I. Product Overview

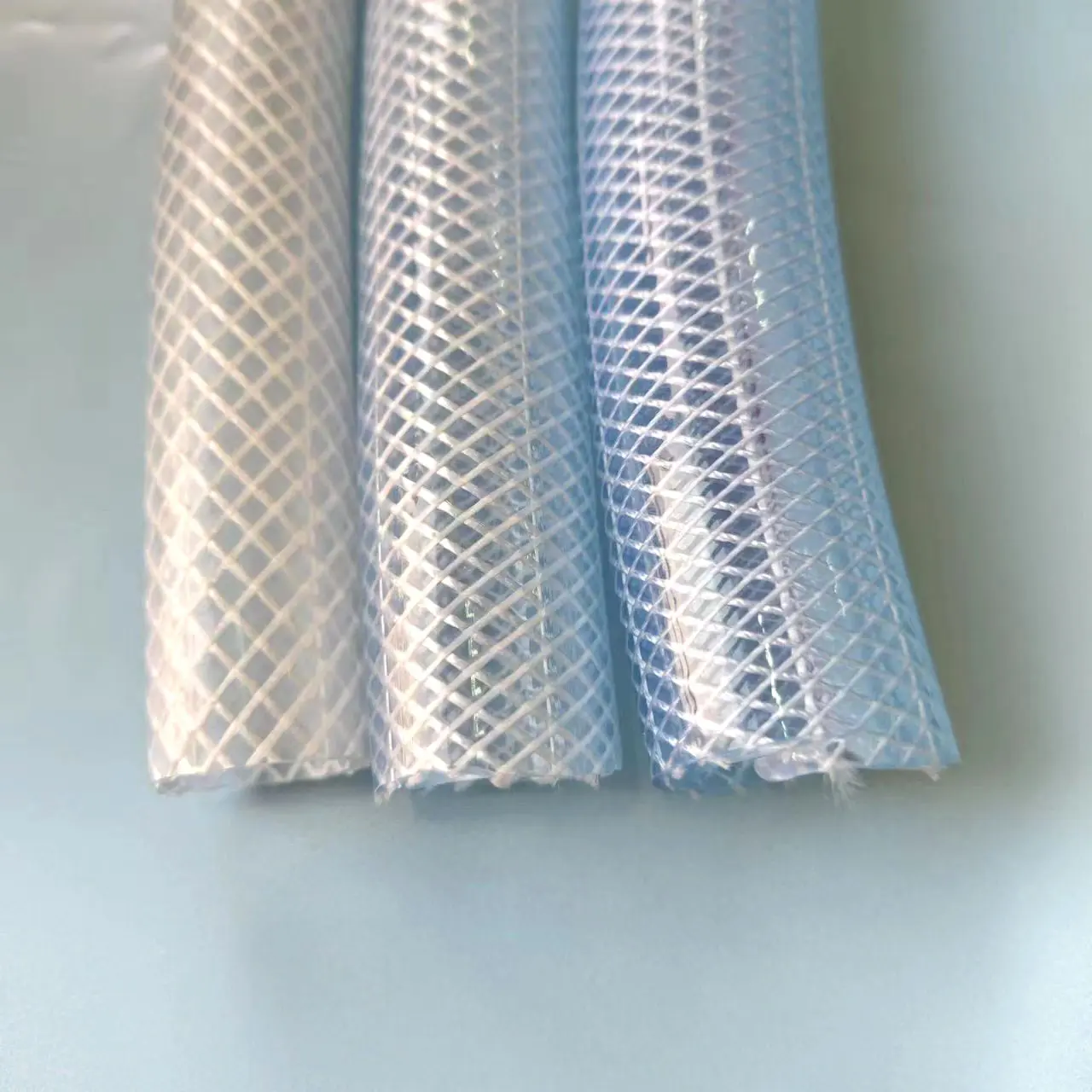

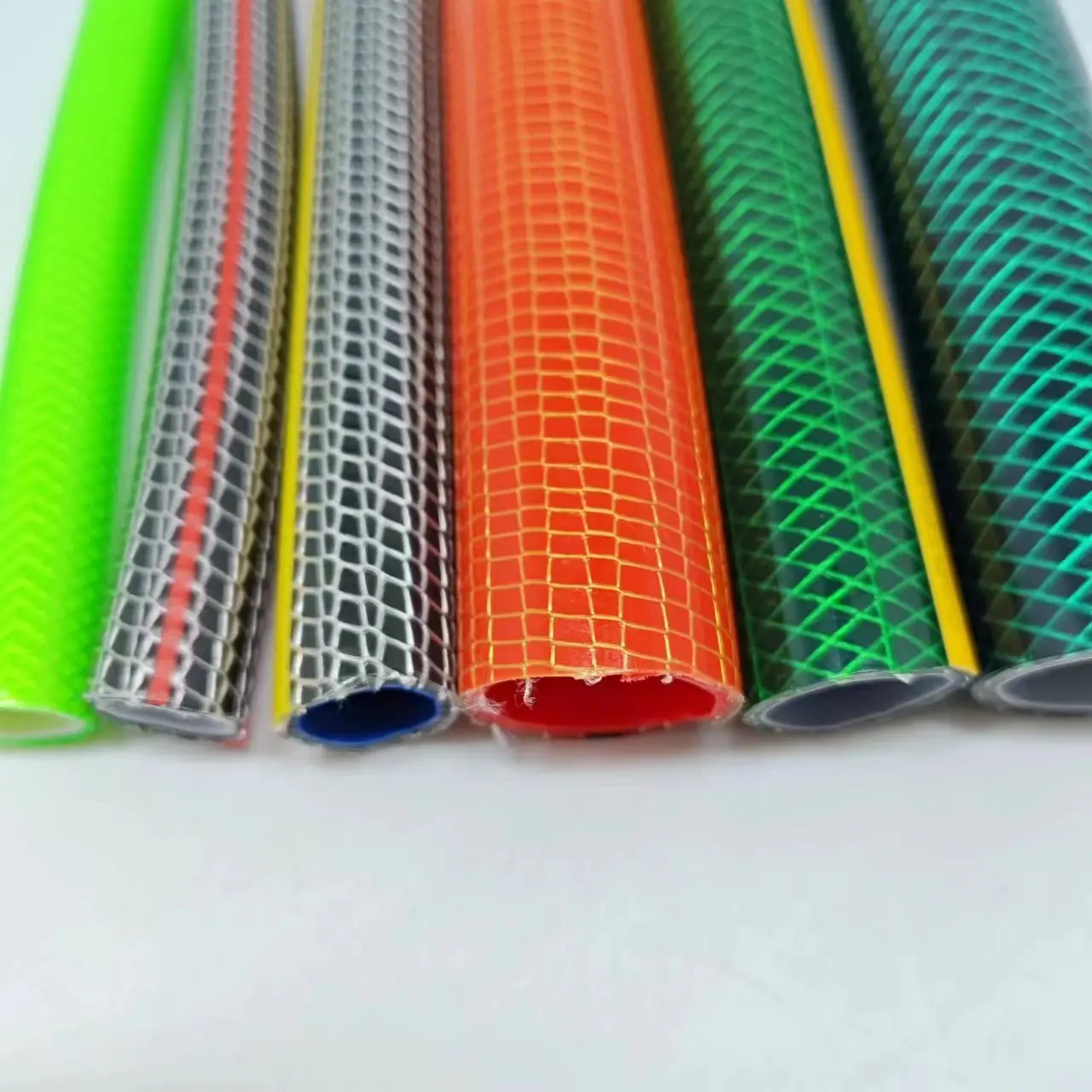

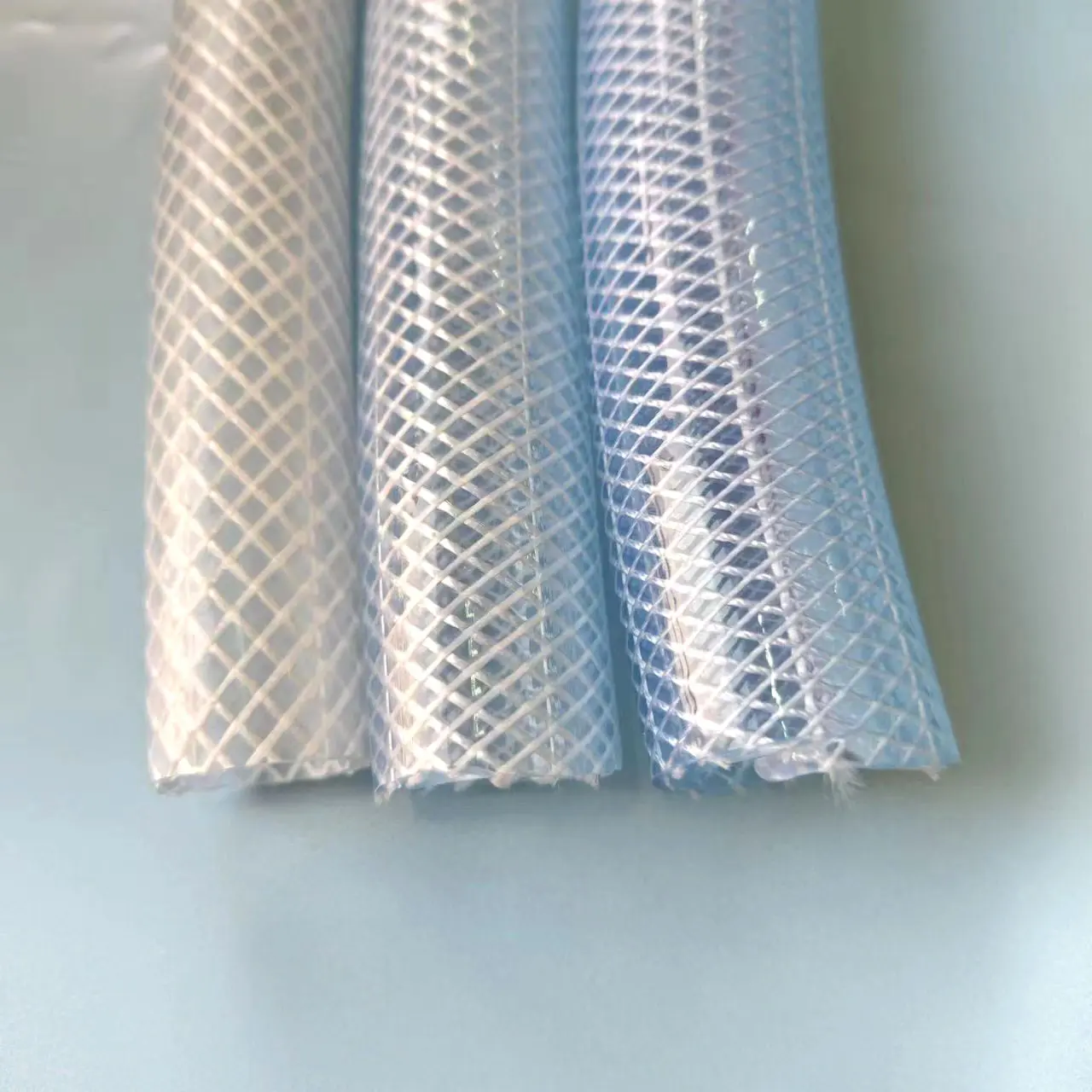

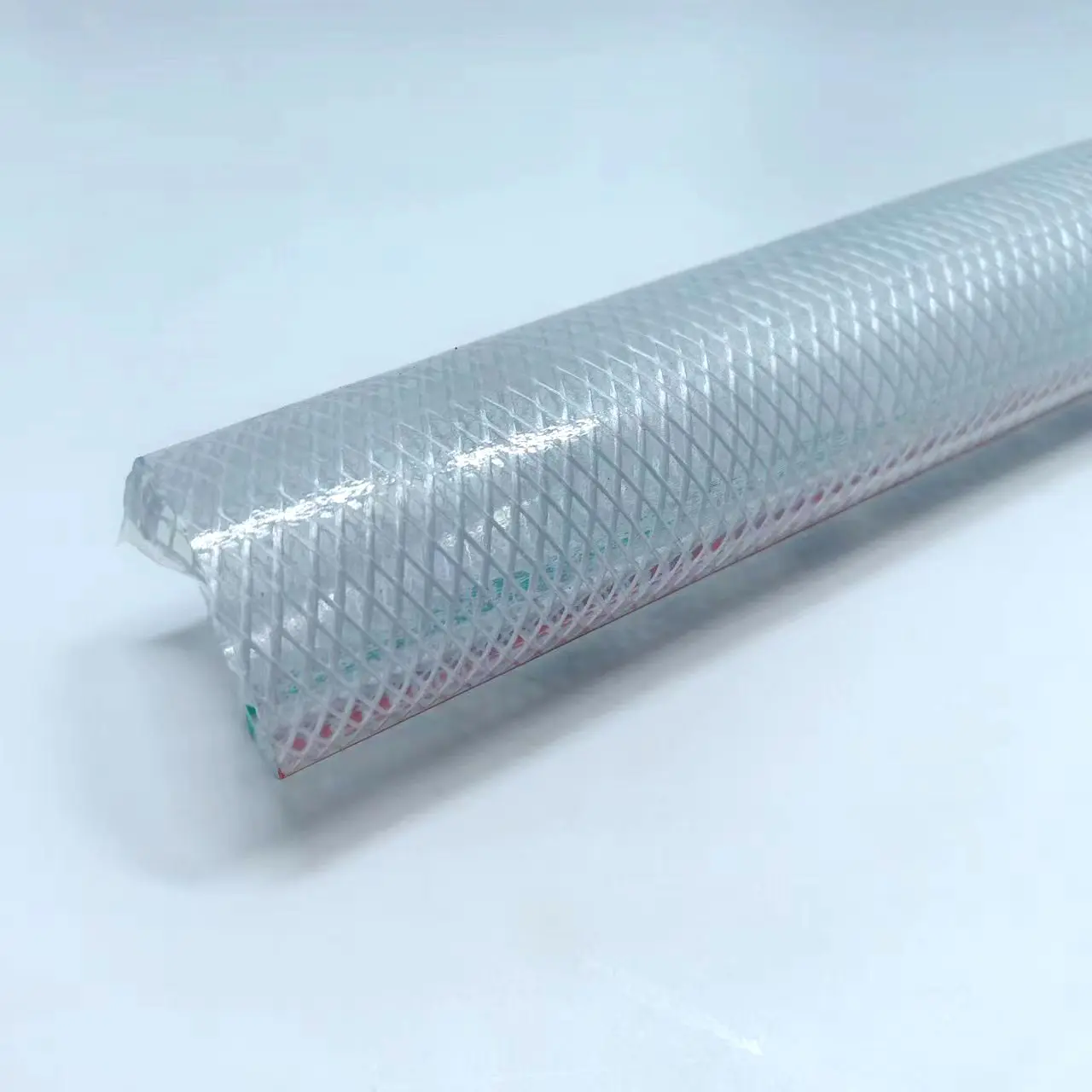

PVC fiber reinforced hose is a type of tubing made by combining a PVC inner layer with a high-strength fiber braided layer. Through special processing, the flexible PVC material and the fiber braided layer are tightly integrated, retaining the lightweight and weather-resistant characteristics of PVC while enhancing its tensile and impact resistance through the fiber reinforcement layer. This design makes it an ideal fluid delivery tool in industries such as manufacturing, agriculture, and construction, offering both flexibility and durability to adapt to various complex application scenarios.

II. Application Scenarios

Industrial Sector

Compressed air delivery in factories, water treatment system connections, and automation production line support.

Suitable for machinery cooling water circulation and dust spray systems.

Agricultural Sector

Farmland irrigation, greenhouse spraying, and livestock watering pipes.

Its UV resistance makes it suitable for long-term outdoor use, reducing replacement frequency.

Construction Sector

Temporary water supply and drainage systems on construction sites.

Used in home renovations for water pipe modifications or underfloor heating manifold connections.

