Flexible PVC Clear Braided Fiber Reinforced Hose

Discover the ultimate solution for your fluid transfer needs with our Flexible PVC Clear Braided Fiber Reinforced Hose. Engineered with precision and crafted with quality, this hose is designed to meet the highest standards of durability, flexibility, and transparency. Whether you're dealing with industrial applications or household tasks, our PVC fiber-reinforced hose offers unmatched performance and reliability.

Why Choose PVC Fiber Reinforced Hose

1. Exceptional Physical Properties

High Strength and Durability: Reinforced with high-strength materials such as polyester fibers, PVC Fiber Reinforced Hose exhibits outstanding tensile, compressive, and tear resistance, enabling it to withstand long-term use in harsh environments without easily degrading.

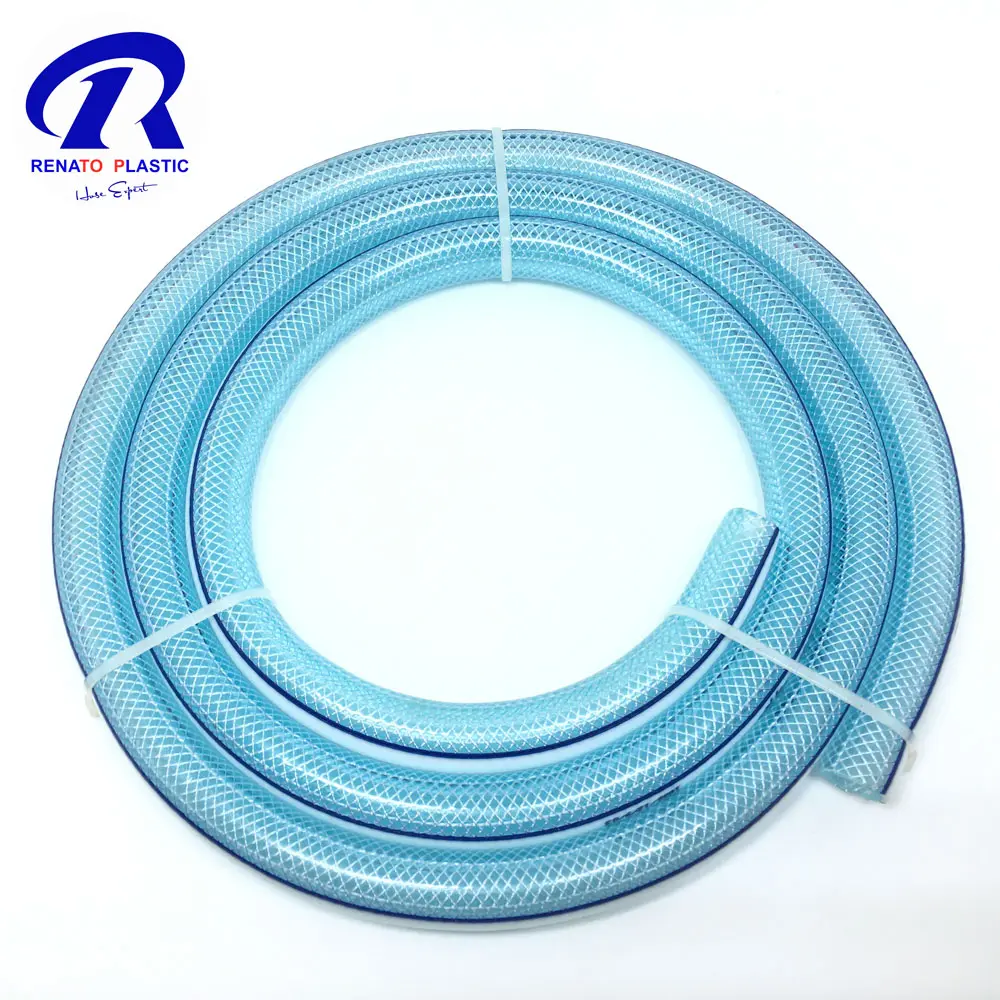

Flexibility: This hose boasts excellent flexibility, allowing it to adapt to various complex installation environments and spatial constraints, facilitating easy installation and usage.

