Helix Sprial Pvc Suction Hose For Water Suction And Discharge

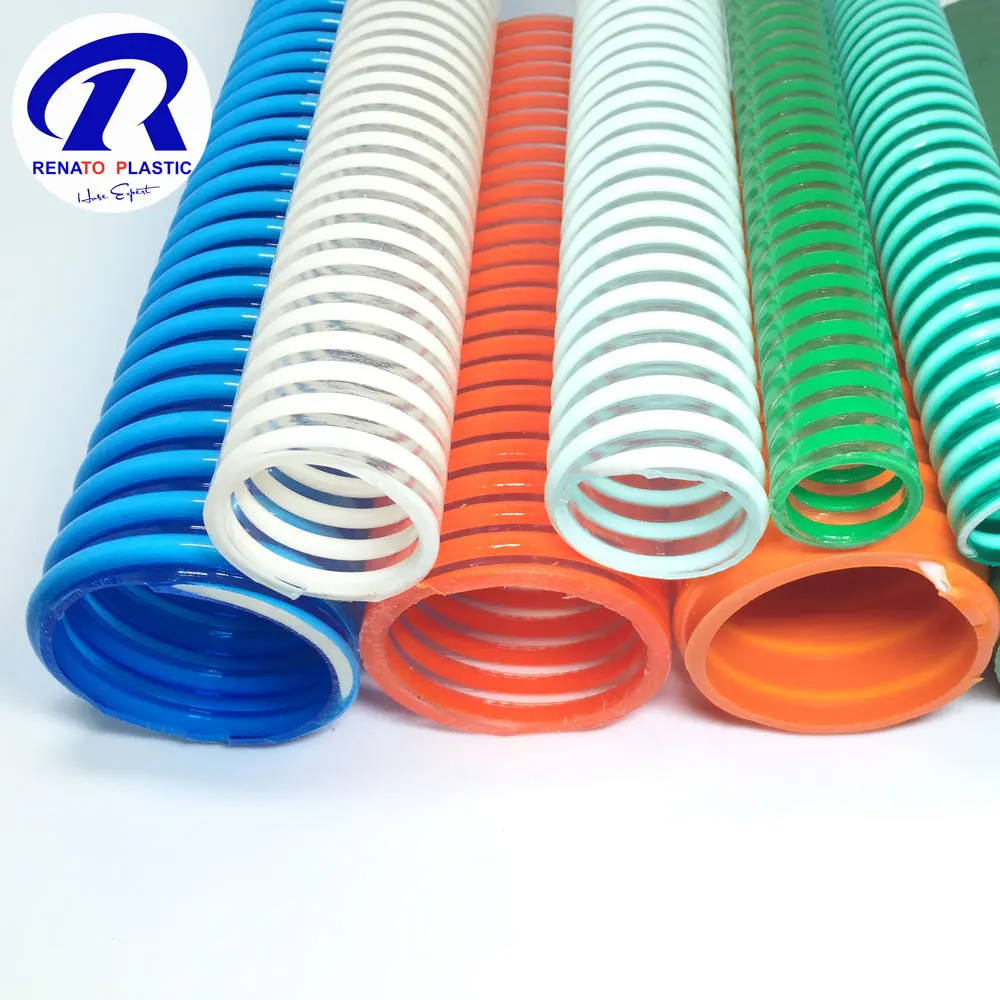

At Renato Hose, we pride ourselves on delivering top-tier products crafted with precision and expertise honed over 15 years in the industry. Our Helix Spiral PVC Suction Hose stands as a testament to our commitment to quality and innovation.

Crafted with high-quality PVC reinforcement, our suction hose boasts a robust construction capable of withstanding up to -2 bar vacuum pressure, ensuring reliability even in demanding environments. Its long working life guarantees durability, providing you with a dependable solution for your water suction and discharge requirements.

