You've probably used dozens of hoses, some cheap, some expensive, and everything in between. If you've tried the Steel Wire UV Resistant Water Hose, you'll likely be pleasantly surprised: It won't turn brittle in the harsh midday sun like many other hoses. It's a durable PVC water hose.

Product Overview

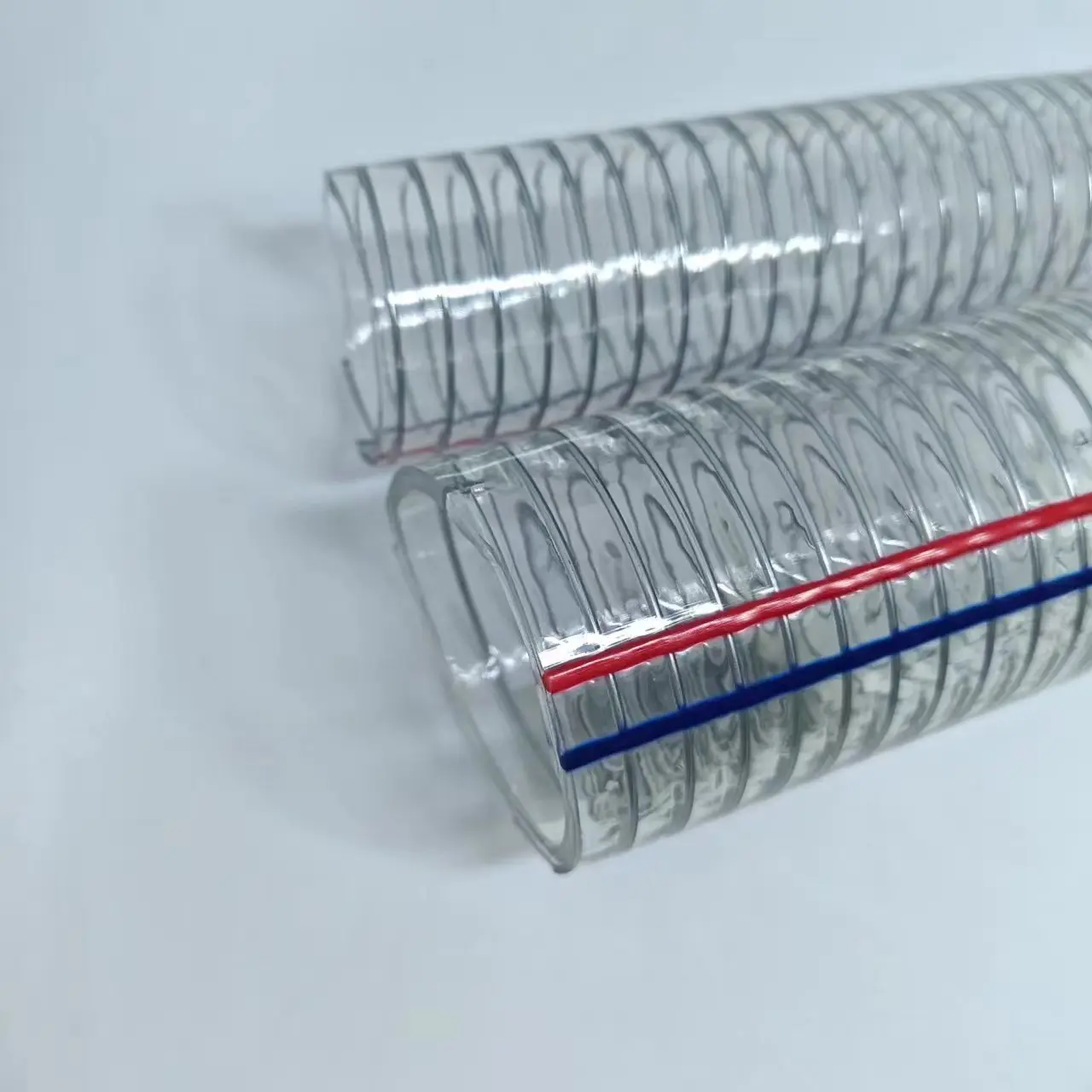

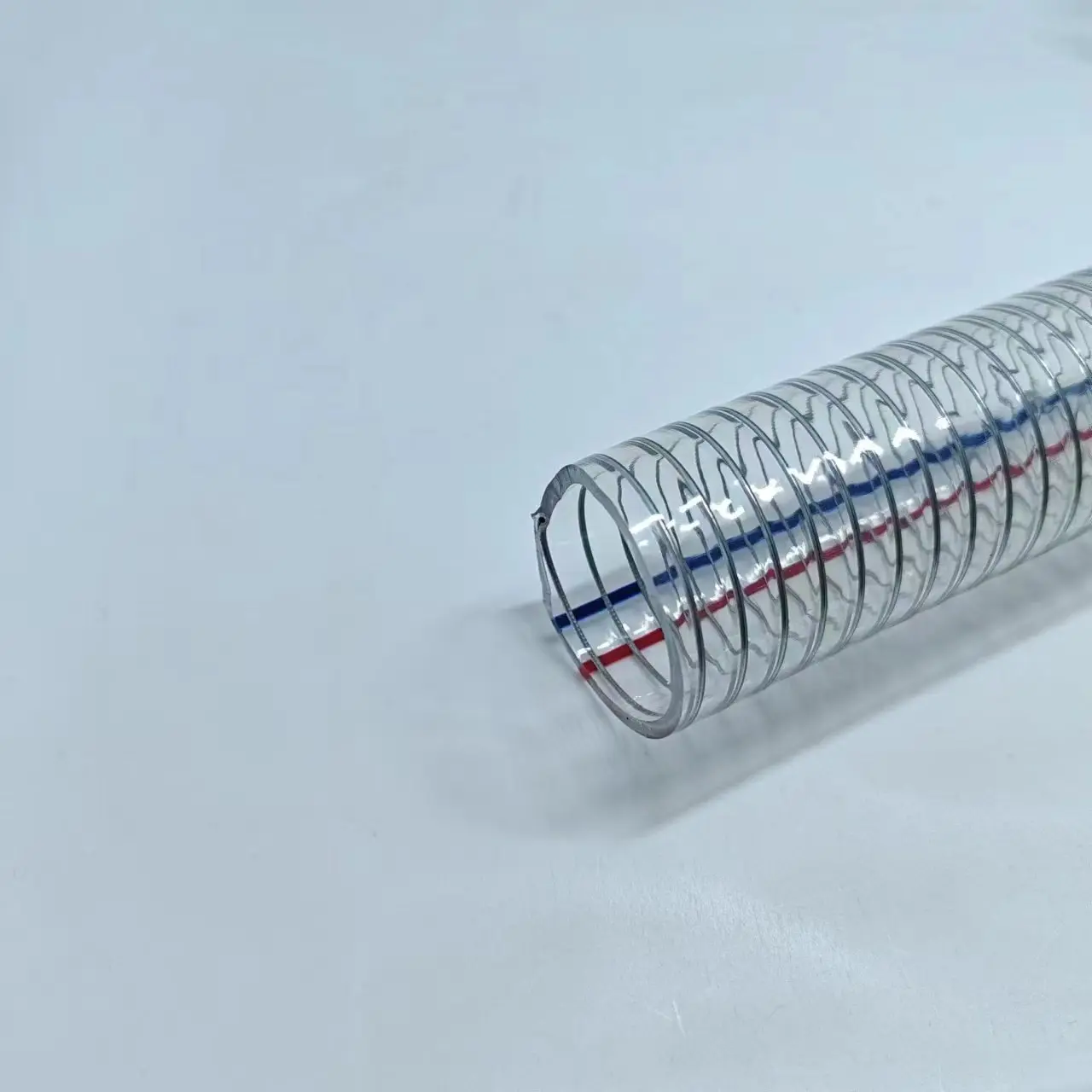

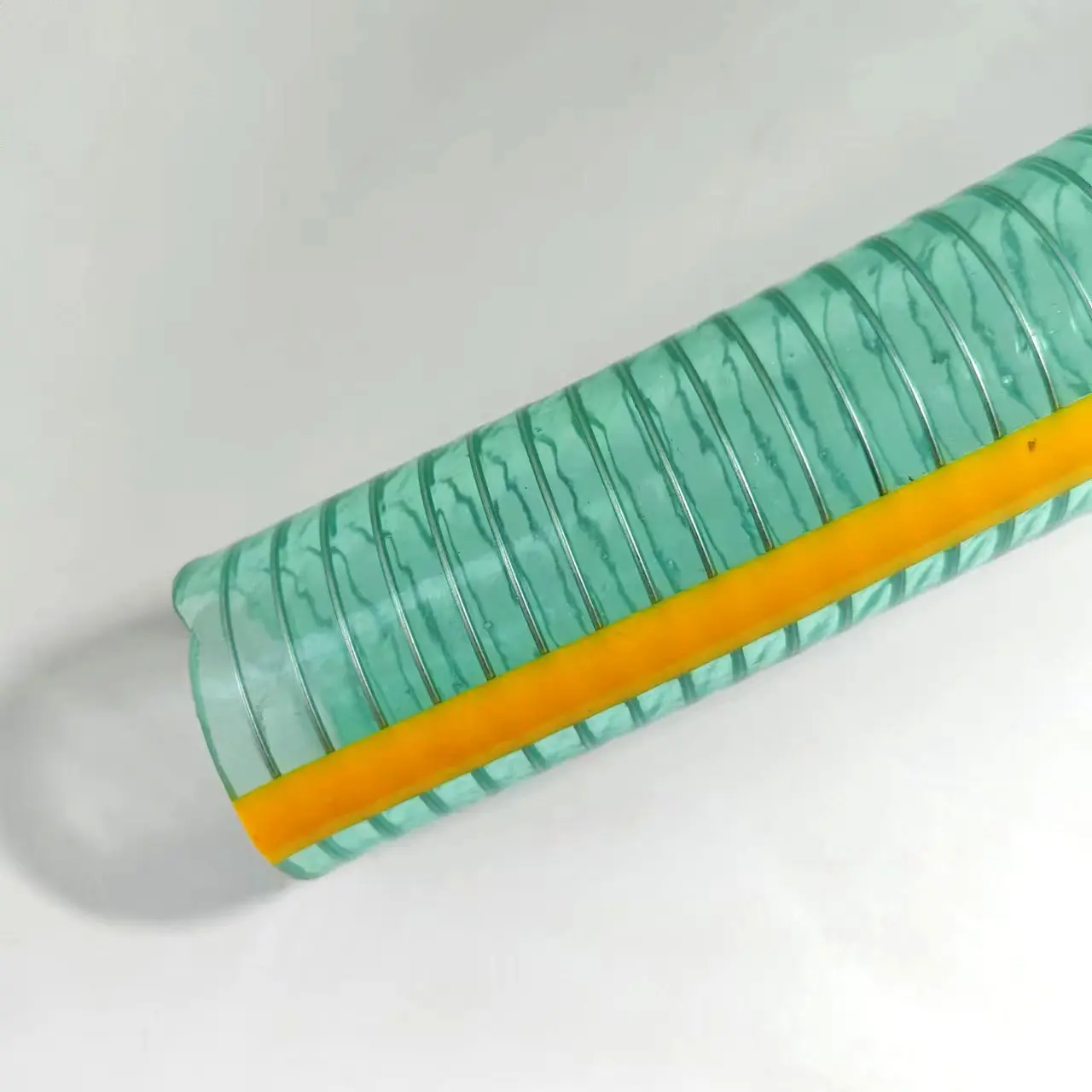

