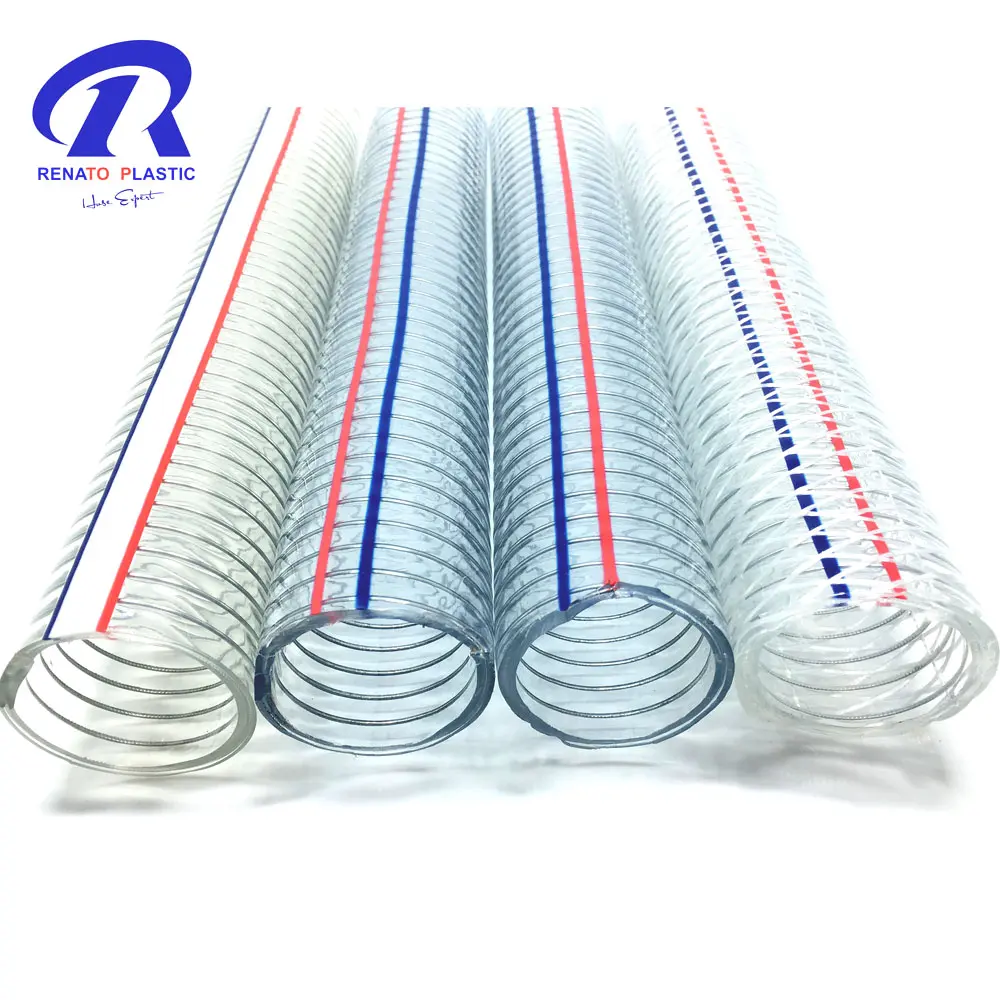

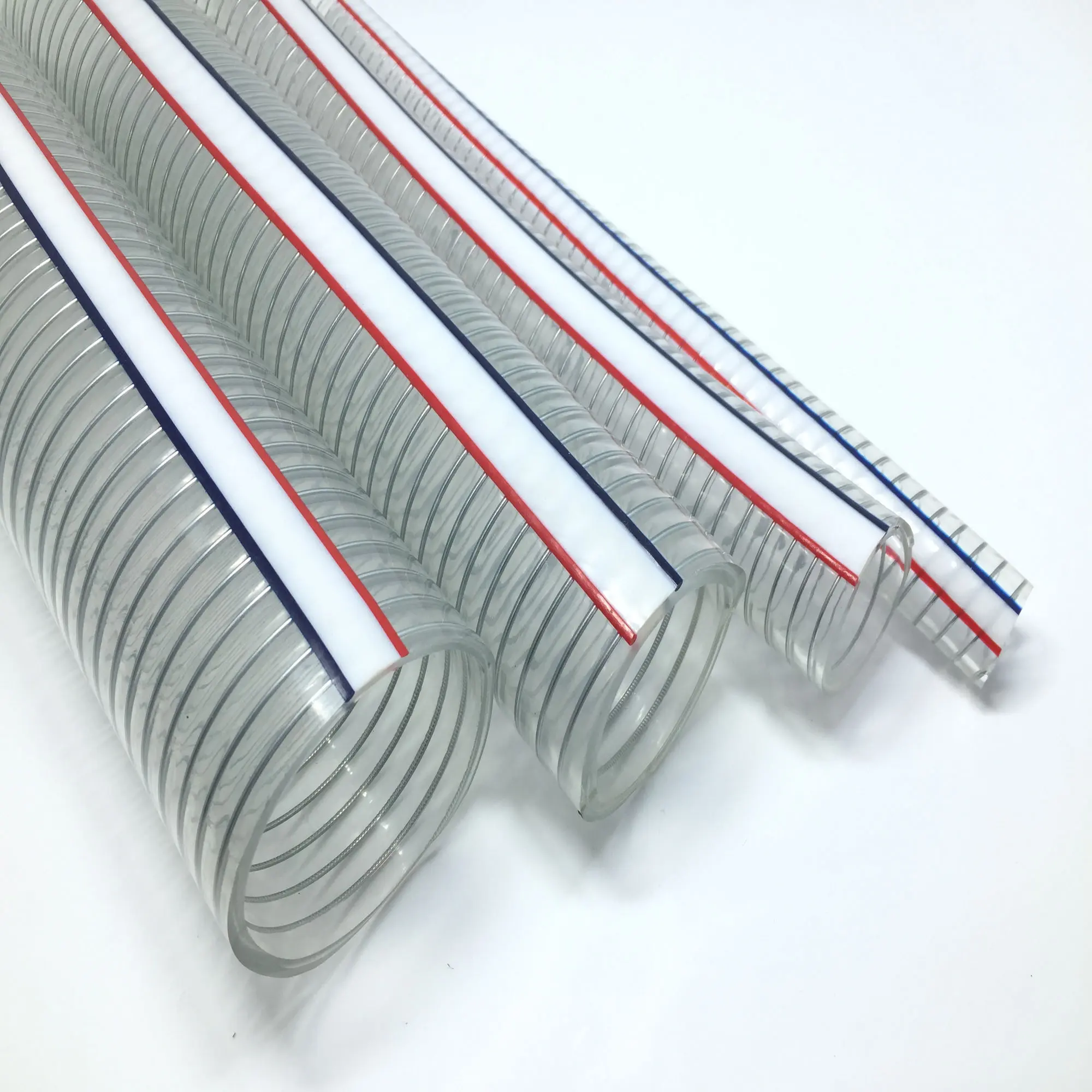

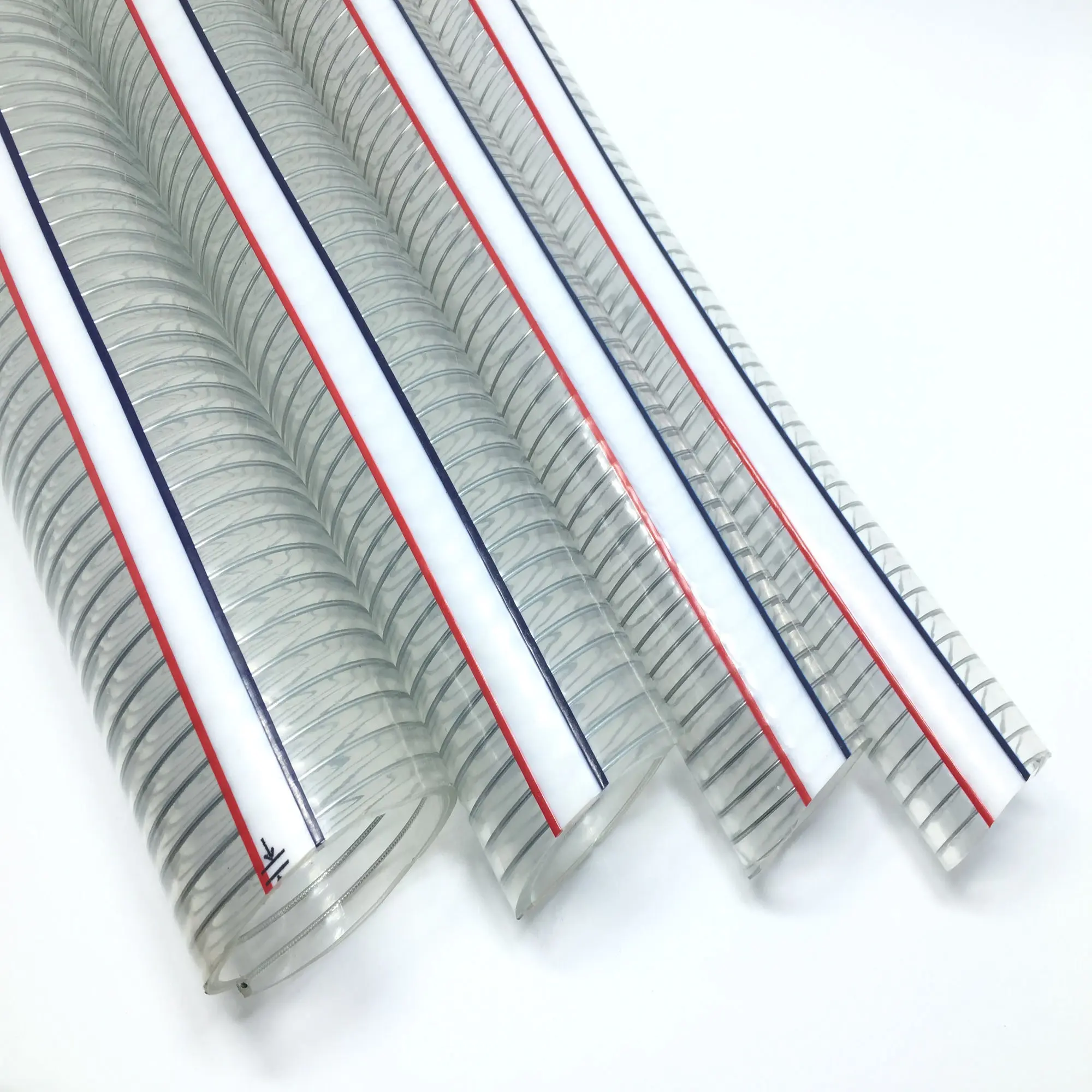

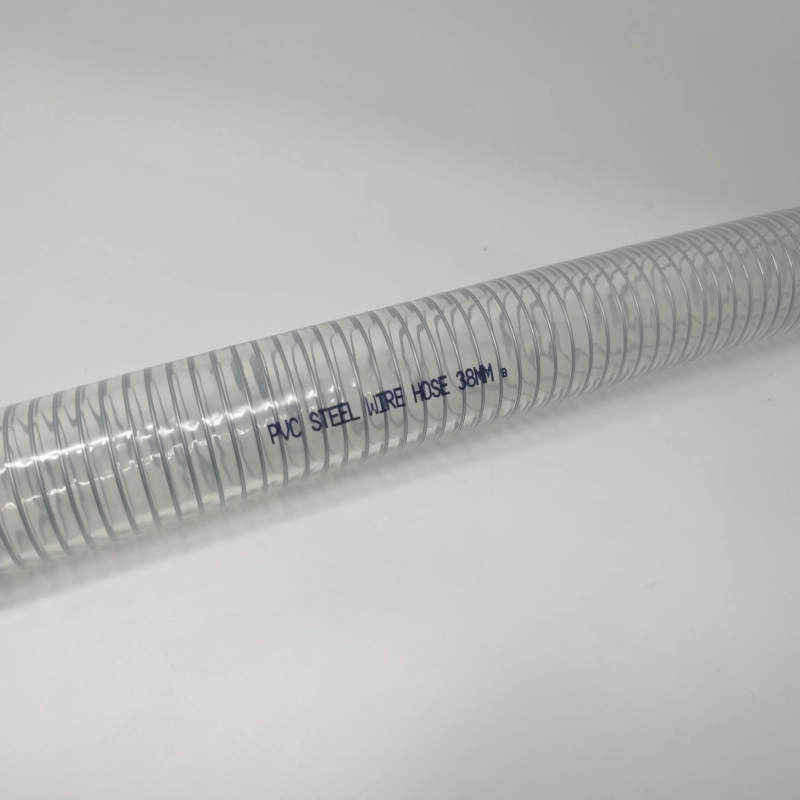

UV Resistant PVC Steel Wire Water Conveying Hose

A UV-resistant PVC steel wire water conveying hose is a specialized type of hose made from polyvinyl chloride (PVC) reinforced with a steel wire helix. This design provides a combination of flexibility, durability, and the ability to withstand high pressure, making it ideal for various applications in industries such as agriculture, construction, and industrial fluid transfer.

This hose is a reliable choice for industries that require a robust yet flexible solution for fluid transfer, offering excellent performance and durability in a wide range of environmental conditions.

Specifications Table

| Specification | Description |

|---|---|

| Material | High-quality polyvinyl chloride (PVC) with embedded steel wire helix |

| Inner Layer | Flexible, smooth PVC for efficient water flow |

| Reinforcement | Steel wire spiral for enhanced structural integrity and pressure resistance |

