3 Inch PVC Reinforced Spring Steel Wire Hose with Food Grade

In the fast-paced world of food and beverage processing, the choice of materials and equipment is crucial to maintaining product quality, ensuring safety, and optimizing operational efficiency. Among the various components required in these applications, the hose plays a vital role in fluid conveyance, impacting both the performance and hygiene of the entire process. The 3-inch PVC reinforced spring steel wire hose with food-grade certification stands out as a premium choice that meets the rigorous demands of the food and beverage industry.

Durability and Strength

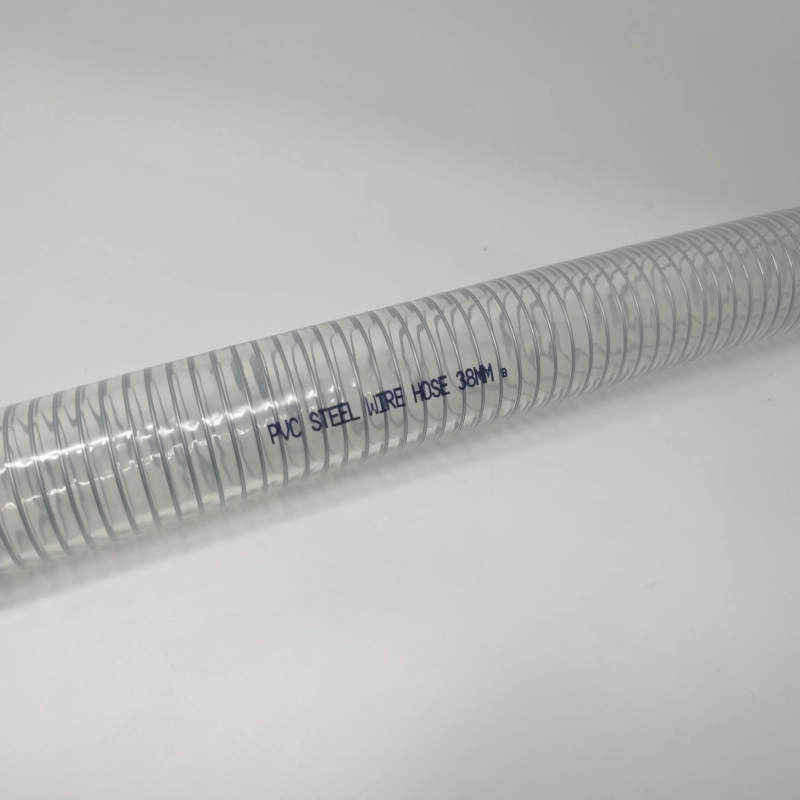

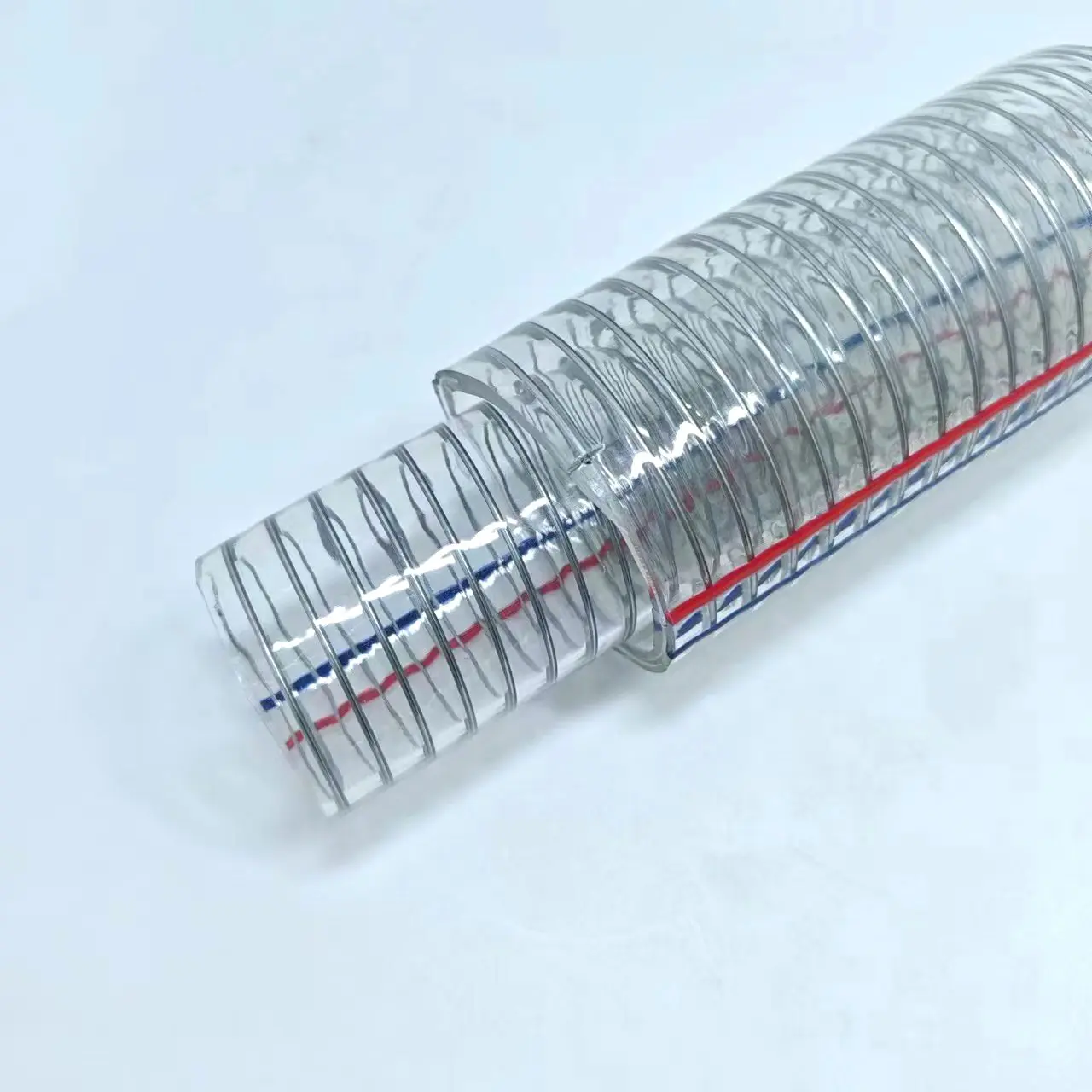

Engineered with a reinforced spring steel wire helix embedded within the PVC wall, this hose combines the flexibility of plastic with the strength of metal. The PVC material itself is known for its resistance to a wide range of chemicals and temperatures, making it suitable for various food and beverage processing environments. The addition of the spring steel wire provides exceptional tensile strength and pressure resistance, ensuring that the hose can withstand the rigorous conditions of industrial use. This robust construction prevents kinking, crushing, and wear, thereby extending the lifespan of the hose and reducing the need for frequent replacements.

Flexibility and Versatility

The flexibility of the 3-inch PVC spring steel wire hose is another key feature that makes it ideal for food and beverage processing applications. The hose can be easily bent and maneuvered around tight spaces and obstacles, allowing for versatile installation options. This flexibility also accommodates changes in the process layout and facilitates maintenance and cleaning tasks. Whether the hose is used in a fixed installation or requires frequent repositioning, its flexibility ensures optimal performance and ease of use.

Hygiene and Safety

In the food and beverage industry, hygiene is paramount. The 3-inch PVC teel wire hose with food-grade certification meets the highest standards of cleanliness and safety. The hose is made from materials that comply with food contact regulations, ensuring that it does not release harmful substances into the conveyed fluids. The smooth inner surface of the hose reduces the risk of contamination and facilitates easy cleaning, which is crucial for maintaining product quality and consumer safety. The hose can be cleaned using various methods, including high-pressure water jetting, steam cleaning, and chemical sanitation, ensuring that it remains in optimal condition throughout its lifespan.

