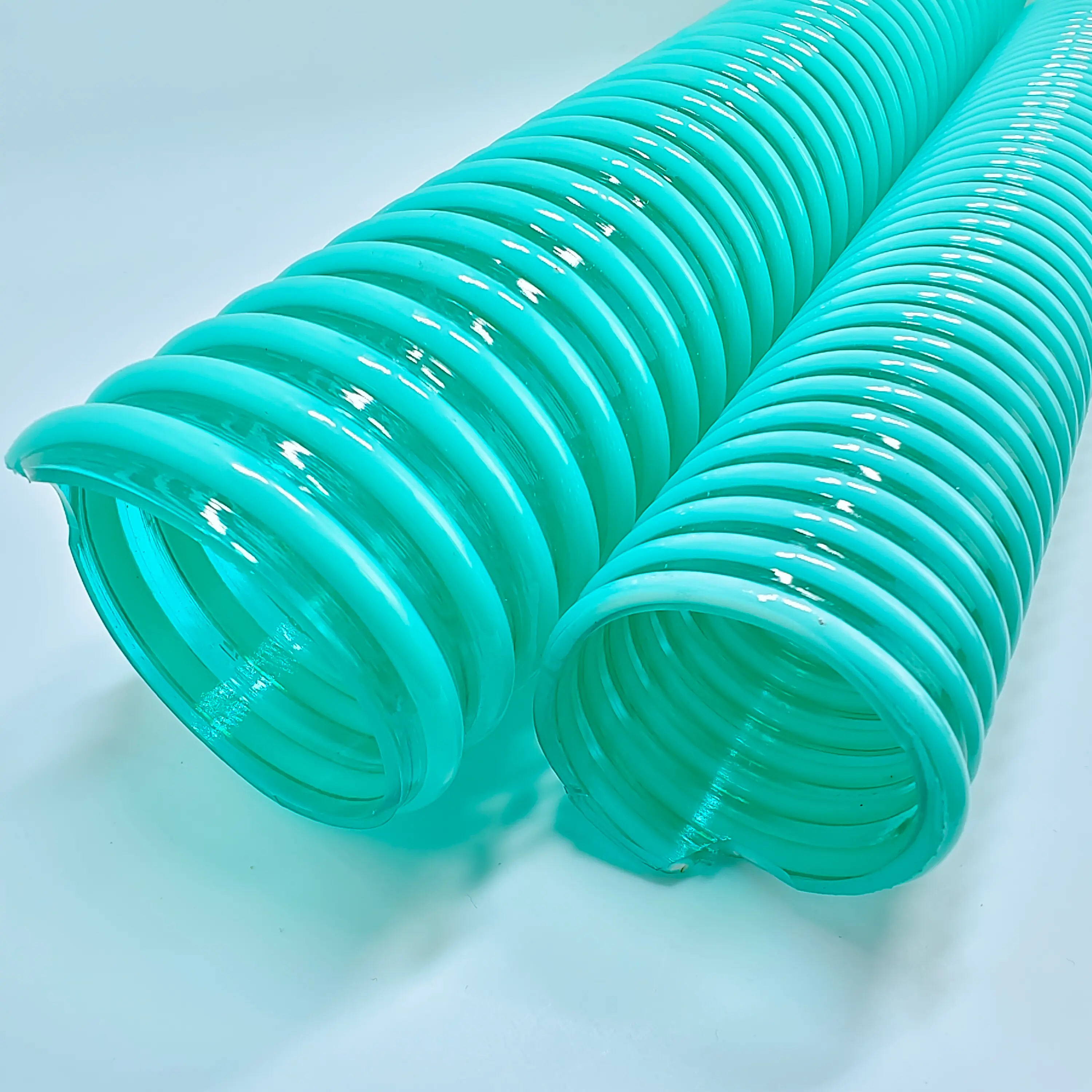

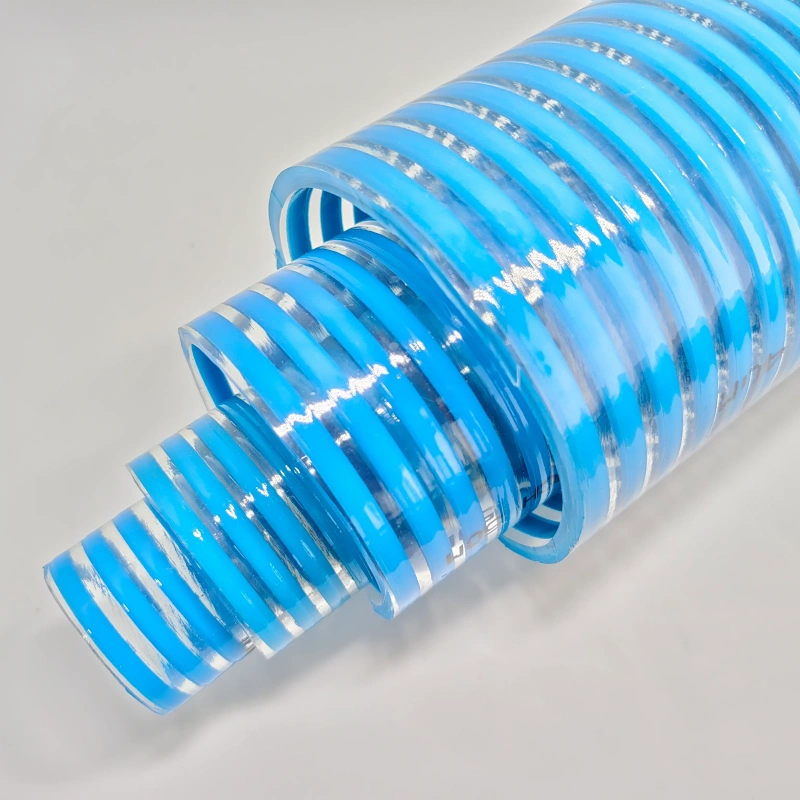

1. What Is a Vacuum PVC Helix Spiral Wound Suction Hose?

The Vacuum PVC Helix Spiral Wound Flexible Hose is a specialized flexible pipe designed for negative-pressure suction applications, widely used in sewage treatment, chemical transfer, agricultural irrigation, and industrial vacuum systems. Its key features include:

Helical Steel Reinforcement: Embedded high-tensile steel wire resists collapse, maintaining flow under vacuum.

PVC Material: Chemical-resistant and lightweight (30% lighter than rubber hoses), ideal for mobile operations.

Flexible Design: Bendable and coilable, suitable for complex layouts.

Typical Applications:

Sewage suction trucks for sludge extraction

Corrosive liquid transfer in chemical plants

Agricultural drainage and irrigation

Industrial central vacuum dust collection

2. Key Performance Parameters

When purchasing, focus on the following specifications to avoid "specification traps":

| Parameter | Industry Standard | Low-Quality Red Flags |

|---|---|---|

| Inner Diameter (ID) | 25mm–300mm | Uneven wall thickness, actual ID shrinks by 5%+ |

| Working Pressure | -0.09MPa (vacuum) | Hose deforms or steel wire protrudes under vacuum |

| Temperature Range | -10°C to +60°C | Cracks in cold/softens in heat |

| Steel Wire Material | 304 Stainless Steel | Galvanized steel (prone to rust) |

| Tensile Strength | ≥1.5x hose weight | Delamination at joints |

Case Study: A wastewater treatment plant opted for a "budget hose" ($8/m) with galvanized steel wire, which rusted within 3 months, reducing vacuum efficiency by 40% and increasing replacement costs.

PVC Suction Hose Technical Specifications

| Inner Diameter | Thickness | Length per Roll | Weight | Working Pressure (23°C) | ||

