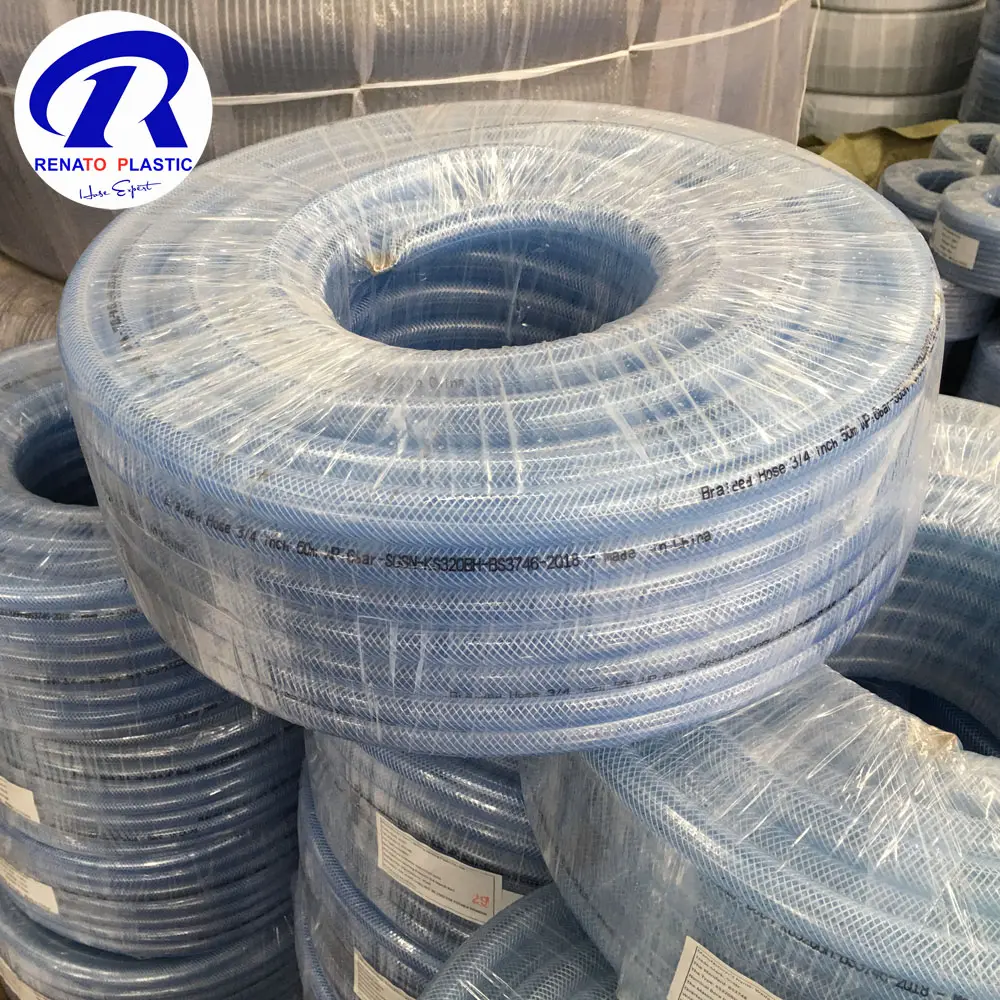

Flexible Nylon Fiber Reinforced Drinking Water Pipe Hose – Food Grade Hose

Qingdao Renato Plastic Co., Ltd. is a leading manufacturer of high-quality PVC hoses with over 15 years of production experience. Our company specializes in providing a wide range of hoses, including Layflat Hose, Suction Hose, Fiber Reinforced Hose, and many others. We are proud to offer the Flexible Nylon Fiber Reinforced Drinking Water Pipe Hose – a premium, food-grade hose designed for the safe transport of drinking water. Engineered with durability and safety in mind, this hose meets the highest standards for potable water applications, ensuring peace of mind for both residential and commercial users.

Key Features of Food-grade Hoses

Non-toxic and Odorless: Food-grade hoses are made from non-toxic and harmless materials, ensuring no unpleasant odors or harmful substances are released during use, thereby maintaining the purity and safety of food.

