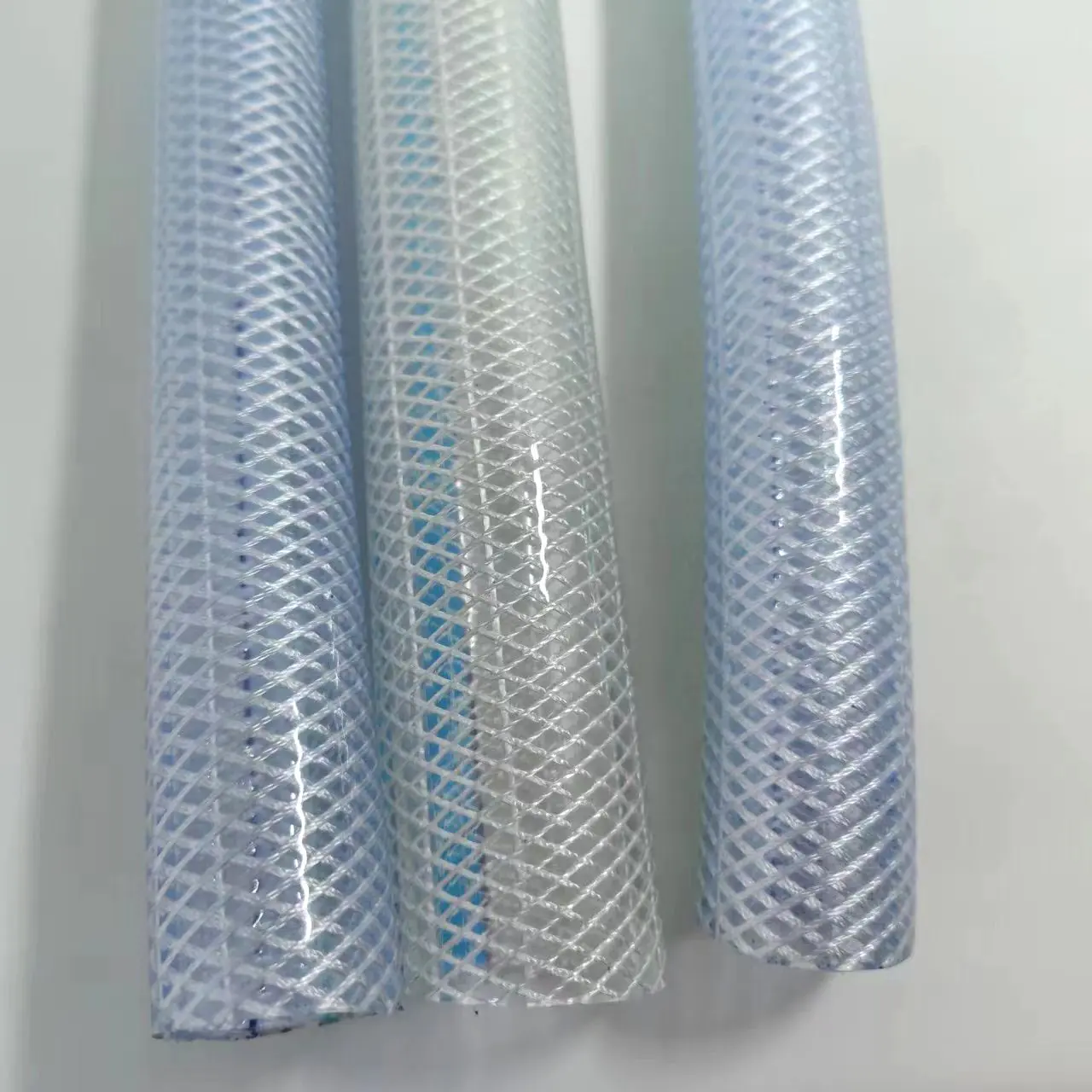

Nylon Fiber Braided Reinforced Hose

- A Durable, Lightweight, and Cost-Effective Solution for Fluid Transfer

When it comes to performance, the Nylon Fiber Braided Reinforced Hose stands out for all the right reasons. Manufactured by QINGDAO RENATO PLASTIC CO., LTD, this hose combines strength, flexibility, and durability into a single, high-performing solution. Whether you're handling agricultural irrigation, water discharge, or industrial fluid transfer, this hose delivers consistent reliability.

