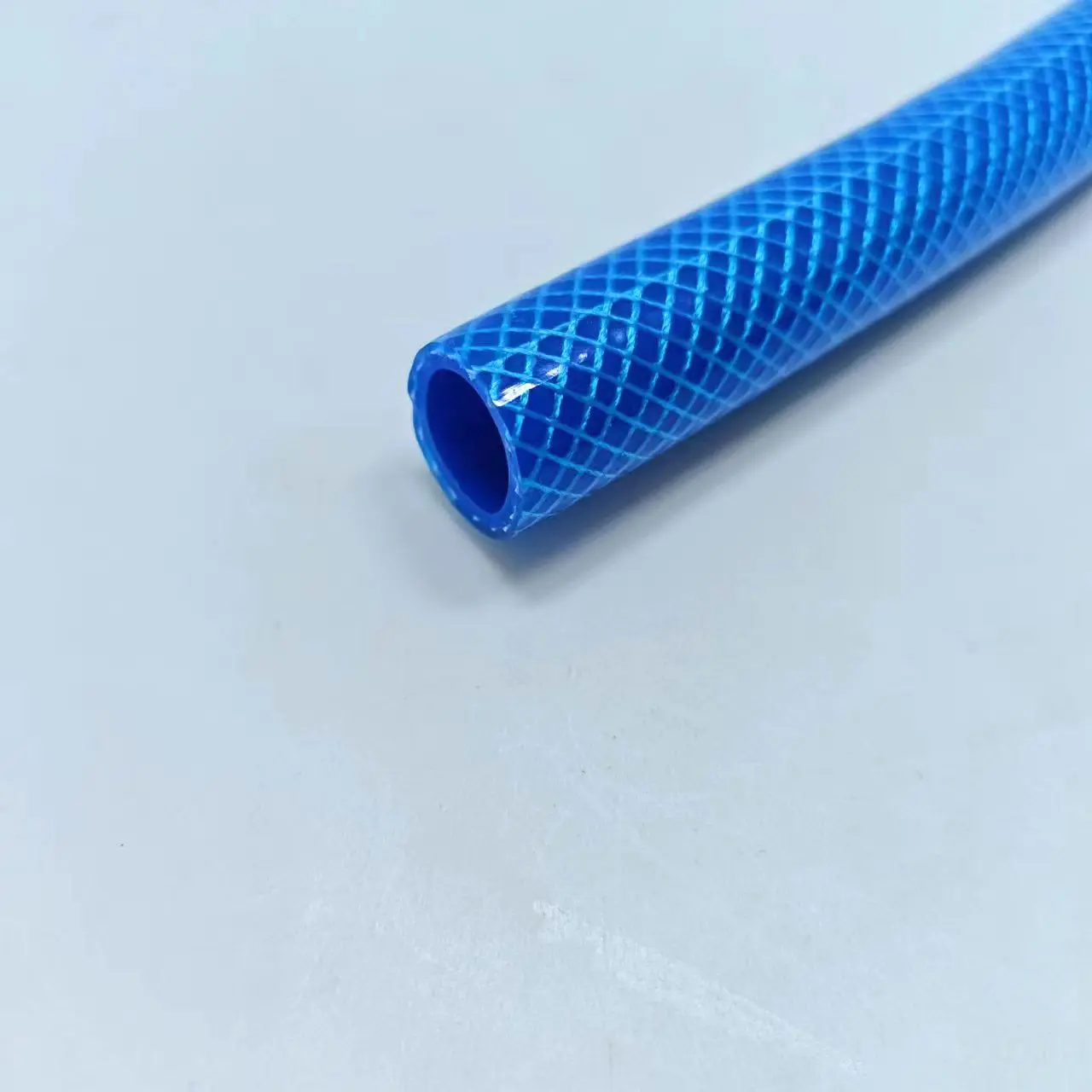

Product Overview

PVC Fiber Reinforced Hose is a flexible tube made from polyvinyl chloride (PVC) material combined with a high-strength fiber reinforcement layer. It features excellent flexibility, lightweight design, and ease of handling, making it widely used in agricultural irrigation, construction drainage, industrial liquid transfer, and other applications involving the transport of water, air, and other non-corrosive fluids.

The key advantage of PVC Fiber Reinforced Hose lies in its superior tensile strength and abrasion resistance, ensuring stable performance even in demanding environments. Compared to standard PVC hoses, the fiber reinforcement significantly enhances pressure resistance, preventing deformation or rupture under higher workloads. Additionally, its lightweight construction makes it easy to transport and install, ideal for scenarios requiring frequent movement or temporary setups.

