Product Overview

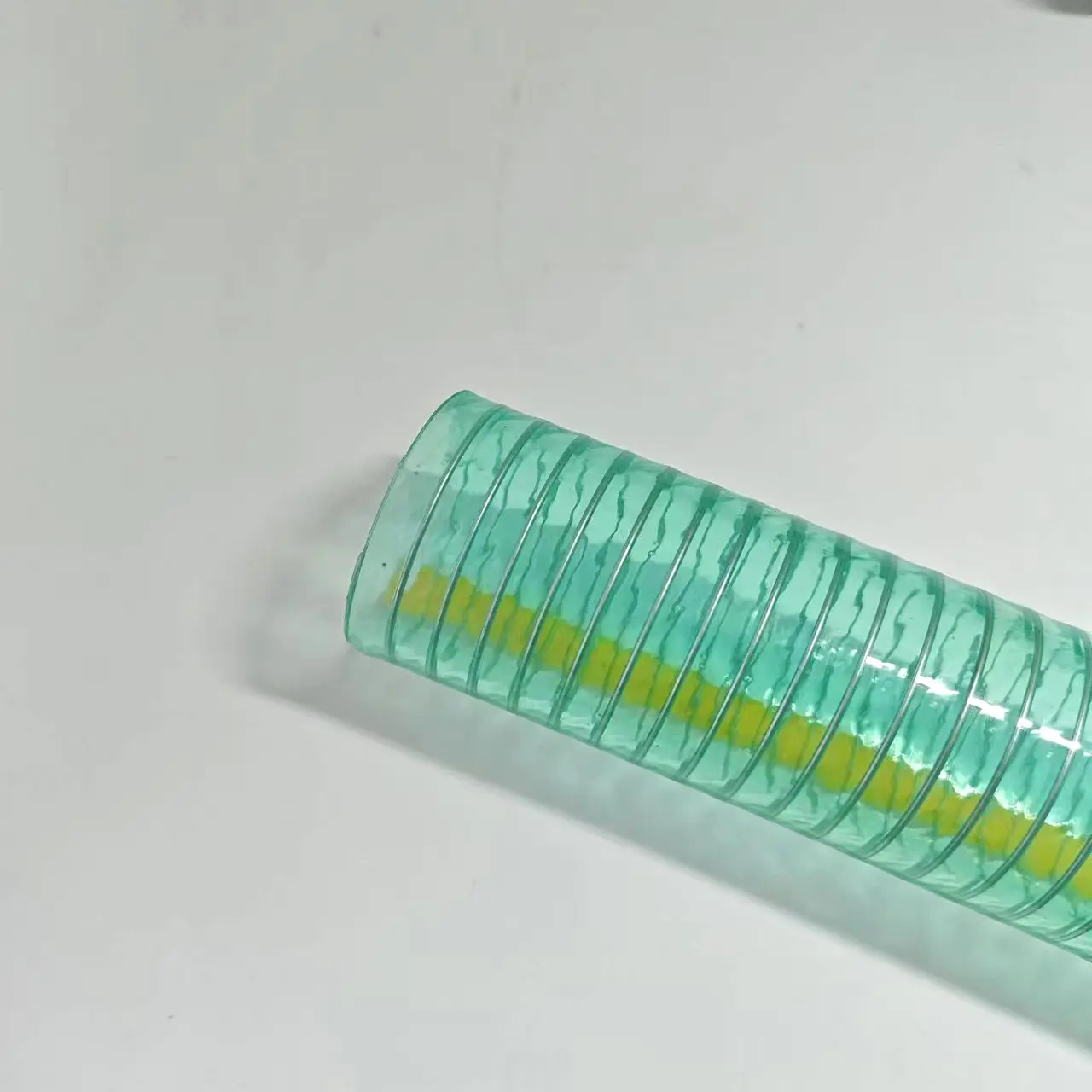

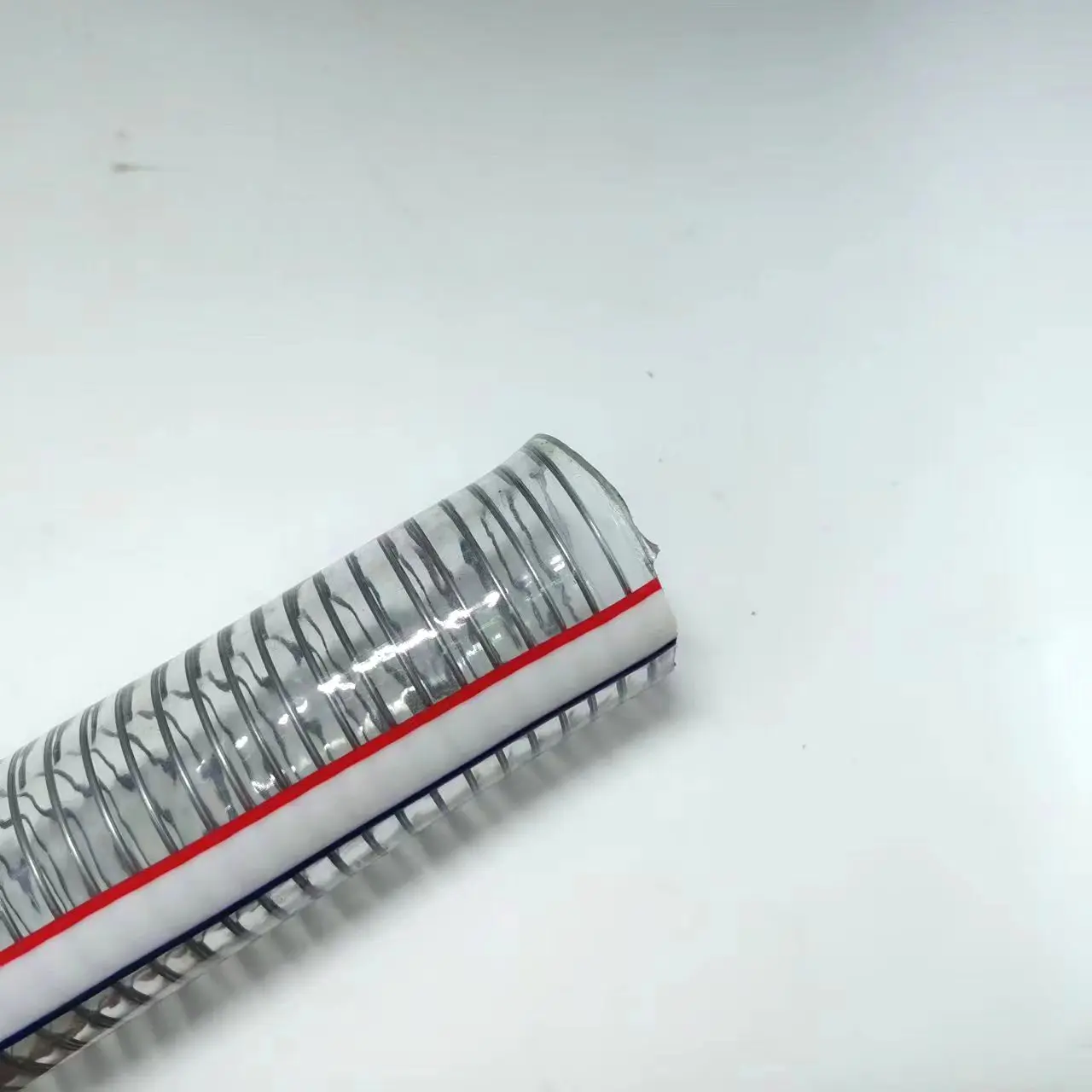

