Heavy Duty PVC Layflat Hose for Water Discharge: Product Introduction

Renato Hose's Heavy Duty PVC Layflat Hose for Water Discharge – the ultimate solution for high-pressure water discharge needs across various industries. With over 15 years of expertise in manufacturing top-tier PVC hoses, Renato Hose ensures unparalleled quality and reliability in every product.

Our Heavy Duty PVC Layflat Hose boasts high-quality fiber reinforcement, guaranteeing superior durability and longevity even under the most demanding conditions. With a robust design capable of withstanding 8-10 bar working pressure and a staggering 24-30 bar bursting pressure, this hose is engineered to deliver exceptional performance consistently.

The heavy duty PVC layflat hose for water discharge is an essential tool designed to provide reliable performance in demanding applications. This robust and flexible hose is widely used in agriculture, construction, and industrial sectors, offering efficient and effective water discharge solutions.

Specifications Table for Heavy Duty PVC Layflat Hose

| Specification | Description |

|---|---|

| Material | High-quality PVC with reinforced polyester fiber |

| Inner Diameter (ID) | Ranges from 1 inch (25mm) to 12 inches (300mm) |

| Wall Thickness | 2.0mm - 4.5mm, depending on the diameter |

| Working Pressure | 4 bar - 10 bar (58 psi - 145 psi) |

| Burst Pressure | 12 bar - 30 bar (174 psi - 435 psi) |

| Temperature Range | -10°C to 60°C (14°F to 140°F) |

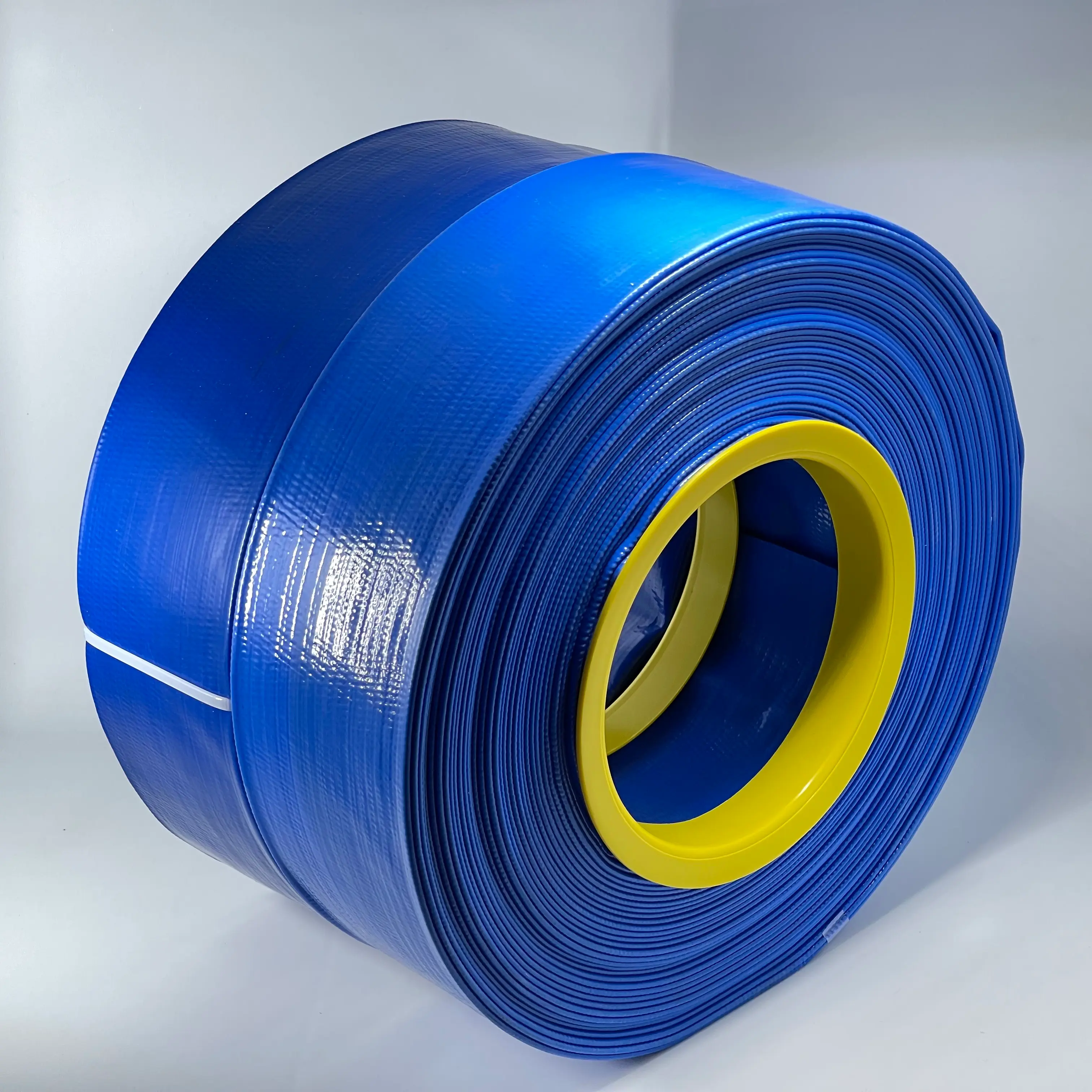

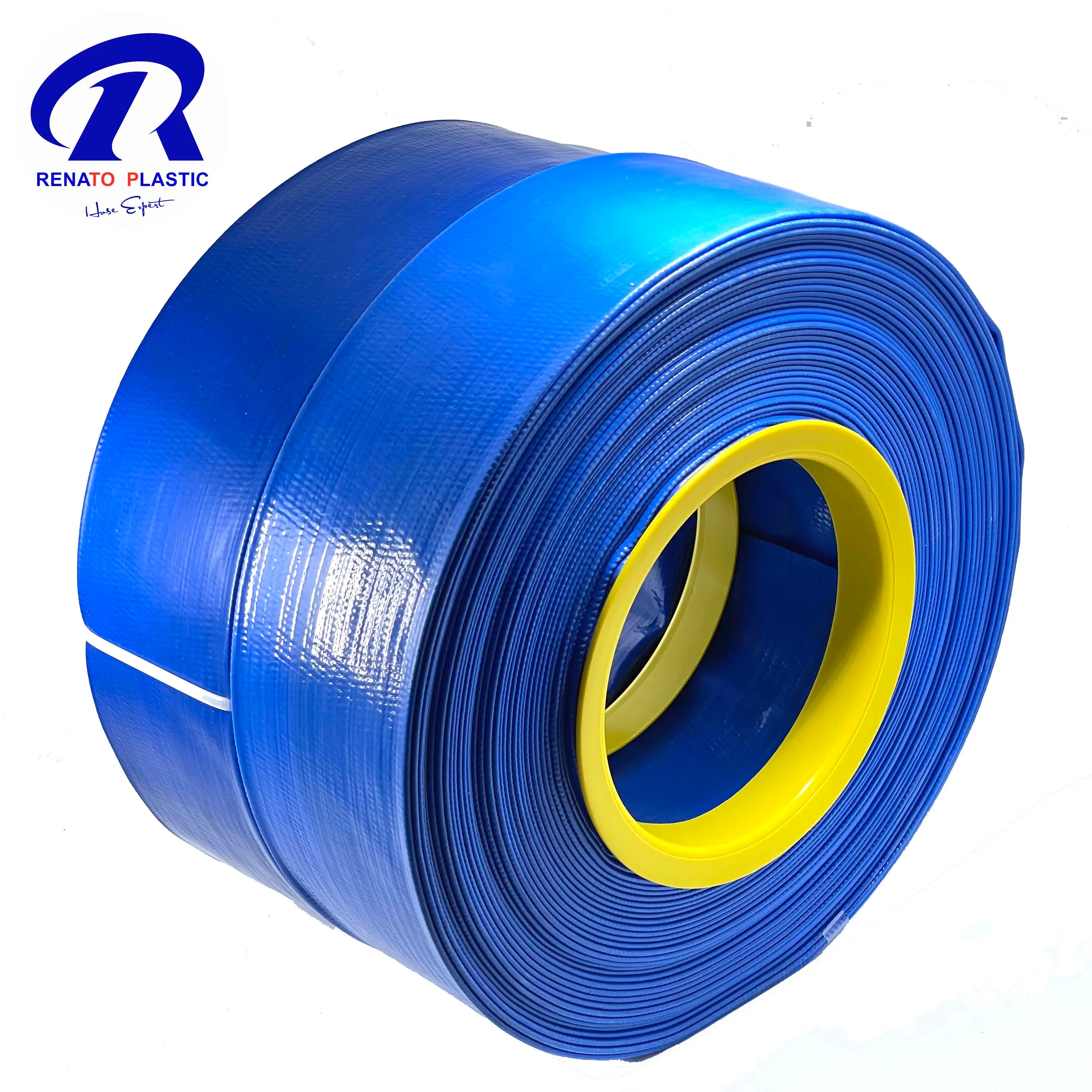

| Length per Roll | Standard rolls of 50m, 100m, with custom lengths available |

