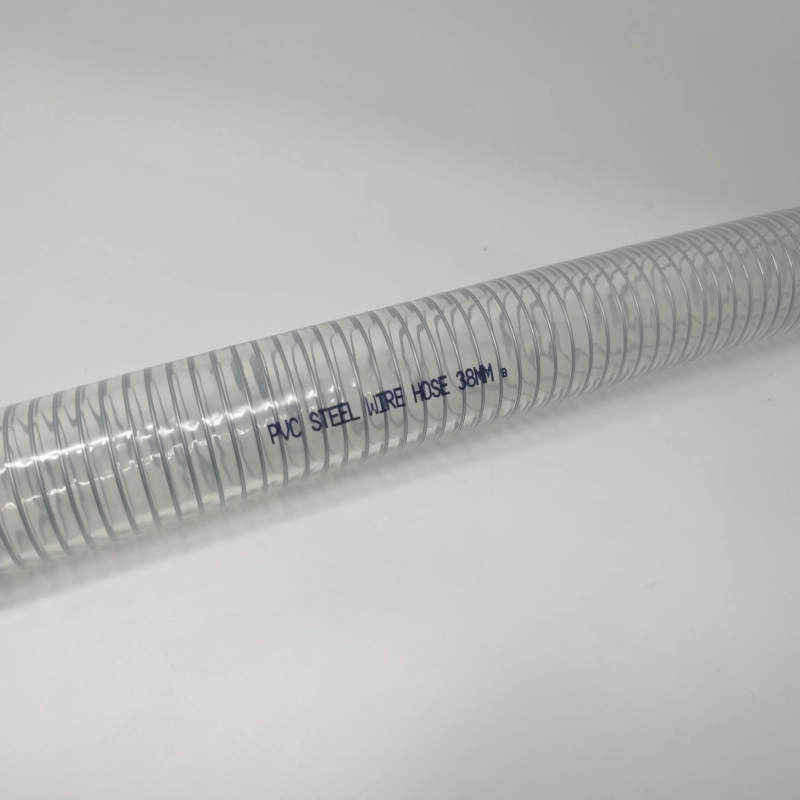

What is PVC steel wire reinforced hose?

