difference between Anti-Static PVC Steel Wire Hose and ordinary PVC Steel Wire Hose lies in their anti-static performance. Specifically:

Anti-Static Performance:

Anti-Static PVC Steel Wire Hose: Through special formulation and process treatment, it has an extremely low surface resistivity, effectively dissipating static charges accumulated during production processes and preventing damage to the surrounding environment and products caused by electrostatic discharge. This is crucial for scenarios where electrostatic interference and damage need to be prevented, such as electronic production lines, medical device manufacturing, and other industries sensitive to static electricity.

Ordinary PVC Steel Wire Hose: It usually does not possess anti-static properties or has poor anti-static performance, unable to effectively dissipate static charges. It may generate electrostatic discharge in certain environments, causing damage to equipment and products.

Application Fields:

Anti-Static PVC Steel Wire Hose: Widely used in industries sensitive to static electricity.

Ordinary PVC Steel Wire Hose: Mainly used in general industrial fields, such as drainage, ventilation, and liquid transportation, where the requirement for anti-static performance is not high.

Other Performances:

In addition to anti-static performance, both types of hoses may be similar in terms of durability, corrosion resistance, chemical stability, and flame retardant properties, but specific performances depend on their respective formulations and process treatments.

Storage Methods

I. Storage Environment

Avoid Direct Sunlight:

PVC steel wire hose should be stored in a place that avoids direct sunlight, as prolonged exposure to ultraviolet rays can cause material aging, affecting the performance of the hose.

Keep Dry and Ventilated:

The storage environment should be kept dry and ventilated to prevent moisture and mildew. A humid environment can lead to the growth of bacteria or mold on the inner wall of the hose, while also affecting its flexibility and durability.

Keep Away from Heat Sources:

The hose should be kept away from fire sources and high-temperature areas to prevent deformation or damage. High temperatures can soften the PVC material, causing the hose to lose its original shape and strength.

II. Storage Methods

Coil Storage:

For longer PVC steel wire hoses, it is recommended to store them coiled to save space. However, the diameter of the coil should not be too small to avoid damage from excessive bending. At the same time, ensure that the coils are neat and avoid mutual squeezing of the hoses.

Avoid Heavy Pressure:

The hose should be protected from being crushed by heavy objects during storage to prevent deformation or damage. Special hose racks or shelves can be used for storage to ensure that the hose maintains its original shape and strength.

Prevent Chemical Corrosion:

Avoid contact with acids, alkalis, and other chemical substances during storage to prevent corrosion of the hose. If the hose needs to be stored with other items, ensure that these items will not cause chemical corrosion to the hose.

III. Regular Inspection and Maintenance

Regular Inspection:

Regularly inspect the stored PVC steel wire hose to check for any damage, aging, or deformation. If any issues are found, they should be addressed or the hose should be replaced promptly.

Cleaning and Maintenance:

Before storage, the hose should be cleaned and maintained to remove surface dirt and impurities. This helps maintain the cleanliness and appearance of the hose while also extending its service life.

Uncompromising Quality, Backed by Expertise

At Qingdao Renato Plastic Co., Ltd., we don’t just manufacture hoses; we engineer solutions. With 15+ years of industry expertise, 10 state-of-the-art workshops, and a team of 120+ skilled professionals, we bring cutting-edge technology to industrial hose production. Our commitment to quality assurance, customer satisfaction, and continuous innovation ensures that every hose meets the highest standards before reaching your hands.

Contact Us

Renatoflex Factory is your trusted partner for high-quality lay flat discharge hoses. For more information on our products and services, visit our website or contact our customer service team. We are always ready to help you with your fluid transfer needs.

820 Buliding C Qingdao Plaza, No.379 Dunhua Road, Qingdao 266034 China.