| UV Resistance | UV-stabilized for prolonged outdoor use |

| Flexibility | High flexibility for easy storage and maneuvering |

| Reinforcement | High-tensile polyester yarn for enhanced durability |

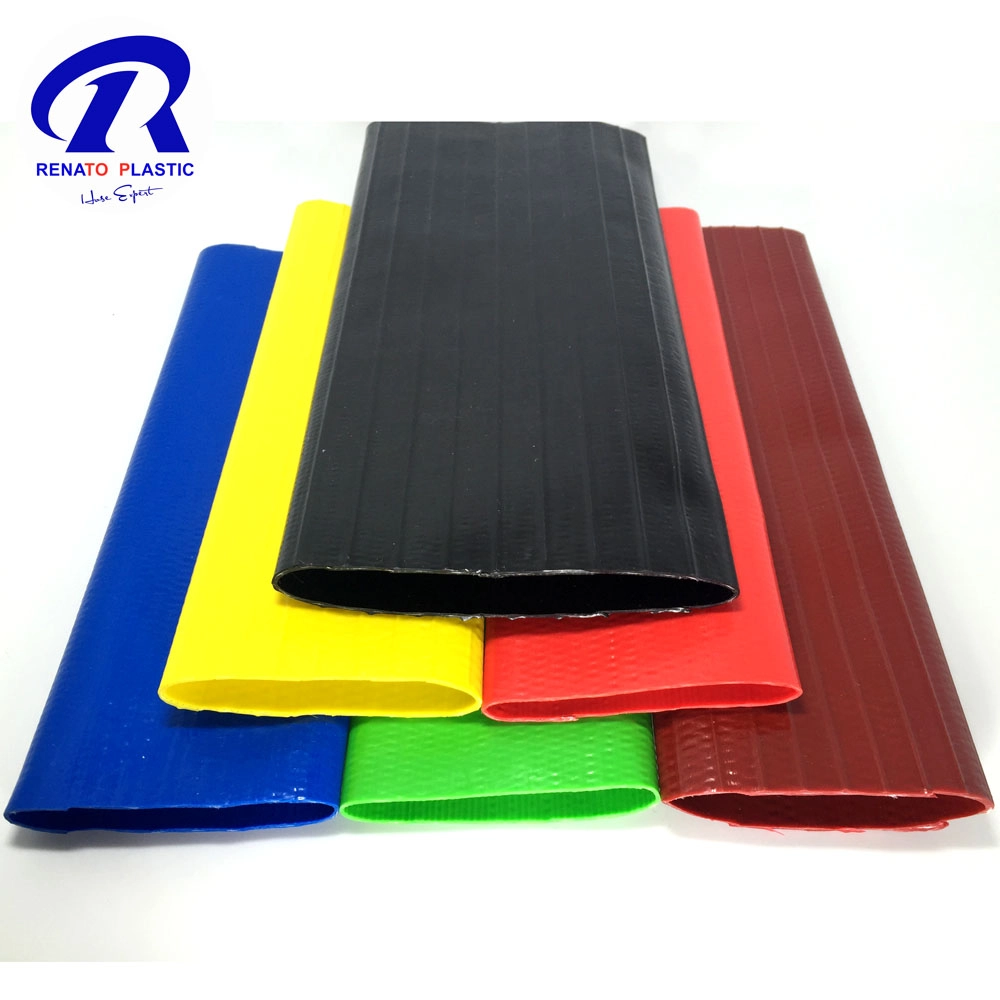

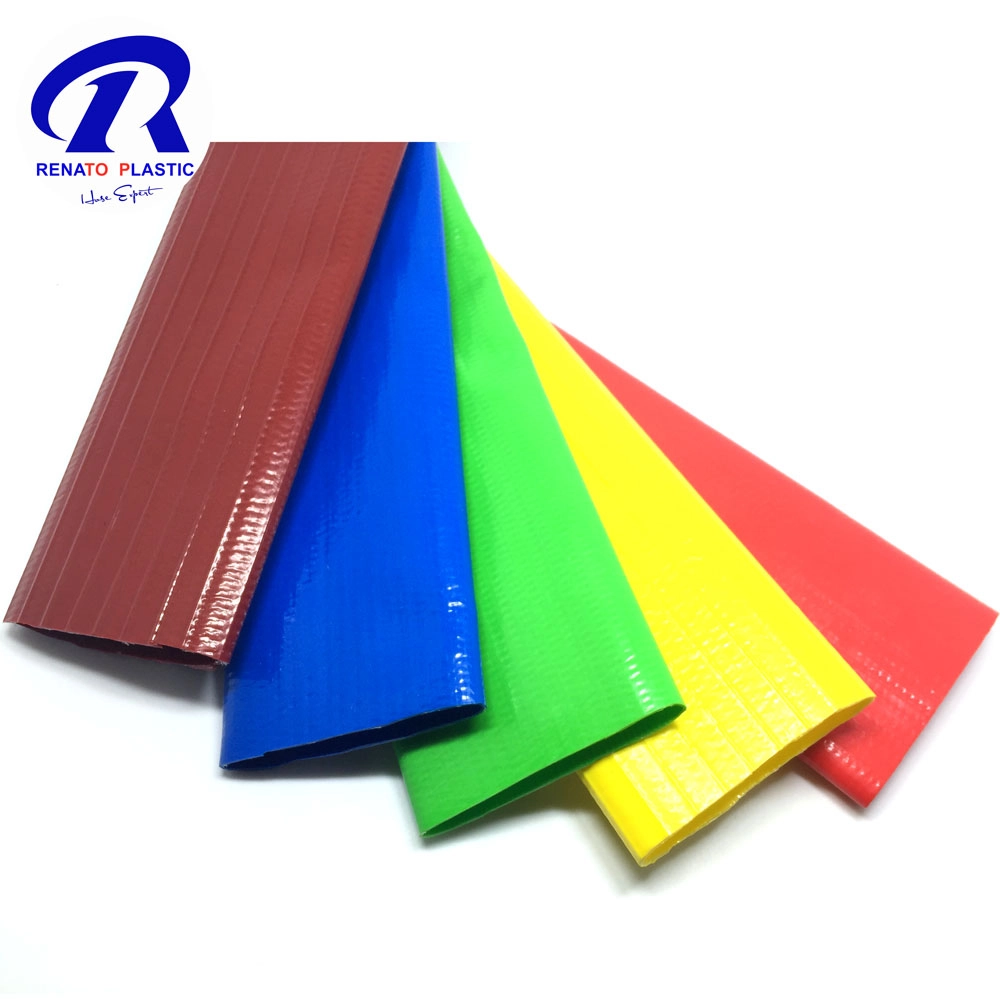

| Color Options | Blue, red, yellow, and custom colors |

| Weight | Lightweight for easy transportation and setup |

| Compliance | Meets ISO 9001 standards for quality control |

Key Features

High-Quality PVC Construction

Durable Material: Made from high-quality polyvinyl chloride (PVC), the hose offers excellent durability and longevity. The material is resistant to abrasion, chemicals, and UV radiation, ensuring reliable performance in harsh conditions.

Polyester Reinforcement: Reinforced with high-tensile polyester yarn, the hose gains additional strength and flexibility, allowing it to withstand high pressures and prevent kinking.

Heavy-Duty Design

High Burst Pressure: Designed to handle high-pressure applications, the heavy duty PVC layflat hose has a high burst pressure, ensuring safety and reliability in demanding environments.

Thick Wall Construction: The thicker wall of the hose enhances its durability and resistance to punctures, ensuring a long service life even under rigorous use.

Flexibility and Easy Handling

Layflat Design: When not in use, the hose can be laid flat, making it easy to roll up, store, and transport. This design minimizes storage space requirements and prevents kinking and twisting during operation.

Lightweight: Despite its robust construction, the hose remains relatively lightweight, facilitating easy handling and maneuvering.

