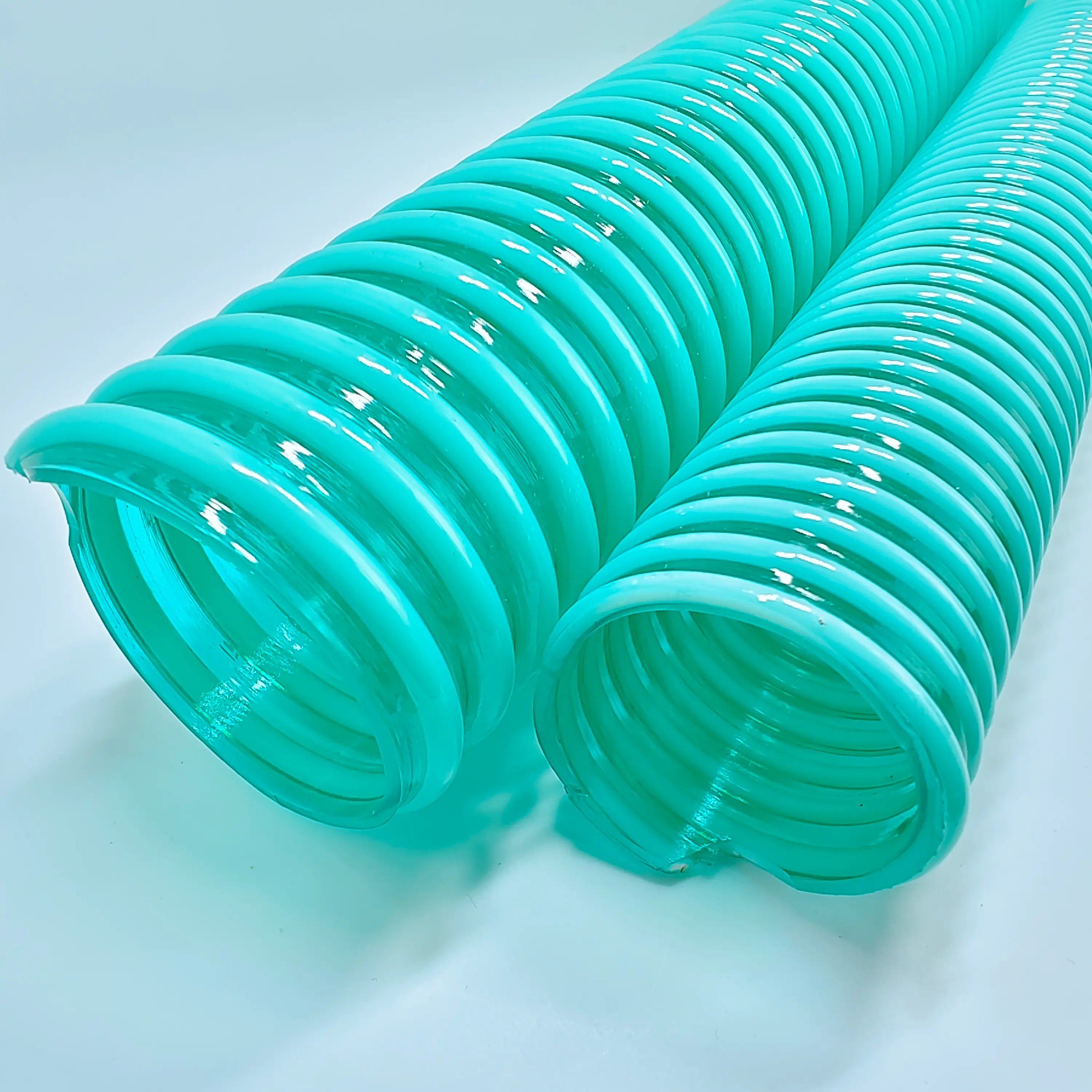

PVC Suction Helix Hose for Sewage Suction and Delivery

Introducing the PVC Suction Helix Hose by Qingdao Renato Plastic Co., Ltd., your ultimate solution for efficient sewage suction and delivery. Specifically engineered to withstand the demanding conditions of sewage systems, our helix hose combines flexibility, durability, and high performance, making it the perfect choice for a wide range of heavy-duty applications.