| Outer Layer | UV-resistant PVC compound to prevent cracking and degradation |

| Working Pressure | 3 to 10 bar (varies by diameter and wall thickness) |

| Burst Pressure | 9 to 30 bar, generally three times the working pressure |

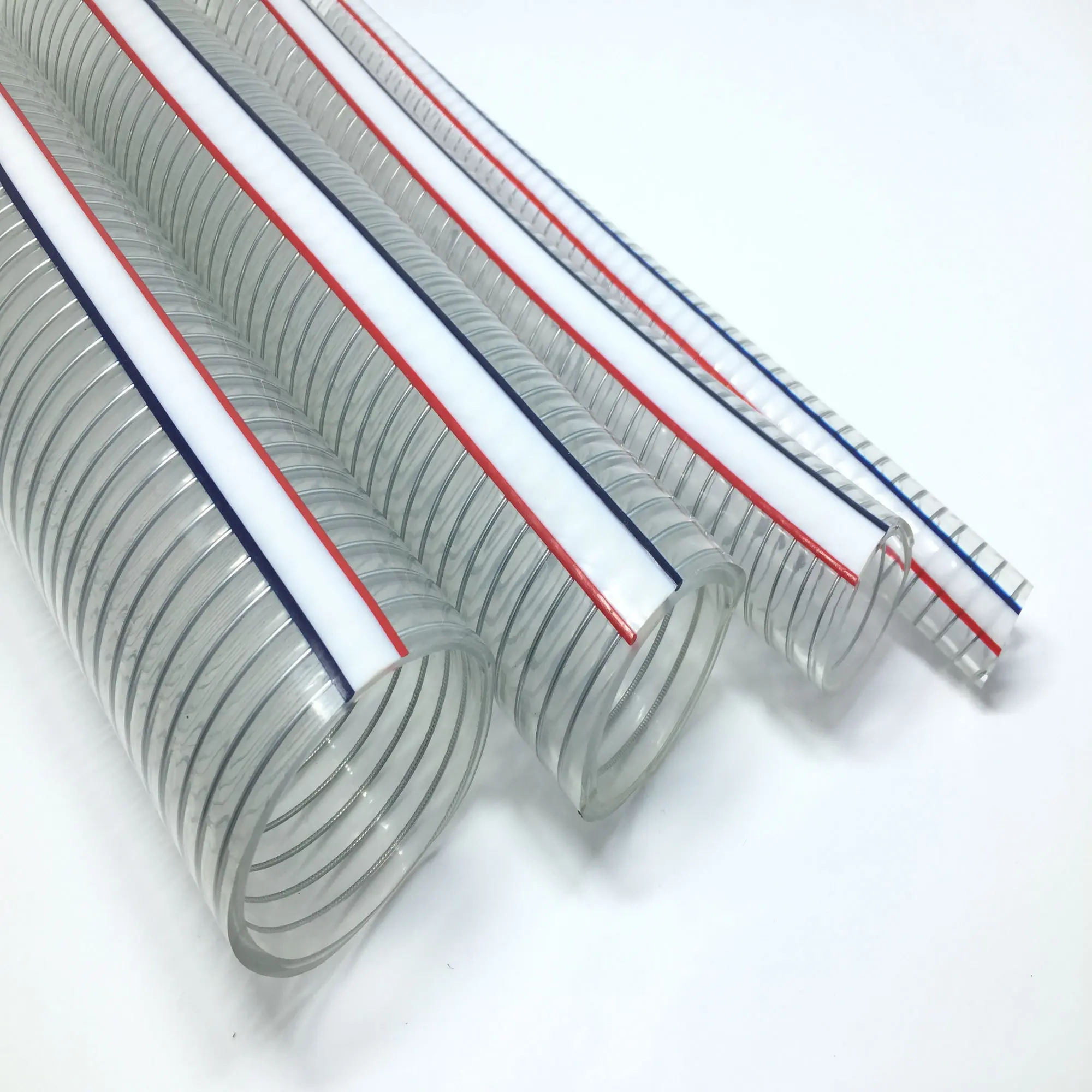

| Inner Diameter (ID) | Ranges from 10mm to 100mm |

| Wall Thickness | 2mm to 8mm, depending on pressure rating |

| Temperature Range | -5°C to +60°C |

| Length Options | Standard 10m, 20m, 30m, 50m, and 100m lengths; custom lengths available |