Wide Range of Applications

Agriculture: Ideal for irrigation, slurry handling, and water transfer, ensuring efficient water distribution across large fields.

Construction: Suitable for dewatering, water bypass, and pumping applications, maintaining dry and safe working conditions on construction sites.

Industrial: Supports the transfer of various fluids, including chemicals, fuels, and wastewater, making it suitable for diverse industrial processes.

Temperature and Chemical Resistance

Wide Temperature Range: The hose is designed to perform effectively in a broad range of temperatures, from extreme cold to high heat, making it versatile for different climates and conditions.

Chemical Resistance: Resistant to a variety of chemicals and oils, the heavy duty PVC layflat hose can handle corrosive fluids, enhancing its applicability in industrial settings.

Customizable Options

Various Sizes and Lengths: Available in different diameters (e.g., 2 inch, 3 inch, 4 inch, 6 inch, 8 inch) and lengths (e.g., 50 feet, 100 feet, 200 feet) to meet specific application requirements.

Fittings and Couplings: Can be equipped with quick-connect fittings, camlock couplings, or other connectors to ensure easy attachment to pumps, hydrants, and other equipment.

Price List for Heavy Duty PVC Layflat Hose for Water Discharge

| Inner Diameter (ID) | Wall Thickness | Length | Working Pressure | Factory Price (USD per Roll) | Factory Price (USD per Ton) |

|---|---|---|---|---|---|

| 1 inch (25mm) | 2.0mm | 100m | 6 bar (87 psi) | $30 - $50 | $1,100 - $1,300 |

| 2 inches (50mm) | 2.5mm | 100m | 6 bar (87 psi) | $60 - $80 | $1,050 - $1,250 |