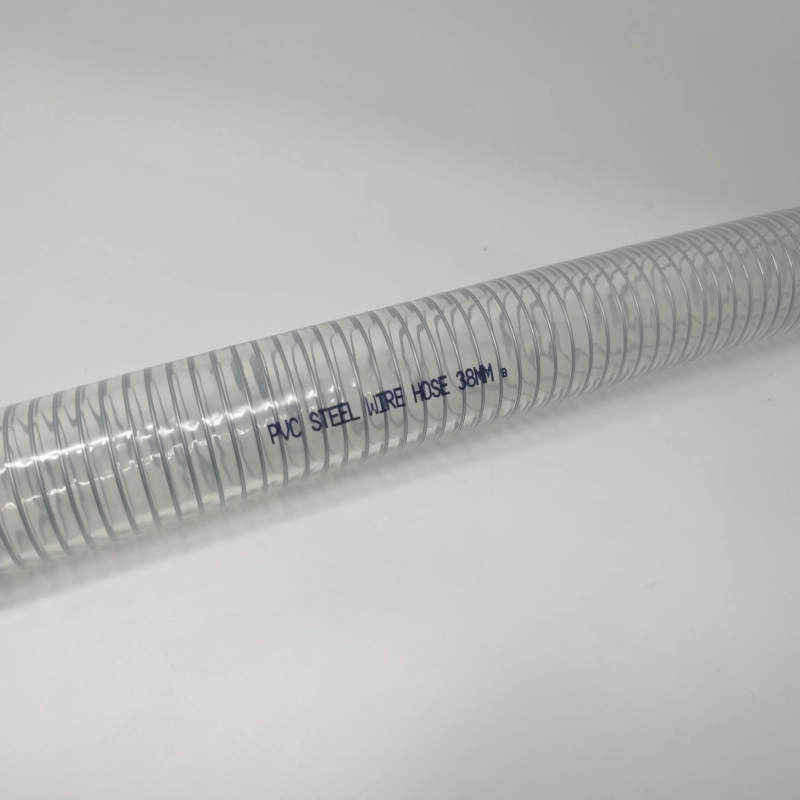

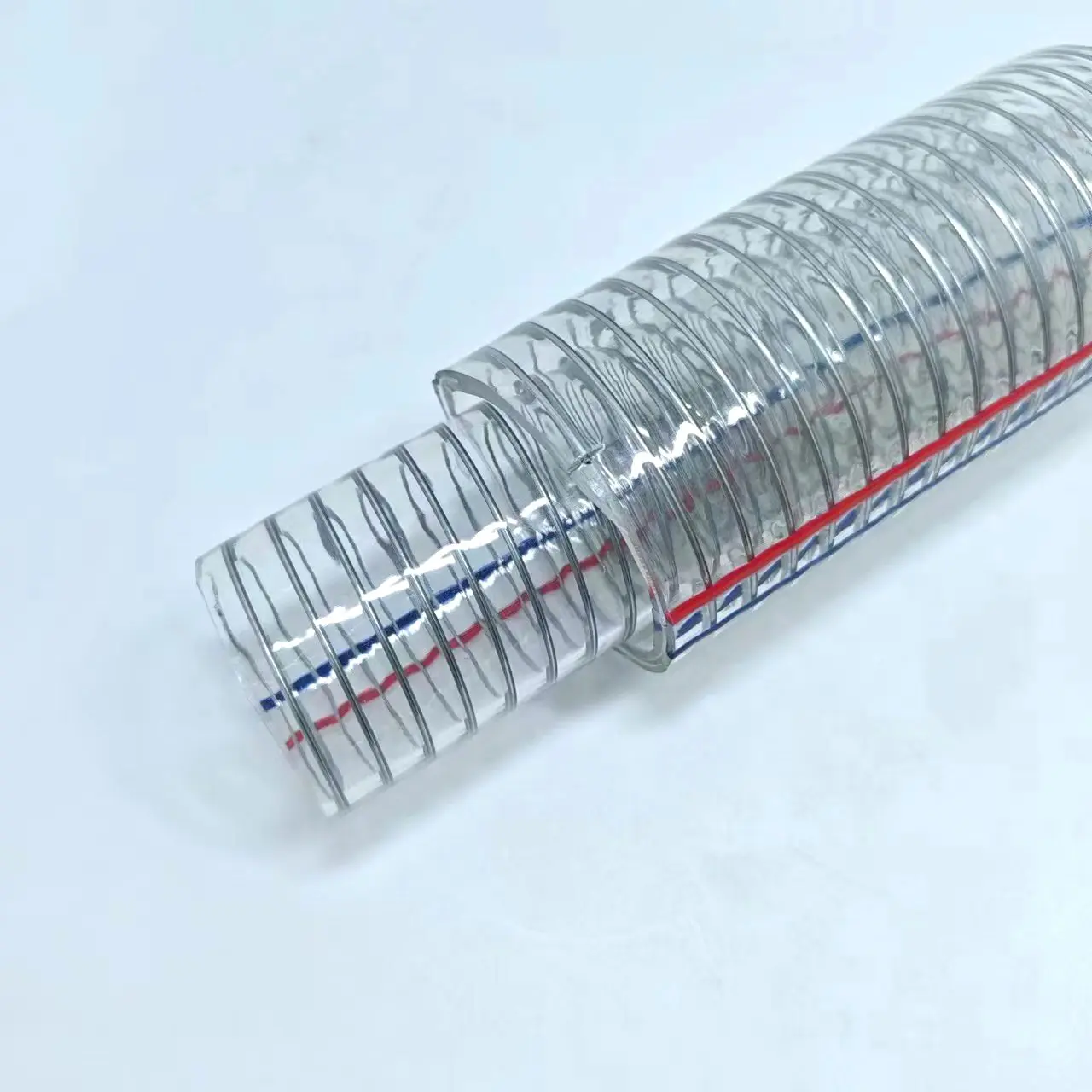

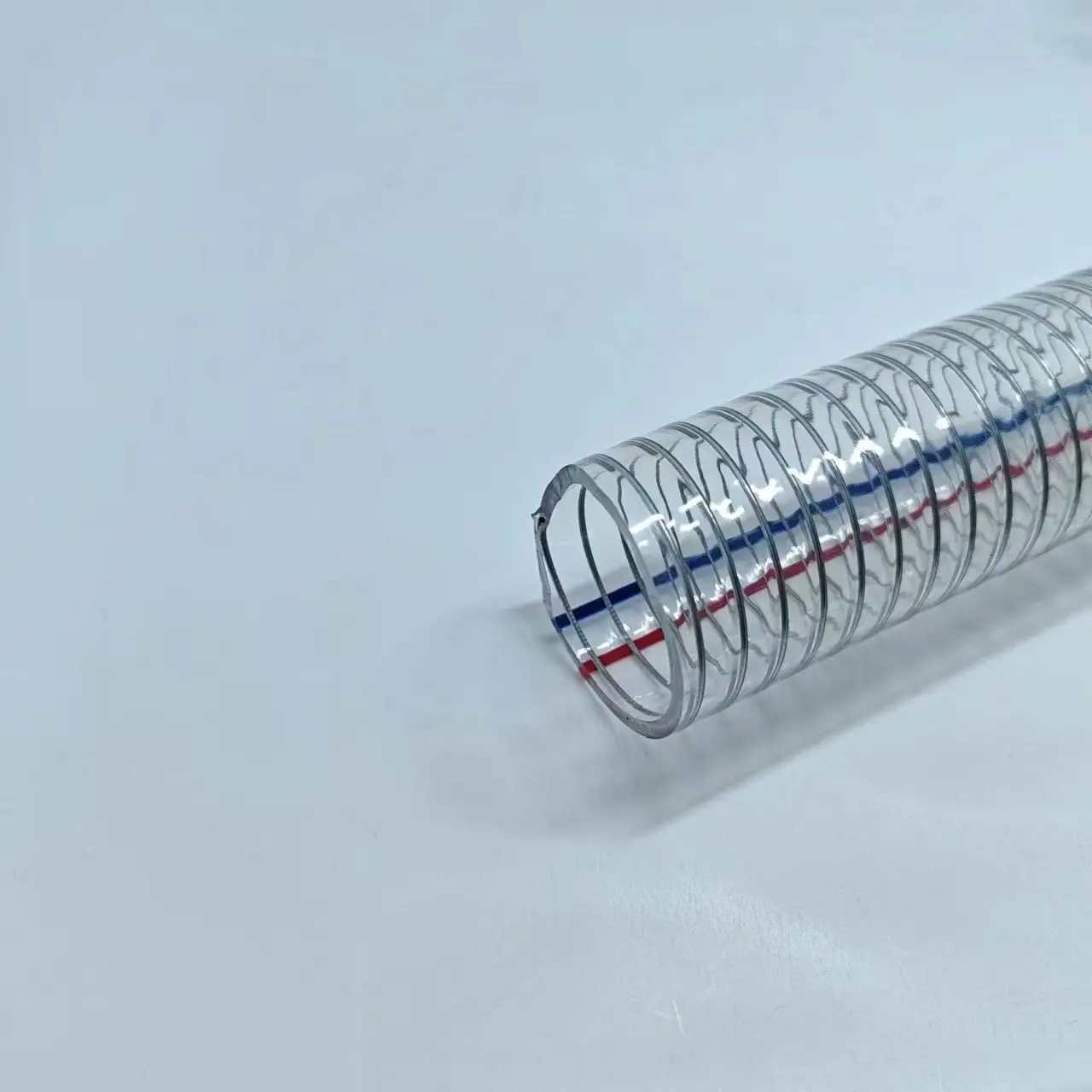

PVC Steel Wire Hose is a flexible hose composed of a high-strength PVC inner layer and a spiral steel wire reinforcement layer, primarily used for transporting water, air, and other non-corrosive fluids. Its design balances flexibility and pressure resistance, making it suitable for medium- to