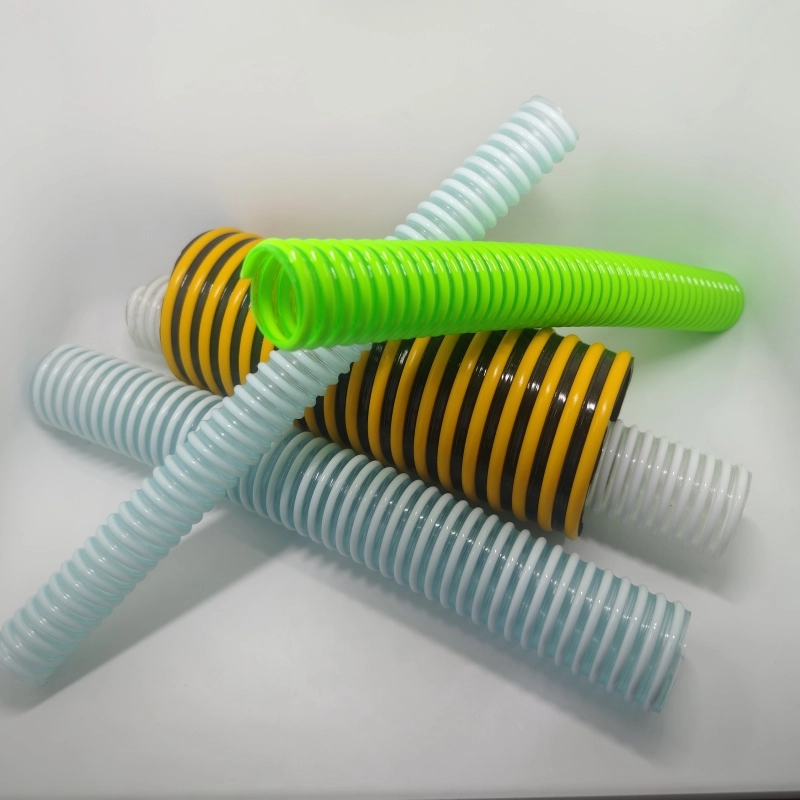

There are different colors of suction hose for you to choose from, or you can contact us to tell us the color you need, and we will customize it for you.

What is Suction Hose Pipe?

Suction hose pipe is a type of flexible tubing designed for use in applications that require the suction or transfer of liquids, gases, or other fluids. It is typically made of durable and flexible materials that can withstand the rigors of various environments and applications.

Suction hose pipe is often used in agricultural, industrial, and construction settings. In agriculture, for example, it can be used for irrigation systems to deliver water to crops efficiently. In industrial applications, it may be used for transferring chemicals, fuels, or other liquids within a factory or manufacturing facility. In construction, suction hose pipe can be utilized for pumping water or other fluids during various stages of a building project.

The flexibility of suction hose pipe allows it to conform to different shapes and sizes, making it suitable for use in a wide range of scenarios. It can also be easily connected to pumps, valves, and other equipment to create a complete fluid transfer system. Additionally, suction hose pipe is often designed to be lightweight and easy to handle, which makes it convenient for use in field or on-site applications.

This is a cross-sectional picture of the product. The outer wall is smooth and flat, and there are no bumps or defects, which can ensure that it is not easy to be damaged by external objects during use.

Applications

This hose is widely used for industry in both positive and negative pressure applications, ideally for conveying and suction of water, oil, powder, granules in pump industries, constructions, mining industries, chemical factories and many other industry applications.

Characteristics

This hose is made from high quality flexible PVC material and high strengthen PVC bones. Excellent flexibility, light weight, crush and abrasion resistant, smooth tube for less friction loss, smooth cover allows easy dragging, weathering resistant, clear to have full visual flow of materials, corrosion resistant to light chemicals, various lengths available and can be supplied with different couplings and clamps, ideal replace for bulkier and heavier ply-wrapped rubber hose.

◢ This kind of hose is an ideal products to use for suction and discharge.

◢ It is cystal clear, flexible, bright colors, very easy to know what's going on inside the hose.

◢ No odor, environmental protection products.

◢ Working Temperature: -5°C-65°C

This is a picture of suction hose after simple packaging.