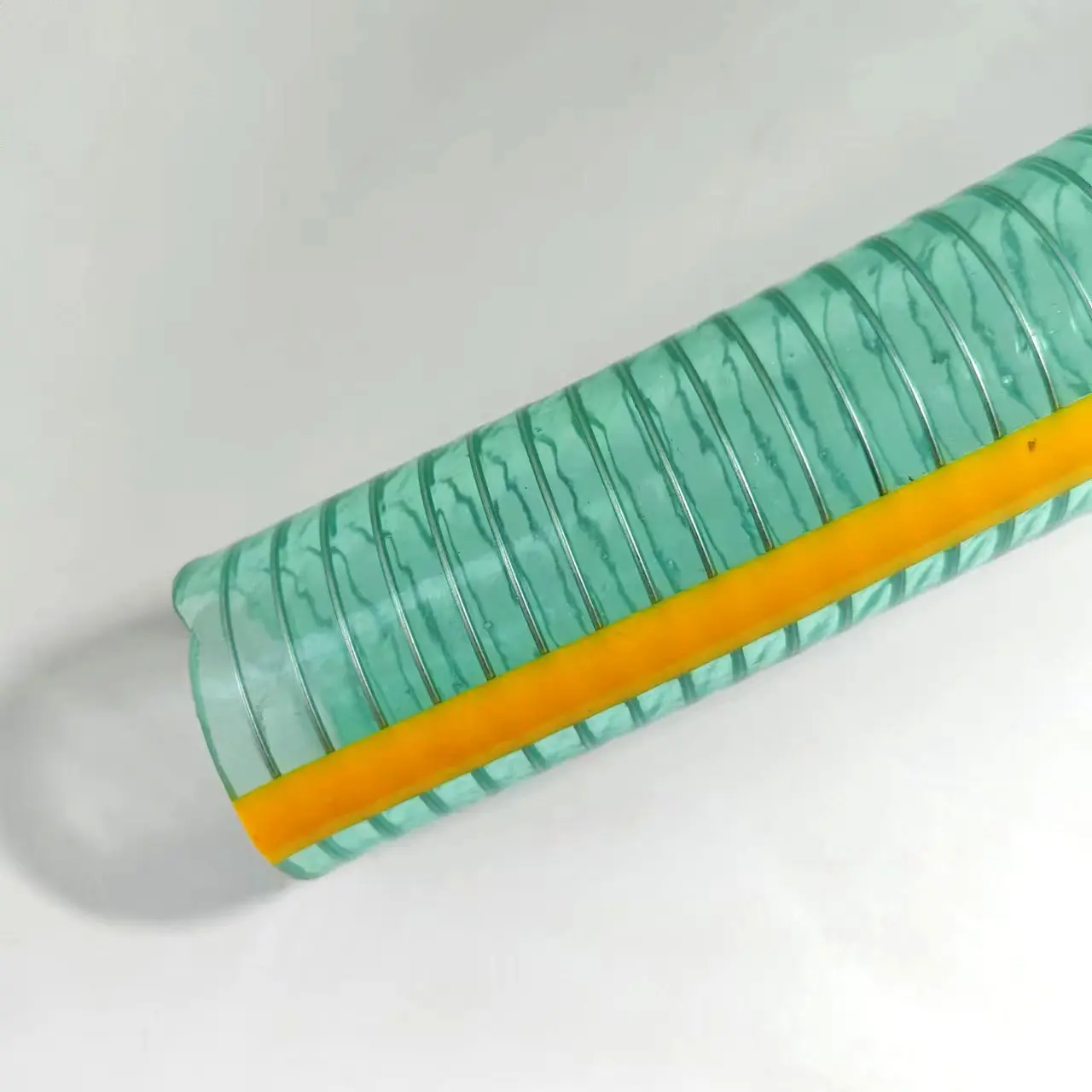

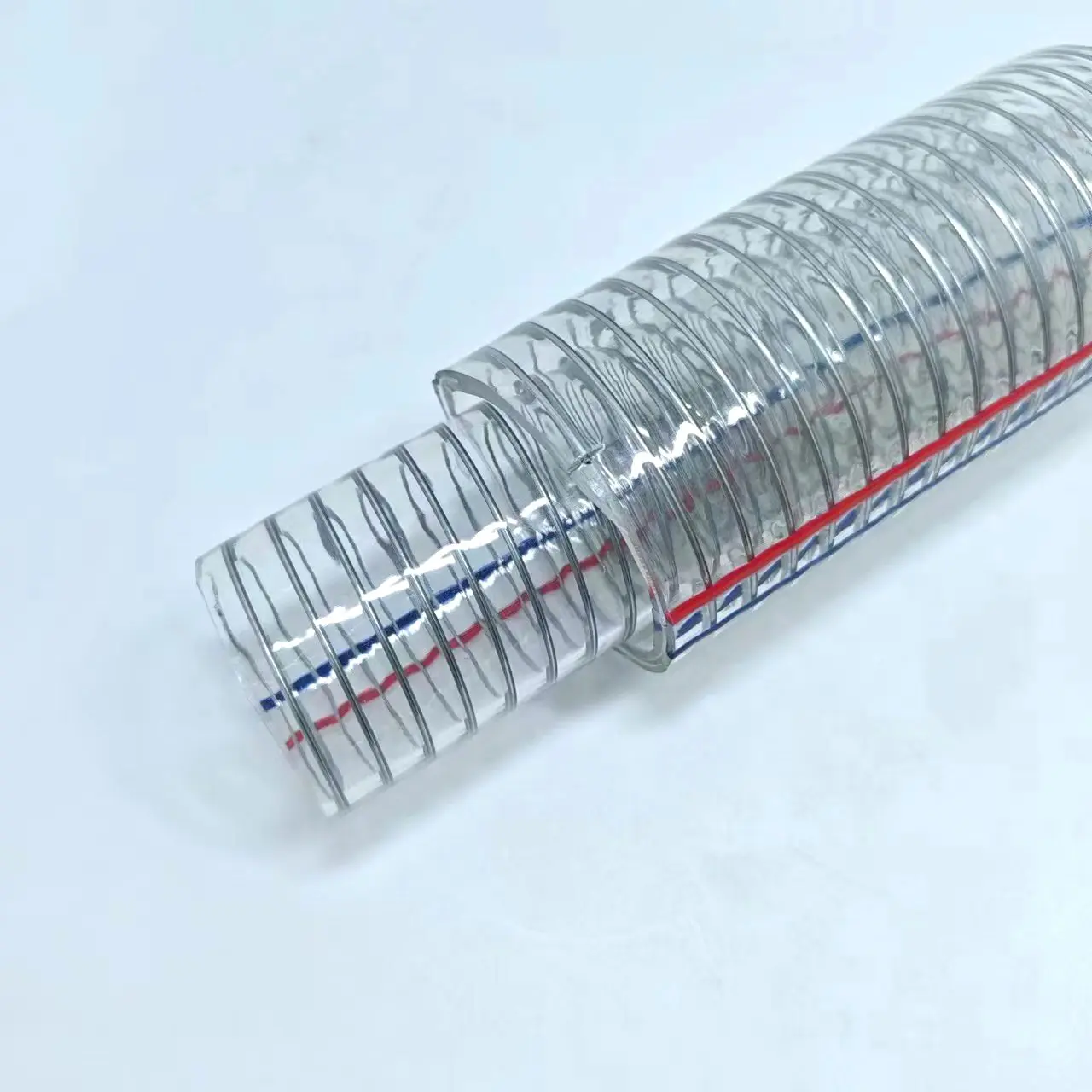

| Color Options | Transparent, with optional color tints (blue, green, red) |

| Bending Radius | 4 times the inner diameter, ensuring flexibility without kinking |

| UV Resistance | UV-stabilized outer layer for outdoor use |

| Abrasion Resistance | Good resistance to wear and tear |

| Applications | Water conveyance, agricultural irrigation, industrial fluid transfer |

| Standard Compliance | ISO 4649 for abrasion resistance, REACH, and RoHS compliant |

Pricing Table

| Order Quantity | Price Per Meter (USD) |

|---|---|

| Retail (1-100 meters) | $1.50 - $2.50 |

| Wholesale (100-500 meters) | $1.20 - $1.80 |

| Bulk Order (500+ meters) | $0.90 - $1.30 |

| Customization Fees | $0.10 - $0.25 per meter for custom colors, lengths, or branding options |

Factory Technical Details

| Technical Specification | Description |

|---|---|

| Production Capacity | 500,000 meters per month |

| Production Equipment | High-speed PVC extrusion machines, steel wire braiding machines |

| Quality Control | 100% pressure testing, UV resistance tests, dimensional accuracy checks |

| Minimum Order Quantity (MOQ) | 500 meters for standard hoses, 1,000 meters for custom designs |

| Lead Time | 10-15 days for standard orders, 20-25 days for custom orders |

| Packaging Options | Coils wrapped in plastic film, or spooled on wooden reels for large orders |

| Certifications | ISO 9001 for quality management, ISO 14001 for environmental management |

Production Formulation Table

| Material Component | Percentage (%) | Function |

