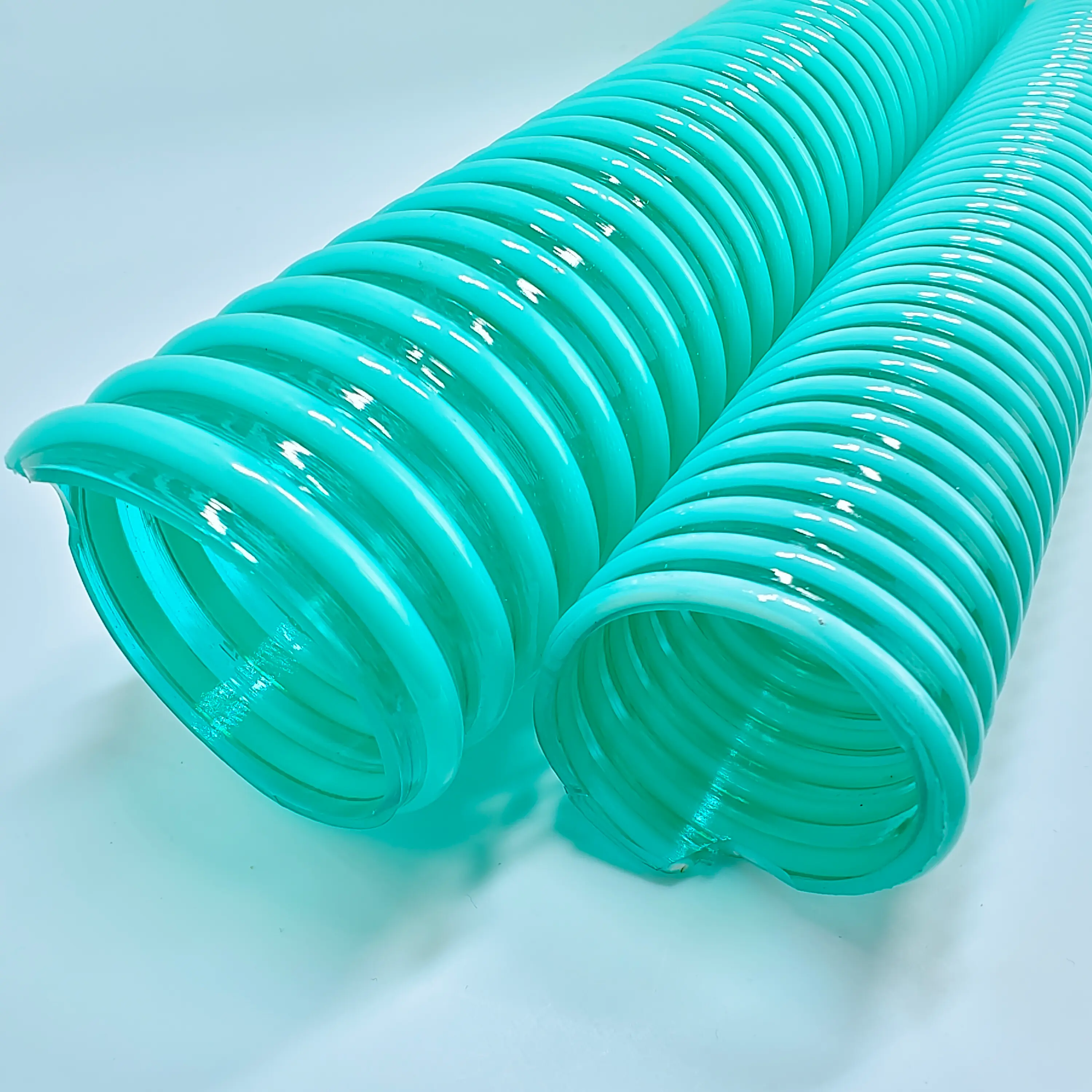

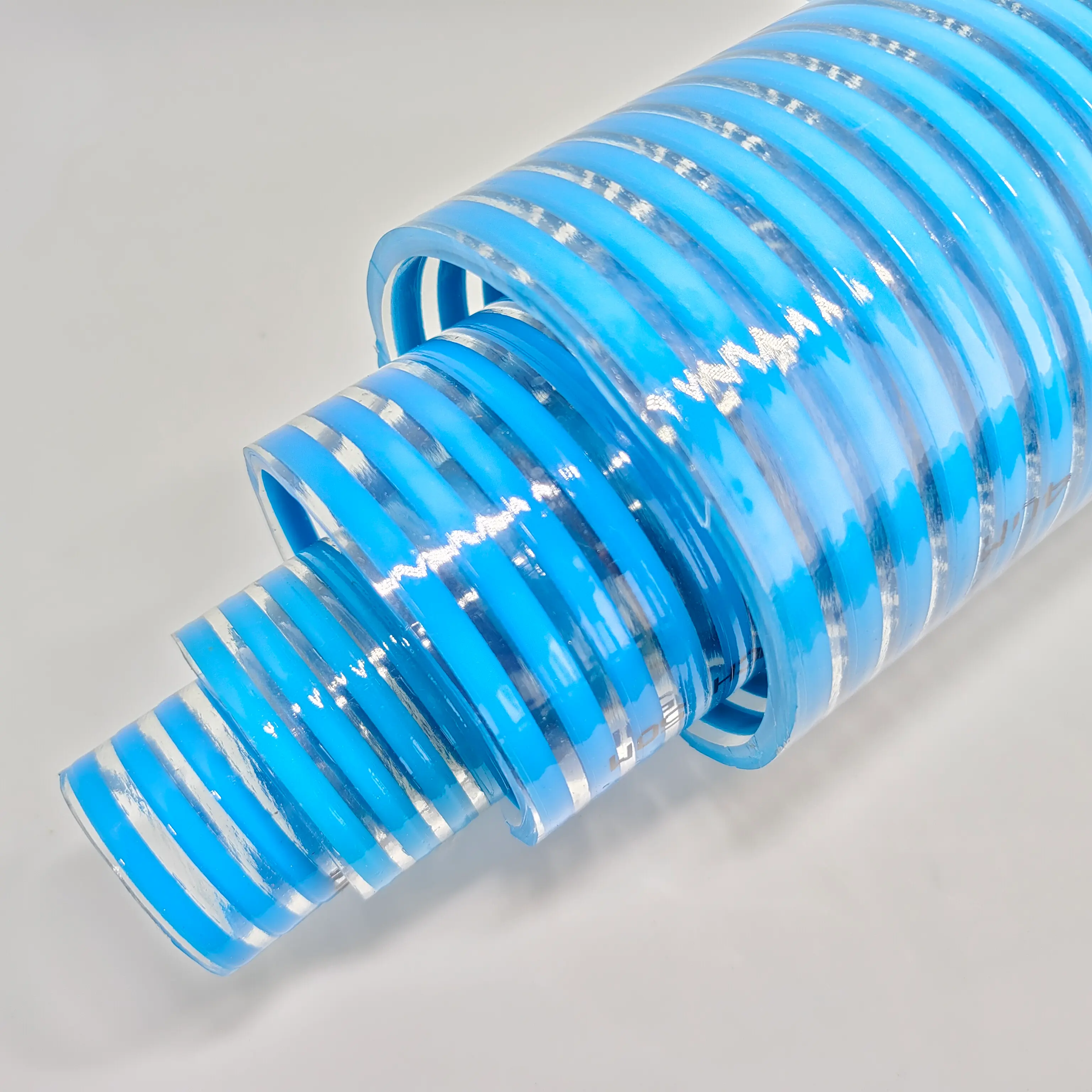

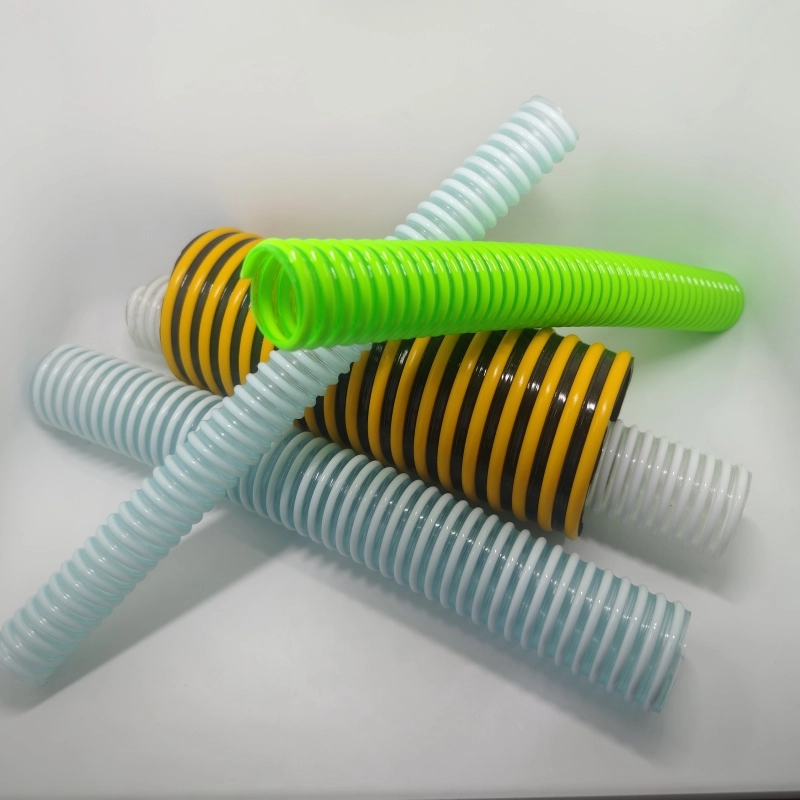

PVC Corrugated Suction Dust Collector Hose

Looking for a durable and flexible solution for industrial dust collection and debris removal? Qingdao Renato Plastic Co., Ltd. presents the PVC Corrugated Suction Dust Collector Hose, designed to offer outstanding efficiency in managing dust and debris in various environments. Whether it's industrial cleaning, workshops, construction sites, or household tasks, this hose is engineered to provide superior performance and reliability, making it an essential tool for dust collection systems.

Specifications

Here is a typical specifications table for a PVC Corrugated Suction Dust Collector Hose:

| Specification | Details |

|---|---|