Specifications of PVC Suction Hose

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | ||

| inch | mm | mm | m | kg/m | bar | psi |

| 3/4 | 19 | 2.5 | 50 | 0.25 | 8 | 120 |

| 3 | 50 | 0.28 | 9 | 135 | ||

| 1 | 25 | 2.5 | 50 | 0.32 | 8 | 120 |

| 3 | 50 | 0.35 | 9 | 135 | ||

| 1 1/4 | 32 | 3 | 50 | 0.4 | 8 | 120 |

| 4 | 50 | 0.55 | 9 | 135 | ||

| 1 1/2 | 38 | 3 | 50 | 0.55 | 6 | 90 |

| 4 | 50 | 0.7 | 7 | 105 | ||

| 2 | 50 | 4 | 50 | 0.92 | 6 | 90 |

| 5 | 50 | 1.1 | 7 | 105 | ||

| 2 1/2 | 63 | 3.5 | 30 | 0.95 | 5 | 75 |

| 4.5 | 30 | 1.23 | 6 | 90 | ||

| 3 | 75 | 4 | 30 | 1.45 | 4 | 60 |

| 5 | 30 | 1.65 | 5 | 75 | ||

| 4 | 100 | 5 | 30 | 2.3 | 4 | 60 |

| 6 | 30 | 2.9 | 5 | 75 | ||

| 5 | 127 | 6 | 20 | 3.3 | 4 | 60 |

| 8 | 20 | 4.7 | 5 | 75 | ||

| 6 | 152 | 7 | 20 | 5 | 4 | 60 |

| 9 | 20 | 6.3 | 5 | 75 | ||

| 8 | 200 | 7 | 10 | 6.3 | 4 | 60 |

| 8 | 10 | 7 | 4 | 60 | ||

| 10 | 250 | 8 | 10 | 10 | 4 | 60 |

| 9 | 10 | 11 | 4 | 60 | ||

| 12 | 305 | 12 | 10 | 18 | 4 | 60 |

| 14 | 355 | 12 | 10 | 20 | 4 | 60 |

The Application of Floating Sand Gravel Dust Water Liquid Powder PVC Suction Hose

The application of Floating Sand Gravel Dust Water Liquid Powder PVC Suction Hose refers to the various uses and scenarios where this type of hose is employed. This hose, made of PVC (Polyvinyl Chloride), is designed with a floating feature that allows it to adjust and adapt to different conditions and terrains, making it suitable for a wide range of applications.

Here are some of the key applications of the Floating Sand Gravel Dust Water Liquid Powder PVC Suction Hose:

Construction and Mining: In construction sites and mining operations, this hose is used to suction and transport sand, gravel, dust, and other materials efficiently. Its floating design allows it to move freely across uneven surfaces, making it highly versatile in these environments.

Environmental Cleanup: For environmental cleanup tasks, such as suctioning wastewater, sludge, or other contaminants, this hose is an effective tool. It can be used in various settings to help with pollution control and waste management.

Agriculture and Irrigation: In agricultural settings, the PVC suction hose can be used for water and fertilizer delivery systems. It can suction and transport water mixed with fertilizers for precision irrigation, promoting healthier crop growth.

Chemical and Food Processing: In chemical and food processing industries, this hose is used to transfer liquids and powder-form raw materials. Its resistance to corrosion and ability to handle various substances make it a suitable choice for these applications.

Dust Control and Material Handling: The hose's ability to suction dust and other fine particles makes it valuable in industries where dust control is critical, such as woodworking or metalworking shops.

How to Make Suction Hose?

The production process of PVC suction hose typically involves the following steps:

Material Preparation: Initially, PVC resin, plasticizers, stabilizers, and other necessary additives are prepared and mixed in specific proportions.

Mixing and Plasticization: The aforementioned materials are placed in a mixer for blending and plasticization through heating to form a uniform PVC mixture.

Extrusion Molding: The plasticized PVC mixture is fed into an extruder and extruded through a specific die to form the preliminary shape of the PVC suction hose.

Cooling and Solidification: The extruded PVC hose undergoes a cooling and solidification process to ensure stability in its shape and properties.

Quality Inspection: The manufactured PVC suction hose undergoes quality checks, including inspections on dimensions, wall thickness, pressure resistance, and other aspects, to ensure compliance with standards.

Cutting and Packaging: The qualified PVC suction hose is cut into the desired lengths and undergoes necessary packaging processes for convenient transportation and storage.

Company Advantages

Extensive Experience: With over 15 years of production expertise, Qingdao Renato Plastic Co., Ltd. is a trusted name in the industry.

Advanced Facilities: Our state-of-the-art factory in Shandong province boasts 10 workshops, over 60 production lines, and a dedicated team of 120 skilled workers, 5 technicists, and 2 QC teams.

Global Reach: Serving customers in more than 60 countries, our products have gained widespread acclaim and recognition for their quality and performance.

Customer-Centric Philosophy: We prioritize our customers with a "Customers Always First" philosophy, ensuring 7x24 hours quick response to all inquiries and needs.

For a reliable partner in hoses and assemblies, look no further than Qingdao Renato Plastic Co., Ltd. Your inquiries will be addressed promptly, with a commitment to providing top-quality products and services.

Reach out to us today to experience the Renato difference.