2. Wide Applicability

Diverse Applications: PVC Fiber Reinforced Hose is suitable for a myriad of scenarios, including factories, farms, construction sites, mines, households, and more. It can be used to transport water, oil, air, and other media.

Temperature Adaptability: With a broad operating temperature range, typically between -5°C to +65°C, it caters to the needs of most application scenarios.

3. Environmental Friendliness and Safety

Eco-Friendly Materials: PVC materials are non-toxic and odorless, meeting environmental requirements without polluting the environment.

Safety Performance: Due to its high strength and corrosion resistance, PVC Fiber Reinforced Hose ensures high safety during media transportation, reducing the risk of leaks and accidents.

4. Economic Efficiency

Cost-Effectiveness: Compared to other types of hoses, PVC Fiber Reinforced Hose offers a higher cost-to-performance ratio, enabling users to maintain performance while reducing costs.

Ease of Maintenance: Its simple structure and durable materials make this hose relatively easy to maintain, lowering maintenance costs and time.

5. Customization Services

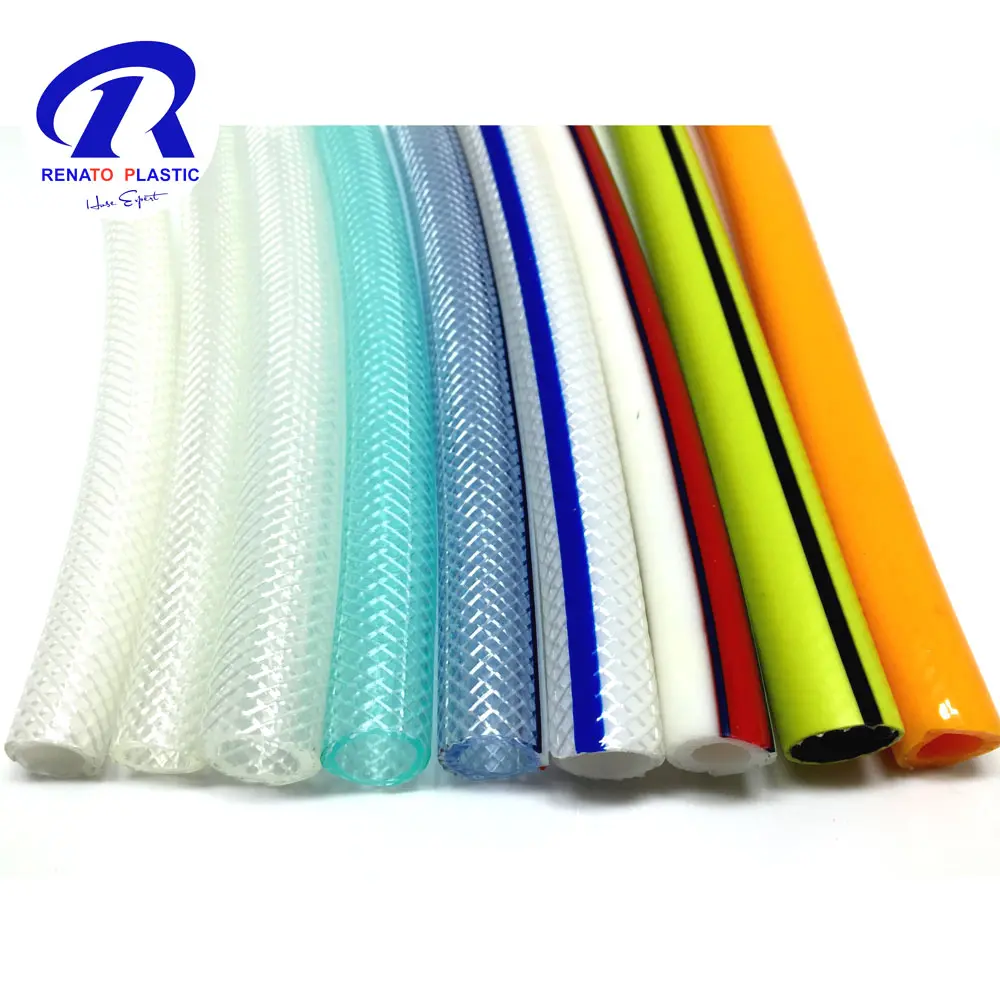

Diverse Specifications: Available in various specifications and sizes, PVC Fiber Reinforced Hose caters to the needs of different customers.

Customized Production: Some manufacturers offer customization services, producing hoses with specific specifications and performance tailored to customer requirements.

In conclusion, PVC Fiber Reinforced Hose, with its exceptional physical properties, wide applicability, environmental friendliness and safety, economic efficiency, and customization services, has become the preferred hose product for numerous industries and sectors.

