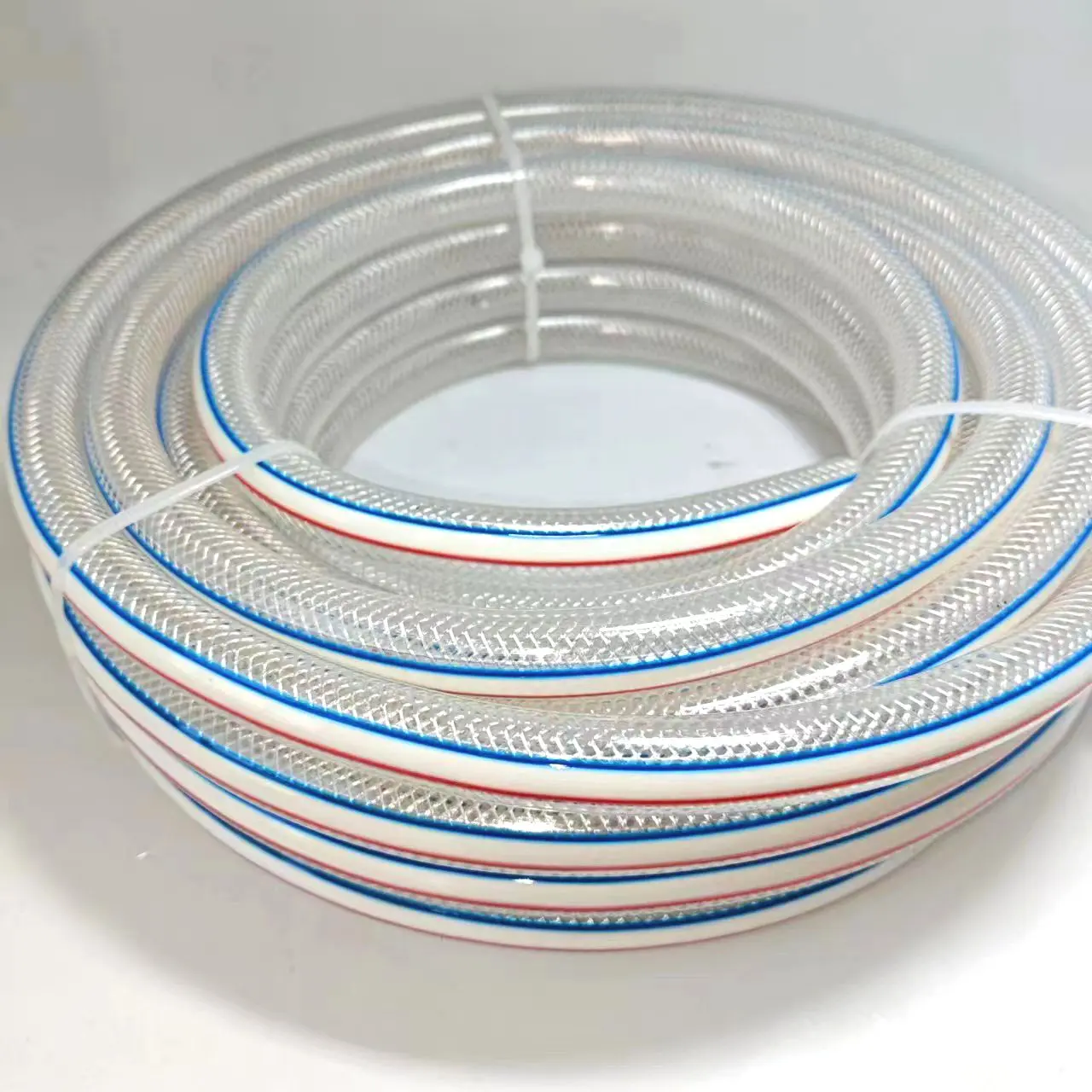

Basic Characteristics and Advantages of PVC Fiber Reinforced Hose

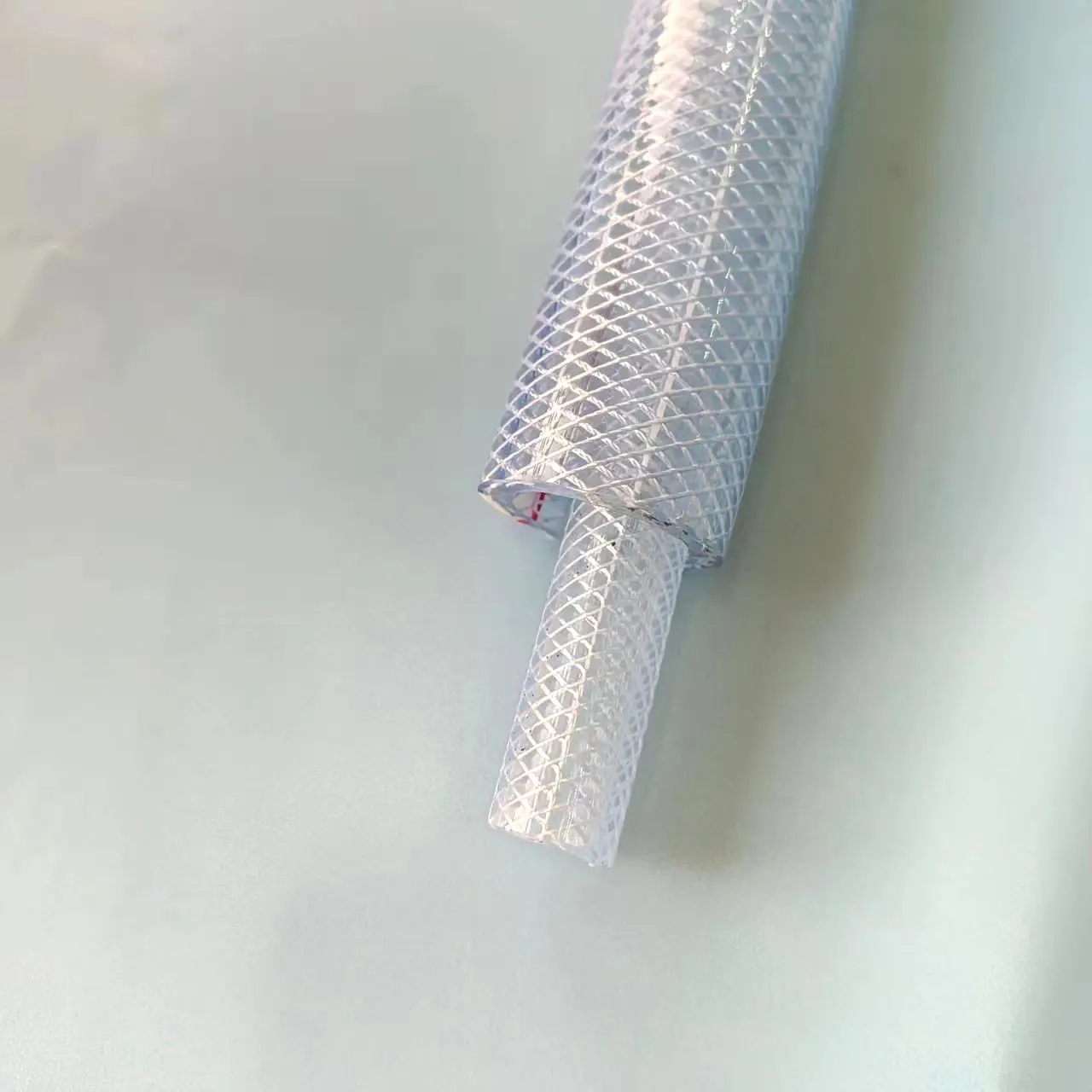

PVC Fiber Reinforced Hose is a flexible hose made from polyvinyl chloride (PVC) and reinforced with high-strength fiber layers. This type of hose is widely used in Canada due to its lightweight, durability, and ease of handling. Compared to hoses made from other materials, PVC Fiber Reinforced Hose offers distinct advantages in terms of cost, flexibility, and versatility, making it particularly suitable for the transport of water, air, and other non-corrosive fluids under low to medium pressure.

In Canada, the popularity of this hose is partly due to its ability to adapt to varying climatic conditions. Canada's vast geography results in significant climate differences, from the frigid northern regions to the relatively mild southern areas. PVC Fiber Reinforced Hose performs well across these conditions. For example, many models are treated for UV resistance, making them suitable for long-term outdoor use, while modified versions remain flexible in low temperatures, reducing the risk of cracking. Additionally, its lightweight design makes it easy to transport and install, which is particularly beneficial for construction sites, agricultural irrigation, and temporary industrial applications.

Key Application Areas in the Canadian Market

(1) Construction Industry

Water Supply and Drainage on Job Sites: Used to transport clean water or drain rainwater and groundwater during construction.

Concrete Work Support: Used to deliver water for concrete mixing or curing, as well as for compressed air equipment.

Temporary Ventilation Systems: Used to supply fresh air or exhaust fumes in enclosed construction environments.

