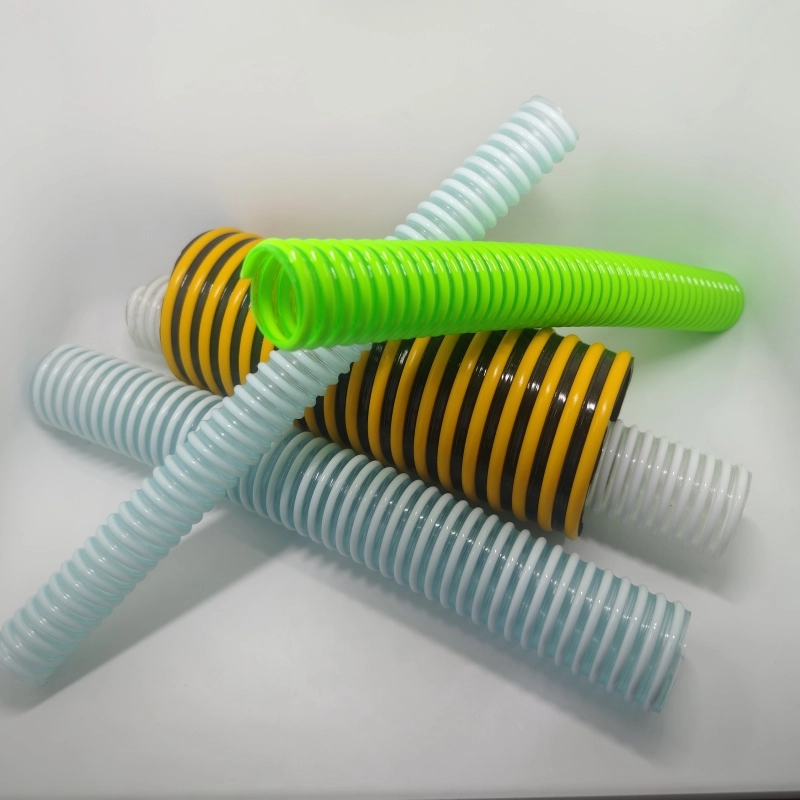

What is PVC Suction Hose?

A suction hose for a water pump is a flexible, reinforced pipe designed to transfer water or other fluids from a source to a pump. These hoses are typically used for applications like irrigation, drainage, and transferring water in agricultural or industrial settings. The hoses are constructed from durable materials such as PVC or rubber and reinforced with a spiral helix to maintain shape under suction without collapsing.

Here's a breakdown of the specific sizes:

1 Inch Suction Hose: Suitable for smaller water pumps used in light-duty applications such as garden irrigation or small drainage systems.

1.5 Inch Suction Hose: A mid-sized hose often used for small to medium water transfer tasks, including residential and light commercial irrigation.

2 Inch Suction Hose: This size is common for medium-duty tasks, such as draining larger ponds, transferring water in industrial settings, or handling construction dewatering.

3 Inch Suction Hose: Designed for heavy-duty applications like high-capacity water transfer, large irrigation systems, and industrial or agricultural water management.

Suction hoses are often used with centrifugal water pumps for draining flooded areas, moving water in farms, or transferring fluids in construction and mining. When selecting the right hose size, consider the flow rate and pump capacity for optimal performance.

Key Features:

Material:

High-Quality PVC: The hose is made from premium PVC material, offering excellent flexibility and long-term durability. PVC is known for its resistance to chemicals, abrasion, and various environmental factors.

Reinforcement: The hose is reinforced with a rigid PVC helix or braided polyester, providing extra strength and preventing collapsing under suction pressure.

Flexibility:

Ease of Handling: Designed to be flexible, the hose allows for easy handling and maneuvering during installation and operation. Its lightweight nature reduces the effort required for transportation and installation.

Adaptability: Suitable for use in various temperatures and conditions without compromising performance.

Durability:

Abrasion Resistance: The PVC construction provides resistance to abrasion, ensuring a long service life even in harsh conditions.

Weather Resistance: The hose is resistant to UV rays, ozone, and other environmental factors, making it suitable for outdoor use.