Specification

| Parameter | Details |

|---|---|

| Brand Name | Renflex |

| Material | PVC (Polyvinyl Chloride) |

| Reinforcement | Braided Fiber |

| Temperature Range | -5°C to +65°C |

| Working Pressure | 2 - 10 bar |

| Burst Pressure | Up to 30 bar (varies by size and thickness) |

| Color Options | Green, Yellow, Blue, Orange, Black, Red, Customizable |

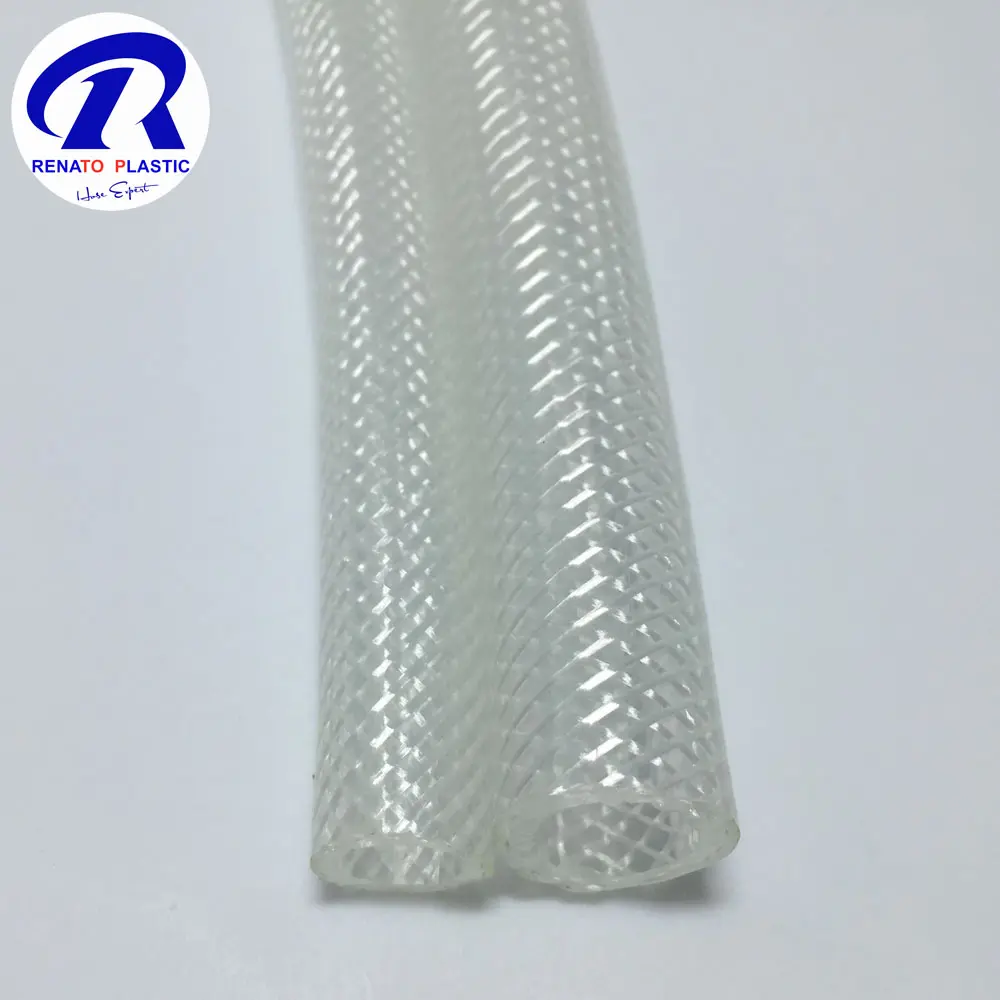

| Transparency | Transparent for easy monitoring of fluid flow |

| Application | Garden Irrigation, Water Discharge, Fluid Conveyance |

| Certifications | RoHS, REACH, CE |

| Compliance | Meets international quality and safety standards |

| Key Features | High durability, flexibility, lightweight, wear-resistant |

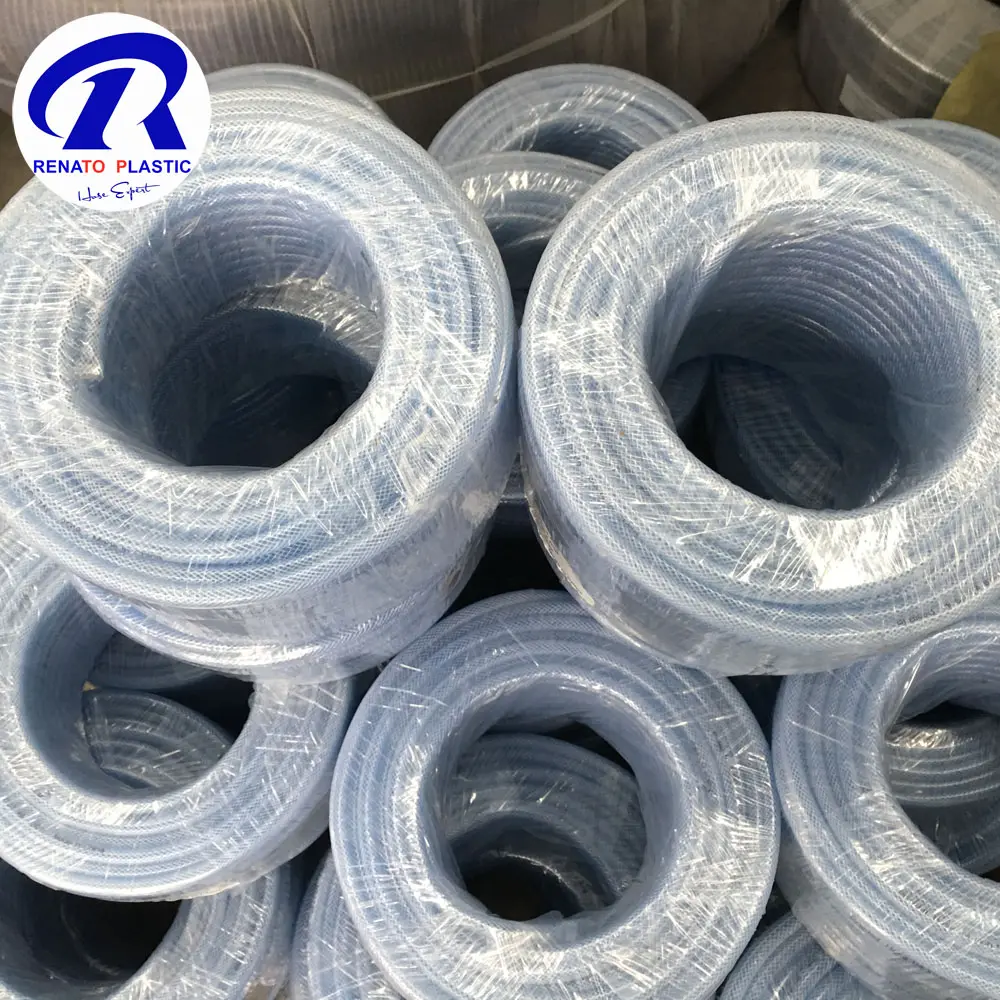

| Packaging Options | Paper Card / Shrink Wrap |

| Compatible Fittings | Brass Fittings, Nozzle Guns |

| Inner Diameter | Outer Diameter | Wall Thickness | Available Lengths | Working Pressure | Burst Pressure |

|---|---|---|---|---|---|

| 3/16 inch (4.8mm) | 9.0mm | 1.5mm | 10m, 20m, 50m | 8 bar | 24 bar |

| 1/4 inch (6.4mm) | 10.8mm | 2mm | 10m, 20m, 50m | 8 bar | 24 bar |