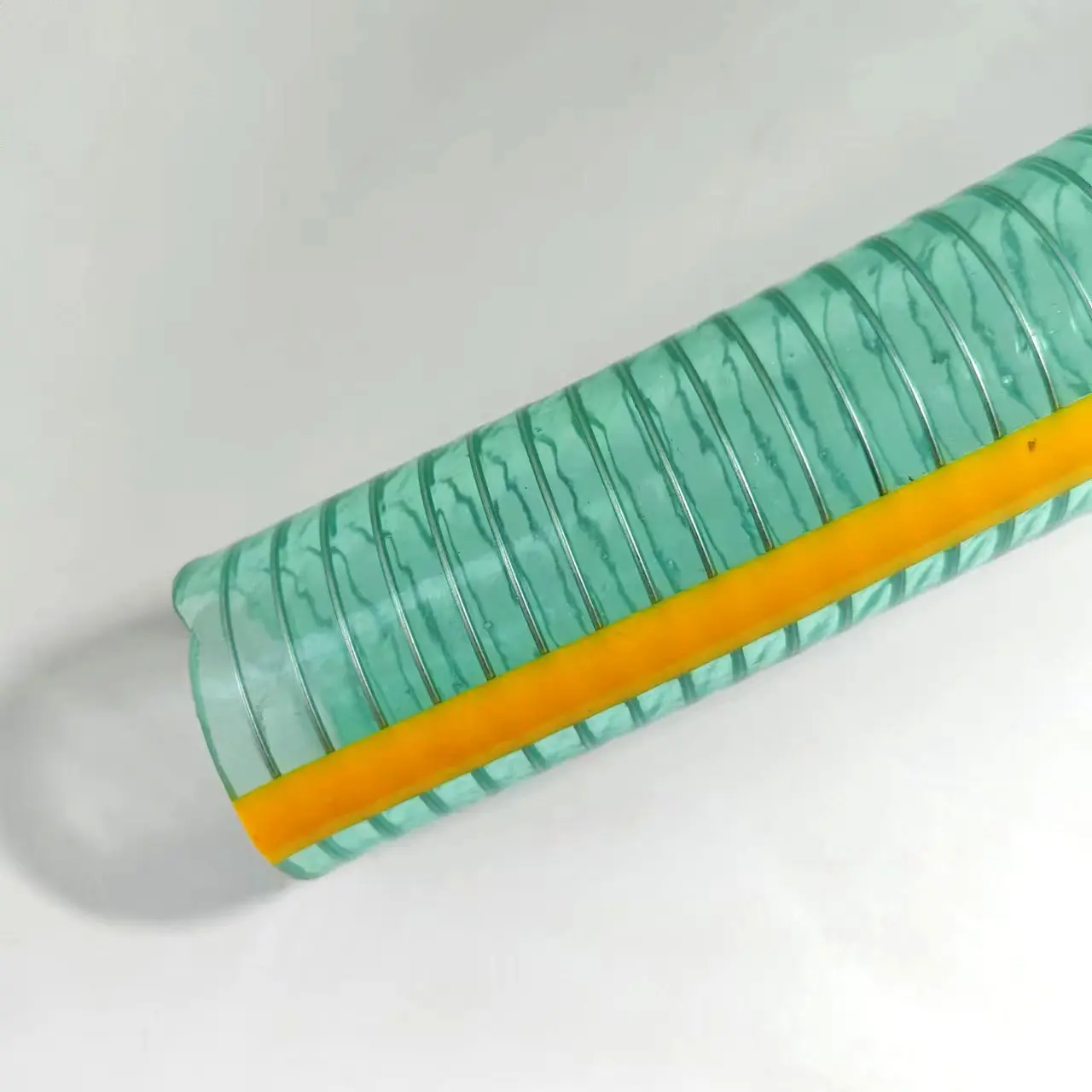

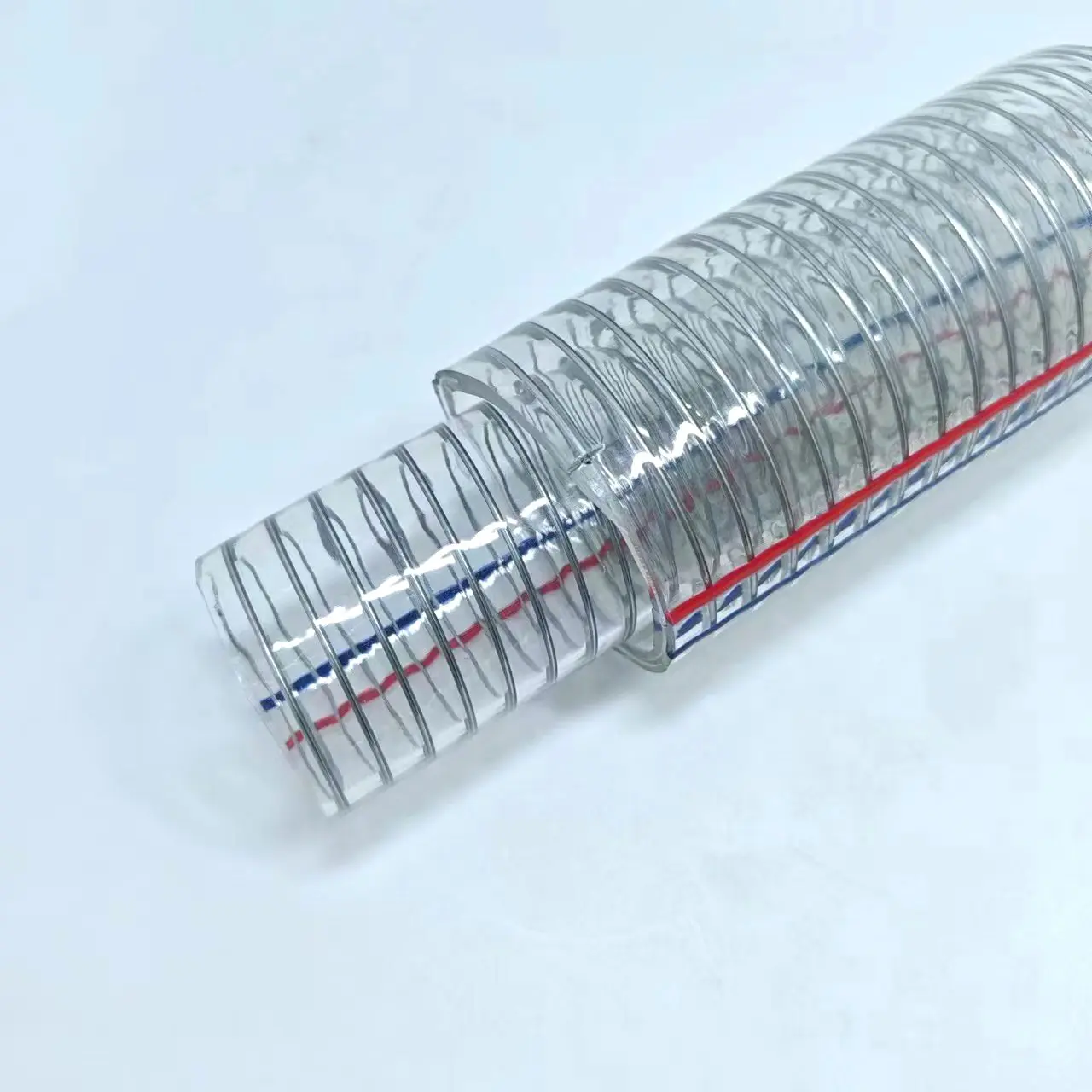

The PVC steel wire reinforced hose is a high-quality, durable hose designed for various industrial applications. It combines the flexibility of PVC with the strength of a steel wire helix, making it an ideal solution for transporting liquids, gases, and light solids. This hose is widely used in industries such as agriculture, construction, manufacturing, and more due to its excellent performance under pressure and its resistance to kinks, abrasion, and weather conditions.