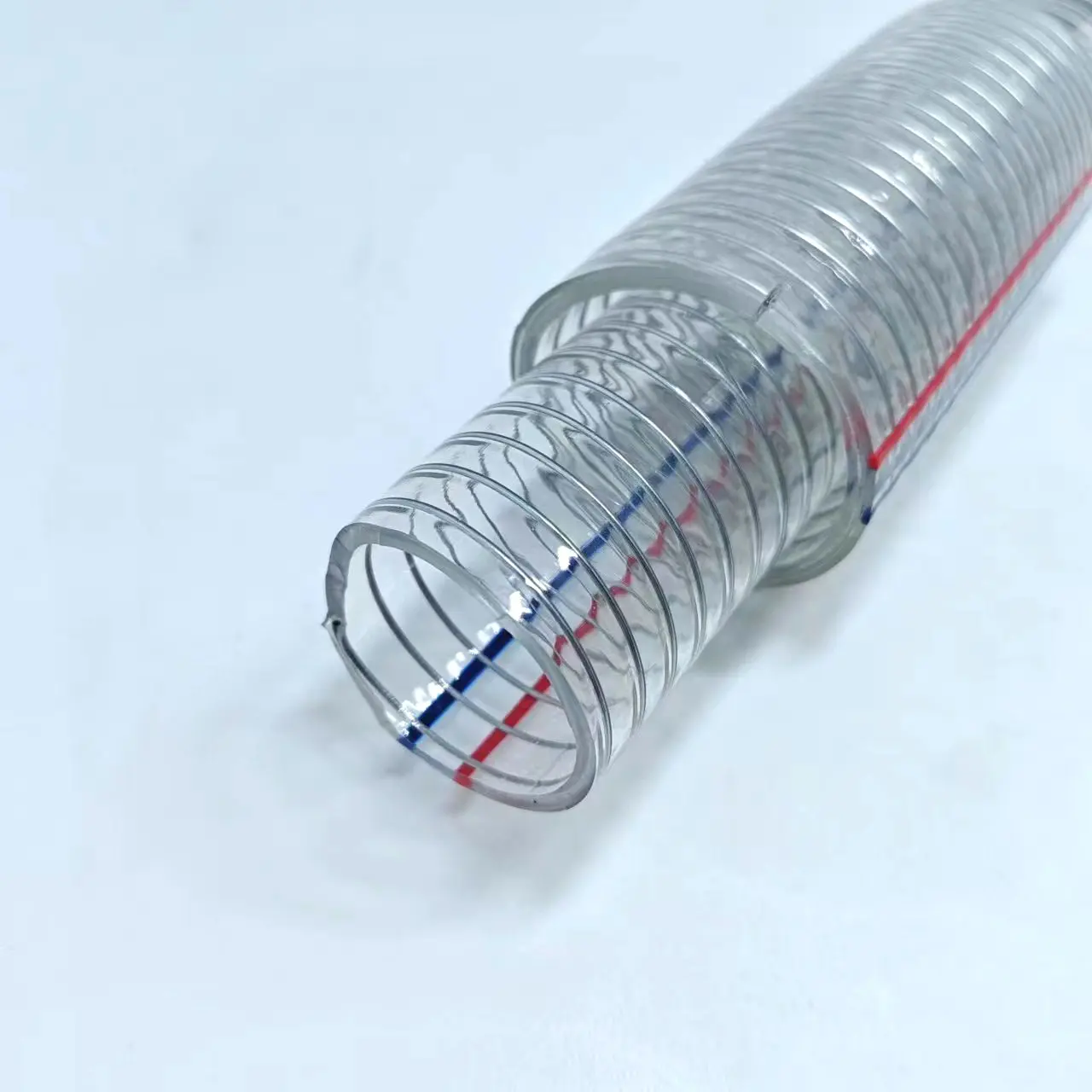

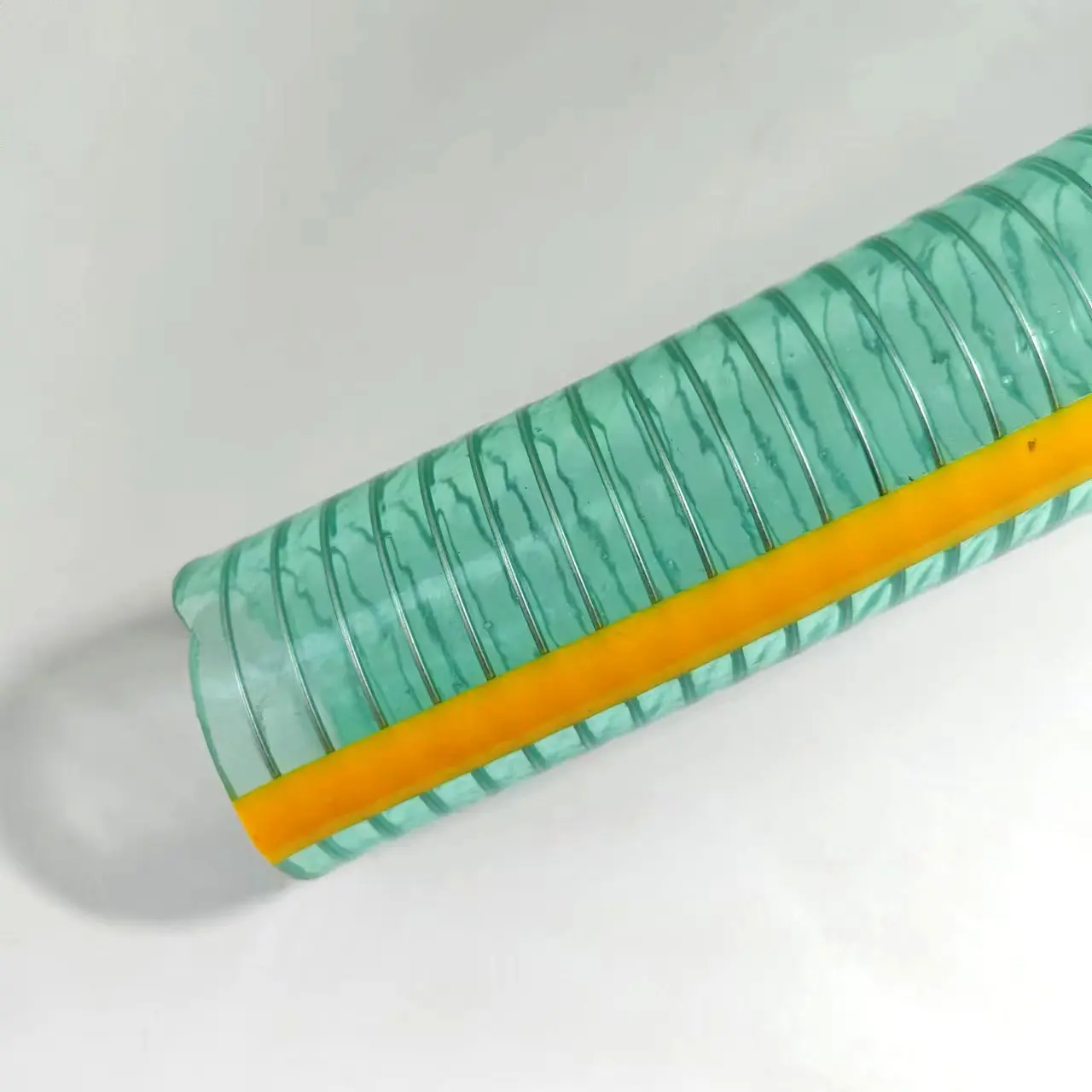

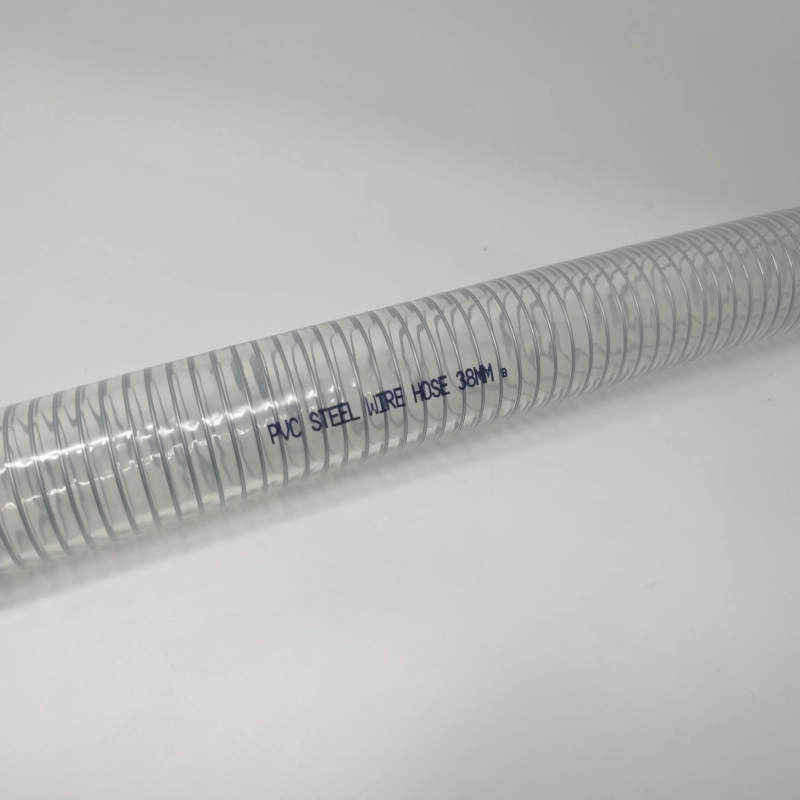