Performance:

Smooth Bore: The inner surface of the hose is smooth, minimizing friction losses and ensuring efficient fluid flow.

High Suction Capacity: Designed to handle high suction pressures, preventing collapse and maintaining consistent flow rates.

Versatility:

Various Sizes: Available in a wide range of diameters and lengths to meet different needs and applications.

Multiple Applications: Suitable for handling water, light chemicals, and other non-corrosive liquids.

Common Applications:

Agricultural Use:

Irrigation: Efficiently pumps water from ponds, rivers, and wells for irrigation purposes.

Fertilizer and Pesticide Transfer: Ideal for transferring liquid fertilizers and pesticides.

Industrial Use:

Construction: Used for dewatering sites, pumping water from trenches, pits, and foundations.

Manufacturing: Utilized in various industrial processes that require liquid transfer.

Residential Use:

Water Transfer: Perfect for transferring water in residential settings, such as draining pools, hot tubs, and garden ponds.

Emergency Flood Relief: Effective in pumping out water during flood emergencies.

Benefits of PVC Suction Hoses:

Chemical Resistance: Capable of handling various liquids without degrading, ensuring long-lasting performance.

Durable Construction: Built to withstand rough handling, harsh environmental conditions, and high suction pressures.

Cost-Effective: Provides excellent value with a long service life and minimal maintenance requirements.

Ease of Installation: Lightweight and flexible, making it easy to install and maneuver.

Reliable Performance: Ensures consistent flow rates and suction capabilities for efficient operation.

Technical Specifications:

Pressure Rating: Designed to handle high suction and discharge pressures.

Temperature Range: Suitable for use in a wide range of temperatures, typically from -10°C to 60°C.

Diameter: Available in various diameters, commonly ranging from 1/2 inch to 8 inches.

Length: Customizable lengths to meet specific application needs.

PVC suction hoses for water pumps are an essential tool for efficient liquid transfer across various applications. Their durability, flexibility, and resistance to chemicals and environmental factors make them a reliable choice for agricultural, industrial, and residential use. Whether for irrigation, construction, or emergency flood relief, PVC suction hoses deliver the performance and reliability needed for effective water transfer.

Specifications for 1, 1.5, 2, 3 Inch PVC Suction Hose for Water Pump

PVC suction hoses come in various sizes to meet different application requirements. Here are the detailed specifications for the 1 inch, 1.5 inch, 2 inch, and 3 inch PVC suction hoses designed for water pump use.

Here is the technical specifications table for 1, 1.5, 2, and 3 inch suction hoses used for water pumps:

| Specification | 1 Inch | 1.5 Inch | 2 Inch | 3 Inch |

|---|---|---|---|---|

| Inside Diameter (ID) | 25 mm (1 inch) | 38 mm (1.5 inches) | 50 mm (2 inches) | 76 mm (3 inches) |

| Outside Diameter (OD) | Approx. 30-32 mm | Approx. 43-45 mm | Approx. 56-60 mm | Approx. 85-88 mm |

| Material | Flexible PVC or Rubber | Flexible PVC or Rubber | Flexible PVC or Rubber | Flexible PVC or Rubber |

| Reinforcement | Rigid PVC helix or Spiral Helix | Rigid PVC helix or Spiral Helix | Rigid PVC helix or Spiral Helix | Rigid PVC helix or Spiral Helix |

| Wall Thickness | 2.5 mm - 3 mm | 3 mm - 3.5 mm | 3.5 mm - 4 mm | 4 mm - 5 mm |

| Working Pressure | 4-6 Bar | 4-6 Bar | 4-6 Bar | 3-5 Bar |

| Burst Pressure | 12-15 Bar | 12-15 Bar | 12-15 Bar | 9-12 Bar |

| Temperature Range | -10°C to +60°C | -10°C to +60°C | -10°C to +60°C | -10°C to +60°C |

| Bend Radius | 150 mm | 225 mm | 300 mm | 450 mm |

| Length Options | 10 m, 20 m, 30 m, Customizable | 10 m, 20 m, 30 m, Customizable | 10 m, 20 m, 30 m, Customizable | 10 m, 20 m, 30 m, Customizable |

| UV Resistance | Yes | Yes | Yes | Yes |

| Application | Water pump suction and discharge | Water pump suction and discharge | Water pump suction and discharge | Water pump suction and discharge |

| End Fittings | Standard or custom couplings | Standard or custom couplings | Standard or custom couplings | Standard or custom couplings |

