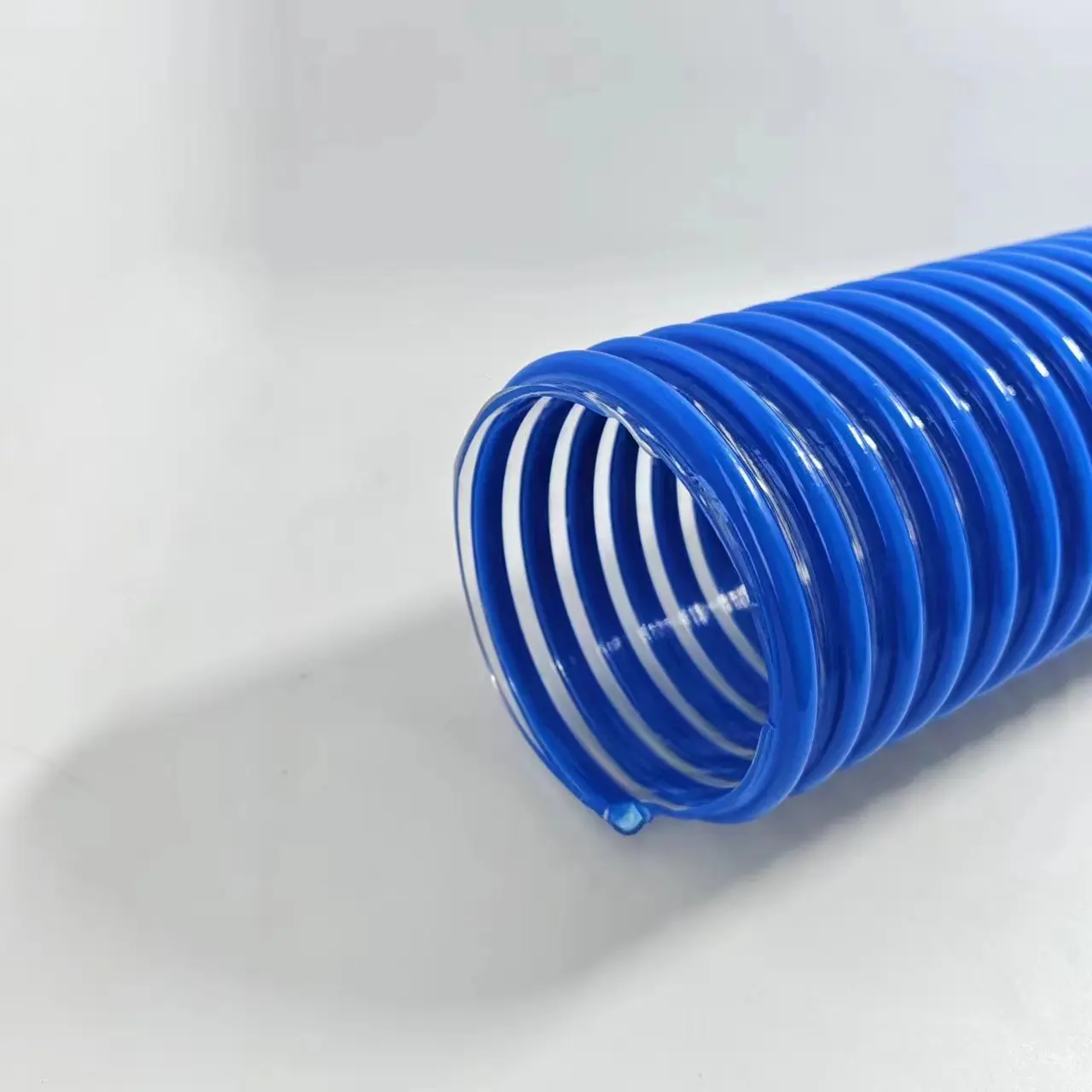

When it comes to choosing the right hose for water extraction tasks, the 2 Inch Corrugated Water Suction Hose stands out as a versatile, durable, and reliable option. Whether you’re handling agricultural irrigation, dewatering construction sites, or responding to emergency flood situations, this hose is a workhorse you can depend on. As someone who has spent years working with various types of hoses, I can confidently say this one ticks all the boxes for anyone in need of a practical and high-performing solution.

