Water Discharge PVC Suction Hose Factory

As a leading PVC suction hose factory specializing in water discharge solutions, we combine cutting-edge technology, rigorous quality control, and decades of expertise to deliver high-performance hoses for agriculture, industrial, and construction applications. Established in the early 2000s, our facility has earned global recognition for producing durable, flexible, and corrosion-resistant PVC hoses tailored to meet diverse operational demands.

Our commitment to innovation and customer-centric services—including OEM/ODM support—ensures we remain a trusted partner for businesses worldwide. Below, we outline our factory’s capabilities, product specifications, and competitive advantages.

This image shows a Water Discharge PVC Suction Hose. The hose is bright yellow with a ribbed exterior for added flexibility and durability. It is being measured with a caliper, indicating its diameter. This type of hose is commonly used in industrial settings for water suction and discharge applications.

Why Choose Our PVC Suction Hoses?

Advanced Material Engineering

Our hoses are crafted from high-grade PVC reinforced with steel wire or fiber braiding, ensuring exceptional tensile strength and resistance to abrasion, UV rays, and chemical exposure. The multi-layered design (e.g., five-layer knit structures) enhances flexibility while preventing kinking, even under high-pressure conditions

Wide Application Range

Designed for water discharge, irrigation, and industrial fluid transfer, our hoses are ideal for:

Agricultural irrigation systems

Construction site dewatering

Industrial water and oil delivery

Polluted water handling (featuring anti-clogging inner walls)

Customization & Compliance

We offer tailored solutions, including variations in diameter, length, and pressure ratings. All products comply with ISO 9001, RoHS, and SGS certifications, guaranteeing safety and environmental sustainability

Factory Capabilities

State-of-the-Art Production Lines: Equipped with automated extrusion machines from Europe and the U.S., we produce over 10,000 meters of hose daily.

Quality Assurance: Every batch undergoes 100% inspection for leaks, pressure endurance, and material integrity.

R&D Expertise: Our team develops specialized hoses, such as spiral-reinforced and high-temperature-resistant models, to address niche market needs.

Global Logistics: Supported by secure payment systems and efficient shipping networks, we ensure timely delivery to clients in 50+ countries.

Product Specifications

Below is a detailed specification table for our flagship Water Discharge PVC Suction Hose:

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | ||

| inch | mm | mm | m | kg/m | bar | psi |

| 3/4 | 19 | 2.5 | 50 | 0.25 | 8 | 120 |

| 3 | 50 | 0.28 | 9 | 135 | ||

| 1 | 25 | 2.5 | 50 | 0.32 | 8 | 120 |

| 3 | 50 | 0.35 | 9 | 135 | ||

| 1 1/4 | 32 | 3 | 50 | 0.4 | 8 | 120 |

| 4 | 50 | 0.55 | 9 | 135 | ||

| 1 1/2 | 38 | 3 | 50 | 0.55 | 6 | 90 |

| 4 | 50 | 0.7 | 7 | 105 | ||

| 2 | 50 | 4 | 50 | 0.92 | 6 | 90 |

| 5 | 50 | 1.1 | 7 | 105 | ||

| 2 1/2 | 63 | 3.5 | 30 | 0.95 | 5 | 75 |

| 4.5 | 30 | 1.23 | 6 | 90 | ||

| 3 | 75 | 4 | 30 | 1.45 | 4 | 60 |

| 5 | 30 | 1.65 | 5 | 75 | ||

| 4 | 100 | 5 | 30 | 2.3 | 4 | 60 |

| 6 | 30 | 2.9 | 5 | 75 | ||

| 5 | 127 | 6 | 20 | 3.3 | 4 | 60 |

| 8 | 20 | 4.7 | 5 | 75 | ||

| 6 | 152 | 7 | 20 | 5 | 4 | 60 |

| 9 | 20 | 6.3 | 5 | 75 | ||

| 8 | 200 | 7 | 10 | 6.3 | 4 | 60 |

| 8 | 10 | 7 | 4 | 60 | ||

| 10 | 250 | 8 | 10 | 10 | 4 | 60 |

| 9 | 10 | 11 | 4 | 60 | ||

| 12 | 305 | 12 | 10 | 18 | 4 | 60 |

| 14 | 355 | 12 | 10 | 20 | 4 | 60 |

OEM/ODM Services

We partner with global brands to develop custom hoses, including:

Branding: Print company logos or labels directly on hoses.