Efficient Fluid Conveyance

The 3-inch diameter of the hose allows for efficient fluid conveyance, making it suitable for a wide range of food and beverage processing applications. The hose can handle a variety of fluids, including water, dairy products, beverages, oils, and syrups, ensuring that the processing line operates smoothly and efficiently. The large diameter also minimizes pressure drop and friction losses, reducing energy consumption and operational costs.

Compatibility with Various Equipment

The 3-inch PVC spring steel wire hose is compatible with various types of equipment used in food and beverage processing. It can be easily connected to pumps, tanks, valves, and other components using standard fittings and adapters. This compatibility ensures that the hose can be seamlessly integrated into existing processing lines, minimizing downtime and simplifying installation tasks.

Customizable Options

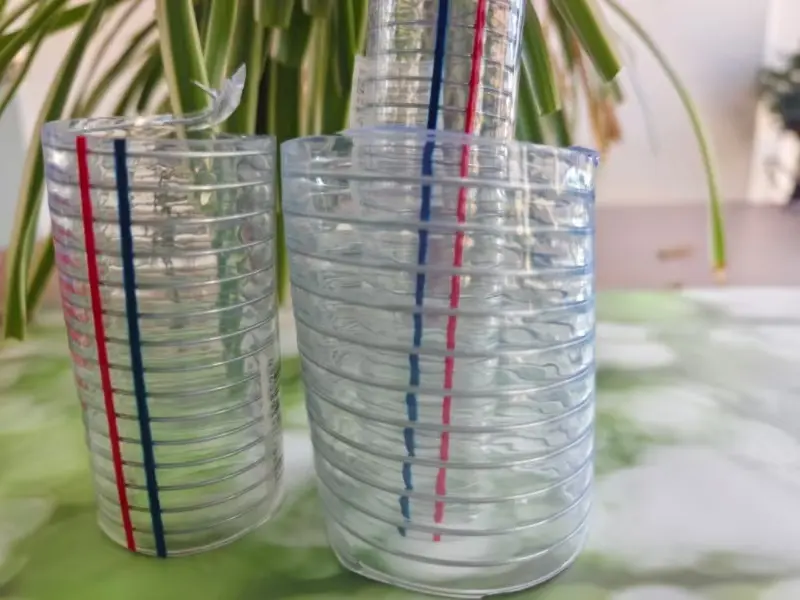

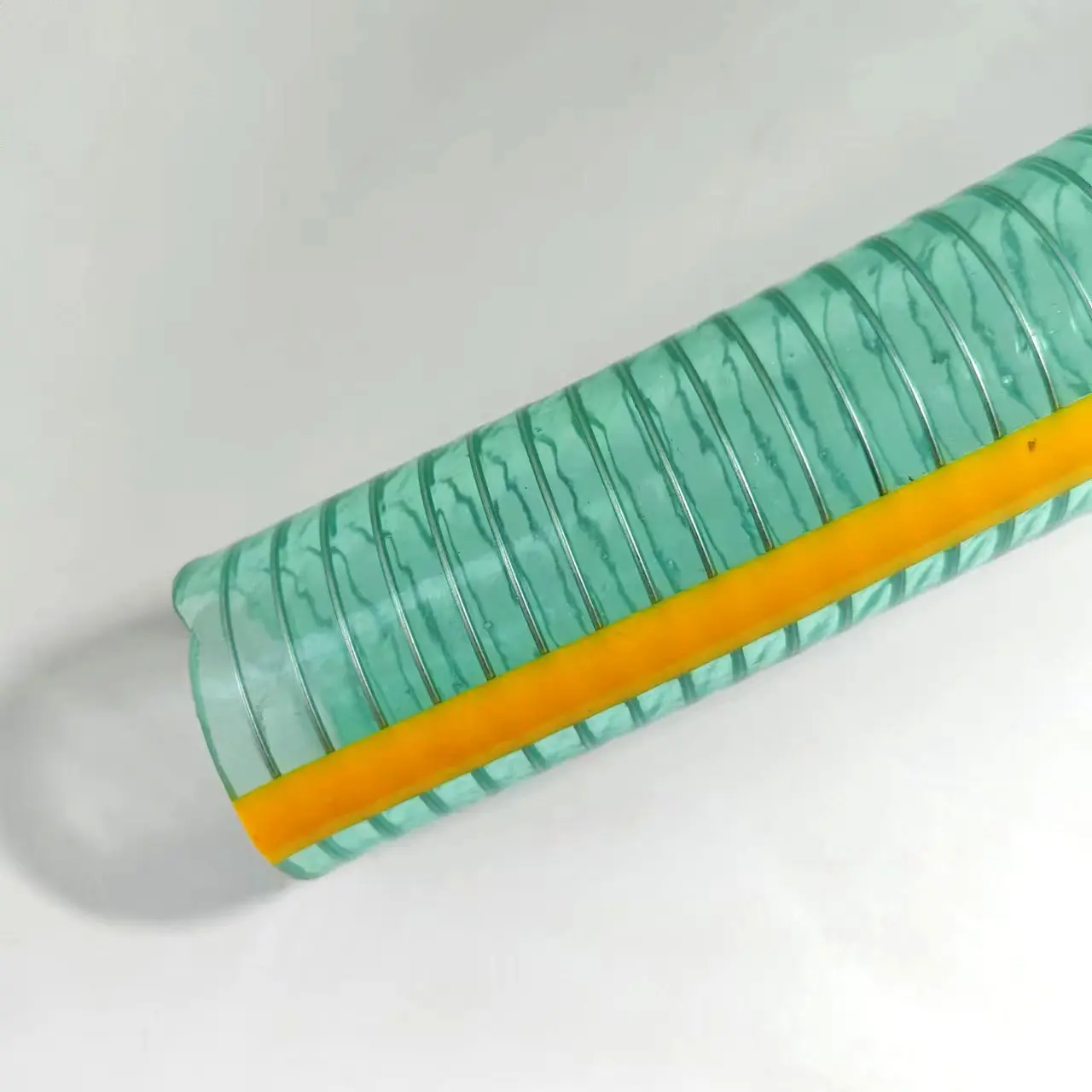

In addition to its standard features, the 3-inch PVC spring steel wire hose can be customized to meet specific application requirements. Options such as different lengths, end connections, and color coding can be provided to suit the unique needs of each processing line. This customizability ensures that the hose can be tailored to fit perfectly into any food and beverage processing environment, enhancing overall performance and satisfaction.

Specification Sheet

1. Technical Requirements

| Feature | Details |

|---|---|

| Material | PVC & Spring Steel Wire |

| Food-Grade Certification | RoHS, REACH, CE, Food-Grade Approved |

| Working Temperature | -30°C to +160°C |

| Working Pressure | 2 - 10 bar |

| Burst Pressure | Up to 30 bar (varies by diameter) |

| Bending Radius | Highly flexible, depending on diameter |

| Transparency | Allows for easy monitoring of internal flow |

| Chemical Resistance | Resistant to most acids, alkalis, and solvents |

| UV Resistance | Designed to withstand outdoor use and UV exposure |

| Odor-Free | No odor, ensuring no contamination to conveyed substances |

| Safety | High durability under high negative pressure environments |

| Applications | Suction and discharge of water, oil, powder, granules, milk, beer, etc. |