Why Choose PVC Suction Hose?

1. Excellent Properties of PVC Material

Chemical Stability: PVC exhibits strong resistance to oxidants, reductants, and strong acids, ensuring durability and longevity of the hose.

Physical Performance: PVC boasts high strength and rigidity, capable of withstanding pressure and loads, making it suitable for suction hose applications.

Weather Resistance: Its good weather resistance ensures stable performance under different climatic conditions, resisting aging.

Cost-Effectiveness: The relatively low cost of PVC material translates to a more economical solution for suction hose production.

2. Wide Range of Applications

Industrial Sector: Widely used in industries such as chemicals, petroleum, and food processing for conveying liquids and gases due to its chemical resistance and weather resistance.

Agricultural Irrigation: In agriculture, PVC suction hose is employed in irrigation systems for its lightweight and durable nature, facilitating easy installation and maintenance.

Environmental Protection: Suitable for sewage treatment, sludge transportation, and other environmental applications due to its acid and alkali resistance.

3. Easy Processing and Maintenance

Easy Processing: PVC material can be easily molded into various shapes and sizes, allowing customization of PVC suction hose length, diameter, and connections according to specific requirements.

Simple Maintenance: Its durability reduces the likelihood of damage, and replacement or repairs can be carried out swiftly, minimizing maintenance costs and downtime.

4. Environmental Friendliness

Recyclability: PVC is recyclable, enabling the reuse of discarded PVC suction hose, minimizing environmental impact.

Low Toxicity: Modern PVC production processes significantly reduce toxicity, ensuring minimal harm to humans and the environment during usage.

In summary, the choice of PVC suction hose stems from its impressive chemical and physical properties, broad applicability, ease of processing and maintenance, and environmentally responsible characteristics, catering to the diverse needs of various industries.