|---|---|---|

| PVC Resin | 55% | Provides flexibility and strength to the hose structure |

| Steel Wire | 15% | Reinforces the hose, enabling it to withstand high pressure |

| Plasticizers | 20% | Enhances flexibility and workability of the PVC material |

| Stabilizers | 5% | Improves heat and UV resistance, preventing degradation |

| UV Stabilizers | 2% | Increases the hose's resistance to UV rays for outdoor durability |

| Colorants (Optional) | 1% | Adds tint to the hose, available in custom colors |

| Processing Aids | 2% | Improves the extrusion process for smoother surfaces |

This detailed overview of the UV-resistant PVC steel wire water conveying hose provides comprehensive insights into its technical specifications, pricing, production capabilities, and formulation. It is an ideal solution for industries requiring durable, UV-resistant hoses for water transfer and other applications, combining flexibility with robust construction.

Advantages

High Strength and Ring Rigidity: With a steel wire framework embedded inside, PVC steel wire hose exhibits significantly enhanced compressive strength and hardness, providing excellent ring rigidity and resistance to external pressure without deformation or cracking.

Corrosion Resistance: PVC material inherently possesses excellent corrosion resistance, capable of withstanding acids, alkalis, salts, and various chemical substances. This makes PVC steel wire hose perform exceptionally well in fields such as chemicals, drainage, and wastewater treatment, avoiding the corrosion issues of traditional metal piping and extending its service life.