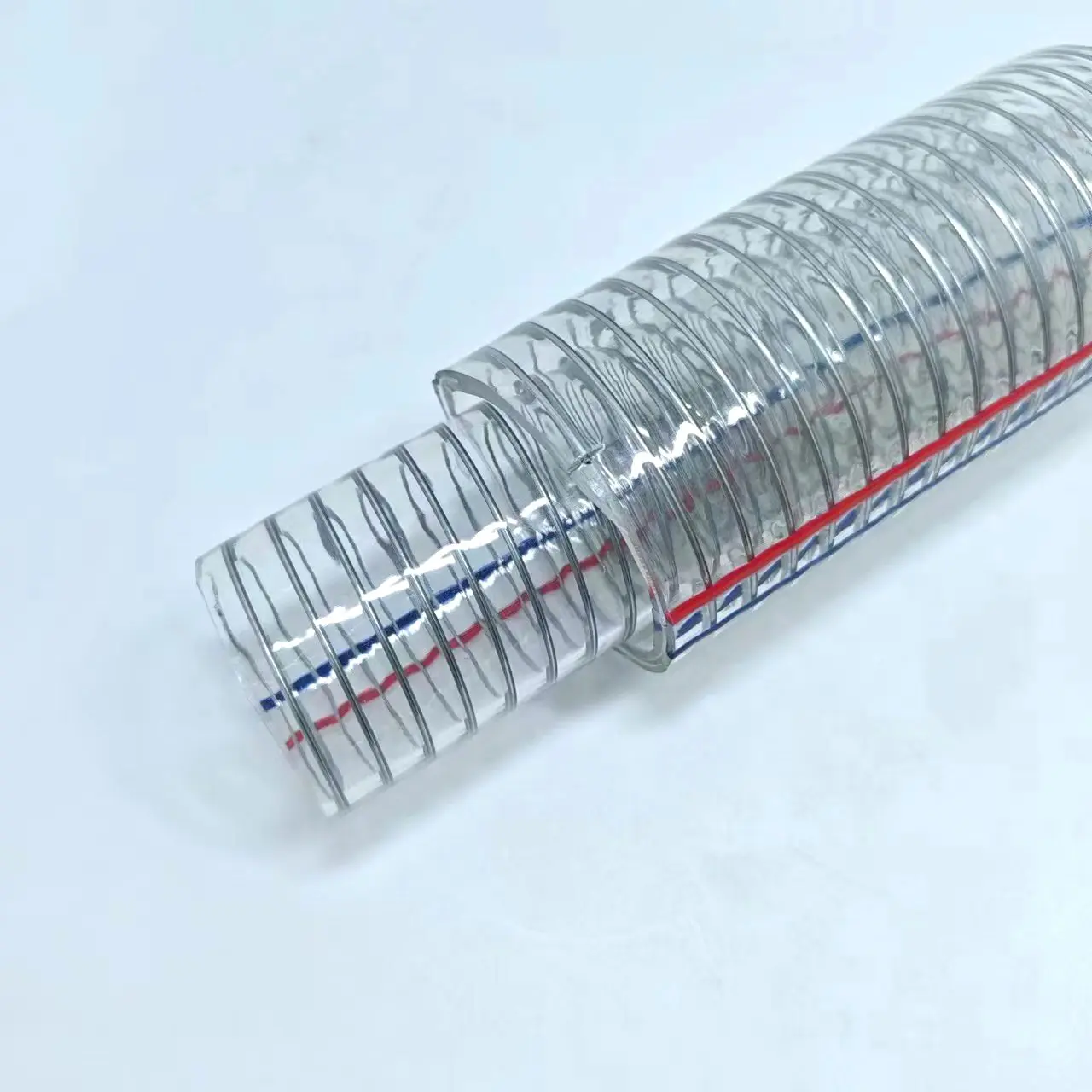

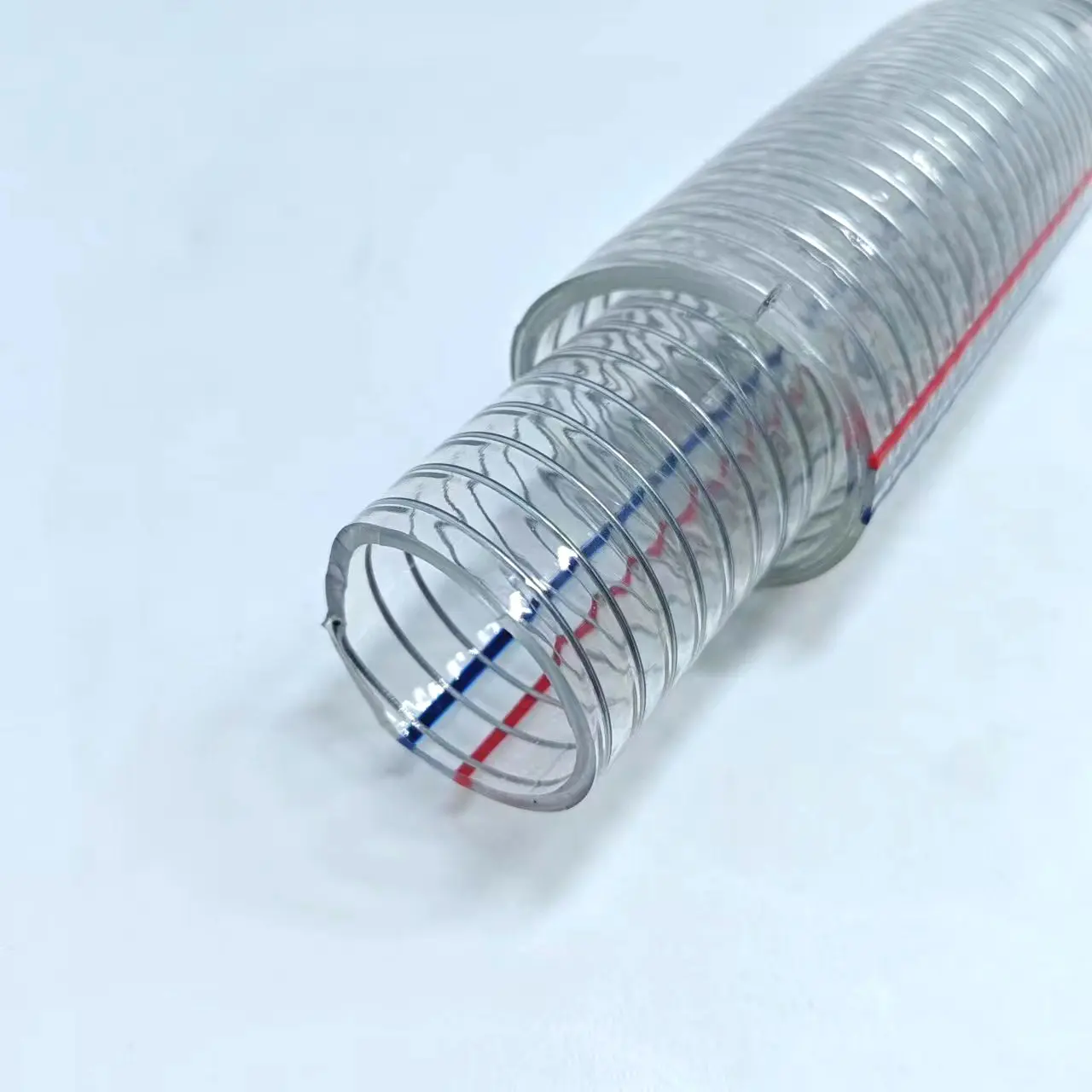

PVC steel wire reinforced hose is an industrial hose made of polyvinyl chloride material with an integrated steel wire spiral structure, primarily used for conveying various liquids and gases. Compared to standard PVC hoses, its unique steel wire reinforcement provides superior shape retention, making it particularly suitable for suction applications requiring negative pressure resistance.

