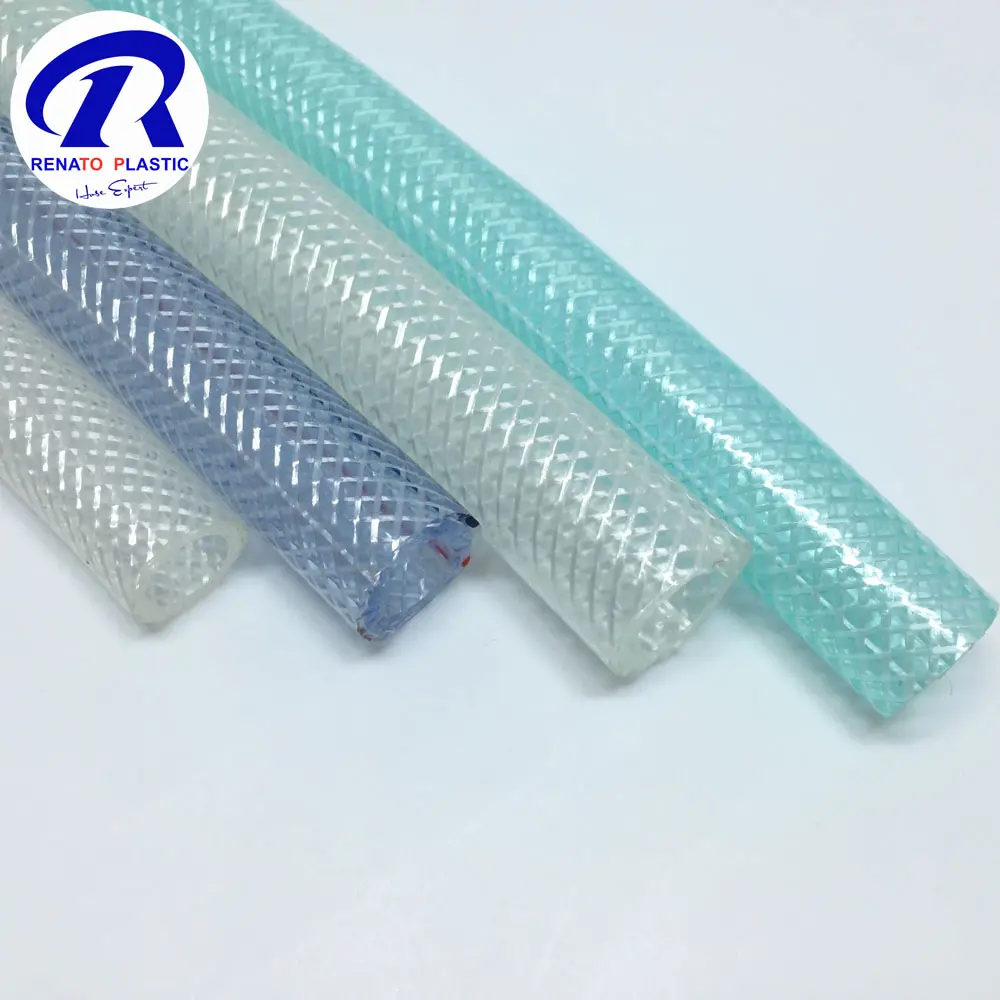

Flexible PVC Fiber Reinforced Hose for Water Delivery

Introducing the Flexible PVC Fiber Reinforced Hose by Qingdao Renato Plastic Co., Ltd.—a robust and reliable solution engineered for efficient water delivery across a range of applications. Whether you’re managing irrigation systems, plumbing installations, or industrial water transfers, this hose pipe offers exceptional performance with the durability and flexibility required to meet your needs.