Nylon Fiber Braided Reinforced Hose is a lightweight, durable, and cost-effective fluid transfer hose widely used across various industries. Its unique structural design allows it to withstand certain pressures while maintaining flexibility and ease of operation.

Structure and Materials: The Perfect Blend of Strength and Flexibility

Inner Layer: Made of high-quality PVC material, it ensures a smooth inner wall, reducing fluid flow resistance and preventing blockages.

Reinforcement Layer: Composed of high-strength polyester fibers, it provides excellent pressure resistance and tensile strength, ensuring the hose remains stable even under high-pressure conditions.

Outer Layer: Made of wear-resistant and anti-aging PVC material, it effectively protects the reinforcement layer from external environmental factors, extending the hose's lifespan.

This three-layer design combines strength and flexibility, enabling the hose to adapt to various complex environments.

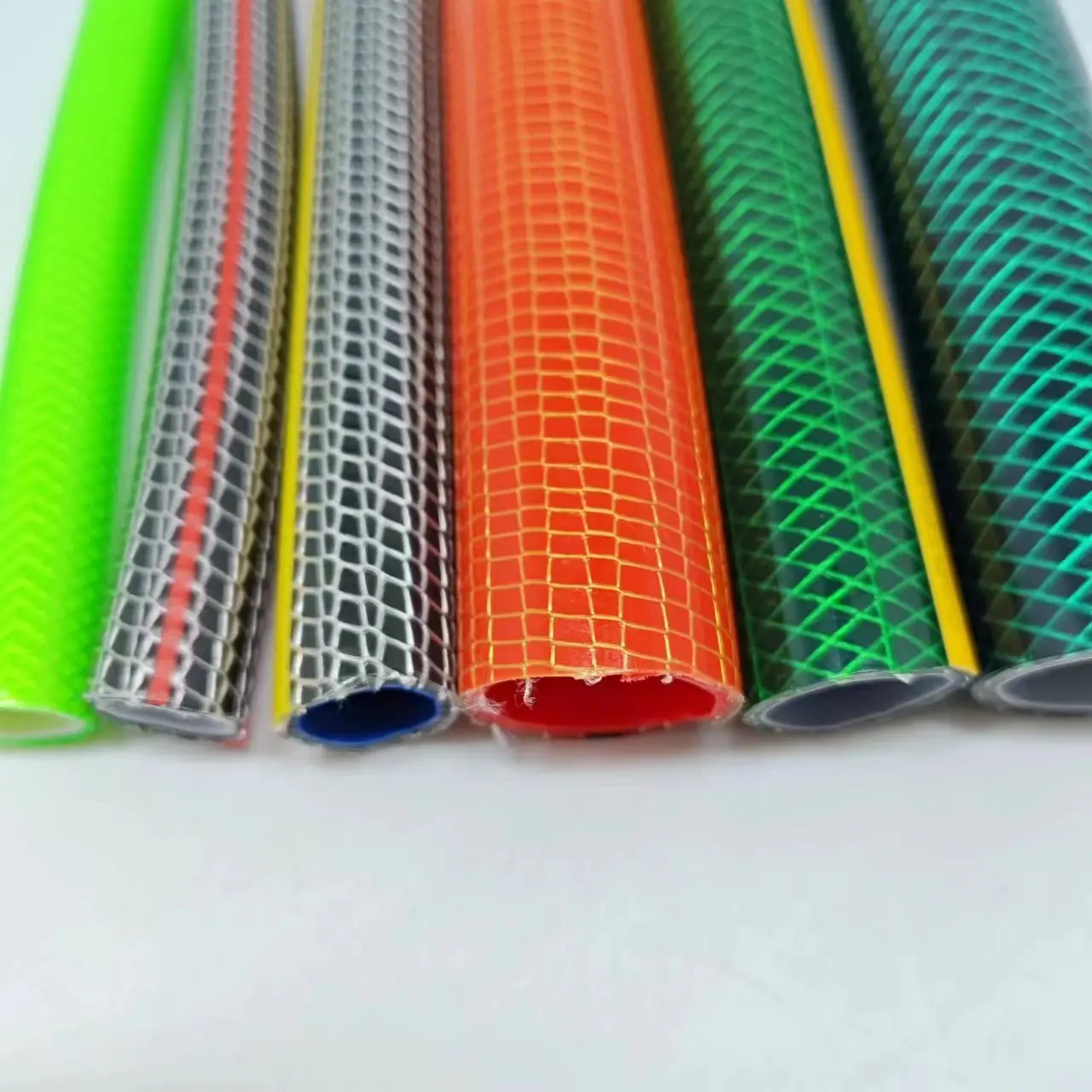

Two Nylon Fiber Braided Reinforced Hoses are shown. These hoses feature a transparent outer layer with a nylon fiber braided structure inside, providing enhanced strength and durability. They are marked with red and green lines, likely for identification or indication purposes. The hoses are connected to metallic fittings, suitable for applications that require flexible yet robust fluid transfer.