2. Specification Sizes

| Nominal Diameter (Inch) | Inner Diameter (mm) | Outer Diameter (mm) | Length (m) | Wall Thickness (mm) | Working Pressure (bar) | Weight (kg/m) |

|---|---|---|---|---|---|---|

| 1/4 | 6.5 | 11.5 | 10/30/50/100 | 2.5 | 10 | 0.08 |

| 1/2 | 13 | 18 | 10/30/50/100 | 2.5 | 10 | 0.15 |

| 1 | 25 | 30 | 10/30/50/100 | 2.5 | 8 | 0.28 |

| 1-1/2 | 38 | 45 | 10/30/50/100 | 3.5 | 8 | 0.50 |

| 2 | 51 | 61 | 10/30/50/100 | 5 | 8 | 0.85 |

| 3 (Featured) | 76 | 88 | 10/30/50/100 | 6 | 6 | 1.50 |

| 4 | 102 | 116 | 10/30/50/100 | 7 | 6 | 2.20 |

| 6 | 152 | 168 | 10/30/50/100 | 8 | 5 | 3.85 |

| 8 | 203 | 221 | 10/30/50/100 | 9 | 5 | 5.50 |

| 10 | 254 | 274 | 10/30/50/100 | 10 | 4 | 7.50 |

Note: Specifications may vary slightly based on specific requirements and configurations. Custom sizes are also available upon request.

Comprehensive Description of PVC Steel Wire Hose

PVC Steel Wire Hose, a PVC hose embedded with a steel wire spiral structure, is widely used in various industries due to its excellent performance. The following provides a detailed description of PVC Steel Wire Hose from several aspects, including material composition, performance characteristics, application fields, production processes, quality control, and advantages and disadvantages, with approximately 1200 words dedicated to each aspect.

Material Composition

The primary materials of PVC Steel Wire Hose consist of PVC (Polyvinyl Chloride) and steel wire. PVC, as a plastic material, features corrosion resistance, acid and alkali resistance, high elasticity, and resistance to aging, making it widely used in pipe manufacturing. The incorporation of steel wire significantly enhances the strength and pressure resistance of the hose. The steel wire is usually woven or spirally wound within the PVC pipe wall, forming a three-layer structure with PVC on both the inner and outer layers and steel wire in the middle. This structure maintains the flexibility and corrosion resistance of the PVC hose while imparting the strength and pressure resistance of steel wire, allowing PVC Steel Wire Hose to excel in various environments.

Performance Characteristics

Strong Pressure Resistance: Due to the internally reinforced steel wire structure, PVC Steel Wire Hose can withstand high pressure without breaking or deforming.

Corrosion Resistance: PVC material exhibits good tolerance to most acids, alkalis, and salts, enabling PVC Steel Wire Hose to be used in corrosive environments for an extended period.

High Elasticity: The PVC material's good elasticity allows PVC Steel Wire Hose to adapt to various complex environments, such as bending and stretching.

Excellent Weather Resistance: PVC material is resistant to aging and deterioration, even when exposed to sunlight or oxidation for long periods, without becoming brittle or hardened.

Long Service Life: Due to the above advantages, PVC Steel Wire Hose has a relatively long service life, reducing replacement frequency and costs.

Application Fields

PVC Steel Wire Hose is widely used in various industries due to its excellent performance:

Industrial Field: Used for conveying industrial water, oil, sewage, powders, chemical raw materials, etc. In mines, ports, docks, and other settings, PVC Steel Wire Hose can withstand high pressure and wear, ensuring smooth and safe conveyance.

Agricultural Field: Used in agricultural water pump machinery, irrigation systems, etc. The corrosion resistance and high elasticity of PVC Steel Wire Hose make it suitable for various agricultural environments.

Construction Field: Used for reinforcing concrete pipes within concrete piping. Additionally, in building construction, PVC Steel Wire Hose can be used to reinforce structural columns and walls.