The transparent body of the hose allows for easy monitoring of the flow of materials, ensuring safety and efficiency in various applications. With its robust construction, the PVC steel wire reinforced hose provides long-lasting service in demanding environments, making it a popular choice for professionals and businesses worldwide.

Size Specifications Table

| Inner Diameter (mm) | Outer Diameter (mm) | Working Pressure (MPa) | Burst Pressure (MPa) | Length per Roll (m) |

|---|---|---|---|---|

| 6 | 11 | 0.6 | 2.0 | 50 |

| 8 | 14 | 0.6 | 2.0 | 50 |

| 10 | 16 | 0.5 | 1.8 | 50 |

| 12 | 18 | 0.5 | 1.8 | 50 |

| 16 | 22 | 0.4 | 1.5 | 50 |

| 19 | 26 | 0.4 | 1.5 | 50 |

| 25 | 32 | 0.3 | 1.2 | 50 |

| 32 | 39 | 0.3 | 1.2 | 50 |

Technical Specifications Table

| Specification | Details |

|---|---|

| Material | High-quality PVC with steel wire helix |

| Working Temperature | -10°C to +65°C |

| Reinforcement | High-tensile steel wire |

| Transparency | Crystal clear for visible flow monitoring |

| UV Resistance | Yes |

| Abrasion Resistance | High |

| Flexibility | Excellent, easy to handle and maneuver |

| Bend Radius | Low, allowing for tight turns and ease of use |

| Chemical Resistance | Resistant to many chemicals, acids, and alkalis |

| Pressure Resistance | Withstands high pressure, varying by hose size |

| Compliance | Meets ISO 9001 standards |

| Available Colors | Transparent, customized colors available on request |

Main Applications of PVC Steel Wire Reinforced Hose

Industrial Fluid Transfer

The hose is widely used for the transportation of water, oil, and other liquids in various industrial settings. Its transparency allows users to monitor the flow and detect any blockages or contamination.Agricultural Irrigation

In agricultural fields, the hose is commonly used for irrigation systems to transport water and fertilizers. Its durability and UV resistance ensure long-lasting performance, even under direct sunlight.Vacuum Systems

Thanks to the steel wire reinforcement, the hose can maintain its shape under negative pressure, making it suitable for vacuum applications in industries such as cleaning and manufacturing.Air Ducting and Ventilation

The hose’s flexibility and ability to handle gases make it a great option for ventilation systems in both industrial and commercial buildings.Food and Beverage Industry

In food processing, the hose can transport liquids like juices and water safely. PVC is non-toxic and free of harmful chemicals, making it suitable for non-potable food and beverage uses.Chemical Transport

The hose is resistant to many chemicals, making it ideal for transferring various industrial chemicals, acids, and alkalis. Its flexibility and transparency make it easy to monitor and manage the transfer process.Construction

Used in construction sites for transporting sand, gravel, cement, and other light materials. The hose’s abrasion resistance ensures that it can withstand the rough conditions typically found in construction environments.

Features of PVC Steel Wire Reinforced Hose

High Strength and Durability: The steel wire reinforcement provides additional strength and pressure resistance, ensuring the hose can handle demanding applications without kinking or collapsing.

Flexible and Lightweight: Despite its robust construction, the hose remains flexible and lightweight, allowing for easy handling and installation in tight spaces.

Chemical Resistance: Suitable for transporting a wide range of chemicals and industrial liquids, making it versatile for different sectors.

Transparency for Monitoring: The clear body allows users to monitor the flow and detect any blockages, enhancing safety and operational efficiency.

Weather Resistant: Designed to withstand various environmental conditions, including UV exposure, heat, and cold.

Easy to Install: The hose is easy to cut and install with the right fittings, and its flexibility allows for installation in complex layouts.

Manufacturing Process of PVC Steel Wire Reinforced Hose

Raw Material Selection

The production process begins with the careful selection of raw materials. High-quality polyvinyl chloride (PVC) resin is chosen for the hose's flexible structure, while high-tensile steel wire is selected for reinforcement. Additives such as plasticizers, stabilizers, and colorants are also incorporated to improve the hose’s flexibility, durability, and appearance.