Key Characteristics

1. High Strength and Durability

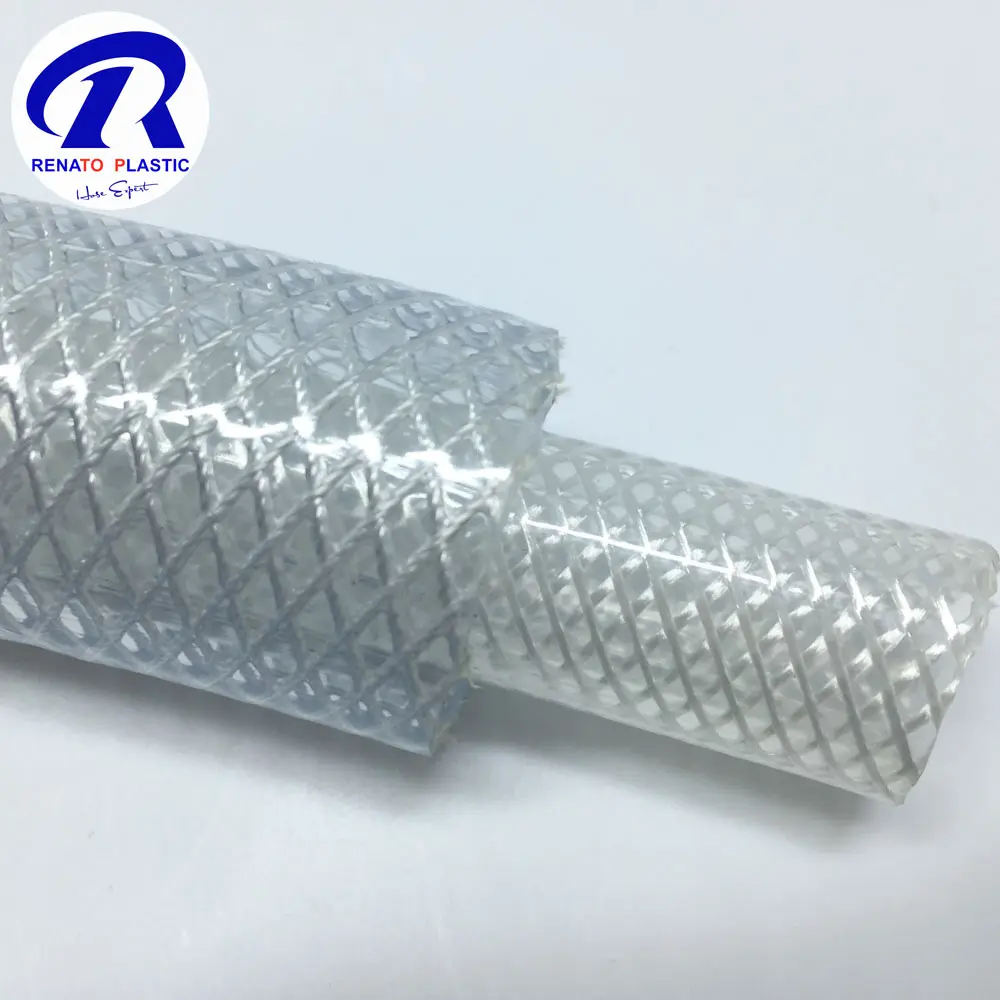

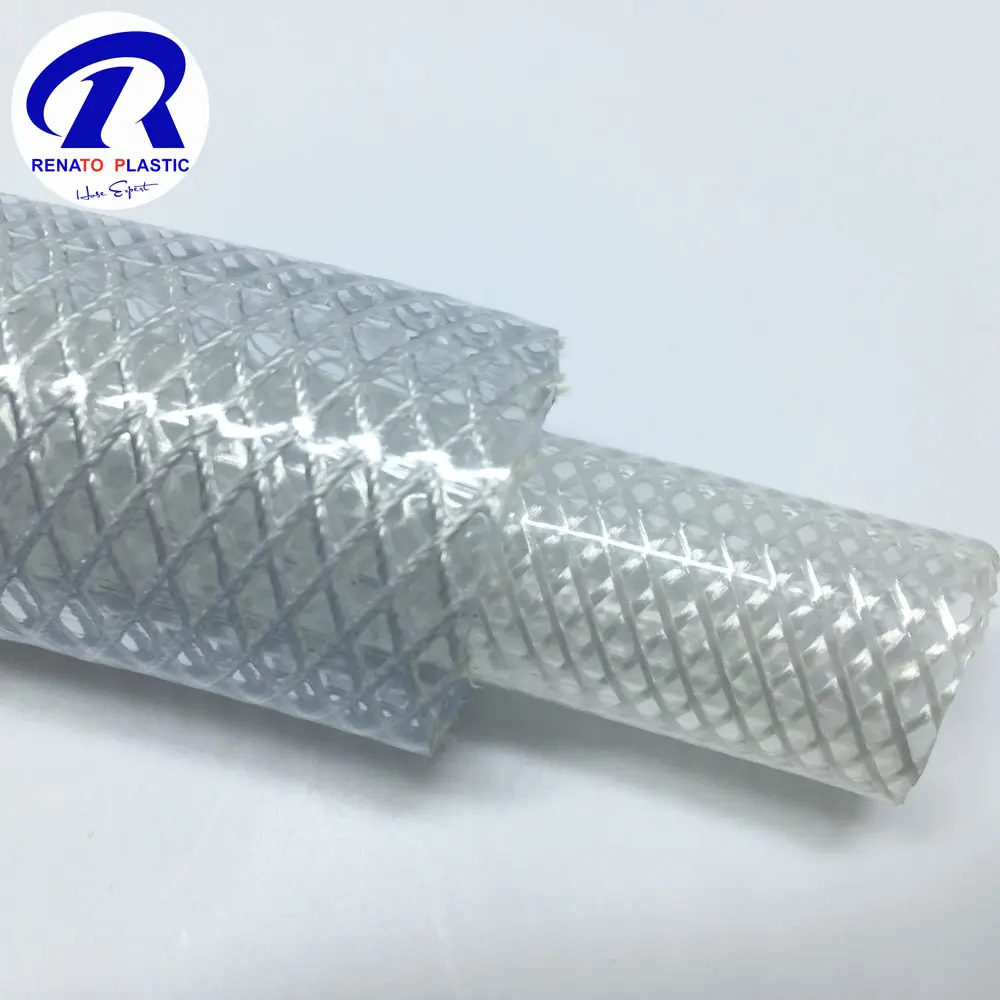

Fiber Reinforcement: By incorporating fiber materials (such as polyester or nylon fibers), PVC fiber reinforced hose significantly enhances its tensile, compressive, and tear resistance. This reinforcement design allows the hose to withstand high pressures and loads over extended periods without damage.

Wear Resistance: The outer fiber braid layer effectively resists abrasion and cuts, extending the hose's service life.

2. Flexibility and Bendability

Soft and Bendable: The inherent flexibility of PVC material, combined with the fiber reinforcement, enables the hose to bend easily in complex environments, adapting to diverse installation and usage requirements.

Easy Laying: Its excellent bendability simplifies installation, reducing construction difficulty and costs.

3. Chemical Resistance

Chemical Stability: PVC exhibits robust chemical stability, resisting erosion from various acids, alkalis, salts, and other chemicals. Consequently, PVC fiber reinforced hose finds widespread application in the chemical, petrochemical, pharmaceutical, and other industries.

4. Lightweight and Portable

Lightweight: Compared to metal or rigid pipes, PVC fiber reinforced hose weighs significantly less, facilitating handling and installation.