| 5/16 inch (7.9mm) | 12.3mm | 2.2mm | 10m, 20m, 50m, 100m | 6 bar | 18 bar |

| 3/8 inch (9.5mm) | 14.0mm | 2.3mm | 10m, 20m, 50m, 100m | 6 bar | 18 bar |

| 1/2 inch (12.7mm) | 16.5mm | 2.4mm | 10m, 20m, 50m, 100m | 5 bar | 15 bar |

| 3/4 inch (19.0mm) | 23.0mm | 2.5mm | 10m, 20m, 50m, 100m | 5 bar | 15 bar |

| 1 inch (25.4mm) | 30.4mm | 2.5mm | 10m, 20m, 50m, 100m, 150m | 4 bar | 12 bar |

| 1 1/4 inch (31.8mm) | 37.8mm | 3mm | 10m, 20m, 50m, 100m | 4 bar | 12 bar |

| 1 1/2 inch (38.1mm) | 45.1mm | 3.5mm | 10m, 20m, 50m, 100m | 3 bar | 10 bar |

| 2 inch (50.8mm) | 58.8mm | 4mm | 10m, 20m, 50m, 100m, 150m | 3 bar | 10 bar |

Application

Industrial Transfer:

In industrial settings, the PVC Fiber Reinforced Hose is utilized for transferring fluids such as water, oil, and gases. Its high strength, wear resistance, and corrosion resistance make it an indispensable tool for industrial fluid transportation.

Agricultural Irrigation:

In agriculture, this hose is employed in irrigation systems, efficiently delivering water to farmland, enhancing irrigation efficiency, and reducing maintenance costs.

Maritime & Construction:

On ships, the PVC Fiber Reinforced Hose is used to transport fuels, freshwater, and other liquids, ensuring the smooth operation of maritime vessels. Additionally, in the construction industry, it serves as a conduit for water supply and drainage systems within buildings.

Household Use:

In domestic settings, this hose functions as a shower hose, providing users with a comfortable and convenient showering experience. Furthermore, it can be utilized as inlet and outlet pipes for household appliances such as washing machines and dishwashers.

Food Industry:

Specially designed food-grade PVC Fiber Reinforced Hoses are employed for conveying food-grade liquids like milk, beverages, and beer, ensuring food safety and hygiene.

Performance Advantages

High Strength & Wear Resistance:

Reinforced with high-strength polyester fibers, the PVC Fiber Reinforced Hose exhibits exceptional tensile and compressive strength. Its wear resistance significantly extends the hose's service life.

Corrosion Resistance:

The PVC material inherently possesses good corrosion resistance, allowing the hose to withstand various chemical attacks.

Flexibility & Ease of Bending:

The hose's flexibility and ease of bending facilitate installation and usage in complex environments.