In terms of manufacturing, PVC Fiber Reinforced Hose is typically produced using extrusion molding technology, ensuring uniform wall thickness and a smooth inner surface to minimize flow resistance. The reinforcement layer, usually made of polyester or nylon, is tightly bonded with the PVC inner layer through weaving or winding processes, enhancing overall structural stability.

Product Features

(1) High Flexibility

The hose exhibits excellent bending performance, adapting to various installation angles without damage from frequent flexing.

(2) Lightweight & Easy to Handle

Compared to rubber or metal hoses, PVC Fiber Reinforced Hose is much lighter, allowing for easy transport and installation by a single person, improving work efficiency.

(3) Abrasion Resistance

The fiber reinforcement layer enhances durability, allowing long-term use even on rough surfaces or in high-friction environments.

(4) Smooth Inner Surface

The optimized PVC inner layer ensures smooth fluid flow, reducing sediment buildup and minimizing clogging risks.

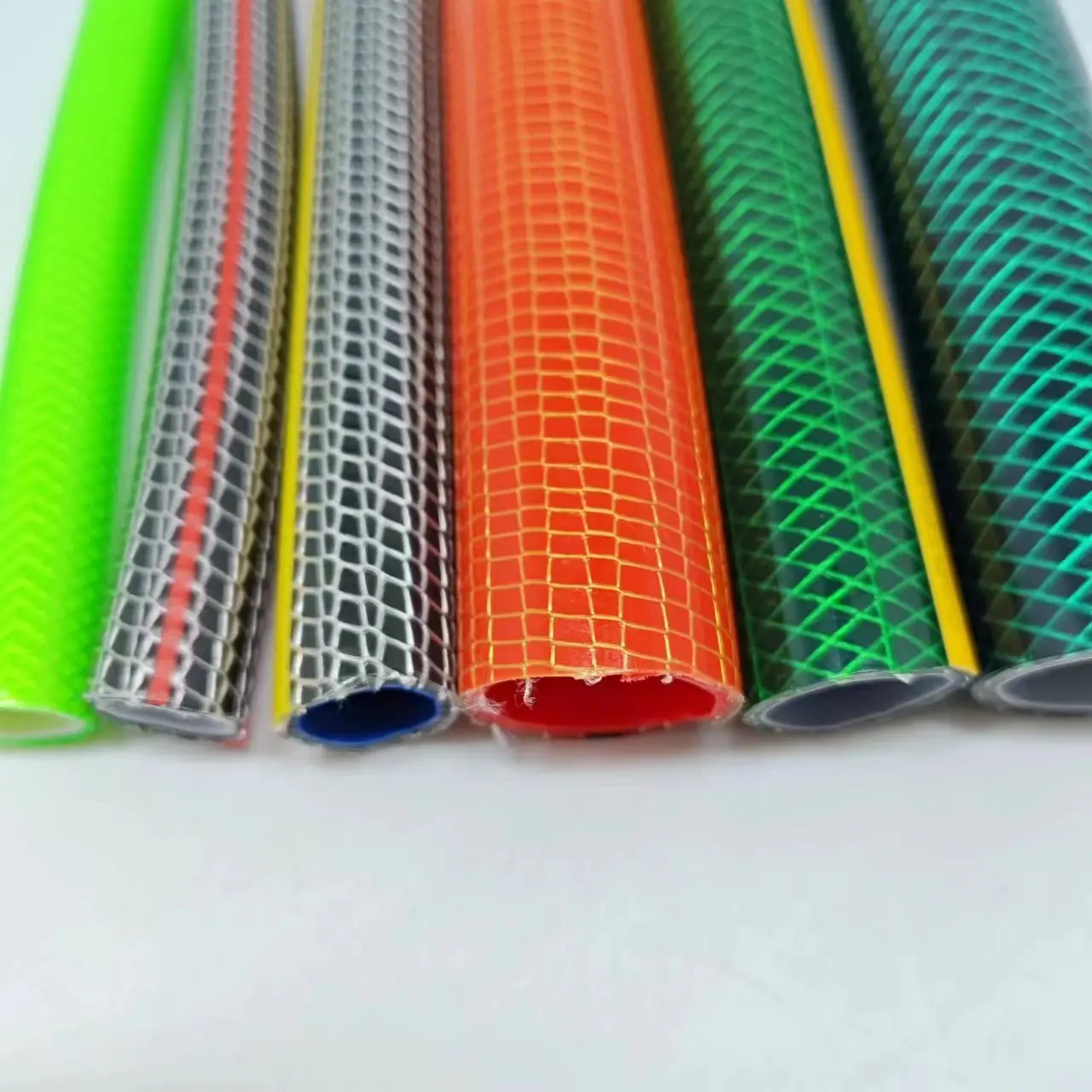

(5) Multiple Color Options

Available in various colors for easy identification in different piping systems, improving management efficiency.