1 Inch PVC Suction Hose:

Inner Diameter: 1 inch (25.4 mm)

Outer Diameter: Approximately 1.26 inch (32 mm)

Wall Thickness: Approximately 0.13 inch (3.3 mm)

Working Pressure: Up to 150 PSI

Burst Pressure: Up to 450 PSI

Vacuum Rating: Up to 28 inHg

Temperature Range: -10°C to 60°C (14°F to 140°F)

Standard Lengths: 25, 50, 100 feet

Reinforcement: Rigid PVC helix or braided polyester

Applications: Light-duty water transfer, irrigation, small-scale dewatering

1.5 Inch PVC Suction Hose:

Inner Diameter: 1.5 inches (38.1 mm)

Outer Diameter: Approximately 1.77 inch (45 mm)

Wall Thickness: Approximately 0.13 inch (3.4 mm)

Working Pressure: Up to 125 PSI

Burst Pressure: Up to 375 PSI

Vacuum Rating: Up to 28 inHg

Temperature Range: -10°C to 60°C (14°F to 140°F)

Standard Lengths: 25, 50, 100 feet

Reinforcement: Rigid PVC helix or braided polyester

Applications: Medium-duty water transfer, construction dewatering, agricultural irrigation

2 Inch PVC Suction Hose:

Inner Diameter: 2 inches (50.8 mm)

Outer Diameter: Approximately 2.24 inch (57 mm)

Wall Thickness: Approximately 0.15 inch (3.8 mm)

Working Pressure: Up to 100 PSI

Burst Pressure: Up to 300 PSI

Vacuum Rating: Up to 28 inHg

Temperature Range: -10°C to 60°C (14°F to 140°F)

Standard Lengths: 25, 50, 100 feet

Reinforcement: Rigid PVC helix or braided polyester

Applications: Heavy-duty water transfer, flood control, large-scale irrigation, construction

3 Inch PVC Suction Hose:

Inner Diameter: 3 inches (76.2 mm)

Outer Diameter: Approximately 3.39 inch (86 mm)

Wall Thickness: Approximately 0.20 inch (5 mm)

Working Pressure: Up to 90 PSI

Burst Pressure: Up to 270 PSI

Vacuum Rating: Up to 28 inHg

Temperature Range: -10°C to 60°C (14°F to 140°F)

Standard Lengths: 25, 50, 100 feet

Reinforcement: Rigid PVC helix or braided polyester

Applications: Extra heavy-duty water transfer, large-scale flood control, industrial dewatering, construction sites

Common Features:

Material: High-quality PVC for excellent flexibility and chemical resistance.

Construction: Reinforced with a rigid PVC helix or braided polyester for strength and durability.

Flexibility: Designed to be flexible for easy handling and maneuverability.

Chemical Resistance: Resistant to a wide range of chemicals, ensuring longevity.

Weather Resistance: UV and abrasion-resistant for outdoor use.

PVC suction hoses are available in various sizes to accommodate different water pump applications. The 1 inch, 1.5 inch, 2 inch, and 3 inch hoses each offer specific benefits and are designed to handle different levels of pressure, vacuum, and environmental conditions. These hoses are essential for efficient water transfer in agricultural, industrial, and construction settings.

Applications of 1, 1.5, 2, and 3 Inch PVC Suction Hoses for Water Pumps

Water pumps are indispensable tools in agriculture, construction, industry, and residential settings. They play a critical role in moving water from one location to another, whether for irrigation, dewatering, or general water transfer. PVC suction hoses, available in various sizes—1 inch, 1.5 inches, 2 inches, and 3 inches—are the perfect companions for water pumps, enhancing their efficiency and performance. This article delves into the advantages and applications of these hoses, with a focus on their use with water pumps.