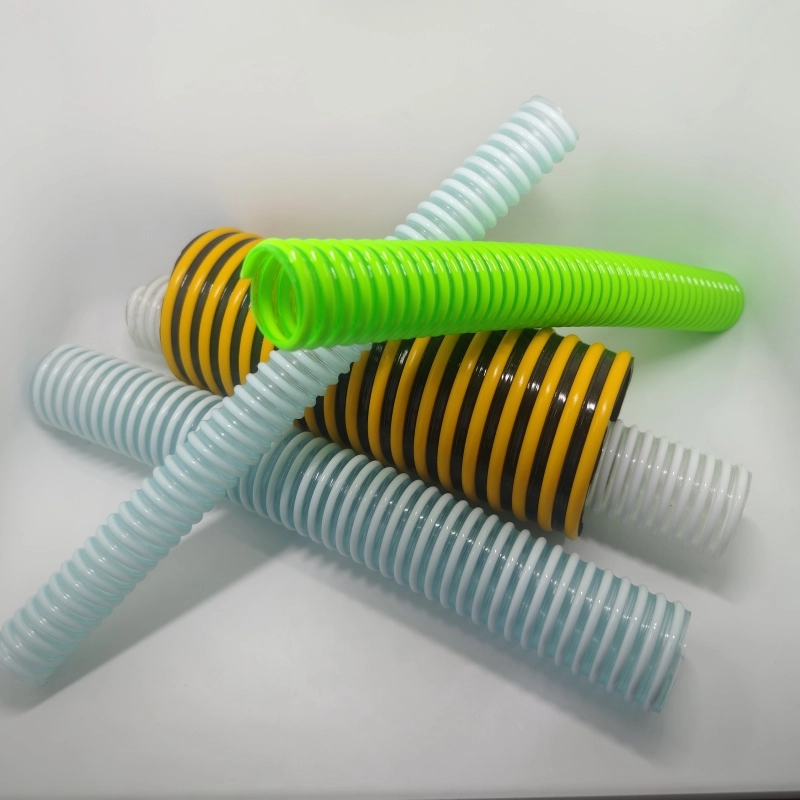

Advantages and Disadvantages of PVC Suction Hose

Advantages

Strong Corrosion Resistance: PVC material exhibits good corrosion resistance to various chemicals, maintaining stable performance in multiple harsh environments and being suitable for conveying various corrosive liquids.

Lightweight and Durable: Compared to metal or other heavy materials used to make suction hoses, PVC suction hose is lighter in weight, facilitating easy handling and installation, while also possessing good durability to withstand certain pressures and abrasions.

Cost-Effective: The relatively low cost of PVC material, combined with mature production processes, makes PVC suction hose highly competitive in price, suitable for large-scale production and application.

Disadvantages (Focusing on Large Volume and Inconvenience in Transportation)

Bulky and Space-Consuming: PVC suction hose typically has a certain length and diameter, resulting in a large overall volume that occupies considerable space during storage and transportation, increasing warehousing and transportation costs.

Transportation Inconvenience and Vulnerability to Damage: Due to its large volume and relatively flexible nature, PVC suction hose is prone to damage during transportation due to compression and collisions, requiring additional protective measures to ensure safe transportation.

Difficult Handling: The bulky nature of PVC suction hose makes the handling process relatively complex, requiring specialized handling equipment and personnel for operation, which increases handling costs and risks.