| Material | PVC with reinforced rigid PVC helix |

| Inner Diameter | 25mm (1") to 305mm (12") |

| Wall Thickness | 1.5mm - 3.0mm (depending on diameter) |

| Length | Customizable (Standard lengths: 10m, 15m, 30m) |

| Working Temperature | -10°C to +60°C |

| Color | Transparent with optional color helix |

| Vacuum Rating | 10 - 28 inHg (depending on size) |

| Bending Radius | 4 to 30 inches (depending on diameter) |

| Pressure Rating | 10 psi to 60 psi |

| Reinforcement | Rigid PVC spiral helix |

| Weight | Light to medium weight (varies with size) |

| Application | Dust collection, suction of light materials, industrial vacuum systems |

| Surface | Corrugated for flexibility and crush resistance |

| Resistance | Abrasion, chemical, and moisture resistance |

Let me know if you'd like to adjust any details based on specific requirements!

Characteristics

Material Properties:

PVC (Polyvinyl Chloride) is a widely utilized thermoplastic material known for its excellent physical and chemical properties. The PVC suction hose, being made from PVC, inherits many of these advantages.

Corrosion Resistance:

The PVC suction hose exhibits excellent resistance to a wide range of chemicals, including inorganic acids, alkalis, salts, and more. This makes it particularly suitable for applications involving corrosive liquids, such as in the chemical, electroplating, and textile printing industries.

Abrasion Resistance:

Although PVC material has a relatively low hardness, specially treated PVC suction hoses can withstand a certain degree of abrasion, making them suitable for situations requiring frequent movement or friction.