Performance Advantages: Meeting Diverse Application Needs

Lightweight and Easy to Handle: Compared to metal pipes, Nylon Fiber Braided Reinforced Hose is lightweight, making it easy to transport, install, and dismantle, significantly reducing labor intensity.

Excellent Flexibility: The hose has good bending performance, allowing it to easily navigate around obstacles and adapt to complex installation environments.

Wear Resistance: The outer PVC material offers excellent wear resistance, protecting the hose from friction and abrasion, thereby extending its lifespan.

UV Resistance: Some models of Nylon Fiber Braided Reinforced Hose are treated with UV inhibitors, effectively resisting sunlight and preventing aging.

Cost-Effective: Compared to hoses made of other materials, Nylon Fiber Braided Reinforced Hose is more competitively priced, offering high cost performance.

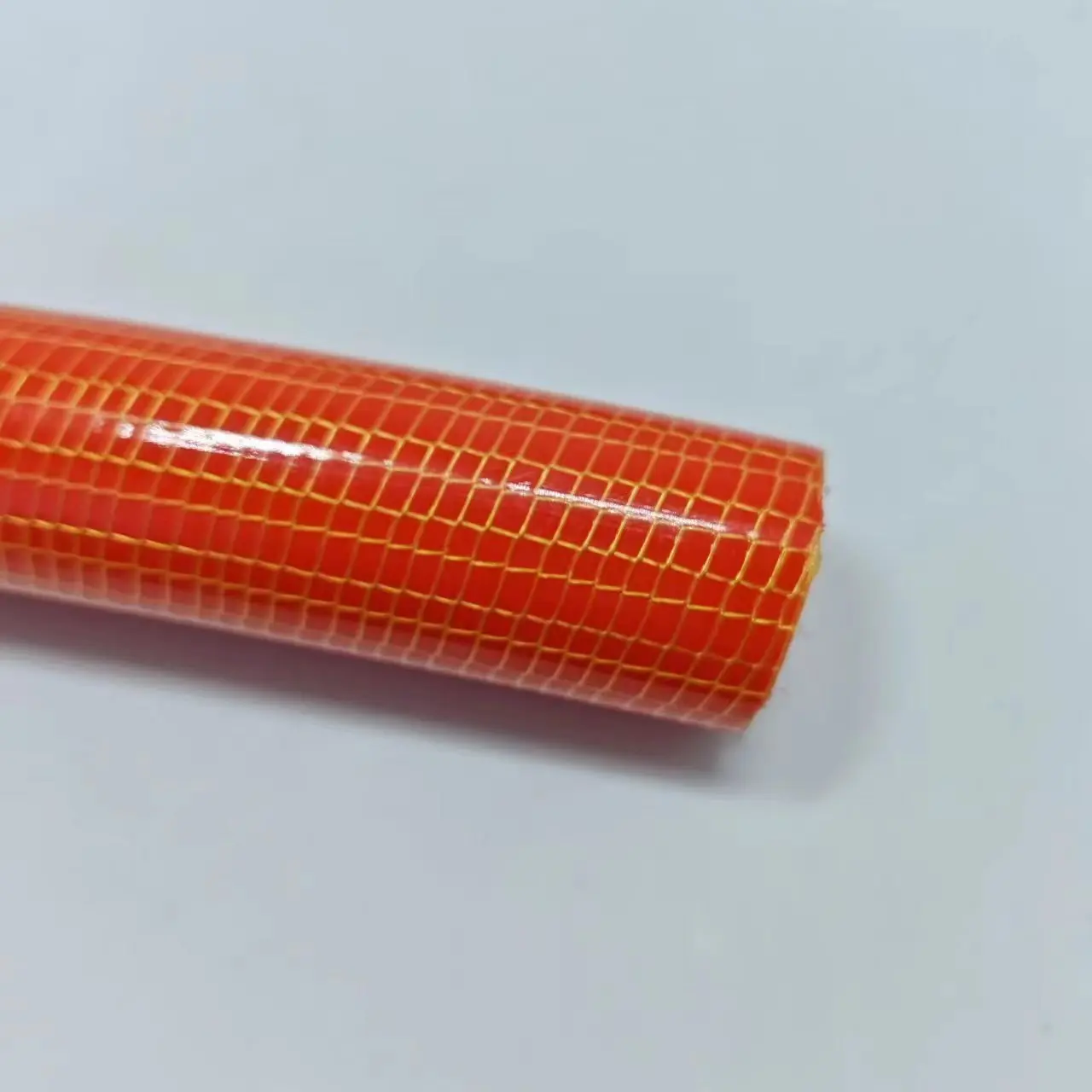

This is a Nylon Fiber Braided Reinforced Hose. Its outer layer is bright orange, with a distinct golden - colored nylon fiber braided pattern that reinforces its structure. This design enhances the hose's strength and durability, making it suitable for various applications where reliable fluid transfer is required.

Application Fields: Widely Used Across Various Industries

| Industry | Application Scenarios |

|---|---|

| Agriculture | Irrigation, drainage, pesticide spraying |

| Industrial | Transfer of water, air, oil, and other fluids |

| Construction | Concrete transfer, drainage, ventilation |

| Landscaping | Watering, irrigation, cleaning |

| Household | Garden watering, car washing |

Selection Guide: Choosing the Right Hose for Your Needs

Inner Diameter: Choose the appropriate inner diameter based on flow requirements to ensure smooth fluid transfer.

Working Pressure: Select a hose with a working pressure higher than the actual usage pressure to ensure safety and reliability.

Temperature Range: Choose a hose material suitable for the fluid temperature to avoid damage caused by excessively high or low temperatures.

Length: Select the appropriate hose length based on the actual usage distance to avoid excessive or insufficient length.

Usage and Maintenance: Extending the Hose's Lifespan

Avoid Over-Bending: Excessive bending can damage the hose's internal structure, affecting its lifespan.

Prevent External Damage: Avoid contact with sharp objects to prevent scratches or punctures.