Corrosion Resistance: The materials used in these hoses exhibit excellent chemical stability, resisting erosion from acids, alkalis, and other corrosive substances, extending their service life.

Heat Resistance: Some food-grade hoses maintain stable performance under high-temperature conditions, suitable for use in food processing equipment that requires heating or insulation.

Flexibility and Ease of Bending: The flexible design of these hoses facilitates installation and use, allowing them to adapt to various complex piping layouts.

Specification Sheet

Technical Requirements

| Parameter | Details |

|---|---|

| Brand Name | Renflex |

| Material | PVC with Nylon Fiber Reinforcement |

| Certification | RoHS, REACH, CE, Food Grade |

| Application | Drinking Water Transport, General Water Supply, Irrigation |

| Working Temperature | -5°C to +65°C |

| Working Pressure | 2 - 10 bar |

| Transporting Medium | Water |

| Color Options | Green, Yellow, Blue, Orange, Black, Red (Customizable) |

| Packaging | Paper Card, Shrink Wrap |

| Connection Types | Brass Fittings, Nozzle Guns |

| Reinforcement Type | Nylon Fiber Reinforcement |

| Wall Thickness | 1mm, 2mm, 3mm, 4mm, 5mm, 6mm |

| UV Resistance | Yes, UV resistant for prolonged outdoor use |

| Chemical Resistance | Resistant to a variety of chemicals, including salts and acids |

| Compliance | Complies with international drinking water safety standards |

Specification Sizes

| Specification Size | Inner Diameter (mm) | Outer Diameter (mm) | Length (m) | Thickness (mm) |

|---|---|---|---|---|

| 3/16 inch | 4.75 | 7.5 | 10, 20, 50, 100, 150 | 1, 2, 3, 4, 5 |

| 1/4 inch | 6.35 | 9.0 | 10, 20, 50, 100, 150 | 1, 2, 3, 4, 5 |

| 3/8 inch | 9.53 | 13.0 | 10, 20, 50, 100, 150 | 1, 2, 3, 4, 5 |

| 1/2 inch | 12.7 | 16.0 | 10, 20, 50, 100, 150 | 1, 2, 3, 4, 5 |

| 3/4 inch | 19.05 | 23.0 | 10, 20, 50, 100, 150 | 2, 3, 4, 5, 6 |

| 1 inch | 25.4 | 30.0 | 10, 20, 50, 100, 150 | 2, 3, 4, 5, 6 |

| 1 1/4 inch | 31.75 | 37.0 | 10, 20, 50, 100, 150 | 2, 3, 4, 5, 6 |

| 1 1/2 inch | 38.1 | 44.0 | 10, 20, 50, 100, 150 | 2, 3, 4, 5, 6 |

| 2 inch | 50.8 | 57.0 | 10, 20, 50, 100, 150 | 2, 3, 4, 5, 6 |

Applications of Food-grade Hoses

Drinking Water Systems: Used in water dispensers, water purifiers, faucets, and other equipment to ensure the safety and hygiene of drinking water.

Food Processing: In food production lines, they are utilized to transport various liquid or semi-solid food ingredients such as dairy products, juices, and sauces.

Medical Equipment: In the medical field, food-grade hoses are employed for intravenous infusions, suctioning, and other medical procedures to ensure the safety and hygiene of medical procedures.

Other Fields: They are also used for aquarium water changes, gardening irrigation, industrial fluid transportation, and other occasions where contact with food is required.

Primary Materials of Food-grade Hoses

Silicone: Silicone hoses exhibit excellent heat and cold resistance, are non-toxic and odorless, and are commonly used in food-grade applications.

PVC: Certain specially treated PVC hoses can also be used for food-grade applications, but attention must be paid to ensuring that the plasticizer content meets relevant standards.

Stainless Steel: Stainless steel hoses offer superior corrosion resistance but are more costly, typically used in scenarios with extremely high safety requirements.

Other Materials: Materials such as PE, PP, rubber, and alloys can also be used to manufacture food-grade hoses based on specific needs.

Suggestions for Purchasing Food-grade Hoses

Check Certifications: Verify that the hoses possess relevant food safety certifications, such as FDA and LFGB certifications.

