Suction Hose Can be Used for Pumping Slurry

Qingdao Renato Plastic Co., Ltd. is a trusted name in the manufacturing of high-performance PVC hoses. With over 15 years of experience, we specialize in creating durable, reliable hoses suitable for various applications, including agriculture, construction, and mining. Among our premium products, our PVC Suction Hose for Pumping Slurry stands out for its exceptional strength, flexibility, and resistance to wear and tear. Designed to handle the challenges of slurry transport, this hose ensures efficient and uninterrupted operations.

Basic Characteristics of Plastic-Reinforced Pipes

Plastic-reinforced pipes, as their name suggests, are composite pipes that combine plastic materials with reinforcing structures. Typically, they utilize high-density polyethylene (HDPE), polypropylene (PP), or other polymeric materials as the base, reinforced internally or externally with high-strength steel wires, glass fibers, or other materials. This combination ensures excellent flexibility while significantly enhancing the pipes' pressure-bearing capacity, wear resistance, and impact resistance. PRP boasts lightweight, corrosion resistance, easy installation, and long service life, making them an ideal alternative to traditional metal and pure plastic pipes.

Diverse Application Scenarios of PRP in Mud Extraction

Mining:

During mining operations, especially in open-pit and underground mines, large quantities of mixed mud containing ore debris, sand, and water are generated. If not promptly handled, this mud can hinder ore extraction efficiency and pollute the surrounding environment. PRP's high pressure-bearing capacity and wear resistance enable efficient transportation of this mud from mining areas to treatment stations or storage facilities, facilitating subsequent ore processing and environmental protection.

Tunneling and Underground Engineering:

In tunnel excavation and subway construction, mud is often used to stabilize excavation faces and prevent groundwater infiltration. PRP's corrosion resistance, flexibility, and ease of installation make it ideal for complex underground spaces. It can be flexibly arranged to ensure stable operation of the mud circulation system, reducing the impact of groundwater on the project and ensuring construction safety.

Environmental Treatment and Restoration:

Mud extraction is a crucial step in river dredging, lake remediation, and contaminated soil restoration projects. PRP safely and efficiently transports mud containing various pollutants from pollution sources to treatment stations, facilitating subsequent treatment and disposal. Its corrosion and wear resistance ensure long-term stable operation even in corrosive or particulate-laden mud.

Construction Sites and Foundation Engineering:

PRP is also commonly used for mud extraction in construction sites and foundation engineering projects (e.g., pile foundation construction, deep excavation). These projects generate substantial mud containing soil, gravel, and water, which, if not promptly handled, can affect construction progress and site conditions. PRP quickly and effectively removes this mud, maintaining cleanliness and dryness in the construction area.

Agriculture and Water Conservancy:

PRP plays a vital role in agriculture and water conservancy projects. For instance, in farmland drainage and river dredging, PRP efficiently extracts excess mud and water, improving drainage conditions in farmland and rivers, enhancing agricultural productivity, and flood control capabilities.

In summary, PRP's diverse application scenarios in mud extraction encompass mining, tunneling, environmental restoration, construction sites, and agriculture/water conservancy, showcasing its superior performance and widespread applicability as an indispensable tool in mud treatment processes.