| 3 inches (75mm) | 3.0mm | 100m | 8 bar (116 psi) | $90 - $120 | $1,000 - $1,200 |

| 4 inches (100mm) | 3.2mm | 100m | 8 bar (116 psi) | $130 - $160 | $950 - $1,150 |

| 6 inches (150mm) | 3.5mm | 100m | 10 bar (145 psi) | $200 - $250 | $900 - $1,100 |

| 8 inches (200mm) | 4.0mm | 100m | 10 bar (145 psi) | $280 - $350 | $850 - $1,050 |

| 10 inches (250mm) | 4.5mm | 50m | 10 bar (145 psi) | $350 - $450 | $800 - $1,000 |

Note: Prices vary depending on location, shipping, and specific customization needs.

Manufacturing Process

Material Selection

Choose high-quality PVC and polyester yarn for reinforcement.

Mixing and Compounding

Mix PVC with necessary additives like plasticizers, stabilizers, and colorants to create a homogeneous compound.

Extrusion of the Inner Layer

Feed the compound into an extruder to form a tubular inner layer of the hose.

Rapidly cool the extruded tube to set its shape.

Reinforcement

Pass the cooled PVC tube through a braiding or knitting machine to wrap it with high-tensile polyester yarn.

Extrusion of the Outer Layer

Apply an outer layer of PVC through a second extruder to encapsulate the reinforced tube, providing additional durability.

Curing

Pass the hose through a curing oven to bond the layers properly.

Cooling

Rapidly cool the hose in a water bath to stabilize its shape.

Quality Control

Conduct visual inspections, pressure tests, and dimensional checks to ensure the hose meets all specifications and performance standards.

Cutting and Fittings

Cut the hose to desired lengths and attach fittings or couplings as required by the customer.