low-pressure applications in industries such as manufacturing, agriculture, and construction.

Key Features:

◇ Structural Stability: The smooth PVC inner layer reduces fluid resistance, while the outer spiral steel wire prevents collapse or deformation.

◇ Lightweight and Durable: Lighter than metal hoses, making it easier to handle and install, while maintaining good pressure resistance.

◇ Compatible Media: Suitable for non-corrosive substances like water, air, and dust.

Notes:

Recommended operating temperature ranges from -10°C to +60°C. Avoid extreme environments.

Prolonged exposure to UV rays may accelerate outer layer degradation. For outdoor use, opt for UV-resistant models.

Structure and Material Composition

The durability of PVC Steel Wire Hose stems from its layered design, combining different materials for stable performance:

| Layer | Material | Function |

| Inner Layer | Food-grade PVC (optional) | Smooth interior to prevent residue buildup and clogging |

| Reinforcement | High-carbon steel wire spiral | Provides pressure resistance and prevents twisting |

| Outer Layer | Wear-resistant PVC | Protects the steel wire layer, extending lifespan |

Material Properties (Bullet Points):

◇ PVC Inner Layer:

Complies with certain hygiene standards (e.g., requires specific certification for potable water transport).

Anti-adhesion design, suitable for fluids with small particles (e.g., slurry).

◇ Steel Wire Reinforcement:

Optimized wire spacing balances flexibility and pressure resistance.

High-carbon steel resists rust, but inspect regularly in humid environments.

◇ Outer Protection:

Some models include UV inhibitors for short-term outdoor use.