Applications with Water Pumps:

Agricultural Irrigation:

1 Inch and 1.5 Inch Hoses: Ideal for small to medium-scale irrigation systems, helping to deliver water efficiently to crops.

2 Inch and 3 Inch Hoses: Suitable for large-scale irrigation, ensuring high water flow rates to cover extensive agricultural fields.

Construction Dewatering:

1.5 Inch and 2 Inch Hoses: Perfect for removing water from construction sites, trenches, and foundations, keeping work areas dry and safe.

3 Inch Hoses: Used for heavy-duty dewatering tasks, efficiently handling large volumes of water.

Residential Water Transfer:

1 Inch Hoses: Ideal for residential applications such as draining pools, hot tubs, and garden ponds.

1.5 Inch Hoses: Suitable for medium-scale water transfer tasks around the home.

Flood Control:

2 Inch and 3 Inch Hoses: Essential for emergency flood relief, these hoses can quickly remove large amounts of water from flooded areas, protecting property and infrastructure.

Industrial Applications:

1.5 Inch and 2 Inch Hoses: Used in various industrial processes that require efficient water transfer.

3 Inch Hoses: Handle the most demanding industrial water transfer tasks with high flow rate requirements.

PVC suction hoses in sizes 1 inch, 1.5 inches, 2 inches, and 3 inches are essential tools for enhancing the performance of water pumps. Their versatility, durability, flexibility, and high performance make them suitable for a wide range of applications, from agricultural irrigation to industrial water transfer and emergency flood control. By choosing the right size and type of PVC suction hose, users can ensure efficient and reliable water pump operations, maximizing productivity and reducing downtime.

Industry Standards for PVC Suction Hoses for Water Pumps

PVC suction hoses are essential components in various applications involving water pumps. These hoses must adhere to industry standards to ensure safety, reliability, and performance. Here are the key industry standards that 1 inch, 1.5 inch, 2 inch, and 3 inch PVC suction hoses typically meet:

Industry Standards:

ISO 4641:

Description: International standard for rubber and plastic hoses, including those used for water suction and discharge.

Requirements: Specifies the performance requirements for hoses used in water suction and discharge applications, including pressure rating, flexibility, and resistance to environmental factors.

EN ISO 2398:

Description: European standard for rubber and plastics hoses, specifying requirements for hoses used in general applications.

Requirements: Covers various aspects such as burst pressure, tensile strength, elongation, and resistance to environmental conditions.

SAE J517:

Description: Standard from the Society of Automotive Engineers (SAE) for hydraulic hoses.

Requirements: Includes specifications for hose construction, performance, and dimensions. While primarily for hydraulic applications, its guidelines influence the construction of high-quality suction hoses.

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals):

Description: European Union regulation concerning the production and use of chemical substances.

Requirements: Ensures that the materials used in PVC suction hoses are safe and do not contain hazardous substances that could harm users or the environment.

RoHS (Restriction of Hazardous Substances Directive):

Description: EU directive restricting the use of specific hazardous materials in electrical and electronic equipment.

Requirements: Ensures that PVC suction hoses do not contain hazardous substances such as lead, mercury, cadmium, hexavalent chromium, and certain flame retardants.

FDA Compliance:

Description: U.S. Food and Drug Administration regulations for materials used in food-related applications.

Requirements: If the hoses are used in applications involving potable water or food processing, they must be made from materials that comply with FDA standards for safety and hygiene.

NSF/ANSI Standard 61:

Description: North American standard for drinking water system components.

Requirements: Ensures that the materials used in the hoses do not leach harmful substances into water, making them safe for potable water applications.

Performance Criteria:

Pressure Rating:

Working Pressure: The maximum continuous pressure the hose can handle during operation.

Burst Pressure: The maximum pressure the hose can withstand before rupturing. Typically, the burst pressure is four times the working pressure.

Temperature Range:

Specifies the temperature limits within which the hose can operate effectively without degrading. Common ranges are from -10°C to 60°C (14°F to 140°F).