Aging & UV Resistance:

Specially formulated and processed, the PVC Fiber Reinforced Hose can withstand UV exposure and aging, maintaining stable performance over time.

Wide Temperature Range:

The hose operates within a broad temperature range, adapting to varying environmental conditions.

Safety & Environmentally Friendly:

Made from non-toxic, odorless PVC, the hose complies with food safety and environmental regulations.

The Difference Between Food Grade and Regular

Material Composition and Safety

Food-Grade PVC Fiber Reinforced Hose: Made from PVC materials that comply with food safety standards, typically containing no or minimal amounts of harmful additives such as heavy metals and plasticizers. These materials undergo rigorous screening and testing to ensure that they do not release harmful substances when in contact with food, thereby safeguarding food safety.

Ordinary PVC Fiber Reinforced Hose: While also utilizing PVC materials, the composition may not have undergone strict food safety evaluations and may contain additives or impurities harmful to humans. As such, its safety cannot be fully guaranteed when used in scenarios involving direct food contact.

Application Fields

Food-Grade PVC Fiber Reinforced Hose: Specifically designed for use in scenarios involving food contact, such as food transportation pipelines and beverage production lines. It ensures that food is not contaminated during transportation, safeguarding food quality and safety.

Ordinary PVC Fiber Reinforced Hose: Widely used in non-food contact areas, such as industrial transportation, drainage, and sewage disposal. Due to its relatively lower material composition and safety requirements, it is not suitable for direct food contact scenarios.

Regulations and Standards

Food-Grade PVC Fiber Reinforced Hose: Must comply with relevant food safety regulations and standards, such as the EU's (EU) No 10/2011. These regulations and standards impose strict requirements on material composition, safety, migration limits, etc., to ensure product safety and compliance.

Ordinary PVC Fiber Reinforced Hose: May not need to meet such stringent food safety regulations and standards, with relatively lower production and quality control standards.

Production Processes and Quality Control

Food-Grade PVC Fiber Reinforced Hose: Requires more stringent production processes and quality control measures during manufacturing to ensure product safety and quality. This includes rigorous control over raw material procurement and inspection, production environment cleanliness and disinfection, product testing and inspection, etc.

Ordinary PVC Fiber Reinforced Hose: May adopt relatively simpler production processes and quality control measures to meet general usage requirements.

Productive Process

I.Raw Material Preparation

PVC Resin: High-quality PVC resin is selected as the base material for the hose to ensure its physical properties and chemical stability.

Fiber Reinforcement Material: Typically, high-strength, corrosion-resistant polyester fibers or other synthetic fibers are used as reinforcement materials to enhance the hose's tensile strength, compressive strength, and wear resistance.

Additives: According to product requirements, appropriate amounts of stabilizers, lubricants, plasticizers, and other additives are added to improve the processing performance of PVC and the hose's service performance.

II. Mixing and Plasticization

Mixing: The PVC resin, fiber reinforcement materials, and additives are mixed in a certain proportion to form a uniform mixture.

Plasticization: The mixture is fed into an extruder, where it is heated and sheared, causing the PVC resin to plasticize and encapsulate the fiber reinforcement materials, forming a continuous hose billet.

III. Extrusion Molding

Extrusion: A twin-screw or single-screw extruder is used to extrude the plasticized hose billet into the desired shape and size. During extrusion, parameters such as extruder temperature, pressure, and screw speed must be precisely controlled to ensure hose quality.

Cooling and Sizing: The extruded hose billet undergoes rapid cooling through a cooling device to maintain its shape and size. Meanwhile, a sizing device further shapes the hose to improve its dimensional stability and appearance quality.

IV. Post-Processing

Cutting: The cooled and sized hose is cut to predetermined lengths.

Inspection and Packaging: Quality inspections are conducted on the cut hoses, including visual checks, dimensional measurements, and performance tests. Qualified products are then packaged for storage and preparation for sale and use.