Packaging

Coil, label, and package the hose for safe transportation and storage.

The heavy duty PVC layflat hose for water discharge is a vital tool for high-pressure and demanding applications across various industries. Its durable construction, flexibility, and resistance to extreme conditions make it a reliable choice for professionals in agriculture, construction, and industrial sectors. By selecting the right materials and adhering to stringent manufacturing processes, manufacturers ensure that these hoses deliver superior performance and long-lasting durability.

Applications

This hose is widely used for water discharge at high working pressure in agriculture irrigation, forestry sprinkler irrigation, construction project, industrial and mining enterprise.

Our Layflat Hose can be perfectly combined with Suction Hose through a water pump, one for water intake and the other for drainage, providing a rapid solution for water logging, mine drainage, flood relief, farmland irrigation, and various other applications.

846530.webp)

Regarding the color options for our Layflat Hose, we offer a wide range of choices, among which blue and red are the most popular. The blue hose is designed for medium pressure, with a working pressure ranging from 4 bar to 6 bar. While the red hose is for high pressure, with a working pressure ranging from 8 bar to 10 bar.

How to Use Heavy Duty PVC Layflat Hose for Water Discharge

1. Preparation and Setup

Select the Right Hose: Choose the appropriate diameter and length based on the volume of water to be discharged and the distance to the discharge area. Ensure that the working pressure of the hose matches the pressure generated by the pump.

Inspect the Hose: Before use, check the hose for any signs of wear, damage, or leaks to ensure safe operation. Make sure the hose is free from debris or kinks that could impede water flow.

Position the Hose: Unroll the hose along a straight path between the water source (e.g., a pond, river, or tank) and the discharge location. Avoid sharp bends or twists that could reduce the hose's efficiency.

2. Connecting the Hose

Attach to the Pump: Securely connect the PVC layflat hose to the water pump using appropriate fittings, such as hose clamps or camlock couplings. Tighten the connections to prevent leaks during operation.

Use Teflon Tape: Wrap Teflon tape around threaded connections to ensure a watertight seal. This will help to prevent water loss and maintain pressure.

Secure with Hose Clamps: Use heavy-duty hose clamps around the connection points to prevent the hose from detaching under pressure.

3. Starting the Water Discharge

Turn on the Pump: Gradually start the pump to allow water to flow through the hose. Check for any leaks or weak spots along the length of the hose.

Monitor the Flow: Ensure that the water is flowing smoothly and that there are no blockages or twists in the hose. Adjust the hose position as necessary to maintain a consistent flow.

Regulate Pressure: Adjust the pump's speed or flow rate to ensure that the pressure remains within the hose's rated working pressure, preventing damage to the hose.

4. Maintenance and Storage

Drain the Hose After Use: After each use, drain any remaining water from the hose to prevent freezing and cracking, especially if stored in colder environments.

Roll Up Neatly: Roll up the hose neatly and store it in a dry, shaded area to extend its lifespan. Avoid prolonged exposure to direct sunlight when not in use, even if the hose is UV-stabilized.

Regular Inspections: Periodically inspect the hose for wear and replace any damaged sections to ensure safe operation during the next use.

Heavy duty PVC layflat hoses are an essential tool for efficient water discharge in agriculture, construction, and industrial applications. With their robust construction, these hoses offer durability, flexibility, and ease of use, making them ideal for moving large volumes of water quickly. By following the proper setup and maintenance practices, users can maximize the performance and lifespan of their PVC layflat hoses, ensuring reliable water discharge operations for various needs.

Characteristics

The hose is made from PVC tube and PVC cover with high tenacity fibre reinforced layer , by one-step procedure .This product has the characteristics of anti-fracture, resisted high pressure and small expansivity. Increased the radial fibers , improved the tensile strength.

◢ This kind of hose has the advantages of anti-stretch, anti-fracture, resisted high pressure and small expansion rate.

◢ It is light, flexible, bright colors, anti-erosion, anti-aging, abrasion resistance and anti-ultraviolet.

◢ No odor, environmental protection products.

◢ Working Temperature: -5°C-65°C

Specifications of Heavy Duty PVC Layflat Hose

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | Volume | ||

| inch | mm | mm | m | kg/m | bar | psi | cbm |

| 1 | 25 | 1.7 | 100 | 0.2 | 10 | 150 | 0.020 |

| 1 1/4 | 32 | 1.5 | 100 | 0.21 | 10 | 150 | 0.025 |

| 1 1/2 | 38 | 1.9 | 100 | 0.29 | 10 | 150 | 0.030 |

| 2 | 51 | 1.5 | 100 | 0.35 | 8 | 120 | 0.050 |

| 2.1 | 100 | 0.42 | 10 | 150 | 0.056 | ||

| 2 1/2 | 64 | 2.2 | 100 | 0.67 | 10 | 150 | 0.060 |

| 3 | 76 | 2.25 | 100 | 0.66 | 8 | 120 | 0.095 |

| 2.5 | 100 | 0.85 | 10 | 150 | 0.100 | ||

| 4 | 102 | 2.55 | 100 | 1 | 8 | 120 | 0.105 |

| 2.7 | 100 | 1.2 | 10 | 150 | 0.115 | ||

| 6 | 153 | 3.2 | 50 | 2.1 | 8 | 120 | 0.100 |

| 8 | 203 | 3.2 | 50 | 2.8 | 6 | 90 | 0.120 |

The Heavy Duty PVC Layflat Hose Serves Crucial Functions in Drainage

◢ Efficient Drainage: With its larger diameter and thick wall construction, the heavy-duty PVC Layflat Hose can withstand higher water pressure and flow rates. Widely used in industrial and construction settings, it efficiently discharges large volumes of water, such as stormwater or wastewater. This hose swiftly and effectively removes water from surfaces or buildings to designated areas, ensuring the smooth operation of drainage systems.