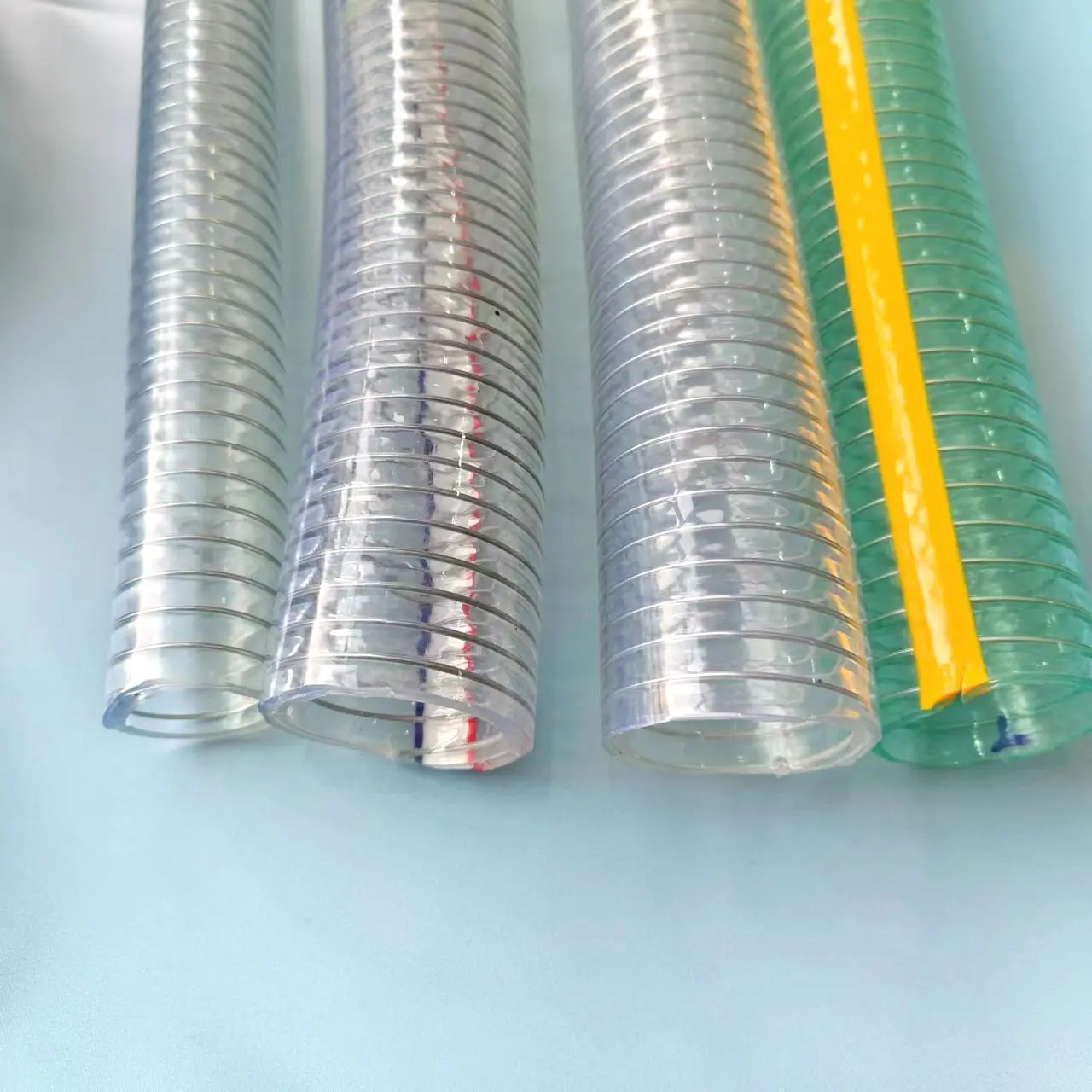

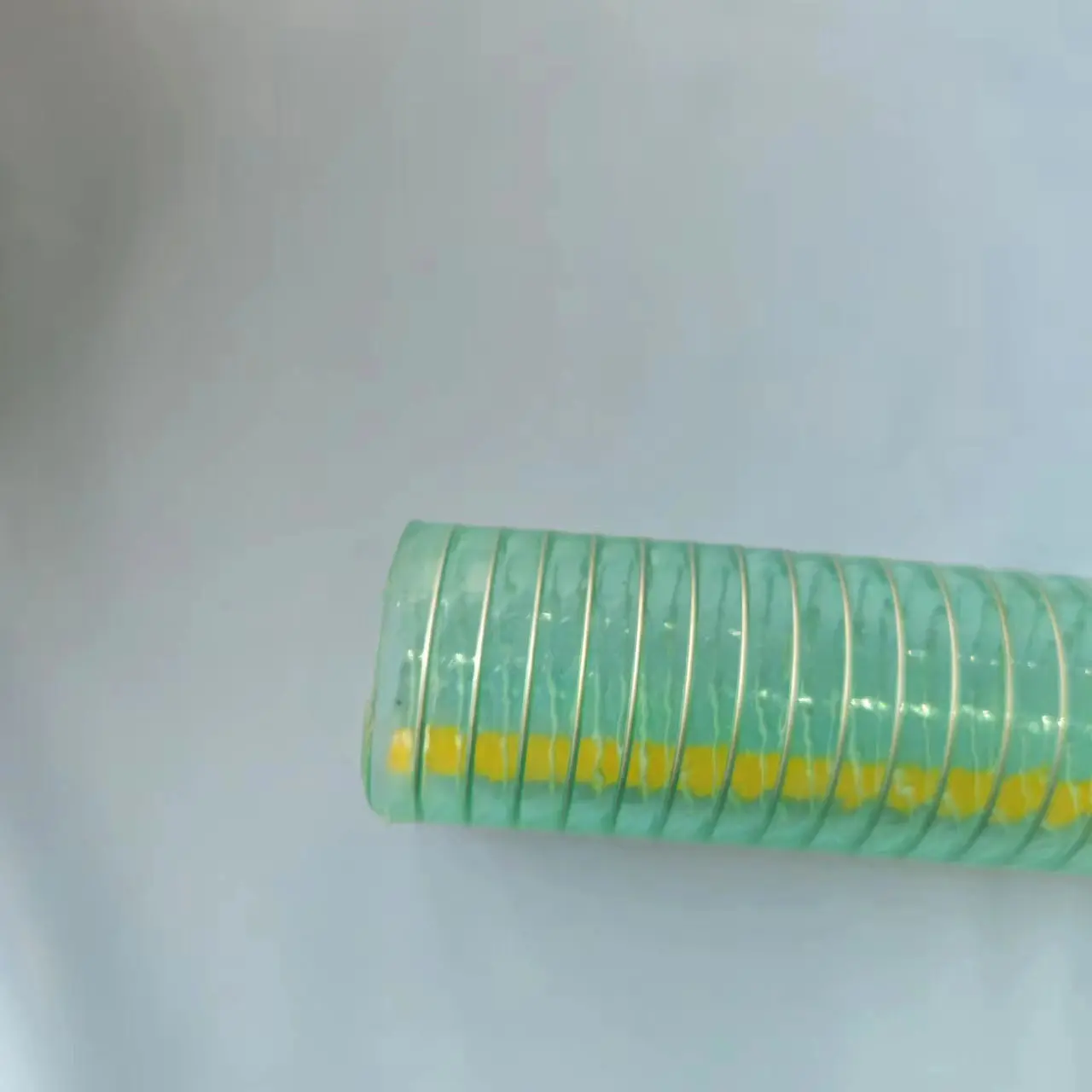

This hose demonstrates stable physical properties at ambient temperatures, typically featuring a smooth inner layer to reduce fluid resistance. Standard products usually come in light gray or transparent colors, with some models incorporating UV inhibitors for outdoor use. It's important to note that while the steel wire reinforcement enhances mechanical strength, excessive bending or crushing may still cause permanent damage.

Key Product Features

(1) Deformation Resistance

The embedded steel wire skeleton effectively prevents hose collapse during use, maintaining an unobstructed flow channel even under negative pressure conditions.

(2) Environmental Adaptability

Standard models are suitable for operating temperatures between -10°C to 60°C, with special formulations available for extended temperature ranges.

(3) Medium Compatibility

Suitable for conveying water, air, and neutral liquids, with certain resistance to oily substances.

(4) Ease of Use

The hose can be cut to required lengths, with standard connection designs for quick attachment to industrial equipment.

(5) Surface Treatment

Most products feature anti-static treatment, with some models adding wear-resistant outer layers for extended service life when dragged on surfaces.

Typical Application Fields

| Industry | Application Scenarios | Usage Characteristics |

|---|---|---|

| Industrial Production | Cooling water circulation, compressed air delivery | Medium/short distance fixed piping |

| Construction | Concrete pumping, site drainage | Temporary piping systems requiring frequent relocation |

| Agricultural Irrigation | Water pump systems, sprinkler irrigation | UV resistance requirements for outdoor environments |

| Municipal Sanitation | Road cleaning, landscaping | Reinforced design for crush resistance |

| Warehousing & Logistics | Pneumatic conveying of granular materials | Special conductive requirements for explosion-proof applications |