Surface can be printed with labels for easy identification.

Steel Wire UV Resistant Water Hose, a durable hose featuring a transparent body with embedded steel wires for strength and resistance to UV rays, suitable for various water - related applications.

Suitable Applications and Limitations

◇ Primary Use Cases:

Industrial Ventilation: Factory exhaust, dust collection (ensure no spark or static risks).

Agricultural Irrigation: Transporting water, fertilizer solutions (avoid contact with sharp tools).

Construction Drainage: Temporary drainage, concrete pumping (not for long-term burial).

◇ Not Recommended For:

Transporting fuels, or chemical solvents (may cause PVC swelling).

Prolonged exposure to high temperatures (e.g., steam pipelines).

High-pressure systems

Installation and Operation Guidelines

Key Steps and Recommendations (Bullet Points):

Pre-Installation Checks:

Inspect the hose for damage, exposed wires, or deformities.

Use properly sized fittings and clamps to prevent leaks.

Bending and Layout:

Minimum bending radius is 3x the hose diameter to avoid wire breakage.

In cold temperatures, flexibility decreases—adjust angles slowly.

Maintenance and Storage:

Clean residue (e.g., sediment) after use to prevent buildup.

Store coiled in a cool, dry place; avoid sharp folds.

Common Issues and Solutions

Q: Are minor surface cracks safe?

A: If cracks don’t penetrate the steel layer, temporary use is possible, but replace soon to prevent rupture.

A: Wire protrusion typically results from:

Mechanical damage: Impact from sharp objects or excessive bending.

Abrasion: Dragging over rough surfaces wears down the outer PVC.

Material fatigue: Long-term stress or UV degradation.

Solutions:

Immediately replace hoses with exposed wires to avoid injury or leaks.

For prevention:

Use protective sleeves in high-abrasion areas.

Avoid sharp bends near connectors.

Store properly to prevent crushing.

Minor surface abrasion without wire exposure may not affect functionality but should be monitored.

Q: Can PVC Steel Wire Hose be used for hot water transportation?

A: This hose is not designed for high-temperature fluids. Its standard operating range is -10°C to +60°C. While it may briefly tolerate warm water (e.g., below 60°C), prolonged exposure to hot water can soften the PVC layer, reducing pressure resistance. For hot water applications (e.g., above 60°C), consider thermoplastic or rubber hoses specifically rated for higher temperatures. Always check the manufacturer's temperature specifications before use.

Selection Guide and Specifications

| Diameter (Inches) | Recommended Use |

| 1/2" - 1" | Household vacuums, small drains |

| 1.5" - 3" | Agricultural irrigation, industrial ventilation |

| 4" - 8" | Construction drainage, large suction |

Selection Tips:

For particle-laden fluids, choose models with thickened inner layers.

Outdoor use: Prioritize UV-resistant outer layers or provide shade protection.

Why Choose QINGDAO RENATO PLASTIC CO., LTD?

We’re not just a factory pushing products. At QINGDAO RENATO PLASTIC CO., LTD, we’re hose people—through and through. With over 15 years in the industry, we’ve mastered the art of PVC hose manufacturing and built a reputation for dependability in more than 60 countries.

Here's what sets us apart:

Large-Scale Production: With 10 workshops, 60+ production lines, and a strong team of 120 skilled workers, we meet large-volume needs without sacrificing quality.

Tailored Assemblies: From Camlock to Storz fittings, hose clamps, nozzles—our range of custom assemblies makes your work seamless.

Rapid Response: We’re serious when we say 7x24 customer service. When you contact us, we reply fast—because your time is valuable.

Two QC Teams, Zero Tolerance for Flaws: Every hose, every fitting, every length is inspected. No compromise.

Customer First Philosophy: We listen, adapt, and deliver based on your unique requirements—because that’s what true partnerships are built on.

Welcome to contact us to get Steel Wire UV Resistant Water Hose!