High Elasticity and Flexibility: PVC steel wire hose boasts good elasticity and flexibility, allowing it to adapt to various complex installation environments and conditions. With a small bending radius, it is easy to install.

Clear and Transparent Hose Body: The inner and outer walls of the hose are clear, smooth, and bubble-free, allowing for clear visibility of the fluid being transported, facilitating observation and maintenance.

Long Service Life: PVC steel wire hose is resistant to aging and has a long service life, maintaining stable performance over time.

Versatile Applications: PVC steel wire hose can be used in multiple fields such as agricultural pump machinery, oil depots, petrochemical equipment, industries, engineering mines, and food manufacturing for the suction and discharge of liquids, gases, oils, and dust. Its high negative pressure resistance, corrosion resistance, and non-toxic materials make it a suitable alternative to rubber hose in many situations.

Safety and Environmental Protection: PVC steel wire hose is produced with stabilizers and plasticizers added to ensure its environmental and safety performance during use. It does not contain toxic substances, will not contaminate the conveyed medium, and complies with environmental and health requirements.

In summary, PVC steel wire hose, with its high strength, corrosion resistance, high elasticity and flexibility, clear and transparent hose body, long service life, versatile applications, and safety and environmental protection features, has been widely used and recognized in construction, agriculture, environmental protection, and other fields.

Applications

Industrial Applications: Due to its high pressure resistance, corrosion resistance, and flexibility, PVC steel wire hose is widely used in industrial settings for the transfer of various fluids, including gases, oils, and chemicals. It is often found in pneumatic and hydraulic systems, compressor lines, and in the transfer of coolants and lubricants.

Agricultural Irrigation: PVC steel wire hose is ideal for agricultural irrigation systems due to its durability and resistance to punctures and tears. It can be used to deliver water and fertilizers efficiently to crops, ensuring even and consistent irrigation.

Automotive Industry: In the automotive industry, PVC steel wire hose is used for fuel lines, brake lines, and other fluid transfer systems. Its ability to withstand high pressures and temperatures makes it suitable for these critical applications.

Construction and Mining: In construction and mining operations, PVC steel wire hose is used for drainage and sewage systems, as well as for the transfer of construction materials like concrete and gravel. Its robust construction ensures it can handle the abrasive and heavy-duty conditions often found in these environments.

Food and Beverage Industry: PVC steel wire hose is also used in the food and beverage industry for the transfer of liquids and gases that are safe for consumption. Its non-toxic materials and ability to withstand cleaning and sanitization processes make it a suitable choice for these applications.

Marine and Offshore Applications: In marine and offshore environments, PVC steel wire hose is used for fuel and water transfer systems, as well as for hydraulic and pneumatic systems. Its corrosion resistance and ability to withstand the harsh conditions of saltwater and exposure to the elements make it a reliable choice for these applications.

OEM and Custom Applications: Due to its versatility and ability to be customized, PVC steel wire hose is often used in original equipment manufacturer (OEM) applications and for custom solutions. It can be tailored to meet specific requirements in terms of size, pressure rating, and material composition.

The Role in Industry Pump Lines

1. Enhancing the Efficiency and Safety of Fluid Transmission

PVC steel wire hose, with its high-strength steel reinforcement layer, can withstand high fluid pressure, ensuring stable fluid transmission during pumping. At the same time, its corrosion resistance and wear resistance make the hose capable of long-term use in harsh industrial environments without easy damage or leakage, thus improving the safety and reliability of fluid transmission.

2. Adapting to Complex and Diverse Pumping Environments

In industry pump lines, the pumping environment is often complex and diverse, including high temperatures, high pressures, and corrosive fluids. PVC steel wire hose has good heat resistance, high-pressure resistance, and corrosion resistance, enabling it to adapt to these harsh conditions and ensure the normal operation of the pumping system. Additionally, the hose has a certain degree of flexibility, allowing easy connection of pumps and pipelines at different angles and positions, improving the flexibility and adaptability of the pumping system.

3. Reducing Maintenance and Replacement Costs

Compared to traditional metal piping, PVC steel wire hose has a longer service life and lower maintenance costs. Due to its good wear resistance and corrosion resistance, the hose is less prone to leakage or damage during use, reducing the frequency of repairs and replacements. This not only lowers the operating costs for enterprises but also improves production efficiency.

4. Improving the Overall Performance of the Pumping System

PVC steel wire hose can also serve as a shock absorber and noise reducer in pumping systems. Due to its elasticity, the hose can absorb vibrations and noise generated during pumping, making the pumping system smoother and quieter. Additionally, the hose can be bent and stretched as needed to adapt to different pumping requirements, enhancing the overall performance and flexibility of the pumping system.