Technical Requirements

| Parameter | Details |

|---|---|

| Brand Name | Renflex |

| Material | High-Quality PVC |

| Reinforcement | Rigid PVC helix for enhanced durability |

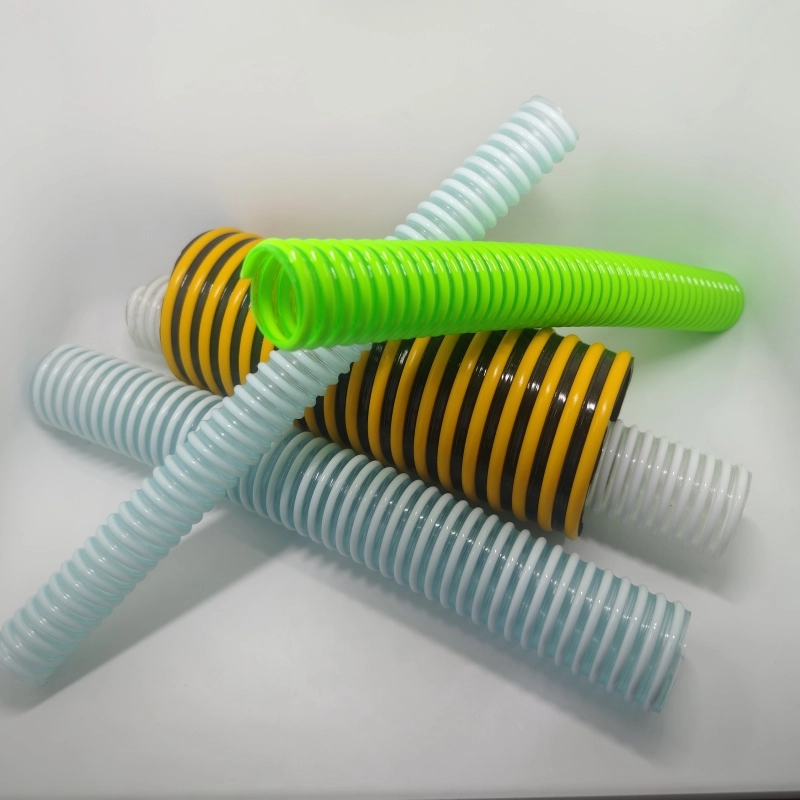

| Color Options | Transparent, Blue, Green, Black, or Customized |

| Working Pressure | 2 - 10 bar |

| Burst Pressure | Up to 30 bar |

| Vacuum Rating | High negative pressure resistance (660mmHg) |

| Temperature Range | -5°C to +65°C |

| Transported Medium | Slurry, Water, Oil, Powders |

| Chemical Resistance | Excellent against oils, alkalis, and mild acids |

| Environmental Adaptability | UV and weather-resistant for outdoor use |

| Standards | ISO9001 Certified |

Specification Sizes

| Internal Diameter (ID) | External Diameter (OD) | Wall Thickness | Length Options | Working Pressure | Weight (kg/m) |

|---|---|---|---|---|---|

| 1 inch (25mm) | 30mm | 2.5mm | 10m / 20m / 30m | 10 bar | 0.4 |

| 2 inch (50mm) | 58mm | 4mm | 20m / 30m / 40m | 8 bar | 0.9 |

| 3 inch (76mm) | 88mm | 6mm | 30m / 40m / 50m | 6 bar | 1.5 |

| 4 inch (100mm) | 116mm | 8mm | 30m / 50m | 6 bar | 2.3 |

| 6 inch (150mm) | 174mm | 12mm | 30m / 40m | 5 bar | 4.5 |

| 8 inch (200mm) | 230mm | 15mm | 20m / 30m | 4 bar | 6.8 |

| 12 inch (300mm) | 350mm | 18mm | 10m / 20m | 3 bar | 12.0 |

Technical Advantages of PRP in Mud Extraction

High Pressure-Bearing Capacity: The reinforcing structures significantly enhance PRP's pressure-bearing performance, ensuring stable operation even during high-pressure mud extraction, reducing leakage risks.

Wear Resistance and Durability: The combination of polymeric base materials and reinforcing materials imparts exceptional wear resistance to PRP, enabling long-term use in mud environments with high sand content and large particles without damage.

Strong Corrosion Resistance: PRP's resistance to acids, alkalis, and other chemicals makes it suitable for operation in complex mud environments, extending pipe lifespan.

Easy Installation: PRP's lightweight and flexibility facilitate quick installation using methods like hot-melt welding and socket connections, significantly shortening construction periods and reducing labor costs.

Environmentally Friendly and Energy-Saving: Compared to traditional metal pipes, PRP's production, transportation, and recycling processes have a smaller environmental impact, aligning with green construction principles. Additionally, its efficient mud extraction capabilities contribute to energy savings and resource utilization.

Case Study

A large-scale mine previously encountered frequent pipe replacements due to wear and corrosion issues with traditional piping, increasing maintenance costs and affecting production schedules. After introducing PRP for mud extraction, over a year of operation, PRP excelled, reducing leakage incidents and significantly lowering replacement and maintenance frequencies, yielding substantial economic and environmental benefits for the mine.

Future Development Trends

With the continuous advancement of technology and the increasing awareness of environmental protection, plastic-reinforced pipes will be more widely used in mud extraction projects. In the future, the materials of plastic-reinforced pipes will pay more attention to environmental protection and sustainability, and more bio-based or biodegradable materials will be developed. At the same time, the application of intelligent technology will also promote the automation, remote monitoring, and intelligent management of mud extraction systems, further improving operational efficiency and safety. In addition, customized and modular plastic-reinforced pipe products tailored to different engineering requirements will become a new trend in market development.

In conclusion, plastic-reinforced pipes play an important role in mud extraction projects with their unique performance advantages, not only improving work efficiency and reducing costs but also promoting environmental protection and sustainable development. With the continuous progress of technology and the continuous expansion of application fields, the application prospects of plastic-reinforced pipes will be broader.

Company Advantages

Advanced Production Facilities: With 10 workshops and over 60 production lines, our facility is equipped to deliver large orders with consistent quality.

Expert Team: A dedicated team of 120 workers, including 5 technicists and 2 QC teams, ensures precision and reliability in every product.

Global Reach: Trusted by customers in over 60 countries, our products meet diverse industrial needs worldwide.

Customization Services: We tailor hoses to match specific requirements, including size, color, and fittings.

Certifications: Certified under ISO9001, ensuring adherence to international quality standards.

For more details or inquiries about our PVC Suction Hose for Pumping Slurry, contact us today!

Conclusion

Qingdao Renato Plastic Co., Ltd. is committed to delivering high-quality hoses that exceed your expectations. Our PVC Suction Hose for Pumping Slurry is the ideal solution for efficient, reliable slurry transport. Trust Renflex for your hose needs and experience unmatched durability and performance. Partner with us today and let us help you achieve your operational goals!