Selection Considerations

When choosing PVC steel wire reinforced hose, focus on actual working condition requirements. For fixed installations, standard models with uniform wall thickness are recommended, while mobile applications require attention to kink resistance.

Medium temperature is a critical parameter - basic models suffice for cold water delivery, while hot fluid transfer requires confirmation of temperature ratings. Regarding connections, flange fittings suit high-pressure systems, while quick-connect couplings better serve environments requiring frequent assembly/disassembly.

Important reminder: Food-grade applications require products with proper hygiene certifications, as standard industrial hoses may contain additives non-compliant with food safety standards.

Maintenance Guidelines

Routine use should prevent steel wire exposure leading to oxidation. For storage, hanging or flat placement is recommended, as long-term coiled storage may cause permanent deformation.

Clean with low-pressure water flow - avoid strong acid/alkaline cleaners. Surface cracks or exposed wires indicate immediate replacement needs to prevent bursting risks. For seasonal use, completely drain residual liquid before storage.

Common Issues & Solutions

Connection Leaks: Mostly from aged seals or loose clamps - replace corresponding components for repair.

Reduced Flow Efficiency: Potentially caused by interior deposits or deformed steel wires reducing diameter - requires professional cleaning or replacement.

Winter Stiffness: Characteristic of PVC material in cold - restore flexibility by gradual warming (avoid forced bending to prevent cracks).

With proper selection and standardized use, PVC steel wire reinforced hose can deliver reliable performance across industrial applications. Quarterly comprehensive inspections are recommended, with timely replacement of aged components to ensure operational safety.