◢ Durability and Stability: Constructed from high-strength PVC material, the heavy-duty PVC Layflat Hose boasts excellent abrasion resistance and durability. Its design enables it to work in various adverse conditions, including maintaining stability under high-pressure and high-flow drainage situations. This durability ensures the long-term reliability of the hose, reducing the need for maintenance and replacement.

◢ Flexibility and Portability: Despite being a heavy-duty pipeline, the heavy-duty PVC Layflat Hose still maintains a degree of flexibility, making it easy to deploy and relocate. This allows for the quick setup of temporary drainage systems in different worksites or emergency situations. Additionally, its relatively lightweight allows for easy rolling and carrying, facilitating rapid emergency drainage when needed.

◢ Environmental Friendliness: Compared to traditional metal pipelines, the heavy-duty PVC Layflat Hose exhibits better environmental characteristics. It doesn't rust or corrode and is recyclable, helping to reduce negative environmental impacts. Moreover, PVC material itself possesses chemical stability, preventing the release of harmful substances into water bodies and ensuring the safety of drainage.

Heavy Duty PVC Layflat Hose for Water Discharge: Pros and Cons

Pros

Durable Construction

High-Quality PVC Material: Made from premium PVC, which provides excellent durability, abrasion resistance, and longevity.

Reinforced with Polyester Yarn: Enhances the hose’s strength and flexibility, making it suitable for high-pressure applications.

High Performance

High Burst Pressure: Capable of withstanding high-pressure applications, ensuring reliability and safety in demanding environments.

Thick Wall Construction: Offers added durability and resistance to punctures, ensuring a long service life even under rigorous use.

Flexibility and Easy Handling

Layflat Design: Can be laid flat when not in use, making it easy to roll up, store, and transport, which saves space and prevents kinking and twisting during operation.

Lightweight: Despite its robust construction, the hose remains lightweight, facilitating easy handling and maneuvering.

Wide Range of Applications

Agriculture: Ideal for irrigation, slurry handling, and water transfer, ensuring efficient water distribution across large fields.

Construction: Suitable for dewatering, water bypass, and pumping applications, maintaining dry and safe working conditions on construction sites.

Industrial: Supports the transfer of various fluids, including chemicals, fuels, and wastewater, making it suitable for diverse industrial processes.

Resistance to Harsh Conditions

Wide Temperature Range: Designed to perform effectively in extreme temperatures, making it versatile for different climates and conditions.

Chemical Resistance: Resistant to a variety of chemicals and oils, enhancing its applicability in industrial settings.

Customizable Options

Various Sizes and Lengths: Available in different diameters and lengths to meet specific application requirements.

Fittings and Couplings: Can be equipped with quick-connect fittings, camlock couplings, or other connectors for easy attachment to pumps and other equipment.

Cons

Initial Cost

Higher Initial Investment: The durable construction and high-quality materials may result in a higher initial cost compared to lighter-duty hoses.

Weight in Large Sizes

Heavier in Larger Diameters and Lengths: Although lightweight for its durability, the hose can become heavy and more difficult to handle in larger diameters and longer lengths.

Storage Space

Storage Space Requirement: While the layflat design saves space, storing large quantities of hose can still require significant storage space.

Flexibility Limitations in Cold Temperatures

Reduced Flexibility in Extreme Cold: In very cold conditions, PVC hoses may become less flexible, making handling more challenging.

Chemical Limitations

Not Suitable for All Chemicals: Although resistant to many chemicals, certain aggressive chemicals may still damage the hose over time, limiting its use in some industrial applications.

The heavy duty PVC layflat hose for water discharge offers numerous advantages, including durability, high performance, flexibility, and resistance to harsh conditions, making it an excellent choice for a variety of demanding applications in agriculture, construction, and industrial sectors. However, it also has some drawbacks, such as higher initial costs, potential weight issues in larger sizes, storage space requirements, reduced flexibility in extreme cold, and limitations with certain chemicals. Evaluating these pros and cons can help in making an informed decision based on specific needs and applications.

How to Make a Heavy Duty Layflat Hose

Manufacturing a heavy duty layflat hose involves a meticulous process to ensure the final product is durable, flexible, and capable of withstanding high pressures and harsh conditions. Here is a detailed overview of the manufacturing process:

1. Material Selection

PVC/Nitrile Rubber or TPU: Choose high-quality polyvinyl chloride (PVC), nitrile rubber, or thermoplastic polyurethane (TPU) for the hose material.