Application Field

| Agricultural Irrigation | Water Pumping for Irrigation: Used to draw water from rivers, lakes, or wells to supply farmland irrigation systems. Drainage: Used to remove accumulated water from fields during rainy seasons or floods. |

| Construction and Building | Construction Site Drainage: Used for drainage operations at construction sites, basements, or tunnels. Slurry Suction: Used to suction slurry or wastewater in foundation construction or piling projects. |

| Industrial Applications | Chemical Suction: Used to convey or suction corrosive chemicals such as acids and alkalis (requires chemical-resistant models). Oil Suction: Used in the petroleum or grease industry to suction fuels, lubricants, and other media. |

| Wastewater Treatment | Sewage Suction: Used in wastewater treatment plants or municipal projects to suction sewage or sludge. Rainwater Discharge: Used in urban drainage systems to suction rainwater or accumulated water. |

Mining and Quarrying | Slurry and Wastewater Handling: Used in mines or quarries to suction slurry, wastewater, or other waste materials. Dust Control: Used to suction dust or particulate matter during mining operations. |

| Shipping and Ports | Ship Drainage: Used for drainage operations in ship compartments. Port Dredging: Used to suction silt or sediment in ports or docks. |

| Food and Beverage Industry | Liquid Suction: Used to suction food-grade liquids such as water, juice, and alcoholic beverages (requires food-grade models). |

| Other Applications | Firefighting Emergencies: Used in firefighting operations to suction water or other fire-extinguishing media. Landscaping: Used for water feature maintenance or drainage in parks or gardens. |

We use the best packaging method to ensure that the product can arrive safely at your designated location.