|---|---|---|---|---|---|---|

| Inch | mm | mm | m | kg/m | bar | psi |

| 3/4 | 19 | 2.5 | 50 | 0.25 | 8 | 120 |

| 3 | 50 | 0.28 | 9 | 135 | ||

| 1 | 25 | 2.5 | 50 | 0.32 | 8 | 120 |

| 3 | 50 | 0.35 | 9 | 135 | ||

| 1 1/4 | 32 | 3 | 50 | 0.4 | 8 | 120 |

| 4 | 50 | 0.55 | 9 | 135 | ||

| 1 1/2 | 38 | 3 | 50 | 0.55 | 6 | 90 |

| 4 | 50 | 0.7 | 7 | 105 | ||

| 2 | 50 | 4 | 50 | 0.92 | 6 | 90 |

| 5 | 50 | 1.1 | 7 | 105 | ||

| 2 1/2 | 63 | 3.5 | 30 | 0.95 | 5 | 75 |

| 4.5 | 30 | 1.23 | 6 | 90 | ||

| 3 | 75 | 4 | 30 | 1.45 | 4 | 60 |

| 5 | 30 | 1.65 | 5 | 75 | ||

| 4 | 100 | 5 | 30 | 2.3 | 4 | 60 |

| 6 | 30 | 2.9 | 5 | 75 | ||

| 5 | 127 | 6 | 20 | 3.3 | 4 | 60 |

| 8 | 20 | 4.7 | 5 | 75 | ||

| 6 | 152 | 7 | 20 | 5 | 4 | 60 |

| 9 | 20 | 6.3 | 5 | 75 | ||

| 8 | 200 | 7 | 10 | 6.3 | 4 | 60 |

| 8 | 10 | 7 | 4 | 60 | ||

| 10 | 250 | 8 | 10 | 10 | 4 | 60 |

| 9 | 10 | 11 | 4 | 60 | ||

| 12 | 305 | 12 | 10 | 18 | 4 | 60 |

| 14 | 355 | 12 | 10 | 20 | 4 | 60 |

3. Pricing Structure & Cost Analysis

1. Market Price Range (for DN100mm inner diameter)

| Quality Tier | Price Range | Features | Best For |

|---|---|---|---|

| Economy Grade | $6–10/m | Standard PVC, galvanized wire | Short-term/low-frequency use |

| Industrial Grade | $12–18/m | UV-resistant PVC, 304 stainless steel wire | Outdoor/corrosive environments |

| Food Grade | $20–30/m | Non-toxic, FDA-approved | Pharmaceutical/food processing |

2. Hidden Costs to Watch For

Fittings: Flanges/quick connectors cost extra (+$5–15 each).

Shipping: Oversized lengths (e.g., 6m) may incur +30% freight fees.

Certifications: NSF/CE-certified hoses cost 15–20% more.

4. Procurement Pitfalls & Solutions

1. Four-Step Supplier Verification

① Material Check

Request steel wire tensile test reports (304 stainless steel must contain ≥8% nickel).

Low-quality hoses often use recycled PVC with a strong odor (premium hoses are odorless or mildly plastic-scented).

② Flexibility Test

Fold 180° without whitening/cracking (recycled material cracks).

③ Vacuum Test

On-site demo: Connect to a vacuum pump; hose should not collapse at -0.08MPa.

④ Certification Review

Must-have documents: MSDS (Material Safety Data Sheet) and third-party test reports (e.g., SGS).

2. Tailored Specifications

Sludge/Solid Transfer: Choose smooth inner walls (friction coefficient ≤0.3).

Corrosive Liquids: Ensure anti-acid/alkali PVC lining (resists 10% sulfuric acid/sodium hydroxide).

Outdoor Use: Add UV protection layer (+$2/m, doubles lifespan).

5. Expert Procurement Advice

1. Bulk Purchase Strategies

Volume Discounts:

100–500m: $15/m

500–1000m: $13.5/m

>1000m: $12/m (negotiate free custom tooling).

Price Lock: PVC prices fluctuate; insist on a "3-month fixed price" clause.

2. After-Sales Negotiation

Warranty: Demand ≥2 years for industrial-grade hoses (in writing).

Spare Parts: Ensure suppliers stock same-batch hoses (to avoid color/performance mismatches).

3. Alternative Comparisons

| Hose Type | Price | Lifespan | Drawbacks |

|---|---|---|---|

| PVC Spiral Hose | $12–18/m | 3–5 years | Not solvent-resistant (e.g., acetone) |

| Rubber Steel Hose | $25–40/m | 5–8 years | Heavy, hard to maneuver |

| Polyurethane Composite | $50–80/m | 8–10 years | Overpriced for most uses |

Conclusion: For most industrial users, PVC spiral hoses offer the best cost-performance ratio.

6. Industry Trends & Innovations

Smart Hoses: Embedded pressure sensors (+$30/m) monitor clogs/leaks in real time.

Biodegradable PVC: Eco-friendly (+25% cost), complies with EU REACH regulations.