Polyester Yarn: Select high-tensile polyester yarn for reinforcement to provide strength and flexibility.

2. Mixing and Compounding

Mixing: Combine the PVC, nitrile rubber, or TPU with necessary additives like plasticizers, stabilizers, and colorants to create a homogeneous compound.

Compounding: Heat and blend the mixture to ensure all components are thoroughly combined, forming the base material for the hose.

3. Extrusion of the Inner Layer

Extrusion: Feed the compound into an extruder that heats and shapes it into a tubular form, creating the inner layer of the hose.

Cooling: Rapidly cool the extruded tube to set its shape.

4. Reinforcement

Braiding or Knitting: Pass the cooled PVC/nitrile/TPU tube through a braiding or knitting machine where high-tensile polyester yarn is wrapped around it. This reinforcement adds strength and prevents the hose from bursting under high pressure.

5. Extrusion of the Outer Layer

Second Extrusion: Feed the reinforced tube through another extruder to apply an outer layer of PVC, nitrile rubber, or TPU. This outer layer encapsulates the polyester yarn, providing additional durability and protection.

6. Curing

Heating: Pass the extruded and reinforced hose through a curing oven where it is heated to a specific temperature. This process ensures that the inner and outer layers bond properly with the reinforcement, creating a strong, cohesive structure.

7. Cooling

Water Bath: Rapidly cool the hose in a water bath to solidify the material and stabilize its shape.

8. Quality Control

Visual Inspection: Check the hose for surface defects, inconsistencies, or irregularities.

Pressure Testing: Subject the hose to pressure tests to ensure it can withstand the specified working and burst pressures.

Dimensional Checks: Measure the hose’s diameter, thickness, and length to ensure they meet the required specifications.

9. Cutting and Fittings

Cutting: Cut the hose into standard or custom lengths as required by customers.

Fittings: Attach quick-connect fittings, camlock couplings, or other connectors if specified, making the hose ready for immediate use.

10. Packaging

Coiling: Neatly coil the hose for easy handling and transport.

Labeling: Label each hose coil with necessary product information, including size, length, pressure ratings, and any relevant certifications.

Packaging: Package the hose in a manner that protects it during transportation and storage, ready for shipment to customers.

The manufacturing process of a heavy duty layflat hose involves careful material selection, precise extrusion, thorough reinforcement, and stringent quality control measures. By adhering to these steps, manufacturers ensure that the final product is robust, flexible, and capable of handling high pressures and harsh conditions, making it suitable for a wide range of demanding applications in agriculture, construction, and industrial fields.

QC

Ensuring the production of high-quality heavy duty layflat hoses involves implementing stringent quality control measures at every stage of the manufacturing process. Here are the key steps our factory takes to maintain and control the quality of our heavy duty layflat hoses:

1. Raw Material Inspection

Supplier Verification: Only source raw materials from verified and reputable suppliers.

Material Testing: Conduct thorough testing of PVC, nitrile rubber, TPU, and polyester yarn upon arrival to ensure they meet the required specifications for strength, flexibility, and durability.

Batch Tracking: Implement a batch tracking system to trace the origin and quality of materials used in each production run.

2. Mixing and Compounding Control

Precision Mixing: Use precise mixing ratios and equipment to ensure a consistent and homogeneous compound.

Sample Testing: Regularly test samples of the compound for proper plasticizer, stabilizer, and colorant distribution.

Temperature Monitoring: Monitor and control the temperature during the compounding process to ensure uniformity.

3. Extrusion Process Control

Equipment Calibration: Regularly calibrate extrusion machines to maintain consistent extrusion thickness and diameter.

Continuous Monitoring: Use automated systems to monitor the extrusion process for any deviations in thickness, diameter, and material flow.

In-process Inspection: Conduct in-process inspections to check for any visible defects such as air bubbles, uneven thickness, or surface irregularities.

4. Reinforcement and Outer Layer Application

Reinforcement Quality: Inspect the polyester yarn for tensile strength and uniformity before use.

Uniform Application: Ensure the braiding or knitting of the reinforcement is uniformly applied to avoid weak spots.

Outer Layer Integrity: Monitor the application of the outer layer to ensure it encapsulates the reinforcement properly and provides adequate protection.

5. Curing and Cooling

Curing Temperature Control: Maintain precise control over curing oven temperatures to ensure proper bonding of layers.

Cooling Rate: Control the cooling rate to prevent material stress and deformation.

6. Final Inspection and Testing

Visual Inspection: Conduct a thorough visual inspection of each hose for surface defects, uniformity, and overall appearance.

Pressure Testing: Perform pressure tests on each batch to verify that the hoses can withstand specified working and burst pressures.

Dimensional Verification: Measure the hose’s diameter, wall thickness, and length to ensure they meet the required specifications.

Flexibility and Durability Testing: Test for flexibility, kink resistance, and durability to ensure the hose performs well under real-world conditions.

7. Documentation and Traceability

Quality Records: Maintain detailed records of all inspections, tests, and production parameters for traceability and quality assurance.

Batch Identification: Assign batch numbers to all products for easy tracking and identification in case of any quality issues.