| Feature | Description |

|---|---|

| Material | High-quality PVC |

| Helix Design | Enhances resistance to kinking and crushing |

| Weight | Lightweight for easy handling |

| Chemical Resistance | Withstands harsh chemicals and abrasives |

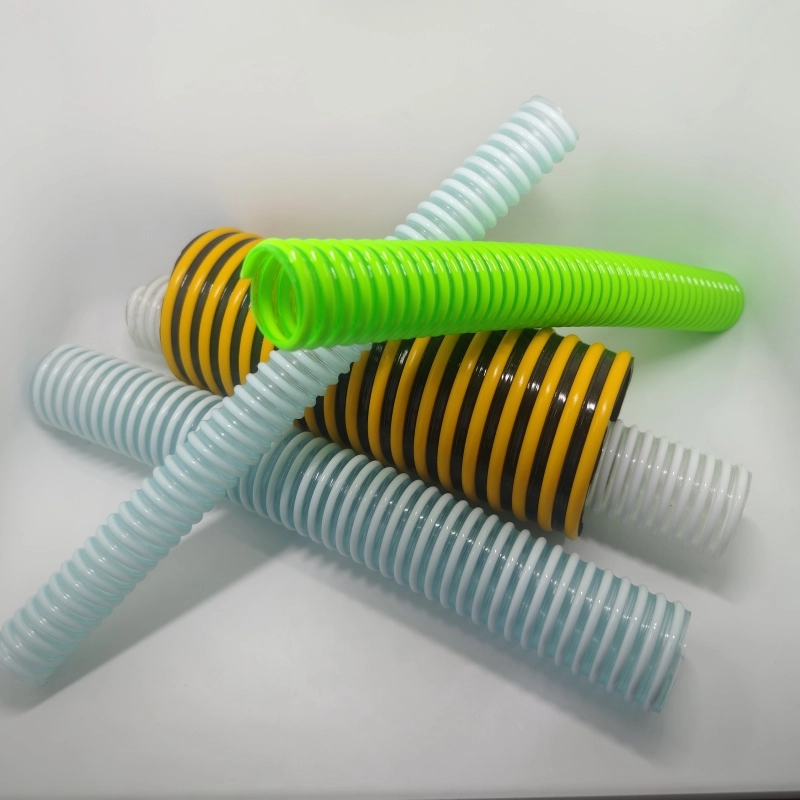

| Color Options | Transparent, Blue, Green, Black, or Customized |

| Temperature Range | -5°C to +65°C |

| Pressure Rating | 2 - 10 bar |

| Applications | Agriculture, Mining, Construction Dewatering |

Specifications Overview

| Specification | Range/Details |

|---|---|

| Diameter | 1 inch to 16 inch |

| Length Options | 10m, 20m, 30m, 40m, 50m |

| Thickness | 2mm to 12mm |

| Standard Compliance | ISO9001 |

| Transporting Medium | Water, Oil, Powder |

| Working Life | Long-lasting durability |

Application Scenarios

Industrial Applications:

Chemical Processing: PVC suction hose is ideal for transferring chemicals and solvents in chemical plants due to its resistance to a wide range of chemicals.

Petroleum Industry: It is used for suction and discharge of petroleum products, including fuels, oils, and lubricants, thanks to its ability to withstand the corrosive effects of these substances.

Manufacturing: In various manufacturing processes, PVC suction hose is employed for conveying water, coolants, and other fluids required for production.

Agriculture:

Irrigation Systems: PVC suction hose is an essential component of agricultural irrigation systems, enabling efficient and cost-effective water distribution across fields.

Fertilizer Application: It is also used for transporting and applying fertilizers, ensuring even distribution and promoting crop growth.

Mining:

Dewatering: In mining operations, PVC suction hose is crucial for dewatering mines and tunnels, helping to maintain safe working conditions.

Slurry Transportation: It is used to transport slurry, a mixture of water and mining waste, from excavation sites to processing facilities.

Construction:

Drainage: PVC suction hose is often employed in construction sites for drainage purposes, helping to remove excess water and prevent flooding.

Concrete Mixing: It can also be used in the concrete industry for suctioning water and mixing materials.

Environmental and Sanitary Applications:

Sewage Treatment: PVC suction hose is used in sewage treatment plants to pump and transport sewage and wastewater.

Sludge Handling: For handling and transporting sludge generated in wastewater treatment processes.

Septic Systems: It is suitable for use in septic systems, helping to maintain and clean these systems effectively.

Food and Beverage Industry:

Liquid Transfer: PVC suction hose that meets food-grade standards is used for transferring liquids such as milk, fruit juices, and other beverages in food processing facilities.

Sanitary Applications: Its smooth interior surface and easy-to-clean properties make it suitable for sanitary applications where hygiene is critical.

General Purpose Applications:

Cleaning: PVC suction hose is often used in cleaning applications, such as suctioning water from flooded areas or cleaning tanks and containers.

Aquarium Maintenance: It can be used for water changes and maintenance tasks in aquariums and fish farms.

| Industry | Application | Medium |

|---|---|---|

| Agriculture | Irrigation | Water |

| Mining | Dewatering | Water, Slurry |

| Construction | Sewage suction and delivery | Sewage, Water |

| Waste Management | Handling waste and sewage | Waste materials |

| Industrial | Chemical transport and drainage | Chemicals, Abrasives |

The Role in Wewage Discharge

1. Strong Corrosion Resistance

The PVC material inherently exhibits excellent corrosion resistance, able to withstand the erosion of various chemicals, including acids, bases, and organic substances found in sewage. This ensures that the PVC suction hose can operate stably and reliably for extended periods without damage or leakage due to corrosion.

2. Lightweight and Easy to Install

Compared to traditional metal pipes, PVC suction hoses are significantly lighter, making them easier to handle, transport, and install. This not only reduces construction difficulties and costs but also improves work efficiency. In scenarios requiring frequent movement or temporary setups for sewage drainage, the PVC suction hose's advantages are particularly evident.

3. Efficient Drainage

The PVC suction hose boasts excellent sealing properties and fluid transmission capabilities, enabling rapid and smooth sewage discharge. Its smooth interior wall minimizes fluid resistance, enhancing drainage efficiency. Furthermore, the hose's flexibility allows it to adapt to various complex drainage environments.

4. Environmentally Friendly and Durable

PVC material is recyclable, aligning with environmental protection requirements. Additionally, PVC suction hoses are highly resistant to wear and aging, resulting in a long service life and reduced replacement frequencies, thereby minimizing waste generation.