V. Special Processes (if required)

Depending on the specific application requirements of the PVC Fiber Reinforced Hose, additional special processes such as coating, vulcanization, fitting processing, etc., may be necessary to enhance the hose's performance and lifespan.

Precautions

Temperature Control: Strict temperature control throughout the production process is essential to ensure the plasticization of PVC resin and the hose's performance.

Raw Material Quality: Using high-quality raw materials and additives is crucial for producing high-quality PVC Fiber Reinforced Hoses.

Equipment Maintenance: Regular maintenance and servicing of production equipment are necessary to ensure its smooth operation and extend its service life.

Please note that the above production process is a general description, and actual production processes may vary due to factors such as product specifications, production equipment, and production environments.

Characteristics of 5 Layers

Material Composition

Inner Layer: Typically constructed from pure PVC, it boasts a smooth interior wall that minimizes fluid resistance and enhances flow efficiency. This layer may also exhibit chemical resistance and wear resistance properties.

Reinforcement Layer: The cornerstone of the hose's strength, this layer comprises high-tensile polyester fibers or other synthetic fibers woven or spirally wound. It significantly boosts the hose's tensile strength, compressive strength, and wear resistance, enabling it to withstand higher working pressures and harsher operating environments.

Intermediate Layers (if applicable): One or more intermediate layers may be incorporated to further enhance the hose's structural stability and durability. These layers could be made of PVC, rubber, or other elastomeric materials.

Outer Layer: Usually composed of PVC with added UV inhibitors and anti-aging agents, this layer safeguards the hose from external environmental factors. It may also possess abrasion resistance and slip resistance properties to improve safety and durability during use.

Special Layers (if required): For specific applications, additional layers such as antistatic or flame-retardant layers may be incorporated to meet particular safety or performance requirements.

Performance Enhancements

High Pressure Resistance: The fiber reinforcement layer enables the PVC Fiber Reinforced Hose to withstand substantial working pressures, making it suitable for various high-pressure transfer scenarios.

Wear Resistance: The combined effect of the inner and outer layers, along with the reinforcement layer, imparts exceptional wear resistance to the hose, prolonging its service life.

Chemical Resistance: The inherent chemical resistance of PVC material safeguards the hose against the corrosive effects of various acids, alkalis, salts, and other chemicals.

Lightweight and Strong: Despite its multi-layer construction, the PVC Fiber Reinforced Hose remains lightweight for easy handling and installation while maintaining high strength and rigidity.

Flexibility and Bendability: The hose exhibits excellent flexibility, allowing it to conform to complex installation environments and transfer paths with ease.

Application Adaptability

Widespread Applications: The PVC Fiber Reinforced Hose's superior performance characteristics render it suitable for diverse applications in fire fighting, agricultural irrigation, industrial transfer, construction drainage, and numerous other sectors.

Customized Services: Many manufacturers offer customization services, tailoring the hose's dimensions, colors, working pressures, and other parameters to meet the specific needs of customers across various application scenarios.

Company Advantages

With over 15 years of manufacturing experience, Qingdao Renato Plastic Co., Ltd. stands as a trusted leader in the production of PVC hoses and hose assemblies. Our factory, located in Shandong province, is equipped with 10 workshops, over 60 production lines, and a dedicated workforce of 120 skilled workers, including 5 technicists and 2 QC teams. Our products have earned the trust of customers in more than 60 countries, thanks to our commitment to quality and customer satisfaction. We offer a wide range of hose assemblies, including Camlock fittings, Storz fittings, nozzle fittings, and hose clamps, to provide comprehensive solutions for all your fluid transfer needs.

If you're looking for a reliable partner for high-quality hoses and assemblies, look no further than Qingdao Renato Plastic Co., Ltd.. Our team is ready to assist you with a quick response and tailored solutions to meet your specific requirements. Don't hesitate to reach out to us – we are here 24/7, ready to serve you. Remember, at Renato Plastic, Customers Are Always First.