Lightweight and Easy Installation:

Compared to traditional metal piping, PVC suction hoses are significantly lighter and more flexible, facilitating easier handling and installation. Additionally, PVC suction hoses offer diverse connection methods, including gluing, flanging, etc., enhancing installation efficiency.

Water Resistance:

PVC suction hoses possess good water resistance, enabling their long-term use in damp or underwater environments. This makes them ideal for applications in water conservancy projects, sewage treatment, and other related fields.

Temperature Adaptability:

PVC suction hoses have a relatively wide operating temperature range. However, it's important to note that PVC material may soften under high temperatures and become harder and more brittle under low temperatures. Therefore, selecting the appropriate PVC piping type based on specific environmental conditions is crucial.

Environmental Friendliness:

PVC material is relatively environmentally friendly during production and use, and PVC suction hoses are recyclable. This aligns with sustainable development principles.

Cost-Effectiveness:

Due to the relatively low cost of PVC material and the low processing and installation costs associated with PVC suction hoses, they offer a cost-effective solution.

It's worth noting that while PVC suction hoses possess many advantages, other piping materials may be more suitable for specific applications, such as those involving high temperatures, high pressures, or extreme corrosivity. Furthermore, proper maintenance and care of PVC suction hoses are essential to prolong their lifespan and prevent safety incidents.

Applications

1. Industrial Sector

Fluid Transfer: PVC Suction Hose is commonly used for transferring fluids such as water, oil, and chemical liquids in industrial settings due to its lightweight, transparency, negative pressure resistance, and excellent weather resistance.

Sewage and Drainage: In sewage and drainage systems, PVC Suction Hose effectively conveys wastewater and sewage due to its corrosion resistance and weather resistance.

Other Industrial Applications: It is also utilized in industrial piping systems, cooling systems, irrigation systems, and as connecting pipes for industrial equipment.

2. Agricultural Sector

Irrigation Systems: PVC Suction Hose plays a crucial role in agricultural irrigation systems, efficiently and stably transporting irrigation water.

Waterlogging and Drainage: During farmland drainage and waterlogging control, PVC Suction Hose ensures smooth operation of the drainage system due to its weather and corrosion resistance.

3. Construction Industry

Building Drainage: In the construction industry, PVC Suction Hose is used for building drainage systems, such as in basements and bathrooms.

Other Construction Applications: It can also be found in building ventilation systems, air conditioning systems, serving as connecting or transfer pipes.

4. Household and Lifestyle

Household Drainage: In residential settings, PVC Suction Hose is used for drainage pipes in appliances like washing machines and dishwashers.

Gardening and Aquaculture: For gardening and aquaculture, PVC Suction Hose is suitable for watering plants, irrigation, and drainage.

5. Other Special Applications

Submersible Pump Accessories: PVC Suction Hose is often paired with submersible pumps as the outlet piping.

Other Special Scenarios: It finds applications in situations requiring negative pressure resistance, corrosion resistance, and excellent weather resistance.

The Function of Using It in Dust Collectors

1. Transmission Medium

Air and Dust Transmission: As a crucial component of vacuum cleaners, PVC suction hose is responsible for transmitting the negative pressure generated inside the vacuum cleaner to the suction head, enabling the inhalation of air and dust. This process requires the hose to possess excellent sealing and durability to ensure effective negative pressure transmission and smooth dust collection.

2. Flexibility and Convenience

Flexible Bending: The PVC material offers good flexibility, allowing the suction hose to bend and twist as needed, facilitating cleaning in different angles and positions. This flexibility enhances the usability and cleaning efficiency of the vacuum cleaner.

Lightweight and Portable: PVC is relatively lightweight, making the suction hose easy to carry and move along with the vacuum cleaner during cleaning tasks.

3. Abrasion Resistance and Durability

Abrasion Resistance: During operation, the suction hose frequently comes into contact and friction with floors, furniture, and other objects. PVC material exhibits good abrasion resistance, resisting wear caused by these frictions and extending the hose's service life.