Flexibility and Bend Radius:

Defines how flexible the hose is and the minimum radius it can be bent without kinking or collapsing. This is crucial for handling and installation.

Chemical Resistance:

Specifies the hose's ability to resist degradation when exposed to various chemicals. PVC hoses should be resistant to many chemicals used in agricultural, industrial, and water transfer applications.

Abrasion and UV Resistance:

Ensures that the hose can withstand physical wear and tear and prolonged exposure to sunlight without degrading.

Conclusion:

Adhering to these industry standards ensures that 1 inch, 1.5 inch, 2 inch, and 3 inch PVC suction hoses for water pumps are safe, reliable, and perform optimally under various conditions. These standards cover aspects such as material safety, pressure handling, temperature resistance, flexibility, and environmental durability, ensuring that the hoses meet the demands of different applications in agriculture, construction, industry, and residential settings.

How to Manufacture PVC Suction Hoses for Water Pumps

Manufacturing PVC suction hoses for water pumps involves several precise steps to ensure the final product meets industry standards for performance, durability, and safety. Below is a detailed guide on how to manufacture 1 inch, 1.5 inch, 2 inch, and 3 inch PVC suction hoses.

Step-by-Step Manufacturing Process:

Material Selection:

PVC Resin: High-quality polyvinyl chloride (PVC) resin is selected for its flexibility, chemical resistance, and durability.

Plasticizers and Additives: These are added to the PVC resin to enhance flexibility, UV resistance, and overall performance.

Reinforcement Material: High-strength synthetic fibers (e.g., polyester) or a rigid PVC helix are chosen to provide the necessary reinforcement.

Compounding:

Mixing: The PVC resin, plasticizers, stabilizers, and other additives are thoroughly mixed in a compounding machine to create a uniform blend.

Quality Control: The compound is tested for consistency, chemical composition, and physical properties to ensure it meets the required specifications.

Extrusion of the Inner Layer:

Extruder Machine: The compounded PVC mixture is fed into an extruder, where it is melted and forced through a die to form the inner layer of the hose.

Cooling: The extruded inner layer is passed through a cooling bath to solidify the material and maintain its shape.

Sizing: The inner layer is sized to the required diameter (1 inch, 1.5 inches, 2 inches, or 3 inches).

Reinforcement Layer:

Helix or Braiding: Depending on the design, a rigid PVC helix or braided synthetic fibers are applied around the inner layer. This reinforcement provides the hose with the necessary strength to resist collapsing under suction pressure.

Bonding: The reinforcement layer is bonded to the inner layer to ensure structural integrity.

Extrusion of the Outer Layer:

Extruder Machine: The hose with the reinforcement layer is passed through another extruder, where the outer layer of PVC is applied.

Cooling and Sizing: The hose is again cooled and sized to ensure the outer layer bonds properly to the reinforcement layer and the hose maintains its dimensions.

Vulcanization (if required):

Heat Treatment: Some hoses may undergo vulcanization, a heat treatment process that cross-links the PVC molecules to enhance strength and durability.

Cutting and Assembly:

Cutting to Length: The continuous length of the hose is cut into specific lengths, typically 25, 50, or 100 feet, depending on customer requirements.

Fitting Attachments: End fittings, such as couplings or connectors, are attached to the hose ends if specified.

Quality Control and Testing:

Pressure Testing: Each hose is subjected to pressure testing to ensure it can handle the rated working pressure and burst pressure.

Vacuum Testing: The hose is tested for its ability to maintain shape and function under vacuum conditions.

Chemical Resistance Testing: Samples are tested to ensure the hose material resists degradation when exposed to various chemicals.

Flexibility and Kink Resistance: The hose is tested for flexibility and resistance to kinking to ensure ease of use.

Marking and Packaging:

Labeling: Each hose is marked with relevant information such as size, pressure rating, material, and manufacturer details.

Coiling and Packaging: The hoses are coiled and packaged appropriately to protect them during storage and transportation.