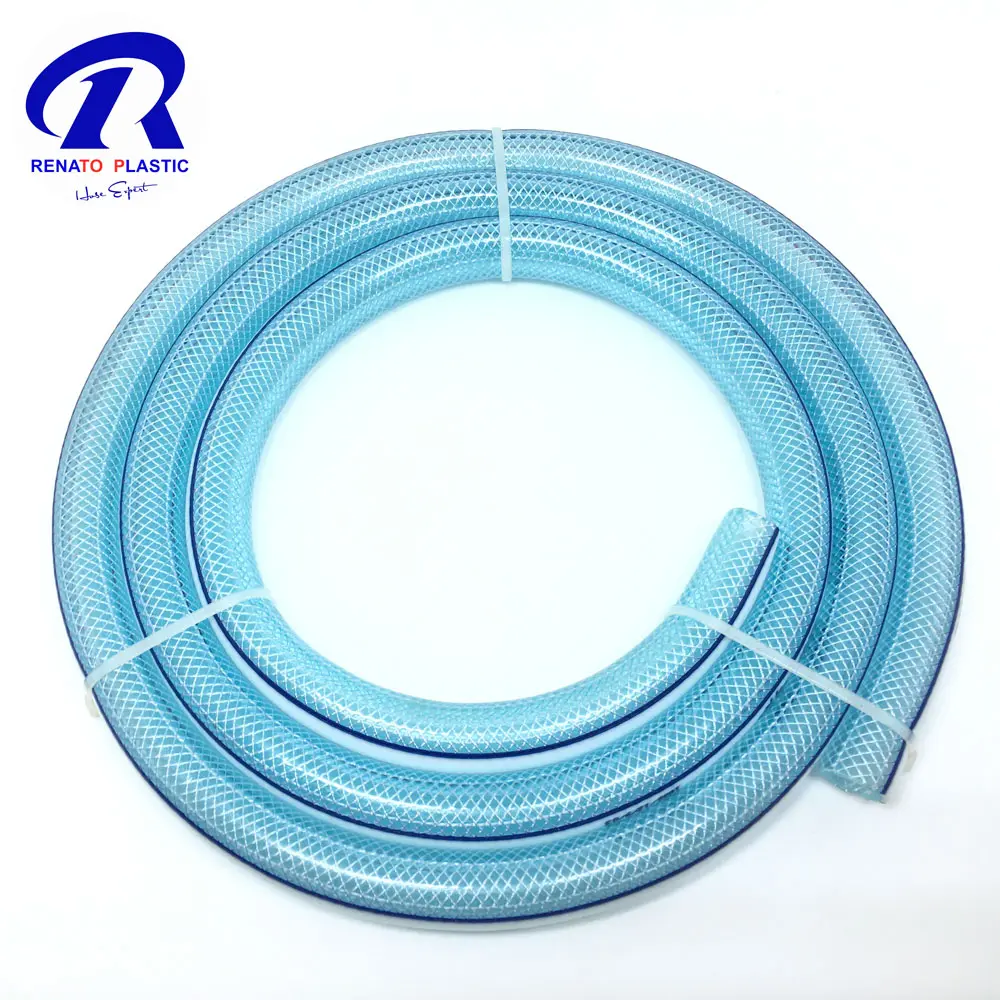

Easy Storage: The hose can be coiled or folded for compact storage, minimizing transport and storage space requirements.

5. Versatile Applications

PVC fiber reinforced hose, due to its superior performance, is extensively used in agriculture (irrigation), landscaping (watering systems and fountains), construction (drainage), petrochemicals, machinery and equipment, and many other sectors.

The Food Grade Fiber Reinforced Hose Appliaction

Safety and Compliance

Non-toxic Materials: Food-grade PVC fiber reinforced hose is made from non-toxic, odorless PVC materials, ensuring no harmful substances are released when in contact with food, thereby safeguarding food safety.

Compliance with Standards: These hoses must comply with relevant food safety standards and regulations, such as those set by the FDA (Food and Drug Administration) in the United States and the EU (European Union), to ensure the safety of their material composition and manufacturing processes.

Chemical Resistance and Cleanability

Corrosion Resistance: Food-grade PVC fiber reinforced hose is resistant to common food-grade acids, alkalis, and cleaning agents, maintaining the integrity of the hose structure and extending its service life.

Easy to Clean: The smooth surface of the hose resists the accumulation of dirt, making it easy to clean and disinfect, which is crucial for meeting the high hygiene standards of the food industry.

Flexibility and Durability

Flexibility: Food-grade PVC fiber reinforced hose exhibits excellent flexibility, allowing it to adapt to various complex installation environments and facilitating flexible arrangement in food production lines.