Specifications

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | ||

| inch | mm | mm | m | kg/m | bar | psi |

| 3/4 | 19 | 2.5 | 50 | 0.25 | 8 | 120 |

| 3 | 50 | 0.28 | 9 | 135 | ||

| 1 | 25 | 2.5 | 50 | 0.32 | 8 | 120 |

| 3 | 50 | 0.35 | 9 | 135 | ||

| 1 1/4 | 32 | 3 | 50 | 0.4 | 8 | 120 |

| 4 | 50 | 0.55 | 9 | 135 | ||

| 1 1/2 | 38 | 3 | 50 | 0.55 | 6 | 90 |

| 4 | 50 | 0.7 | 7 | 105 | ||

| 2 | 50 | 4 | 50 | 0.92 | 6 | 90 |

| 5 | 50 | 1.1 | 7 | 105 | ||

| 2 1/2 | 63 | 3.5 | 30 | 0.95 | 5 | 75 |

| 4.5 | 30 | 1.23 | 6 | 90 | ||

| 3 | 75 | 4 | 30 | 1.45 | 4 | 60 |

| 5 | 30 | 1.65 | 5 | 75 | ||

| 4 | 100 | 5 | 30 | 2.3 | 4 | 60 |

| 6 | 30 | 2.9 | 5 | 75 | ||

| 5 | 127 | 6 | 20 | 3.3 | 4 | 60 |

| 8 | 20 | 4.7 | 5 | 75 | ||

| 6 | 152 | 7 | 20 | 5 | 4 | 60 |

| 9 | 20 | 6.3 | 5 | 75 | ||

| 8 | 200 | 7 | 10 | 6.3 | 4 | 60 |

| 8 | 10 | 7 | 4 | 60 | ||

| 10 | 250 | 8 | 10 | 10 | 4 | 60 |

| 9 | 10 | 11 | 4 | 60 | ||

| 12 | 305 | 12 | 10 | 18 | 4 | 60 |

| 14 | 355 | 12 | 10 | 20 | 4 | 60 |

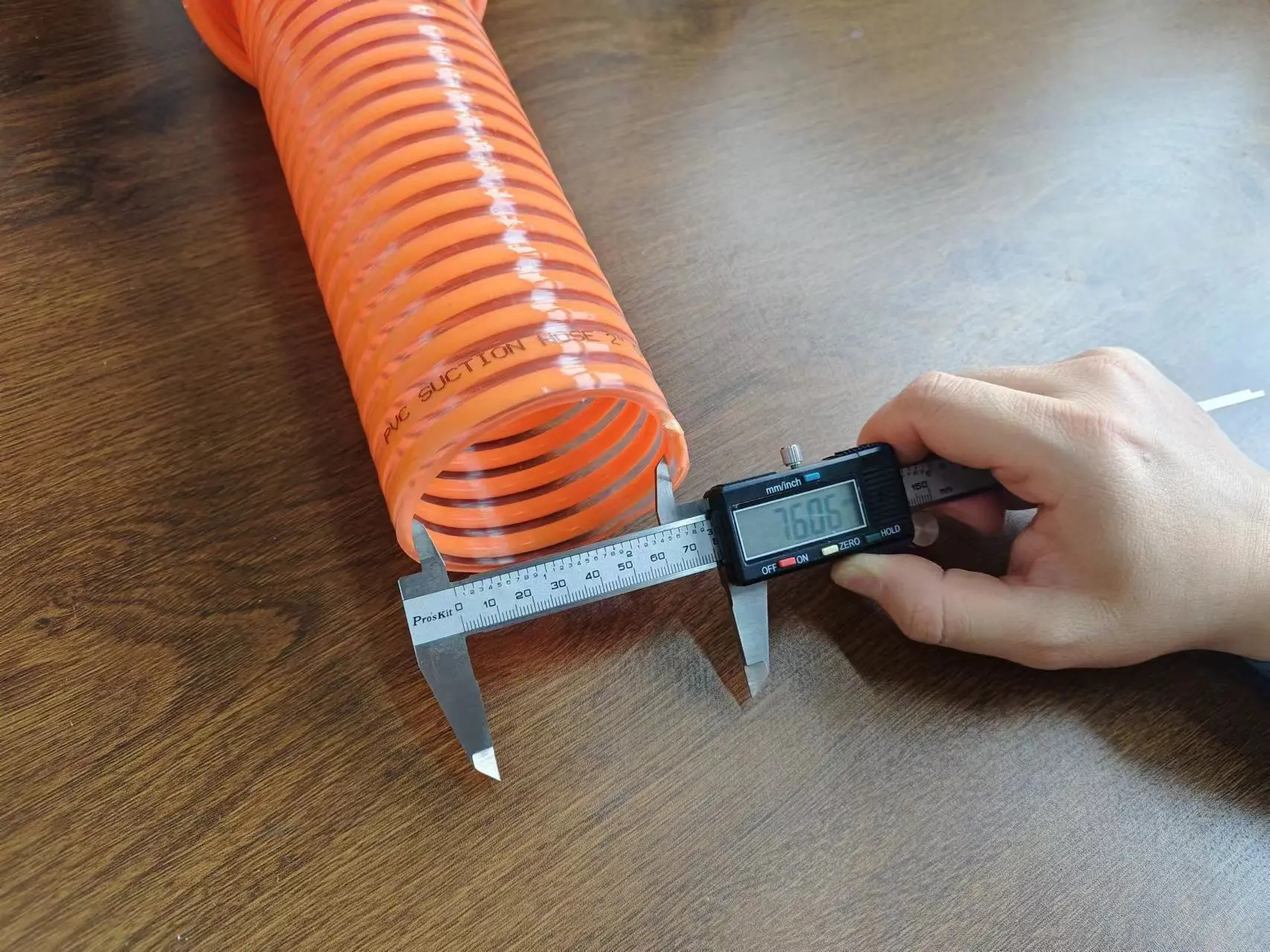

During the production process, we use professional measuring instruments to precisely measure the dimensions of PVC Suction Hose, ensuring that each hose fully meets customer requirements and industry standards. Our measuring equipment includes high-precision calipers, laser rangefinders, and diameter measuring instruments, which enable comprehensive inspection of the hose's inner diameter, outer diameter, wall thickness, and length. Through these advanced instruments, we can control dimensional errors within a minimal range, thereby meeting customers' high demands for precision.