Regular Inspection: Periodically check the hose for cracks, wear, and other issues, and replace damaged hoses promptly.

Proper Storage: After use, clean the hose and store it coiled in a cool, dry place.

This image shows several rolls of PVC pipes neatly packaged in a cardboard box. Each roll of the PVC pipe is wrapped in plastic film, which not only protects the pipes from external damage but also keeps them clean and dry. The pipes are coiled in an orderly manner, ready for storage or transportation.

Company Advantages

QINGDAO RENATO PLASTIC CO., LTD is a trusted manufacturer with over 15 years of experience in producing high-quality PVC hoses and hose assemblies.

Here’s what sets us apart:

Over 60 Production Lines across 10 workshops

5 Skilled Technicians and 2 QC Teams ensure consistent quality

Products exported to 60+ countries, with high customer satisfaction

Full range of hose accessories like Camlock, Storz fittings, clamps, and nozzles

Strong OEM/ODM capabilities for customized branding and packaging

7x24 Hour Service with quick response to all inquiries

We believe in long-term partnerships and are proud that our hoses are helping customers around the globe build, irrigate, and clean more efficiently.

Have a question or ready to place an order? Let’s talk. We promise a fast response, professional support, and timely delivery.

Frequently Asked Questions

1. Can PVC Fiber Reinforced Hose be used for drinking water transfer?

Some models of PVC Fiber Reinforced Hose comply with drinking water standards and can be used for drinking water transfer. However, not all models are suitable for this purpose, so carefully check the product specifications when purchasing.

2. What is the lifespan of PVC Fiber Reinforced Hose?

The lifespan of PVC Fiber Reinforced Hose depends on the usage environment, frequency, and maintenance.

3. How to connect PVC Fiber Reinforced Hose?

PVC Fiber Reinforced Hose can be connected using quick connectors, clamps, or other methods. The choice of connection method depends on factors such as hose size and working pressure.

Conclusion

PVC Fiber Reinforced Hose, with its advantages of being lightweight, durable, and cost-effective, is an ideal choice for fluid transfer in many industries. By understanding its structure, performance, application fields, as well as selection, usage, and maintenance, you can better choose and use PVC Fiber Reinforced Hose to fully leverage its advantages and meet your fluid transfer needs.