Wear Resistance and Durability: The fiber reinforcement layer enhances the hose's wear resistance, enabling it to withstand friction and impact during food production, maintaining stable performance over a long period.

Versatility in Applications

Food Transfer: Suitable for conveying various food raw materials, semi-finished products, and finished products, such as beverages, dairy products, beer, and fruit juices.

Equipment Connection: Provides reliable connections between food production equipment, ensuring that food remains uncontaminated during transfer.

Environmental Friendliness and Sustainability

Recyclability: PVC material is inherently recyclable, and food-grade PVC fiber reinforced hose can be recycled after its service life, reducing environmental pollution.

Green Production: Some manufacturers prioritize energy conservation, emission reduction, and environmental protection during production, adopting green production processes and technologies to minimize environmental impact.

Storage Method

I. Environmental Requirements

Temperature Control:

Store the PVC Fiber Reinforced Hose in an environment with moderate temperatures, avoiding extreme heat and cold. Ideally, the temperature should be maintained between 5°C and 35°C to slow down material aging and deformation.

Humidity Control:

Maintain humidity levels within a reasonable range, typically between 50% and 70%, to prevent moisture, mold, or corrosion.

Light Exposure:

Avoid direct sunlight and strong light exposure, as ultraviolet (UV) rays can accelerate the aging of PVC materials, causing the hose surface to yellow and become brittle.

II. Storage Methods

Flat Stacking:

Choose a flat, solid surface for stacking to prevent the hose from being crushed or deformed.

Keep the stacking height moderate to avoid excessive pressure on the bottom layers of the hose.

Avoid Heavy Loads:

Do not stack heavy objects on top of the hose to prevent unnecessary pressure damage.

Good Ventilation:

Ensure the storage environment is well-ventilated to reduce the accumulation of moisture and harmful gases.

III. Regular Inspection and Maintenance

Regular Inspection:

Periodically inspect the PVC Fiber Reinforced Hose for signs of damage, aging, or deformation.

Pay particular attention to the connection points and bends, which are prone to stress concentration and damage.

Cleaning and Maintenance:

Gently wipe off dust or dirt from the hose surface using a soft cloth. Avoid using chemical solvents or sharp objects for cleaning.

Ensure the hose is completely dry after cleaning to prevent moisture-induced corrosion.

Replacement and Disposal:

Replace damaged or aged hoses promptly to avoid further losses.

IV. Additional Precautions

Avoid Contact with Acids and Alkalis:

PVC material is sensitive to acids and alkalis; avoid direct contact with these substances to prevent corrosion.

Fire Prevention Measures:

Although PVC material is not highly flammable, the storage area should be equipped with necessary fire prevention facilities to address emergencies.

Storage Duration:

Avoid long-term storage of PVC Fiber Reinforced Hose, as prolonged storage can degrade material properties. For extended storage, perform regular checks and implement appropriate maintenance measures.

By adhering to these storage methods, you can extend the lifespan and maintain the optimal performance of your PVC Fiber Reinforced Hose.

Usage Method

I. Inspection and Preparation

Inspect the Hose: Before use, thoroughly inspect the PVC Fiber Reinforced Hose for any signs of damage, cracks, or aging. Ensure the hose surface is free from scratches, and the fiber braiding is intact.

Prepare the Work Environment: Ensure the work area is clean and free of sharp objects or corrosive materials that could damage the hose. Also, check that the connection points on the hose are clean and free of dirt, oil, or other impurities.

II. Connection and Securing

Attach Fittings: Choose the appropriate fittings (such as threaded fittings, quick-connect fittings, etc.) based on your needs and ensure they are securely connected to the hose. Avoid overtightening to prevent damage to the hose or fittings.

Secure the Hose: Use clamps, ties, or other fixtures to secure the hose in place where necessary, preventing it from moving or twisting during operation, which could affect water flow or cause damage.

III. Usage Precautions

Pressure and Temperature: When using the PVC Fiber Reinforced Hose, be mindful of its maximum working pressure and temperature limits. Do not exceed these ratings to prevent ruptures or leaks.