Environmental Protection Field: Used in water treatment, waste gas treatment, and other environmental protection facilities. The corrosion resistance and pressure resistance of PVC Steel Wire Hose make it an ideal choice in the environmental protection field.

Production Processes

The production processes of PVC Steel Wire Hose mainly include raw material preparation, mixing, plasticizing, extrusion, cooling, curling, cutting, and winding.

Raw Material Preparation: Select PVC resin and steel wire that meet quality requirements and dry them to ensure no impurities or moisture.

Mixing: Mix PVC resin, plasticizers, stabilizers, and other additives in a certain proportion to ensure homogeneity for subsequent plasticizing and extrusion processes.

Plasticizing: Plasticize and refine the mixed PVC raw materials to make them suitable for processing.

Extrusion: Extrude the plasticized PVC raw materials into various specifications and shapes of PVC products through molds and dies. During the extrusion process, steel wire is woven or spirally wound within the PVC pipe wall.

Cooling: Rapidly cool and shape the extruded PVC products to ensure stable shape and size.

Curling: Curl the cooled PVC products to facilitate subsequent cutting and winding processes.

Cutting: Cut the curled PVC products to a certain length.

Winding: Collect and organize the cut PVC products into coils or spools for packaging and transportation.

Quality Control

To ensure the quality of PVC Steel Wire Hose, various aspects of the production process need to be strictly controlled:

Raw Material Quality Control: Conduct quality inspections on incoming raw materials to ensure they meet production requirements.

Process Parameter Control: Strictly control processing parameters such as temperature, pressure, time, and additive dosage to ensure rope quality and performance.

Production Process Quality Control: Maintain a clean and hygienic production environment to prevent contaminants such as dust and impurities from affecting rope quality.

Product Inspection and Testing: Conduct appearance inspections, physical performance tests, and safety tests on the produced PVC Steel Wire Hose to ensure it meets requirements.

Advantages and Disadvantages

Advantages:

Strong Pressure Resistance: Can withstand high pressure and wear.

Corrosion Resistance: Exhibits good tolerance to most chemicals.

High Elasticity: Can adapt to various complex environments.

Excellent Weather Resistance: Resistant to aging and deterioration.

Long Service Life: Reduces replacement frequency and costs.

Disadvantages:

Relatively Low Strength and Pressure Resistance: Compared to metal piping, the strength and pressure resistance of PVC Steel Wire Hose have certain limitations.

Poor Light Transmittance: Not suitable for applications requiring transparent piping.

Temperature Sensitivity: Although PVC Steel Wire Hose performs well within a wide temperature range, its performance may be affected in extreme high or low temperatures.

In summary, PVC Steel Wire Hose has become an indispensable material in various industries due to its excellent performance and wide range of applications. When using it, it is necessary to fully understand its characteristics and precautions to ensure optimal performance.

Company Advantages

15+ Years of Experience: With over 15 years of experience, Qingdao Renato Plastic Co., Ltd. has perfected the art of manufacturing PVC hoses, delivering reliable and high-quality products to customers worldwide.

Advanced Manufacturing Facilities: Our factory in Shandong province features 10 workshops, over 60 production lines, and a skilled workforce of 120 professionals, including 5 technicists and 2 QC teams.

Global Reach: Serving clients in over 60 countries, our products have been praised for their durability, flexibility, and performance.

Comprehensive Product Range: Apart from hoses, we also offer various hose assemblies, including camlock fittings, nozzle fittings, hose clamps, and more, ensuring a complete solution for your needs.

Customer-Centric Philosophy: "Customers always come first" is our guiding principle. We offer 7x24 hours quick response to all inquiries, ensuring prompt and efficient service.

Contact Us

For more information about the Clear Anti-Static PVC Spiral Steel Wire Hose with Copper Wire or to discuss your specific requirements, please feel free to reach out to us. Your inquiry will be responded to promptly by our expert team. At Qingdao Renato Plastic Co., Ltd., our philosophy is simple: "Customers are always first."