Maritime Sector

Marine ventilation and water pipes, adapting to the damp and vibrating environment inside ship cabins.

III. Product Advantages

Flexibility and Durability Combined

The fiber braided layer allows the hose to bend to a smaller radius, accommodating complex pipe layouts.

Excellent tensile strength ensures it remains intact and does not deform or break over long-term use.

Weather Resistance and Anti-Aging

The natural UV resistance of PVC prevents fading or brittleness when used outdoors.

Suitable for environmental temperatures ranging from -5°C to +65°C, meeting most application needs.

Environmental Friendliness and Safety

Made from non-toxic PVC raw materials, it complies with drinking water safety standards.

A smooth inner wall inhibits bacterial growth, ensuring fluid cleanliness.

Ease of Installation

Lightweight design reduces construction difficulty, allowing quick connection to standard interfaces.

Flexibility supports on-site cutting to adapt to non-standard size requirements.

IV. Specification and Model Comparison Table

| Model | Inner Diameter Range | Wall Thickness Range | Color Options | Suitable Application Examples |

|---|---|---|---|---|

| 1/4" Size | 6mm-10mm | 2mm-3mm | Transparent, Blue | Small equipment cooling, laboratory water |

| 1/2"-3/4" Size | 13mm-20mm | 3mm-4mm | Transparent, Red | Agricultural irrigation, home water supply |

| 1"-3" Size | 25mm-76mm | 4mm-6mm | Transparent, Black | Industrial compressed air, construction drainage |

V. Usage Precautions (Listed in Points)

Bending Radius Limitations

Avoid excessive bending; maintain a minimum bending radius to prevent damage to the hose.

Medium Compatibility

Only suitable for transporting non-corrosive media such as water and air; do not use for oil or chemicals.

Installation Guidelines

Ensure interface sealing during connections to prevent deformation from long-term pressure or twisting.

Environmental Requirements

Store and use within a temperature range of -5°C to +65°C, avoiding direct sunlight.

VI. Purchase and Maintenance Recommendations

Purchase Guidelines

Choose appropriate specifications based on the application scenario: industrial use should prioritize models with a wall thickness of ≥4mm, while agricultural irrigation can opt for transparent models to observe water flow.

Storage Advice

Store in a dry, ventilated environment, avoiding contact with sharp objects; conduct regular visual inspections during long-term storage.

Cleaning and Maintenance

Drain residual liquids after use and regularly flush the hose with clean water to prevent scale buildup.

Fault Handling

Immediately discontinue use if cracks or deformations are detected; minor damage can be temporarily repaired with specialized tape, while severe damage requires replacement with a new hose.

VII. PVC Fiber Braided Hose for US

Food-grade tubing shows certain demand potential and development space in the U.S. market. In food and beverage-related industries, food-grade tubing, as an essential component for fluid conveyance and ensuring food safety, is widely used in beverage production lines, food processing, and other fields.

Meanwhile, with the growth of markets for healthy foods, organic foods, etc., the requirements for hygiene and safety in food production equipment have increased, driving up the demand for food-grade tubing. Additionally, the environmental trend also prompts enterprises to adopt more sustainable packaging and conveyance materials, bringing new opportunities to the food-grade tubing market. However, the market competition is fierce, and enterprises need to continuously innovate and improve product quality to meet market demands.

In the United States, the demand for food-grade tubing is robust, with widespread applications in the food processing, beverage production, pharmaceutical, and medical industries. Different sizes of tubing vary in sales due to differences in application scenarios, with 1/2" 5/8" and 3/4" sizes being the most popular.

The 8mm- 15mm hose favored for its broad applicability and low cost, is the top choice for small and medium-sized food processing enterprises, beverage filling lines, and laboratory fluid transfer in the United States. This size of tubing meets the needs of general liquid food transfer and is easy to install and maintain.

In contrast, 16 - 32mm inner diameter tubing, with its high-pressure resistance, dominates in large-scale food production lines, dairy processing, beer brewing, and pharmaceutical raw material transfer in the United States. It ensures the stability and hygiene of fluids during long-distance, high-volume transfer, meeting the high standards for food-grade products in the US market.