During the production process, we use professional measuring instruments to precisely measure the dimensions of PVC Suction Hose, ensuring that each hose fully meets customer requirements and industry standards. Our measuring equipment includes high-precision calipers, laser rangefinders, and diameter measuring instruments, which enable comprehensive inspection of the hose's inner diameter, outer diameter, wall thickness, and length. Through these advanced instruments, we can control dimensional errors within a minimal range, thereby meeting customers' high demands for precision.

How to Use PVC Suction Hose and Water Pump Together

1. Selecting the Right PVC Suction Hose and Water Pump

Hose Selection: Choose a PVC Suction Hose with the appropriate material and size based on the medium (e.g., water, slurry, chemicals). Ensure the hose's pressure resistance and corrosion resistance meet the requirements.

Pump Selection: Select the appropriate type of water pump (e.g., centrifugal pump, submersible pump, self-priming pump) based on flow rate, head, and working environment.

2. Connecting the Hose and Pump

Check Connections: Ensure the pump's inlet and outlet sizes match the PVC Suction Hose connections.

Use Adapters: If necessary, use adapters or flanges to securely connect the hose to the pump, ensuring a leak-proof seal.

Secure the Hose: Use hose clamps or clips to fasten the hose to the pump connections, preventing detachment due to pressure or vibration.

3. Installation and Startup

Position the Pump: Place the pump on a flat surface or a fixed bracket to ensure stable operation.

Immerse the Hose: Submerge the suction end of the PVC Suction Hose into the liquid to be suctioned (e.g., water tank, river, well), ensuring it is fully immersed to avoid drawing in air.

Start the Pump: Turn on the pump to begin suctioning the liquid. For self-priming pumps, prime the pump with water during initial use.

4. Operational Considerations

Monitor Pressure: Ensure the working pressure of the PVC Suction Hose and pump remains within the rated range to avoid hose rupture or pump damage due to overpressure.

Check Seals: Regularly inspect the seal between the hose and pump to prevent leaks.

Avoid Dry Running: Ensure the suction end of the hose remains submerged in the liquid to prevent pump dry running, which can damage the equipment.

5. Shutdown and Disassembly

Turn Off the Pump: After completing the suction task, turn off the pump.

Drain the Hose: Empty the liquid from the PVC Suction Hose to prevent residual media from corroding the hose.

Disassemble and Clean: Disconnect the hose and clean its interior and exterior, then store it in a dry, cool place to extend its service life.

6. Application Examples

Agricultural Irrigation: Connect the PVC Suction Hose to the pump to draw water from a source (e.g., river, well) and deliver it to an irrigation system.

Construction Drainage: At construction sites, use the pump and hose to suction accumulated water or slurry and discharge it to a designated area.

Industrial Suction: In chemical plants, use chemical-resistant PVC Suction Hose and pumps to suction chemicals or wastewater.

A Hose You Can Count On

If you’re in the market for a hose that offers both reliability and flexibility, the 2 Inch Corrugated Water Suction Hose should be at the top of your list. Its PVC construction, combined with the corrugated design, makes it ideal for a variety of applications, from agriculture to construction dewatering and even emergency flood response. Whether you need a hose that can handle the daily grind or one that can stand up to extreme conditions, this product has got you covered.

At Qingdao Renato Plastic Co., Ltd., we pride ourselves on delivering top-quality products backed by over 15 years of manufacturing expertise. Our dedication to quality ensures that every Renflex hose and fitting meets international standards like ISO9001. When you choose our hoses, you’re choosing a product that has been tested, trusted, and praised by customers in more than 60 countries.

So, if you’re ready to take your water extraction tasks to the next level, don’t hesitate to reach out. Our 2 Inch Corrugated Water Suction Hose is waiting to work for you. Just like the projects I’ve been part of, it’ll get the job done—efficiently and reliably.

Contact Us

If you're in need of a dependable partner for hoses and assemblies, Qingdao Renato Plastic Co., Ltd. is here to help. Reach out to us for any inquiries or product needs. We offer 7x24 hour quick responses and are committed to putting our customers first. You can contact us via phone, email, or our website to get a prompt response and professional service.