Industry Standards Compliance:

Throughout the manufacturing process, it is crucial to ensure that the hoses meet the following standards:

ISO 4641: Specifications for rubber and plastic hoses used in water suction and discharge.

EN ISO 2398: Performance requirements for general-purpose rubber and plastic hoses.

SAE J517: Guidelines for hose construction and performance (influential for quality control).

REACH and RoHS: Compliance with safety regulations concerning chemical substances.

FDA and NSF/ANSI 61: For hoses used in potable water or food-related applications.

Manufacturing 1 inch, 1.5 inch, 2 inch, and 3 inch PVC suction hoses for water pumps involves a series of meticulous steps, from material selection and compounding to extrusion, reinforcement, and quality testing. Ensuring compliance with industry standards guarantees that the hoses will perform reliably and safely in various applications. These hoses are essential for efficient water transfer in agricultural, industrial, and residential settings.

PVC suction hoses for water pumps prices

Price Table for 1, 1.5, 2, and 3 Inch Suction Hoses for Water Pumps

As a supplier, offering competitive pricing for suction hoses is essential to cater to various customers, including wholesale buyers, brand resellers, and individual retail customers. Below is a detailed price breakdown for 1-inch, 1.5-inch, 2-inch, and 3-inch suction hoses for water pumps, considering factory prices, brand prices, and retail prices:

| Hose Size | Factory Price (Per Meter) | Brand Price (Per Meter) | Retail Price (Per Meter) |

|---|---|---|---|

| 1 Inch | $1.20 - $1.50 | $1.80 - $2.20 | $2.50 - $3.50 |

| 1.5 Inch | $1.50 - $1.80 | $2.20 - $2.80 | $3.00 - $4.00 |

| 2 Inch | $2.00 - $2.50 | $2.80 - $3.50 | $3.50 - $4.50 |

| 3 Inch | $2.80 - $3.50 | $3.80 - $4.50 | $4.50 - $5.50 |

1. Factory Prices (Wholesale)

Target Audience: Wholesale buyers, importers, large-scale distributors.

Price Range: These prices are lower because they are sold in bulk directly from manufacturers. Typically, a supplier or factory price reflects orders of 1000 meters or more, making it ideal for large construction companies, agriculture firms, or other businesses needing hoses in large quantities.

Example: A factory in China might sell 1-inch suction hoses at $1.20 to $1.50 per meter if ordered in bulk.

2. Brand Prices (Reseller/Branded)

Target Audience: Buyers who purchase hoses from companies that brand, package, and market the product.

Price Range: The brand price includes the cost of branding, marketing, and customer support. These hoses are often sold to smaller distributors or retailers who may package them with company logos and support services. Brand prices are generally 20-30% higher than factory prices due to added costs.

Example: A company selling branded 2-inch hoses might price them between $2.80 to $3.50 per meter.

3. Retail Prices

Target Audience: End consumers, individual buyers.

Price Range: These prices are typically 40%-80% higher than factory prices due to additional distribution, retail markup, packaging, and advertising. Retail prices also reflect the cost of dealing with individual customers who purchase small quantities, often 10-30 meters at a time.

Example: A retailer may sell 3-inch suction hoses at $4.50 to $5.50 per meter, providing hoses in smaller quantities to farmers or small contractors.

Key Factors Affecting Price:

Quantity: Factory prices are lower when ordering in bulk, while retail prices increase with smaller quantities.

Custom Branding: Branded hoses that include logos, packaging, and additional marketing support will cost more.

Material Quality: Variations in material quality, such as the type of PVC or rubber, reinforcement (spiral or rigid), and UV/weather resistance, may cause prices to vary within the ranges mentioned.

Shipping and Logistics: Prices can increase depending on the shipping distance, especially for international orders.

Conclusion

When choosing where to buy suction hoses for water pumps, it’s important to consider your volume requirements and whether branding or retail packaging is necessary. Large-scale businesses may benefit from factory-direct pricing, while smaller distributors and individual buyers may opt for brand or retail purchases.

For accurate and up-to-date pricing, it is recommended to contact local suppliers or check online marketplaces and manufacturers directly.