Final Recommendations

Choosing a vacuum PVC hose isn’t about "the cheaper, the better." Instead:

Test Samples First: Spend $50–100 for a 1m sample to verify performance.

Partner with Experts: Work with suppliers offering vacuum system integration (e.g., free pipeline design).

Calculate Total Cost of Ownership: Premium hoses may have 40% lower annualized costs than cheap alternatives.

Top PVC Helix Success Hose Manufacturer

Qingdao Renato Plastic Co., Ltd. is a leading Chinese manufacturer specializing in high-quality vacuum PVC helix spiral wound suction hoses for industrial, agricultural, and municipal applications. With over 15 years of experience in polymer engineering, we combine advanced production technology with strict quality control to deliver durable, high-performance suction hoses trusted by clients worldwide.

Why Choose Us?

In-House R&D & Production

Full control over raw materials (ISO-certified PVC compounds)

Automated extrusion lines ensure consistent wall thickness (±0.1mm tolerance)

Quality Assurance

CE, ISO 9001, and SGS certifications

100% pressure testing before shipment

3-year warranty against manufacturing defects

Global Supply Capability

Annual output: 500,000+ meters

OEM/ODM support for bulk orders

Fast logistics to Europe, Middle East, and Southeast Asia

Competitive Pricing

Factory-direct rates (e.g., DN100mm hose from $12/m FOB Qingdao)

Volume discounts (up to 15% off 1,000m+ orders)

Contact Us

QINGDAO RENATO PLASTIC CO., LTD.

Contact: Mr. Kevin Ren

Phone/Whatsapp/Wechat: 0086-18653281131

Skype: bizchen2012

Email: sales@renatoplastic.com

kevin@renatoplastic.com

bizchen2012@foxmail.com

FAQ

1. What is the maximum working temperature for these hoses?

Our standard PVC suction hoses can withstand temperatures from -10°C to +60°C. For higher temperature applications (up to 80°C), we offer special heat-resistant formulations with added cost of 15-20%.

2. How do I determine the right hose diameter for my application?

Choose based on:

Flow requirements: 50mm (2") for 20-30m³/h, 100mm (4") for 50-80m³/h

Solid particle size: Add 25% to the largest particle diameter

Vacuum power: Larger diameters (150mm+) require stronger vacuum pumps

3. Are these hoses suitable for drinking water?

Yes! We offer NSF/ANSI 61 certified food-grade hoses with:

Non-toxic PVC

Antimicrobial additives

$3-5/m premium over standard hoses

4. What's the difference between 2.5mm and 4mm wall thickness?

Thickness | Pros | Cons | Best For |

2.5mm | Lighter (0.25kg/m for 25mm), more flexible | Less abrasion resistance | Clean water, short-term use |

4mm | Longer lifespan, handles solids better | 40% heavier, less flexible | Slurry, industrial wastewater |

5. Can the hose handle oil and fuel transfer?

Our standard PVC isn't oil-resistant. For hydrocarbons, we recommend:

Polyurethane-coated version (+$8/m)

Nitrile rubber alternative (+$12/m)

Both withstand diesel, gasoline, and lubricants.

6. How do I connect these hoses to my equipment?

We provide multiple connection options:

Clamp-on fittings (included free)

Flanged connections (+$15-50 per end)

Quick-release couplers (+$25-80 per set)

7. What's the minimum bending radius?

As rule of thumb: 5× the hose diameter

50mm hose → 250mm min. bend

100mm hose → 500mm min. bend

Exceeding this may kink the hose and block flow.

8. How do I clean and maintain the hose?

Monthly: Flush with clean water

After chemical use: Neutralize with pH-balanced cleaner

Storage: Hang coiled or lay flat (never folded)

Inspection: Check for wire exposure every 3 months

9. Why choose steel wire over polyester reinforcement?

Feature | Steel Wire | Polyester |

Vacuum resistance | ★★★★★ | ★★★ |

Crush resistance | ★★★★★ | ★★ |

Chemical resistance | ★★★ | ★★★★★ |

Price | $12-30/m | $8-15/m |

10. Do you provide emergency replacement services?

Yes! Our 24/7 Express Program guarantees:

48-hour emergency production

Air shipping with cost-sharing option

On-site technical support (Asia/Europe)

(Minimum order $5,000 applies)