Focus on Materials: Choose the appropriate material based on the usage scenario and requirements to ensure that the hose does not contaminate food during use.

Consider Dimensions: Select the appropriate hose size and length based on actual needs to ensure ease of installation and use.

Cost Considerations: While maintaining quality, control costs reasonably and select products with high cost-effectiveness.

About Packaging

The packaging of food-grade tubing requires adherence to a series of rigorous standards and procedures to ensure its safety and hygiene, thereby meeting the special requirements of the food industry. The following is a detailed elaboration of the packaging process for food-grade tubing:

I. Selection of Packaging Materials

Non-toxic and Harmless: Choose packaging materials that are non-toxic, odorless, corrosion-resistant, and heat-resistant, such as food-grade polyethylene, silicone, and stainless steel. These materials should ensure no contamination of food.

Compliance with Standards: Packaging materials must comply with relevant food safety standards and regulatory requirements, such as FDA and LFGB certifications. These standards guarantee the safety and suitability of packaging materials.

Durability: Considering the various environmental factors that food-grade tubing may encounter during transportation and storage, packaging materials should possess good durability to resist external impacts and wear.

II. Packaging Process

Cleaning: Before packaging, thoroughly clean the food-grade tubing to remove oil, dust, and other impurities from its surface. Use cleaning agents that comply with food safety standards and ensure complete rinsing without residue.

End Protection: The ends of the tubing are the most vulnerable parts and should be protected with plastic caps, protective films, or foam sleeves. These protective measures prevent damage to the tubing ends during transportation due to collisions or compression.

Cushioning Materials: Place foam boards, bubble wraps, fillers, and other cushioning materials inside the packaging box to enhance the tubing's shock resistance. These materials effectively reduce vibrations and impacts during transportation, thereby lowering the risk of damage.

Rational Layout: Arrange the tubing inside the packaging box in a way that avoids collisions between tubing or with the box walls. Use mesh belts, tapes, or other means to secure the tubing, ensuring it remains fixed during transportation and does not roll or shift.

Sealing: Use standard sealing materials and methods to seal the packaging box, preventing external contaminants from entering. Ensure the seal is tight and free from leaks.

III. Packaging Labeling

Product Information: Clearly label the packaging with the food-grade tubing's model, specifications, length, weight, and other relevant information for easy identification and management by users.

Precautions: Include markings such as "Food-Grade," "Non-Toxic and Harmless," as well as cautions like "Handle with Care - Avoid Collisions," "Moisture-Proof and Sun-Proof," to remind transport personnel and users of safety precautions.

IV. Storage and Transportation

Storage Environment: Store the packaged food-grade tubing in a dry, ventilated, odor-free, and sun-protected environment to maintain its excellent quality and performance.

Transportation Safety: During transportation, avoid severe vibrations and collisions to ensure the tubing's safety and integrity. Adhere to relevant transportation regulations and standards to ensure a safe and reliable transportation process.

In summary, the packaging process for food-grade tubing necessitates strict adherence to relevant standards and procedures, with meticulous operations and management throughout the process, from material selection, packaging, labeling, to storage and transportation. Only in this way can the safety and hygiene of food-grade tubing be ensured during transportation, storage, and use.

Company Advantages

15+ Years of Experience: With more than 15 years in the PVC hose manufacturing industry, Renato Plastic Co., Ltd. is a trusted name with a proven track record.

Advanced Manufacturing Facilities: Our factory in Shandong province features 10 workshops, over 60 production lines, and a team of skilled professionals ensuring the highest quality standards.

Global Reach: We export our products to more than 60 countries worldwide, earning a reputation for reliability and excellence in the industry.

Customer-Centric Approach: We prioritize customer satisfaction and offer 24/7 support to ensure quick responses to inquiries, orders, and after-sales service.

Comprehensive Product Line: In addition to high-quality hoses, we also supply a range of hose fittings, including camlock, storz, nozzle fittings, and hose clamps, making us a one-stop solution for all your hose needs.

If you are looking for a reliable partner for your drinking water hose needs, Qingdao Renato Plastic Co., Ltd. is here to provide the best solution for you. Whether you need custom sizes or further technical details, our dedicated team is ready to assist you. Contact us now!