Applications

| Application Field | Specific Uses |

|---|---|

| Agricultural Irrigation | Water delivery for farms, orchards, greenhouses, compatible with sprinkler or drip irrigation systems. |

| Construction Drainage | Temporary drainage at construction sites, basement dewatering, concrete curing, etc. |

| Industrial Liquid Transfer | Cooling water circulation, equipment cleaning, low-pressure fluid transport for non-corrosive media. |

| Landscaping & Gardening | Irrigation systems for parks, golf courses, and other green spaces, allowing easy mobility and adjustment. |

| Household & Commercial Use | Car washing, pool drainage, temporary water supply, and other daily needs. |

Specifications

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | Volume | ||

| inch | mm | mm | m | kg/m | bar | psi | cbm |

| 1/4 | 6 | 2 | 100 | 0.068 | 8 | 120 | 0.015 |

| 3 | 100 | 0.114 | 10 | 150 | 0.019 | ||

| 5/16 | 8 | 2 | 100 | 0.085 | 8 | 120 | 0.020 |

| 3 | 100 | 0.14 | 10 | 150 | 0.029 | ||

| 3/8 | 10 | 2 | 100 | 0.102 | 8 | 120 | 0.025 |

| 3 | 100 | 0.165 | 10 | 150 | 0.030 | ||

| 1/2 | 12 | 2 | 100 | 0.119 | 7 | 105 | 0.034 |

| 2.5 | 100 | 0.154 | 8 | 120 | 0.036 | ||

| 3 | 100 | 0.191 | 10 | 150 | 0.042 | ||

| 5/8 | 15 | 2 | 100 | 0.144 | 6 | 90 | 0.035 |

| 2.5 | 100 | 0.186 | 7 | 105 | 0.042 | ||

| 3 | 100 | 0.229 | 8 | 120 | 0.050 | ||

| 3/4 | 19 | 2 | 100 | 0.178 | 5 | 75 | 0.043 |

| 2.5 | 100 | 0.228 | 6 | 90 | 0.050 | ||

| 3 | 100 | 0.28 | 7 | 105 | 0.060 | ||

| 1 | 25 | 2 | 100 | 0.229 | 3 | 45 | 0.055 |

| 2.5 | 100 | 0.291 | 4 | 60 | 0.065 | ||

| 3 | 100 | 0.356 | 5 | 75 | 0.075 | ||

| 1 1/4 | 32 | 3 | 100 | 0.445 | 4 | 60 | 0.109 |

| 4 | 100 | 0.61 | 5 | 75 | 0.120 | ||

| 1 1/2 | 38 | 3 | 100 | 0.521 | 4 | 60 | 0.141 |

| 4 | 100 | 0.712 | 6 | 90 | 0.143 | ||

| 2 | 50 | 4 | 100 | 0.916 | 2 | 30 | 0.198 |

| 5 | 100 | 1.166 | 3 | 45 | 0.215 | ||

| 6 | 100 | 1.424 | 4 | 60 | 0.300 | ||

Usage Precautions

Avoid Extreme Temperatures: While the hose has some temperature resistance, prolonged exposure to high heat (above 60°C) or extreme cold (below -10°C) may affect its performance.

Protect from Sharp Objects: When laying the hose, avoid contact with sharp rocks, metal edges, or other objects that could puncture or damage it.

Proper Storage: When not in use, coil the hose and store it in a cool, dry place away from direct sunlight or heavy pressure.

Use Compatible Fittings: Ensure proper sealing by using suitable connectors to prevent leaks or disconnections.

Avoid Over-Bending: Excessive bending may create stress points, reducing the hose’s lifespan.

Maintenance & Care

Regular Inspection: Check for cracks, wear, or loose fittings before use, and replace or repair as needed.

Clean Inner Surface: After transporting liquids with impurities, flush the hose with clean water to prevent residue buildup.

Avoid Dragging: When moving the hose, lift it instead of dragging to minimize ground friction.

Winter Protection: In cold climates, drain water from the hose to prevent freezing and cracking.

Purchasing Tips

Hose Diameter: Choose the appropriate diameter based on flow requirements to ensure optimal efficiency.

Reinforcement Material: Different fiber materials (e.g., polyester, nylon) offer varying reinforcement effects—select according to specific needs.

Color Coding: For multi-pipeline systems, opt for different colors for easy identification and management.

Brand & Certification: Purchase from reputable manufacturers to ensure compliance with industry standards and safety.