Avoid Excessive Bending: Try to avoid excessive bending or folding of the hose, as this can slow water flow and shorten the hose's lifespan. Where bending is necessary, ensure the bend radius is not smaller than the hose's minimum bend radius.

Regular Checks: Periodically inspect the hose's connections for looseness, leaks, or damage. Address any issues promptly.

Cleaning and Maintenance: After use, clean the hose's surface of dirt and debris, keeping it dry and clean. When not in use for extended periods, store the hose in a cool, dry place, away from direct sunlight and high temperatures.

IV. Special Applications

For specialized applications of PVC Fiber Reinforced Hose, such as high-pressure water jetting or chemical fluid transfer, pay special attention to:

Selecting the Right Hose: Choose a hose model and specification suitable for your specific application requirements, ensuring it can withstand the necessary pressure and temperature.

Protective Measures: When transferring chemical fluids, ensure the hose is compatible with the fluid and take necessary precautions (e.g., wearing protective gloves and eyewear) to prevent harm to the hose and operators.

Professional Guidance: For complex applications, consult professionals or refer to relevant operating manuals and guidelines to ensure safe and effective use of the hose.

In summary, the usage of PVC Fiber Reinforced Hose encompasses thorough inspection, proper connection and securing, adherence to usage precautions, and specialized considerations for particular applications. By following these steps, you can maximize the safety and reliability of your hose.

Specifications and corresponding prices

Here is a table showing typical specifications and corresponding prices for a Flexible PVC Fiber Reinforced Hose Pipe used for water delivery:

| Specification | Inner Diameter (mm) | Outer Diameter (mm) | Working Pressure (Bar) | Length (m) | Estimated Price (USD per meter) |

|---|---|---|---|---|---|

| Light Duty (General Use) | 12 mm (1/2 inch) | 16 mm | 5 Bar | 30 m | $0.30 - $0.50 |

| Medium Duty (Household Use) | 19 mm (3/4 inch) | 24 mm | 8 Bar | 50 m | $0.50 - $0.80 |

| Heavy Duty (Industrial Use) | 25 mm (1 inch) | 31 mm | 10 Bar | 50 m | $0.80 - $1.20 |

| Extra Heavy Duty (High Pressure) | 38 mm (1.5 inches) | 46 mm | 12 Bar | 100 m | $1.20 - $1.80 |

| Large Diameter (Agricultural) | 50 mm (2 inches) | 60 mm | 10 Bar | 100 m | $1.50 - $2.50 |

Notes:

Prices may vary depending on the manufacturer, customization, order quantity, and region.

Prices are estimated for standard hoses without additional fittings or customization.

For bulk orders, discounts may apply.

This table provides a general idea of the specifications and price ranges for PVC fiber reinforced hoses commonly used for water delivery.

Company Advantages

Qingdao Renato Plastic Co., Ltd. stands as a trusted leader in the PVC hose manufacturing industry, backed by over 15 years of experience. Here’s why we are your ideal partner:

Extensive Expertise: With more than a decade of industry experience, we have honed our production processes to deliver top-quality hoses that meet international standards.

State-of-the-Art Facilities: Our factory, located in Shandong province, is equipped with 10 advanced workshops and over 60 production lines, ensuring consistent and efficient production.

Skilled Workforce: Our team includes 120 dedicated workers, 5 experienced technicists, and 2 rigorous QC teams who ensure each product meets our high standards.

Global Reach: Our products are trusted by customers in over 60 countries, and we have earned widespread praise for the quality and reliability of our offerings.

Customer-Centric Approach: We pride ourselves on providing a 7x24 hour quick response service, ensuring that your inquiries and needs are addressed promptly.

Contact Us

Renatoflex Factory is your trusted partner for high-quality lay flat discharge hoses. For more information on our products and services, visit our website or contact our customer service team. We are always ready to help you with your fluid transfer needs.

820 Buliding C Qingdao Plaza, No.379 Dunhua Road, Qingdao 266034 China.