(2) Agricultural Irrigation

Crop Sprinkler Systems: Used for field crops like wheat and canola.

Greenhouse Cultivation: Used for drip irrigation or misting systems in greenhouses.

Livestock Watering: Provides drinking water for livestock or cleans barns.

(3) Industrial Applications

Compressed Air Transport: Supplies air to pneumatic tools or equipment in factories.

Liquid Transport: Suitable for short-distance transport of non-corrosive liquids like water and oils.

Specification

| Inner Diameter | Thickness | Length/Roll | Weight | Working Pressure (23℃) | Volume | ||

| inch | mm | mm | m | kg/m | bar | psi | cbm |

| 1/4 | 6 | 2 | 100 | 0.068 | 8 | 120 | 0.015 |

| 3 | 100 | 0.114 | 10 | 150 | 0.019 | ||

| 5/16 | 8 | 2 | 100 | 0.085 | 8 | 120 | 0.020 |

| 3 | 100 | 0.14 | 10 | 150 | 0.029 | ||

| 3/8 | 10 | 2 | 100 | 0.102 | 8 | 120 | 0.025 |

| 3 | 100 | 0.165 | 10 | 150 | 0.030 | ||

| 1/2 | 12 | 2 | 100 | 0.119 | 7 | 105 | 0.034 |

| 2.5 | 100 | 0.154 | 8 | 120 | 0.036 | ||

| 3 | 100 | 0.191 | 10 | 150 | 0.042 | ||

| 5/8 | 15 | 2 | 100 | 0.144 | 6 | 90 | 0.035 |

| 2.5 | 100 | 0.186 | 7 | 105 | 0.042 | ||

| 3 | 100 | 0.229 | 8 | 120 | 0.050 | ||

| 3/4 | 19 | 2 | 100 | 0.178 | 5 | 75 | 0.043 |

| 2.5 | 100 | 0.228 | 6 | 90 | 0.050 | ||

| 3 | 100 | 0.28 | 7 | 105 | 0.060 | ||

| 1 | 25 | 2 | 100 | 0.229 | 3 | 45 | 0.055 |

| 2.5 | 100 | 0.291 | 4 | 60 | 0.065 | ||

| 3 | 100 | 0.356 | 5 | 75 | 0.075 | ||

| 1 1/4 | 32 | 3 | 100 | 0.445 | 4 | 60 | 0.109 |

| 4 | 100 | 0.61 | 5 | 75 | 0.120 | ||

| 1 1/2 | 38 | 3 | 100 | 0.521 | 4 | 60 | 0.141 |

| 4 | 100 | 0.712 | 6 | 90 | 0.143 | ||

| 2 | 50 | 4 | 100 | 0.916 | 2 | 30 | 0.198 |

| 5 | 100 | 1.166 | 3 | 45 | 0.215 | ||

| 6 | 100 | 1.424 | 4 | 60 | 0.300 | ||

Regional Demand Variations Across Canada

| Region | Primary Uses | Market Characteristics |

|---|---|---|

| Western Provinces | Agricultural irrigation, mining | High demand, preference for durable hoses |

| Central Provinces | Construction, industrial applications | Focus on cost-effectiveness, standard specs |

| Atlantic Provinces | Fishing, small-scale farming | Smaller market, demand for salt-resistant hoses |

In the western provinces, particularly Alberta and Saskatchewan, agricultural irrigation dominates the market, making UV resistance and durability critical. In Ontario and Quebec, where construction and manufacturing are prominent, industrial-grade hoses are in higher demand. The Atlantic provinces, due to their proximity to the ocean, see some demand for hoses resistant to saltwater exposure.

Seasonal Impact on the Canadian Market

Spring (April–June): Agricultural irrigation demand surges, and construction sites ramp up activity, leading to increased hose sales.

Summer (July–September): Irrigation and construction demand remain high, with frequent outdoor use.

Fall (October–November): Agricultural demand declines, but construction projects continue, keeping demand steady.

Winter (December–March): Outdoor use decreases, but industrial indoor applications (e.g., factory compressed air systems) maintain some demand.

Due to harsh winters, some users opt for cold-resistant hose models or store hoses properly during the off-season to extend their lifespan.

Challenges in the Canadian Market

Extreme Climate Effects: Severe winter cold can make some PVC hoses brittle, shortening their lifespan.

Environmental Regulations: Some users are shifting toward more eco-friendly alternatives, pushing the industry toward recyclable materials.

Intensifying Market Competition: As more brands enter the market, price competition grows fiercer.