8. Employee Training and Compliance

Training Programs: Regularly train employees on quality control procedures, equipment operation, and safety protocols.

Compliance Audits: Conduct internal audits to ensure adherence to quality control standards and identify areas for improvement.

9. Customer Feedback and Continuous Improvement

Customer Feedback: Collect and analyze customer feedback to identify any quality issues and areas for improvement.

Continuous Improvement: Implement a continuous improvement program to regularly review and enhance quality control processes based on feedback and technological advancements.

By following these comprehensive quality control measures, our factory ensures that every heavy duty layflat hose we produce meets the highest standards of durability, reliability, and performance, providing our customers with a product they can trust.

Export Process of Heavy Duty Layflat Hose

Exporting heavy duty layflat hoses requires a structured process to ensure the products clear customs smoothly and reach customers safely. Here is a detailed overview of the export process:

1. Order Confirmation

Customer Order: Confirm the customer’s order, including quantity, specifications, packaging requirements, and delivery time.

Contract Signing: Sign an export contract with the customer, clearly outlining the rights and obligations of both parties.

2. Production and Quality Control

Production Plan: Schedule production according to the order to ensure timely delivery.

Quality Control: Implement strict quality control measures during production to ensure the products meet customer requirements and international standards.

Final Inspection: Conduct final inspections after production, including pressure tests, dimensional checks, and appearance inspections.

3. Packaging

Standard Packaging: Package the hoses as per customer requirements, usually involving neatly coiling and bundling the hoses and placing them in plastic bags or cartons.

Protective Packaging: Use additional protective materials like foam pads and cardboard corners to prevent damage during transportation.

Labeling: Label the packages with product specifications, quantity, customer information, and production batch number.

4. Preparation of Export Documents

Commercial Invoice: Prepare a commercial invoice detailing product names, quantities, unit prices, and total prices.

Packing List: Create a packing list that provides detailed information about the contents of each package.

Certificate of Origin: Prepare a certificate of origin as required by the customer or the destination country.

Inspection Certificates: Include quality inspection certificates, pressure test reports, and other relevant documents.

Bill of Lading: Arrange transportation and obtain the bill of lading (B/L).

Other Necessary Documents: Prepare other documents as needed, such as insurance certificates or hazardous materials certificates (if applicable).

5. Customs Declaration and Clearance

Customs Broker: Hire a professional customs broker to handle the export declaration.

Customs Documents: Submit all required customs documents, including the commercial invoice, packing list, certificate of origin, and bill of lading, to the customs authorities.

Customs Inspection: Be prepared for potential customs inspections of the goods.

Payment of Duties and Fees: Pay any applicable export duties and fees according to the regulations of the exporting country.

6. Transportation and Logistics

Choose Transportation Method: Select the appropriate transportation method based on the quantity of goods and customer requirements, such as sea freight, air freight, or land transport.

Arrange Transportation: Coordinate with a logistics company to arrange the shipment of goods, ensuring timely departure.

Loading and Shipping: Load the goods onto the transport vehicle and ship them to the destination.

7. Import Clearance in Destination Country

Local Agent: Work with a local customs agent in the destination country to ensure smooth import clearance.

Clearance Documents: Provide all necessary clearance documents, including the commercial invoice, packing list, and certificate of origin.

Payment of Import Duties: Pay any applicable import duties and taxes according to the regulations of the destination country.

8. Delivery and After-Sales Service

Delivery: Arrange for the goods to be transported to the customer’s designated location after clearing customs.

Receipt Confirmation: Have the customer confirm receipt of the goods and verify the quantity and quality.

After-Sales Service: Provide necessary after-sales services, such as technical support and usage guidance, to ensure customer satisfaction.

The export process of heavy duty layflat hoses includes order confirmation, production and quality control, packaging, preparation of export documents, customs declaration and clearance, transportation and logistics, import clearance in the destination country, and delivery and after-sales service. By strictly following these steps, you can ensure the products are exported smoothly and delivered safely to customers, thereby enhancing customer satisfaction and trust.

About Us

Our heavy-duty PVC Layflat Hose plays a critical role in drainage, providing reliable drainage solutions for industrial and construction sectors through its efficient drainage capacity, durability, and portability.

Invest in Renato Hose's Heavy Duty PVC Layflat Hose and experience unmatched reliability, durability, and performance in water discharge operations. Trust in our expertise and commitment to quality to elevate your operations to new heights.

Qingdao Renato Plastic Co., Ltd has been committed to the production of PVC Layflat Hose for a long time. Our Layflat Hose is non-toxic, odorless, and has no impact on crops. It is compliant with ISO9001-2000 certification and can be inspected by third-party inspection agencies. The dimensions, weight, and length meet the standards, and the packaging is tight and neat, making it deeply loved by customers.

Contact Us

Welcome to Contact Us!

QINGDAO RENATO PLASTIC CO., LTD.

Contact: Mr. Kevin Ren

Phone/Whatsapp/Wechat: 0086-18653281131

Skype: bizchen2012

Email: sales@renatoplastic.com

kevin@renatoplastic.com

bizchen2012@foxmail.com