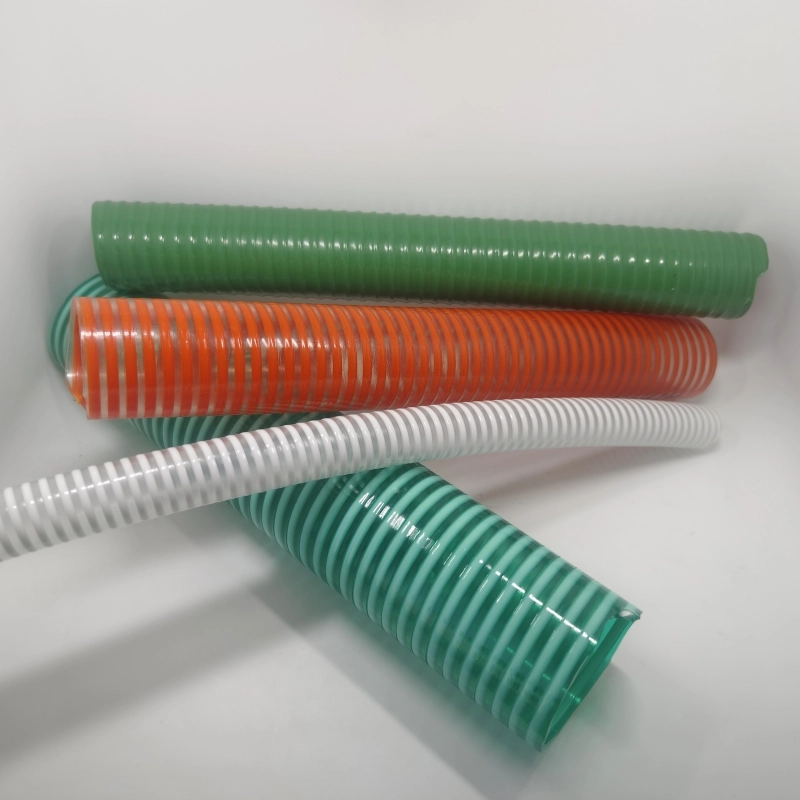

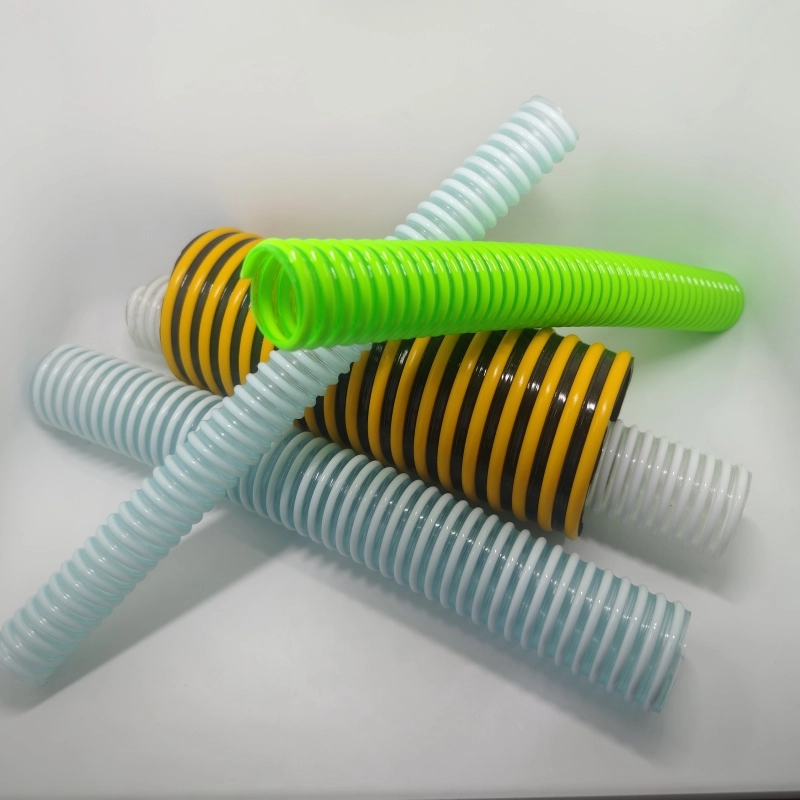

Design Adjustments: Modify diameters, colors, or reinforcement layers.

Packaging: Customize packaging for retail or bulk shipments.

This image shows a shipping container loaded with rolls of Water Discharge PVC Suction Hose. The hoses are neatly packed and wrapped in protective plastic to ensure they remain undamaged during transportation.

Quality Control Process

Raw Material Testing: PVC resins and additives are screened for purity and durability.

In-Line Monitoring: Sensors detect inconsistencies during extrusion.

Final Inspection: Hoses undergo pressure tests (up to 1.5x rated capacity) and visual checks

Company Advantages

15+ Years of Manufacturing Excellence: With over 15 years of production experience, Qingdao Renato Plastic Co., Ltd. has developed a deep understanding of industry requirements, ensuring we meet and exceed customer expectations.

State-of-the-Art Facility: Our factory in Shandong Province is equipped with 10 workshops, over 60 production lines, and a skilled team of 120 workers, including 5 technicists and 2 QC teams. This infrastructure enables us to maintain high production capacity and stringent quality standards.

Global Presence: We have served clients in over 60 countries, earning a reputation for high-quality PVC hoses and fittings.

Custom Solutions and Accessories: In addition to PVC hoses, we offer a range of hose assemblies and fittings (Camlock, Storz, Nozzle, Hose Clamps) to provide complete solutions for your fluid transfer needs.

Dedicated Customer Service: Our customer-first philosophy ensures 7x24 hours quick response and support, addressing your inquiries and requirements promptly and efficiently.