Aging Resistance: PVC also possesses a certain degree of aging resistance, resisting the impact of environmental factors such as ultraviolet rays and oxidation to maintain long-term stability and reliability.

4. Safety

Flame Retardancy: While PVC material itself may not possess outstanding flame retardancy, some high-end vacuum cleaner products may utilize PVC materials treated with flame retardants or combine them with other flame-retardant materials to enhance overall product safety.

Non-toxic and Environmentally Friendly: PVC materials used in the production of suction hoses must comply with relevant environmental standards to ensure they do not harm human health or the environment. Therefore, qualified PVC suction hoses are non-toxic and environmentally friendly.

Usage Instructions

I. Pre-use Preparation

Quality Inspection: Before use, inspect the PVC suction hose and its accessories for any signs of damage, cracks, or aging to ensure safety and efficiency during operation.

Surface Cleaning: Clean the interior and exterior surfaces of the PVC suction hose thoroughly to remove dust, grease, and other impurities. This ensures proper adhesion or connection with glues or fittings.

II. Installation and Connection

Connecting Fittings: Use appropriate fittings (such as connectors, flanges) to connect the PVC suction hose as needed. Ensure a tight fit between the fittings and PVC pipe to prevent leaks.

Applying Glue: If necessary, use specialized PVC glue to adhere the PVC pipe to fittings. Apply the glue evenly over the connection surfaces, avoiding excess that may spill and compromise the bond. Allow the glue to fully cure before proceeding.

Securing the Pipe: During installation, use brackets, clamps, or other fixtures to secure the PVC suction hose in place to prevent movement or detachment.

III. Precautions During Use

Avoid Excessive Bending: Prevent excessive bending or twisting of the PVC suction hose during use to avoid damage or reduced suction efficiency.

Pressure Control: Control the suction pressure when using the PVC suction hose to avoid overpressure that could cause pipe rupture or leaks.

Regular Inspection: Regularly inspect the connections of the PVC suction hose for looseness, aging, or damage, and promptly repair or replace any issues.

IV. Maintenance and Care

Cleaning and Maintenance: After use, promptly clean the interior and exterior surfaces of the PVC suction hose to remove residual dirt and water, preventing bacterial growth and corrosion.

Storage Environment: Store the PVC suction hose in a dry, ventilated, and cool location, avoiding direct sunlight and high temperatures that may cause aging or deformation.

Avoid Chemical Contact: Prevent the PVC suction hose from coming into contact with corrosive chemicals to avoid damage to the pipe.

In summary, the usage instructions for PVC suction hose cover pre-use preparation, installation and connection, precautions during use, as well as maintenance and care. Following these steps and precautions ensures safe, efficient, and reliable operation of the PVC suction hose.

Company Advantages

Qingdao Renato Plastic Co., Ltd. brings over 15 years of expertise in PVC hose manufacturing, producing high-quality hoses and assemblies for diverse applications. Our state-of-the-art factory in Shandong Province houses 10 workshops, 60 production lines, and a team of 120 skilled workers. Supported by 5 technical experts and 2 dedicated QC teams, we ensure that our products meet the highest quality standards. Trusted by customers in over 60 countries, our products are known for reliability, durability, and outstanding performance in the global market.

Contact Us

If you're in need of a dependable partner for hoses and assemblies, Qingdao Renato Plastic Co., Ltd. is here to help. Reach out to us for any inquiries or product needs. We offer 7x24 hour quick responses and are committed to putting our customers first. You can contact us via phone, email, or our website to get a prompt response and professional service.

Conclusion

When it comes to dust collection, the PVC Corrugated Suction Dust Collector Hose from Qingdao Renato Plastic Co., Ltd. delivers the perfect balance of durability, flexibility, and efficiency. Its versatile design ensures superior performance in any environment, making it a reliable tool for both industrial and household applications. Partner with us today and experience the quality and innovation that have made us a trusted leader in the industry for over 15 years. Let’s work together to keep your spaces clean and safe.