5. Versatile Applications

PVC suction hoses find extensive application in sewage collection, transportation, and discharge processes within sewage treatment plants. They are also suitable for use in urban drainage systems, industrial wastewater treatment, agricultural irrigation and drainage, and other related fields.

6. Customized Services

Depending on specific sewage drainage needs and environmental conditions, PVC suction hoses can be customized to meet specific requirements. This includes adjusting parameters such as length, diameter, and wall thickness, as well as adding specialized wear-resistant or corrosion-resistant coatings to suit particular scenarios.

Usage Method

1. Preparation Phase

Select the Appropriate PVC Suction Hose: Choose a PVC suction hose that suits your specific requirements based on factors such as the nature of the fluid, temperature, and pressure. Ensure that the material, specifications, and performance of the selected hose meet the necessary standards.

Inspect Hose Integrity: Before use, thoroughly inspect the PVC suction hose for any signs of damage, cracks, or aging. Ensure that the hose is intact and free from leaks.

2. Installation and Connection

Clean Connections: Before connecting, wipe the hose ends with a clean, dry cloth to remove any dust, grease, or other impurities.

Connect the Hose: Attach the PVC suction hose to the drainage system or other equipment interfaces. These connections can typically be made using threaded fittings, flanges, or quick-connect couplings. Ensure that the connections are tight and secure, with no potential for leaks.

3. Startup and Operation

Activate Pump or Power Equipment: Once the hose is properly connected, start the pump or other power equipment to initiate the flow of sewage or other liquids.

Monitor Operation: During operation, keep a close eye on the PVC suction hose's performance, including flow rates and pressures, to ensure they are within normal ranges. Also, inspect the hose periodically for any signs of leakage or deformation.

4. Maintenance and Care

Regular Cleaning: Regularly clean the PVC suction hose to remove any accumulated dirt or debris, ensuring the hose remains unobstructed.

Inspection and Replacement: Periodically inspect the hose for signs of wear and aging. If you notice any cracks, damage, or excessive aging, replace the PVC suction hose promptly with a new one.

Storage Considerations: When not in use, store the PVC suction hose in a dry, well-ventilated, and shaded area to protect it from direct sunlight and extreme heat.

5. Precautions

Avoid Excessive Bending: During use, try to avoid bending the PVC suction hose excessively, as this can damage the hose or impair fluid flow.

Safety First: When connecting or disconnecting the hose, prioritize safety. Take appropriate precautions, especially when working at heights or in complex environments, to prevent accidents.

Comparison of Hose Types

| Hose Type | Material | Flexibility | Durability | Application |

|---|---|---|---|---|

| PVC Suction Helix Hose | PVC | High | Excellent | Sewage suction and delivery |

| Layflat Hose | PVC | Moderate | Good | Water discharge |

| Fiber Reinforced Hose | PVC + Fibers | Moderate | Very Good | Heavy-duty applications |

| Steel Wire Hose | PVC + Steel | Low | Excellent | High-pressure applications |

| Garden Hose | PVC | High | Fair | Irrigation and gardening |

Company Advantages

Qingdao Renato Plastic Company stands out with its solid market foundation, diversified product lines, and international vision. Established in 2018, the company specializes in the research, development, and sales of plastic products and accessories, with applications spanning various industries such as construction, industry, and agriculture. Its strong capital strength and efficient decision-making mechanism ensure the company's flexibility and continuous innovation in the market.

Not only does the company focus on deepening its domestic market presence, but it also actively expands its import and export business, extending its brand influence overseas. The rich product portfolio combined with exceptional customer service has earned widespread market recognition and customer trust.

Looking ahead, Qingdao Renato Plastic Company will continue to uphold the development philosophy of high quality and efficiency, constantly explore new technologies and fields, and provide even more outstanding products and services to customers, striving for a brighter future together.

Contact Us

Renatoflex Factory is your trusted partner for high-quality lay flat discharge hoses. For more information on our products and services, visit our website or contact our customer service team. We are always ready to help you with your fluid transfer needs.

820 Buliding C Qingdao Plaza, No.379 Dunhua Road, Qingdao 266034 China.