Compounding the PVC Material

The PVC resin is blended with plasticizers and other additives in a compounding process. These additives are essential to give the PVC the right degree of flexibility and to enhance its chemical resistance and durability. The compound is heated and mixed to form a homogenous material that can be easily processed.

Extrusion of the PVC Layer

The compounded PVC is then fed into an extrusion machine. The extrusion machine heats and pushes the PVC material through a die to form the base layer of the hose. The thickness of this layer can be adjusted based on the required specifications of the final hose product.

Steel Wire Reinforcement Application

After the extrusion of the initial PVC layer, the hose passes through a steel wire winding machine. This machine precisely winds the high-tensile steel wire around the PVC layer, ensuring uniform spacing between the coils to provide strength without sacrificing flexibility. This reinforcement layer is what gives the hose its ability to resist high pressures and avoid collapsing under vacuum.

Extrusion of the Outer PVC Layer

Once the steel wire is applied, a second layer of PVC is extruded over the wire to form the outer surface of the hose. This outer layer serves to protect the steel wire from corrosion, environmental elements, and wear, while maintaining the flexibility and transparency of the hose.

Cooling and Cutting

After the outer PVC layer is extruded, the hose is cooled in a water bath to solidify the PVC material. Once cooled, the hose is cut to the desired length, typically ranging from 50 to 100 meters per roll, depending on customer requirements.

Quality Inspection

Each batch of hoses undergoes stringent quality control tests. These tests ensure that the hose meets industry standards for thickness, pressure resistance, flexibility, and durability. Only hoses that pass these tests are approved for packaging and shipping.

How Quality is Ensured in the Manufacturing Process

High-Quality Raw Materials

Ensuring the consistent use of high-quality raw materials is the first step in maintaining product quality. Reputable suppliers are chosen for PVC resins and steel wire to ensure that the final product has the necessary strength, flexibility, and chemical resistance. Additionally, all additives are carefully selected to meet regulatory standards for safety and durability.

Precision Machinery

The manufacturing process uses advanced extrusion and winding machines that ensure accurate and consistent production. Precision machinery is critical in controlling the thickness of the PVC layers and the tension of the steel wire reinforcement, ensuring that each hose produced meets the required specifications.

Quality Control at Every Stage

In-process quality checks are conducted at each stage of production. For example, during extrusion, technicians monitor the thickness and diameter of the hose to ensure it meets the specifications. Similarly, the steel wire winding process is closely monitored to prevent uneven spacing or improper tension, which could affect the hose’s performance.

Pressure and Burst Testing

Hoses are subjected to hydrostatic pressure tests to ensure they can withstand the maximum working pressure specified for each size. Additionally, burst tests are conducted to determine the maximum pressure the hose can handle before failure. These tests verify the integrity of the steel wire reinforcement and the bonding between the PVC layers and the wire.

Chemical and Environmental Testing

Given that PVC steel wire reinforced hoses are often used to transport chemicals or work in harsh environments, they undergo chemical resistance tests to ensure they can handle exposure to various liquids, acids, and alkalis. UV resistance and weathering tests are also conducted to ensure that the hose remains durable under outdoor conditions, such as exposure to sunlight and extreme temperatures.

Dimensional Accuracy

The inner and outer diameters of the hose are measured throughout production to ensure they fall within the specified tolerances. Proper dimensional control is crucial for fitting compatibility and ensuring the hose performs correctly under pressure.

Final Inspection and Packaging

Before the hoses are packaged for delivery, they undergo a final visual and functional inspection. This inspection ensures there are no defects, kinks, or weak points. Only hoses that pass all quality control measures are labeled, coiled, and packaged.

Certifications and Standards Compliance

Reputable factories ensure that their PVC steel wire reinforced hoses meet international standards, such as:

ISO 9001: Quality management standards that ensure consistent product quality.

REACH and RoHS: Compliance with chemical safety standards in the European Union.

FDA: Some hoses used in the food and beverage industry may also require FDA compliance for safe contact with consumable products.

Conclusion

The manufacturing of PVC steel wire reinforced hose involves a carefully controlled process that combines advanced machinery, skilled labor, and rigorous quality control. From selecting the best raw materials to ensuring that every hose meets pressure and chemical resistance requirements, quality is maintained at every step. Factories producing these hoses follow stringent standards to ensure the hoses are durable, reliable, and safe for various industrial and commercial applications.

With precise production techniques and robust testing, manufacturers can deliver PVC steel wire reinforced hoses that meet the demands of both global markets and specialized industries.

The PVC steel wire reinforced hose is a versatile and reliable solution for a wide range of industrial and agricultural applications. Its combination of flexibility, strength, and chemical resistance makes it a preferred choice for professionals who require a durable, long-lasting hose. Whether it's for fluid transfer, ventilation, or vacuum systems, this hose offers excellent performance under pressure and in harsh conditions. With multiple sizes and customization options available, it meets the diverse needs of industries across the EU and beyond.