In summary, PVC steel wire hose has broad application prospects and an important role in industry pump lines. It enhances the efficiency and safety of fluid transmission, adapts to complex and diverse pumping environments, reduces maintenance and replacement costs, and improves the overall performance of the pumping system. Therefore, PVC steel wire hose is undoubtedly a worthwhile option to consider when selecting hoses for industry pump lines.

Factory Technical Details

| Technical Specification | Description |

|---|---|

| Production Capacity | 500,000 meters per month |

| Production Equipment | High-speed PVC extrusion machines, steel wire braiding machines |

| Quality Control | 100% pressure testing, UV resistance tests, dimensional accuracy checks |

| Minimum Order Quantity (MOQ) | 500 meters for standard hoses, 1,000 meters for custom designs |

| Lead Time | 10-15 days for standard orders, 20-25 days for custom orders |

| Packaging Options | Coils wrapped in plastic film, or spooled on wooden reels for large orders |

| Certifications | ISO 9001 for quality management, ISO 14001 for environmental management |

Production Formulation Table

| Material Component | Percentage (%) | Function |

|---|---|---|

| PVC Resin | 55% | Provides flexibility and strength to the hose structure |

| Steel Wire | 15% | Reinforces the hose, enabling it to withstand high pressure |

| Plasticizers | 20% | Enhances flexibility and workability of the PVC material |

| Stabilizers | 5% | Improves heat and UV resistance, preventing degradation |

| UV Stabilizers | 2% | Increases the hose's resistance to UV rays for outdoor durability |

| Colorants (Optional) | 1% | Adds tint to the hose, available in custom colors |

| Processing Aids | 2% | Improves the extrusion process for smoother surfaces |

The Function of UV Resistant PVC Steel Wire Hose

1. UV-Resistant Properties

PVC steel wire hose is typically treated with special additives that enhance its ability to withstand UV radiation. These additives effectively absorb or reflect UV rays, protecting the hose material from UV damage. Therefore, when used in outdoor environments or exposed to sunlight, the hose maintains its stable performance over an extended period without aging or degrading.

2. Extended Service Life

Due to its exceptional UV-resistant properties, the service life of PVC steel wire hose is significantly extended. Traditional PVC materials may degrade, harden, or become brittle due to UV damage when exposed to sunlight for prolonged periods. However, PVC steel wire hose with UV-resistant additives can effectively avoid these issues. This allows the hose to continue operating stably in various harsh environments, reducing the frequency of replacements and maintenance, and lowering operational costs for businesses.

3. Enhanced Reliability

The advantage of PVC steel wire hose in UV resistance also lies in its improved reliability. In applications requiring high pressure, high temperatures, or corrosive fluids, the reliability and stability of the hose are crucial. UV resistance ensures that the hose is less likely to fail or leak during prolonged use, thereby enhancing the reliability of the entire pumping system.

4. Wide Range of Applications

Due to its outstanding UV resistance, PVC steel wire hose is widely used in various situations where UV exposure is a concern. For example, in agricultural irrigation systems, hoses are often exposed to sunlight and require good UV resistance to ensure a long service life. Similarly, in industries such as industrial automation, food processing, and pharmaceuticals, where high reliability and stability are required, PVC steel wire hose is favored due to its excellent UV resistance.

In summary, the role of PVC steel wire hose in UV resistance is evident in its UV-resistant properties, extended service life, enhanced reliability, and wide range of applications. These advantages make PVC steel wire hose an indispensable component in various pumping systems.

Company Advantages

15+ Years of Experience: With a wealth of expertise in PVC hose production, Qingdao Renato Plastic Co., Ltd. has been a trusted supplier to clients in over 60 countries worldwide.

State-of-the-Art Production Facilities: Our factory in Shandong province is equipped with 10 workshops, more than 60 production lines, and a dedicated workforce of 120 employees, ensuring large-scale production capacity and fast delivery times.

Quality Assurance: Our 5 technicists and 2 QC teams meticulously inspect each batch of products, ensuring that every hose meets international quality standards.

Custom Solutions: We offer customization options for sizes, designs, and hose assemblies to meet your specific application needs.

Global Reach: Our products are widely praised for their quality and performance by customers in diverse markets.

Contact Us

For more information about the Clear Anti-Static PVC Spiral Steel Wire Hose with Copper Wire or to discuss your specific requirements, please feel free to reach out to us. Your inquiry will be responded to promptly by our expert team. At Qingdao Renato Plastic Co., Ltd., our philosophy is simple: "Customers are always first."

Conclusion

The UV Resistant PVC Steel Wire Water Conveying Hose from Qingdao Renato Plastic Co., Ltd. is the perfect solution for any water transport needs in outdoor environments. With its robust construction, superior UV resistance, and reinforced design, this hose guarantees longevity and performance in even the harshest conditions. Choose Qingdao Renato Plastic Co., Ltd. for reliable, durable, and high-quality hose solutions tailored to your specific requirements.